12V DC motors are everywhere. They are one of the most common voltage specs in DC motors. You see them in robotics, small automation, automotive accessories, home automation, and DIY builds.

Why? Because they are easy to use, power supply is simple, cost is low, and compatibility is strong.

At TSL MOTOR, we look at 12V DC motors from an engineering angle. We break down motor types, key parameters, selection logic, and real-world applications. The goal is clear: help engineers and DIY users avoid mistakes and make solid choices.

We have been in the DC motor industry for over 15 years. We know the traps, and we know the proven solutions. That’s why we share representative models and tested setups. It helps you find the right motor faster, without wasting time.

Key Takeaways

- 12V DC motors are widely used across consumer, automotive, and automation products.

They offer easy power sourcing and strong compatibility. - Motor selection starts with defining load conditions.

Torque, speed, and duty cycle determine the baseline specs. - Different motor structures fit different engineering needs.

Brushed, coreless, BLDC, and gear motors each serve distinct scenarios. - Power supply capability is a critical selection factor.

The supply must exceed stall current by at least 20%. - Control methods depend on accuracy and functional requirements.

PWM, H-bridge, and closed-loop PID are the common options. - Thermal management directly affects motor lifetime.

Continuous full-load operation can cause overheating and rapid wear. - 12V motors are widely used in automotive, robotics, and small equipment.

They deliver a balance of performance, cost, and reliability.

Why Are 12V DC Motors So Widely Used?

A 12V DC motor runs on a 12V supply. It is popular because power sources are easy to get. It is safe to use. It delivers enough power density. It has a mature ecosystem with strong support.

That is why it is the standard choice for low-power mobile devices. It is also the default option for many stationary systems.

Convenient Power Supply

One big advOne major advantage of a 12V DC motor is compatibility. It works with the most common low-voltage systems, including vehicle power, lead-acid batteries, lithium packs, household adapters, and UPS units. In practice, 12V is a naturally compatible voltage.

For engineers, this means direct integration without DC-DC conversion, lower cost, smaller PCB, and simpler thermal design. 12V supplies are easy to find in labs, factories, and field tests. Safety is higher than 24V or 48V, with lower shock risk.

Because of these benefits, 12V motors have become the default choice for robots, automotive devices, security systems, pumps, smart-home actuators, and DIY projects.

Safe and Adequate Power Density

One major reason 12V DC motors dominate is the balance of safety and power density. 12V is within the SELV range, so it is safe for home appliances, medical devices, and automotive electronics.

| IEC 61140 voltage band | AC RMS voltage | DC voltage | |

| High Voltage | > 1,000 V | > 1,500 V | |

| Low Voltage | ≤ 1,000 V | ≤ 1,500 V | |

| Extra-low voltage | ≤ 50 V | ≤ 120 V | |

With optimized windings and gearboxes, 12V motors deliver 10–150W and 1–50 kg·cm torque. This is enough for pumps, actuators, and robotic joints. 6V lacks power. 24V needs a higher-voltage platform. 12V is the best compromise for portable, automotive, and battery-powered systems.

Mature Ecosystem & Rich Components

The market has built a mature ecosystem around 12V motors. Whether for prototyping, mass production, or custom solutions, engineers can always find compatible and cost-effective parts.

This ecosystem offers clear advantages: high standardization, wide availability, and easy maintenance. Sizes, interfaces, and connectors are interchangeable. Models range from miniature to high-torque. Motors and gearboxes can be swapped without redesign.

As a result, 12V projects rarely start from zero—existing motors, drivers, encoders, brackets, and connectors can be reused, cutting development time.

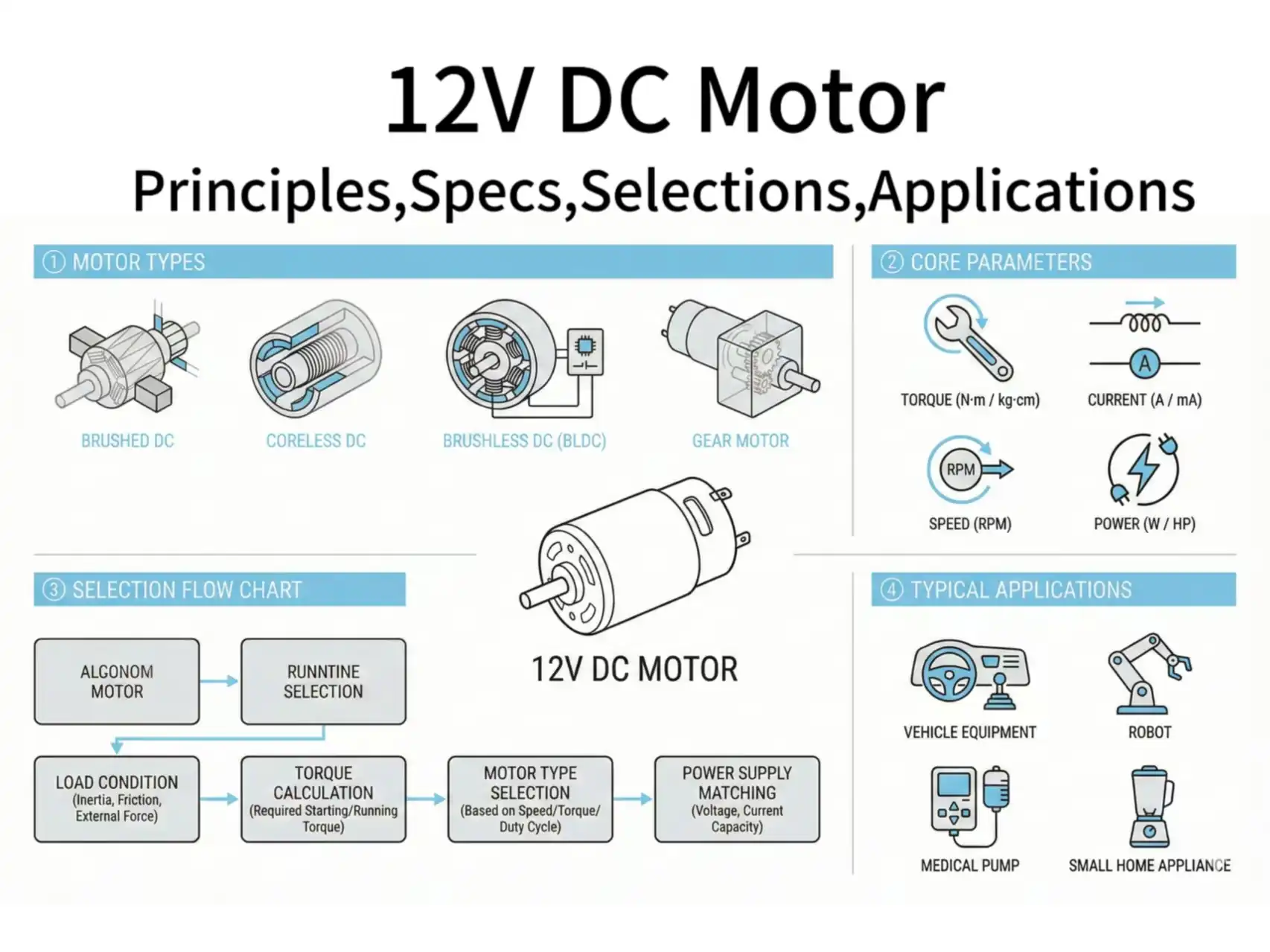

Main Types of 12V DC Motors

The main types of 12V DC motors include brushed DC motors, coreless DC motors, brushless DC motors, and DC gear motors. Each type has unique characteristics and is suited to different applications.

Brushed DC Motor

When DC power is applied, current flows through the brushes. It enters the commutator and then the rotor windings. This produces electromagnetic torque that drives the rotor. The commutator switches the current direction continuously. Torque stays in the forward direction. Rotation is maintained.

Features:

- Simple structure (stator + rotor windings + commutator + brushes)

- Low cost

- Easy control with a simple H-bridge

Applications:

- Automotive: wiper motors, window lifters, seat adjusters

- Home appliances: shavers, blowers, vacuums

- Small machinery: toys, tools, fans

Advantages:

- Easy to drive, fast response

- Low cost

- Simple maintenance (replace brushes)

Disadvantages:

- Brush wear → limited lifetime

- Lower efficiency

- Higher noise and EMI

- Potential overheating under high load

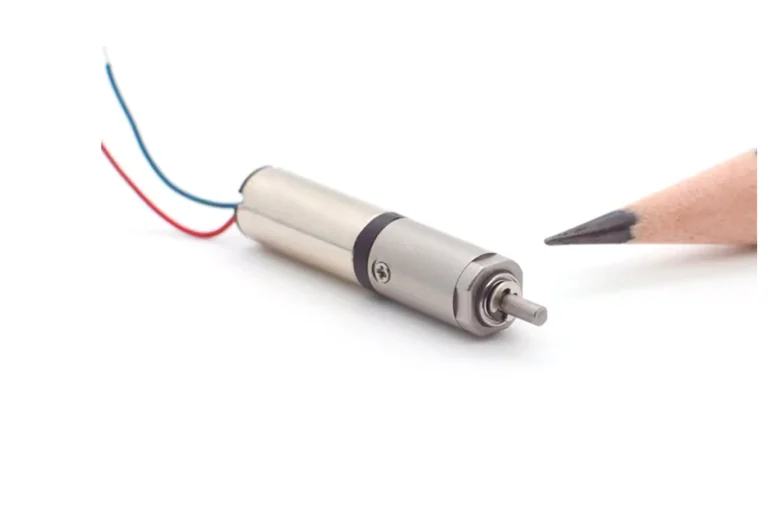

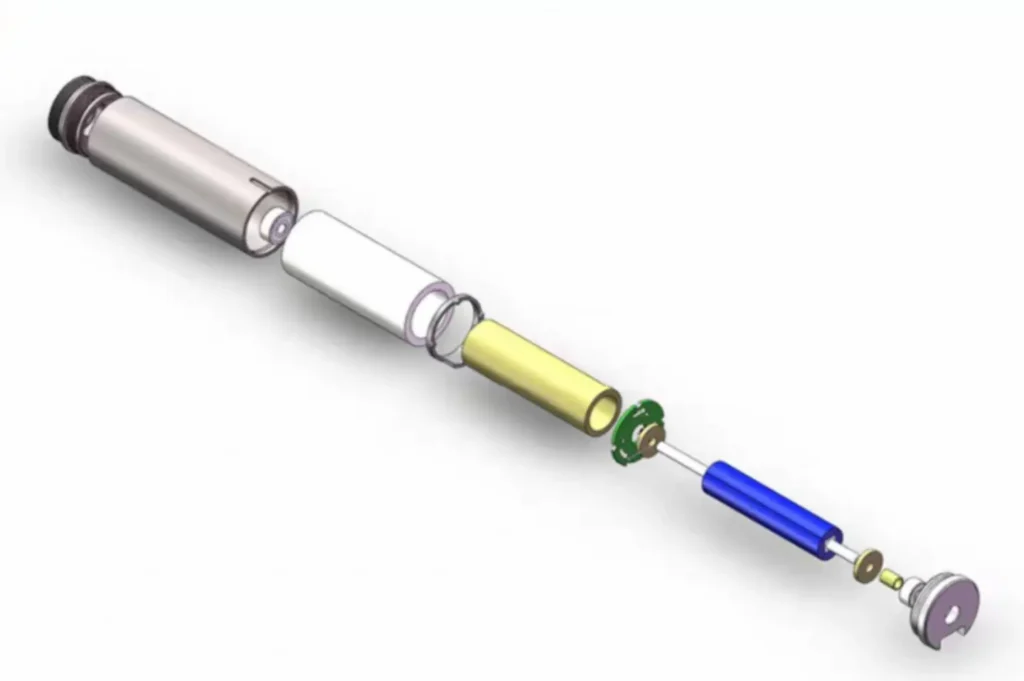

Coreless DC Motor

Unlike traditional iron-core motors, coreless motors use a self-supporting hollow coil as the rotor, without an iron core.

Features:

- Lightweight, low inertia

- High efficiency (no iron loss)

- Smooth operation, no cogging

- High dynamic response

Applications: robotics, drones, medical devices, optics, premium electronics

Advantages:

- Very fast acceleration

- Low noise and vibration

- Suitable for precision control

Disadvantages:

- Higher cost

- Lower load capacity

- More fragile under impact

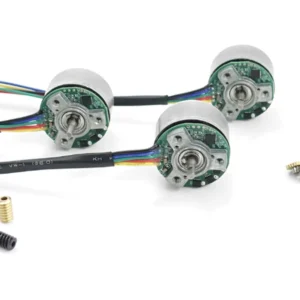

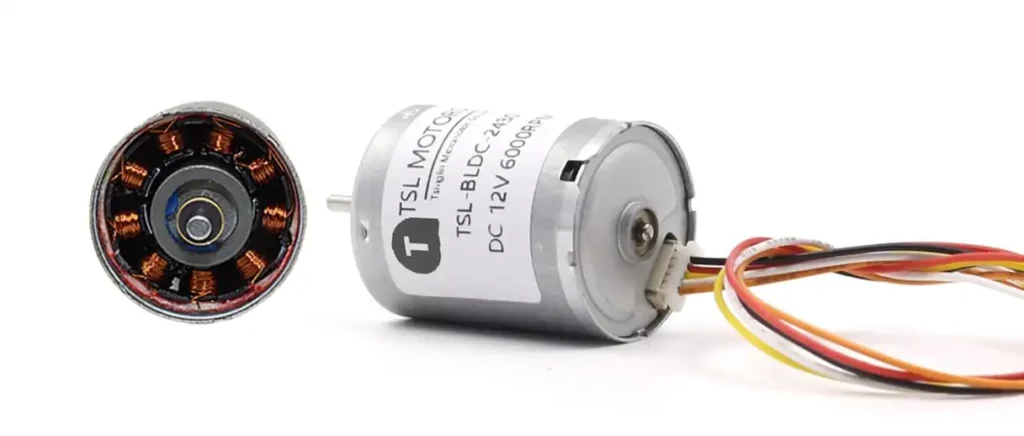

Brushless DC Motor (BLDC)

BLDC motors use electronic commutation via Hall sensors or sensorless algorithms. The stator creates a rotating magnetic field that drives permanent magnets on the rotor.

Features:

- High efficiency (85–90%)

- Long lifespan

- Low noise

- Wide power range

Applications: EVs, drones, robotics, HVAC, medical devices

Advantages: high precision, low noise, excellent efficiency

Disadvantages: higher cost, requires complex controller, EMI concerns

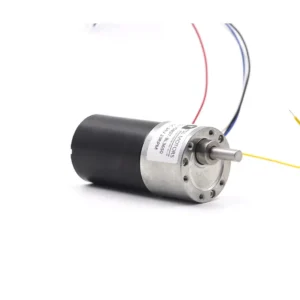

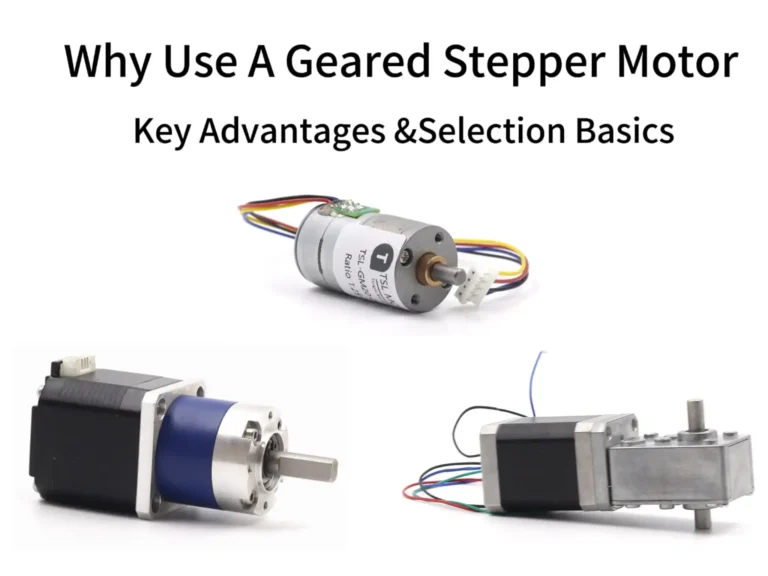

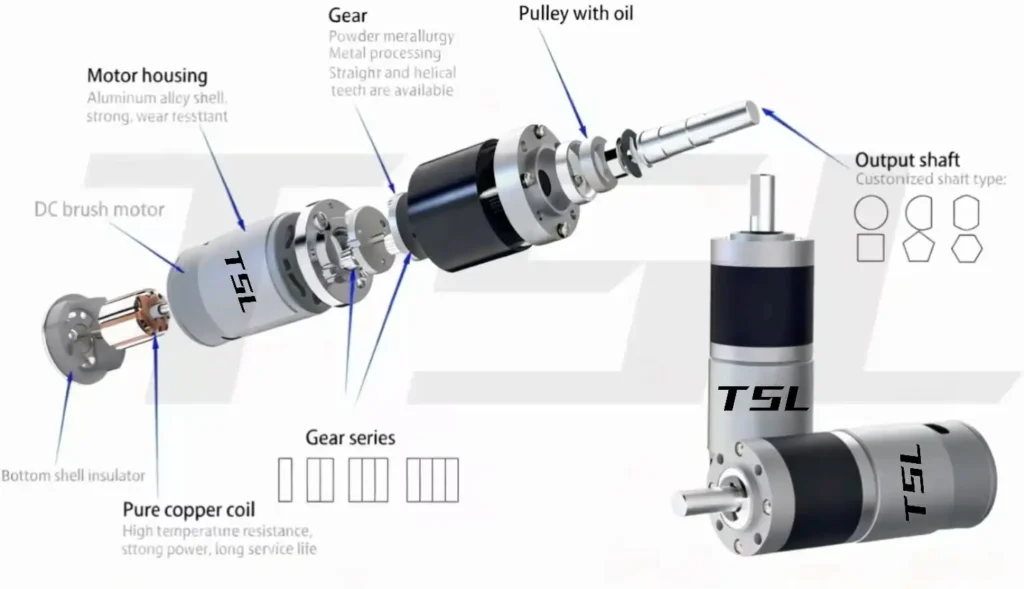

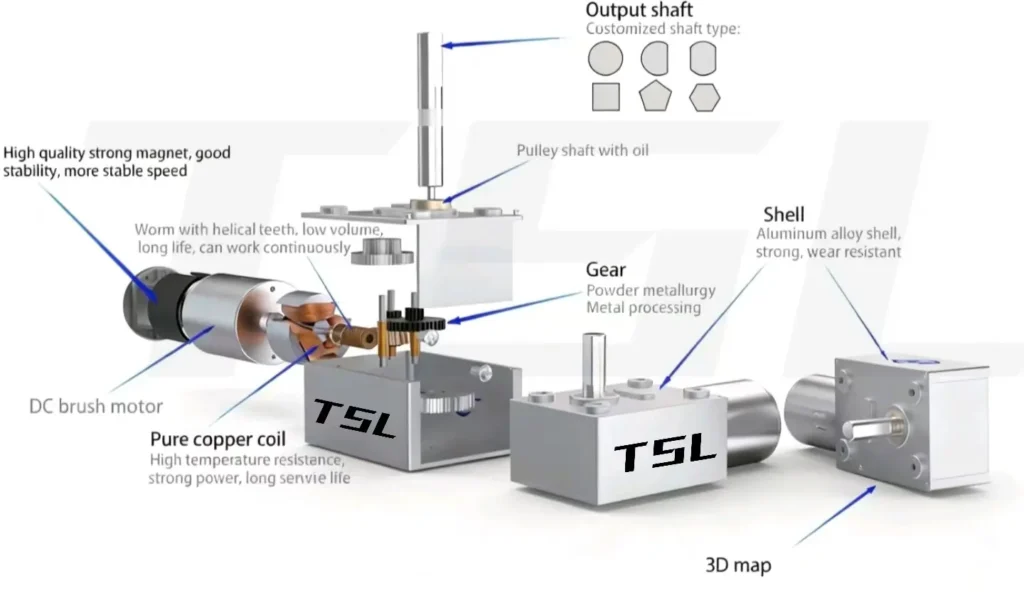

DC Gear Motor

When applications require high torque and low speed, the motor must operate with a gearbox.The 12V DC motor is commonly paired with three types of gearboxes: spur gearbox, planetary gearbox, and worm gearbox.

Spur Gearbox

A spur gearbox uses parallel spur gears. It converts high-speed rotation into low-speed, high-torque output. The motor shaft drives a small gear. The small gear drives a larger gear. Each stage reduces speed and multiplies torque.

Features

- Simplest structure, parallel spur gears.

- Low manufacturing cost, mature process.

- High efficiency (≈95%).

- Higher noise, limited load capacity.

Applications

- Toy cars, small appliances (shavers, fans).

- Light mechanical equipment.

- Low-cost cases with low noise requirements.

Advantages

- Lowest cost, good for mass production.

- High efficiency, low energy loss.

- Simple structure, easy maintenance.

Disadvantages

- Limited load capacity.

- High noise and vibration.

- Shorter gear life, wear at high speed.

Planetary Gearbox

A planetary gearbox has a sun gear, planet gears, and a ring gear. The motor drives the sun gear. Planet gears roll around it. They drive the ring gear or carrier. This produces high torque and low speed.

Features

- Multiple gears share the load.

- Compact structure, small size, high torque.

- High torque density, long life, good efficiency.

- Complex manufacturing, higher cost than spur.

Applications

- Robot joints and servo systems.

- Industrial automation.

- Precision instruments and medical devices.

- EV drives, drone power systems.

Advantages

- Strong load capacity.

- High torque density, small size.

- Long life, reliable.

- Good efficiency, smooth operation.

Disadvantages

- Complex manufacturing, higher cost.

- Difficult assembly and maintenance.

Worm Gearbox

A worm gearbox uses a worm and worm wheel. The motor drives the worm at high speed. The worm pushes the worm wheel slowly. It achieves large reduction ratio and high torque. It also provides self-locking to prevent back drive.

Features

- Worm and worm wheel with angled teeth.

- Large reduction ratio.

- Self-locking function.

- Compact structure, but more friction.

- Lower efficiency than spur or planetary.

Applications

- Car door systems, seat adjusters.

- Lifting platforms, automatic doors, security devices.

- Conveyors, positioning systems.

Advantages

- Strong self-locking, high safety.

- Large reduction ratio, high torque at low speed.

- Smooth operation, low vibration.

- Relatively compact.

Disadvantages

- Low efficiency, higher energy use.

- High friction and heat, wear in long use.

- Lower load efficiency than planetary gearboxes.

Table 1:Common Gearbox Comparison Table

| Gearbox Type | Torque | Efficiency | Noise | Cost | Self-locking | Lifetime |

| Spur | Low–Medium | High | High | Lowest | No | Medium |

| Planetary | Medium–High | Medium–High | Medium | Higher | No | Long |

| Worm | High | Low | Low | Medium | Strong | Medium |

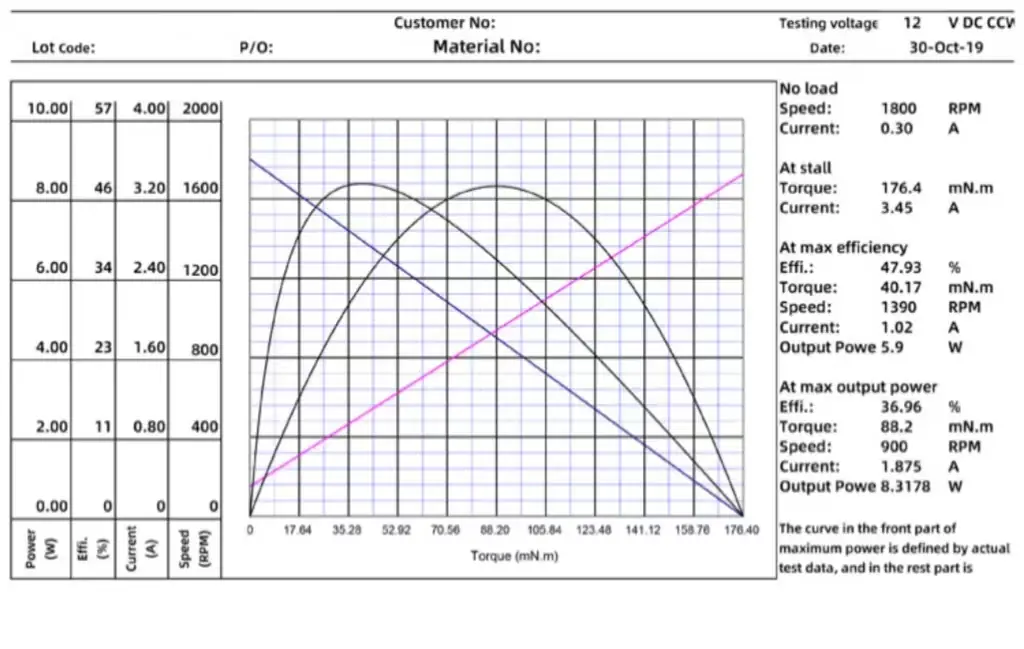

12V DC Motor:Key Parameters

Engineers must consider torque, current, speed, power, lifetime, and noise. They must also reserve margin for driver and power supply. 12V DC motors are convenient and supported by a mature ecosystem. But different applications require different parameter matching.

TSL-GM12-N20-KVA,12V DC, Parameters

| Ratio | No Load | Rated Load | Stall | ||||

| i : 1 | Current | Speed | Current | Speed | Torque | Current | Torque |

| 10:1 | ≤55mA | 2150rpm | ≤0.2A | 1450rpm | 50g.cm | ≤0.5A | 0.13kg.cm |

| 20:1 | ≤55mA | 1075rpm | ≤0.2A | 720rpm | 100g.cm | ≤0.5A | 0.26kg.cm |

| 30:1 | ≤55mA | 717rpm | ≤0.2A | 480rpm | 150g.cm | ≤0.5A | 0.39kg.cm |

| 50:1 | ≤55mA | 430rpm | ≤0.2A | 290rpm | 250g.cm | ≤0.5A | 0.7kg.cm |

| 100:1 | ≤55mA | 215rpm | ≤0.2A | 145rpm | 500g.cm | ≤0.5A | 1.3kg.cm |

| 150:1 | ≤55mA | 143rpm | ≤0.2A | 95rpm | 750g.cm | ≤0.5A | 2.0kg.cm |

| 210:1 | ≤55mA | 102rpm | ≤0.2A | 70rpm | 1000g.cm | ≤0.5A | 2.7kg.cm |

| 298:1 | ≤55mA | 72rpm | ≤0.2A | 48rpm | 1500g.cm | ≤0.5A | 3.0kg.cm |

| 380:1 | ≤55mA | 57rpm | ≤0.2A | 38rpm | 1900g.cm | ≤0.5A | 3.0kg.cm |

| 1000:1 | ≤55mA | 21rpm | ≤0.2A | 14rpm | 3000g.cm | ≤0.5A | 3.5kg.cm |

Torque

- Starting/Stall torque: maximum torque at power-on, decides if load can be overcome.

- Rated torque: stable torque at rated voltage and current, key selection index.

- Peak torque: short-term maximum torque, for shocks or load variations.

Why actual torque is lower than theory?

- Temperature rise: winding heats, resistance increases, current drops.

- Voltage drop: supply or wiring lower than rated voltage.

- Gearbox loss: friction and efficiency reduce output torque.

Engineer tip: keep 20–30% torque margin. Avoid full-load operation for long periods.

Current

No-load current: current with no load, shows friction and internal loss.

Rated current: current at rated load, basis for power design.

Stall current: maximum current when rotor is blocked, 5–10× rated current.

Engineer tip: design power supply for stall current. Reserve 30–50% margin to avoid overload or driver damage.

Speed (RPM)

Typical range at 12V: 3000–12000 RPM, depends on motor type.

High gear ratio → low speed, high torque (robot joints, lifts).

Low gear ratio → high speed, low torque (fans, pumps).

Engineer tip: match gear ratio to load. Avoid “too fast but weak torque” or “too slow but excessive torque.”

Power

Formula: P = V × I.

Typical range: a few watts to several hundred watts.

Power defines load capacity and impacts supply and cooling design.

Lifetime

Brushed motors: brush wear limits life, usually hundreds to thousands of hours.

Brushless motors: no brush wear, life can reach tens of thousands of hours.

Overload, heat, poor lubrication shorten life.

Noise

Brushed: brush friction, sparks.

Gearbox: gear meshing vibration.

Brushless: mainly airflow and bearing noise.

Engineer tip:

- For long life (medical, drones) → choose brushless.

- For noise-sensitive cases (home, office) → focus on gearbox precision and lubrication.

How to Properly Select a 12V DC Motor?

In forums and engineering communities, motor selection is one of the most common topics. The following process summarizes the steps engineers often use in real projects. It includes theoretical calculations and practical experience.

Define load conditions

First, define the basic requirements of the application. This includes load torque, load inertia, duty cycle (continuous or intermittent), and expected lifetime. These conditions determine the basic specification range of the motor. They are also the foundation of the entire selection process.

Calculate the required torque and speed

First figure out the torque your load needs. Add a margin, usually 20–30%, so the motor won’t struggle. Then look at speed. Think in RPM, or convert from linear speed if you’re using screws or gears.

Heavy loads with big inertia need higher peak torque for acceleration. Check the motor’s torque–speed curve against your load profile. Make sure it can handle both continuous torque and short bursts. Use a gearbox if you need to balance speed and torque.

Select the motor structure

Different applications require different motor types.

- Cost-sensitive, low lifetime → Brushed DC Motor

- Precision control, fast response, low noise → Coreless / BLDC

- High torque, low speed, heavy load → DC Gear Motor

- Long lifetime, unattended operation → BLDC Motor

Check current and power capability

Power design is the most easily ignored part.

You must ensure: Peak power supply current ≥ Stall current × 1.2

Otherwise, problems may occur: the motor may not start, the controller may brown out, or the fuse may blow. The driver and power system must reserve enough margin.

Select the proper control method

Choose control strategy based on application.

- PWM speed control → Fans, pumps

- H-bridge forward/reverse → Robot drives

- Hall-based BLDC control → BLDC motors

- PID + encoder closed loop → Precision systems (robot arms, lifters)

If you are still unsure how to choose, feel free to contact our engineers for support.

12V DC Motors:Typical Application

12V DC motors are widely used across different fields, each with specific requirements and suitable models.

Automotive systems (locks, pumps, lifters)

Applications: central door lock, washer pump, seat adjuster, window/TV lifter

Features: medium torque, stability, certain lifetime

Recommended models: RS series brushed motors, BLDC 2838,BLDC 2430

Small pumps (Water Pump / Air Pump)

Applications: water pumps, air pumps

Features: high speed, low torque, lightweight, low cost R

Recommended models: 280 / 370 / 545 motors + spur gearbox,GM16-030

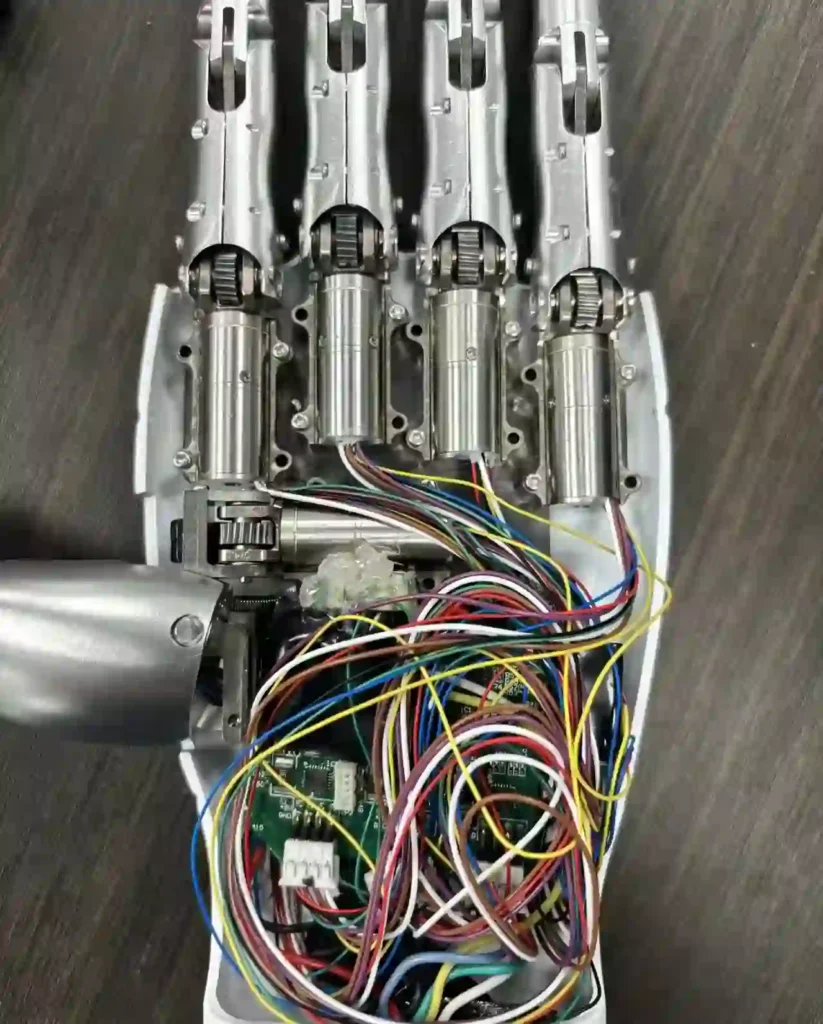

Robotics and automation

Applications: robot drive, automation arms, precision positioning

Features: high torque, compact size, long lifetime

Recommended models: coreless planetary gear motor

Medical and small home appliances

Applications: medical devices, low-noise appliances (toothbrushes, massagers)

Features: low noise, long life, smooth operation

Recommended models: BLDC-2418+Planetary Gearbox

Common Matching Issues in 12V DC Motor Applications

In real projects, 12V motors often face practical problems. Understanding these issues helps engineers choose the right solution.

Automatic door lock

Issue: insufficient torque or unstable power supply causes incomplete lock motion.

Key point: choose a small high-torque geared motor. Consider self-locking (worm gear).

Automotive washer pump

Issue: high current; startup surge burns the fuse or causes power drop.

Key point: check stall current. Power supply must reserve margin. Choose waterproof, dustproof motors.

Lifters

Issue: heavy load and long duty cycle cause overheating or jamming.

Key point: use planetary gear motors for high torque and lifetime. Add overload protection.

Robot drive

Issue: speed/torque mismatch causes unstable movement or fast battery drain.

Key point: choose proper reduction ratio. Prefer BLDC motors for higher efficiency and lifetime.

DC screw actuators

Issue: insufficient thrust or overheating in stall condition.

Key point: use high-torque reduction motors (planetary or worm). Reserve stall current margin.

Water/air pumps

Issue: large startup current and overload; long run causes high temperature.

Key point: choose low-current, high-efficiency motors. Add cooling or intermittent duty.

Servo mechanisms

Issue: low positioning accuracy or back-driving causes drift.

Key point: choose motors with encoders or worm gear reducers for accuracy and self-locking.

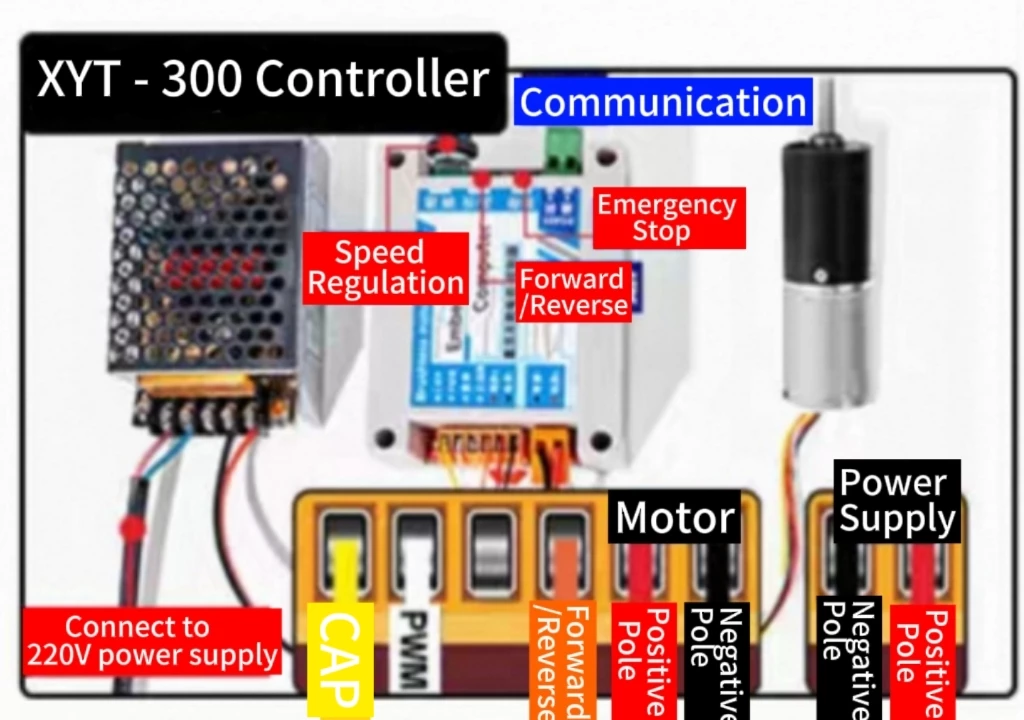

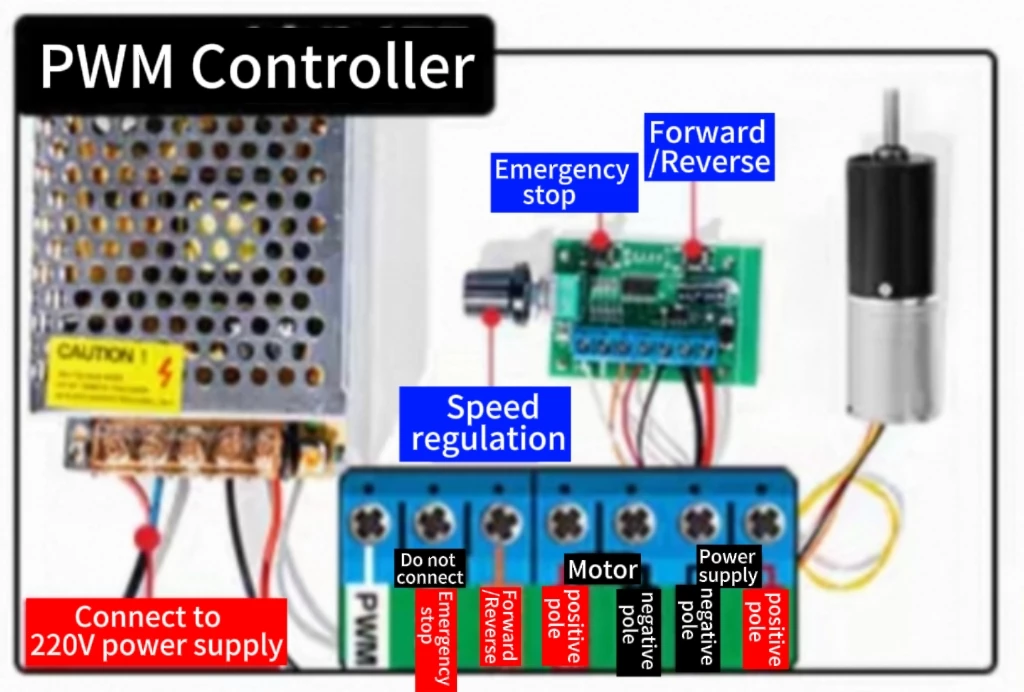

How to Properly Match a 12V DC Motor with Power Supply / Driver?

The key is: current margin + PWM control + protection mechanisms.

Engineers must consider startup and stall current, and reserve enough margin in the power supply and driver. Add thermal and stall protection to ensure stable and reliable operation.

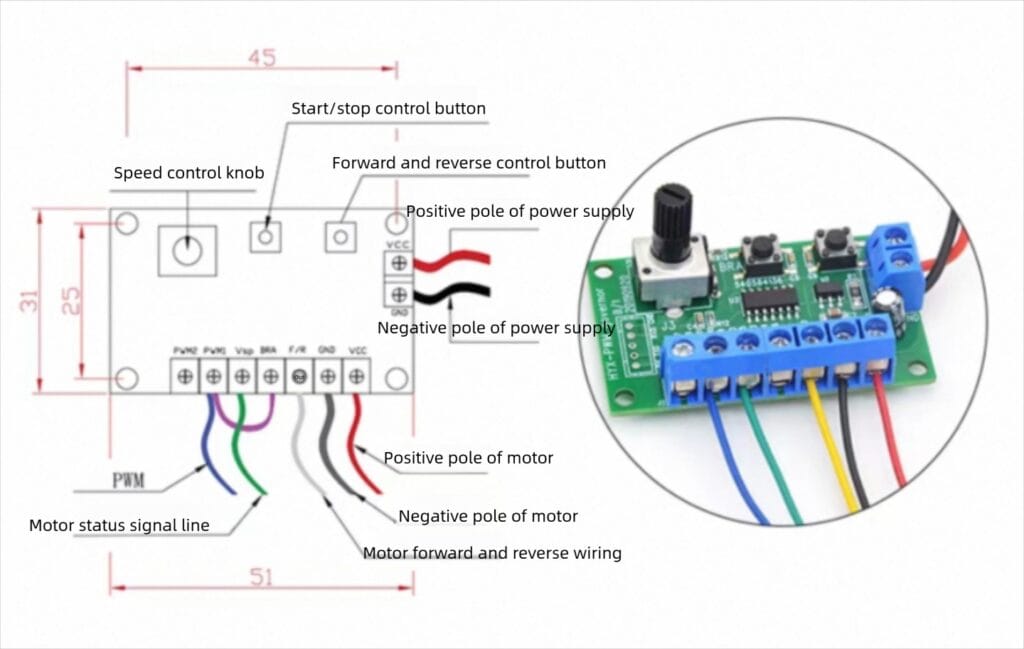

Use PWM control

PWM is the most common speed control method. It adjusts average voltage by changing duty cycle.

Advantages: high efficiency, low heat, fast response.

Note: too low PWM frequency causes vibration and noise. Recommended: several kHz to tens of kHz.

Consider startup current (2–5× rated current)

A 12V motor draws 2–5× rated current at startup or stall. If the driver or power supply cannot provide it, typical issues are:

- Motor fails to start

- Controller resets

- Fuse blows

Power supply must reserve 30–50% margin

Peak supply current ≥ Stall current × 1.2

Common engineering practice:

- Add 30–50% margin above rated current

- For battery systems, consider battery discharge rating (C-rate)

Over-temperature / stall protection

Over-temperature protection: prevents insulation damage. Implement via temperature sensors or built-in driver protection.

Stall protection: prevents burnout during jamming.

Methods: 1.Driver cuts power when current is abnormal 2. Software current limiting + timer protection

Difference between speed control and voltage control

Speed control (PWM): efficient and standard.

Voltage reduction (linear control): simple but inefficient. It may cause hard starting and low torque.

Recommendation:

- Prefer PWM control

- Voltage reduction is only for simple or low-cost cases

Conclusion

12V DC motors remain mainstream in robotics, automotive devices, home automation, and light machinery. The core reasons are the mature power ecosystem, safety, affordability, and sufficient power density. When selecting a motor, engineers must evaluate torque, current, speed, power, lifetime, and noise. Always reserve margin for the driver, power supply, and thermal design.

Choosing the right motor type (Brushed / Coreless / BLDC / Gear Motor) and gearbox type (Spur / Planetary / Worm) directly affects performance, reliability, and cost. Brushed motors suit low-cost, simple-control cases. BLDC motors and planetary gearboxes are better for long life, high efficiency, low noise, and precise control.

With over 15 years of experience in DC motors, TSL MOTOR provides reliable 12V motor solutions for various applications, including standard models and customized designs. We hope this analysis helps engineers and product designers avoid common pitfalls and build reliable, compliant motor systems more efficiently.

12V DC Motor – FAQ

Q1:What are the advantages of using a 12V DC motor?

12V motors are easy to power, low-cost, widely compatible, and suitable for mobile and small automation systems.

Q2:How do I determine the required torque?

Calculate load torque + friction + acceleration torque. Always reserve 20–30% safety margin.

Q3: Can a 12V motor run continuously under full load?

Usually no. Continuous full-load operation causes overheating and reduces motor life.

Q4:What size power supply should I choose?

The supply must handle ≥ 1.2× the motor’s stall current to ensure reliable startup.

TSL-Motor: Custom DC Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

-

Custom Micro Motors5 products

Custom Micro Motors5 products -

DC Gear Motor139 products

DC Gear Motor139 products-

6mm Planetary Gear Motor4 products

6mm Planetary Gear Motor4 products -

6mm Planetary Metal Gear Motor3 products

6mm Planetary Metal Gear Motor3 products -

Brushless Gear Motor17 products

Brushless Gear Motor17 products -

Micro Gear Motor64 products

Micro Gear Motor64 products-

Coreless Gear Motor11 products

Coreless Gear Motor11 products -

N20 Gear Motor26 products

N20 Gear Motor26 products -

Plastic Gearbox Motor8 products

Plastic Gearbox Motor8 products -

Standard Gear Motor15 products

Standard Gear Motor15 products -

Stepper Gear Motor15 products

Stepper Gear Motor15 products

-

-

Planetary Gear Motor29 products

Planetary Gear Motor29 products -

Spur Gear Motor63 products

Spur Gear Motor63 products -

Worm Gear Motor28 products

Worm Gear Motor28 products

-

-

DC Motor78 products

DC Motor78 products-

Brushed DC Motor16 products

Brushed DC Motor16 products -

Brushless DC Motor21 products

Brushless DC Motor21 products-

Inrunner Rotor BLDC Motor6 products

Inrunner Rotor BLDC Motor6 products -

Outrunner Rotor BLDC Motor13 products

Outrunner Rotor BLDC Motor13 products

-

-

Coreless DC Motor13 products

Coreless DC Motor13 products -

Micro DC Motor15 products

Micro DC Motor15 products -

Stepper Motor13 products

Stepper Motor13 products

-

-

Vibration Motors71 products

Vibration Motors71 products-

Brushless Vibration Motor8 products

Brushless Vibration Motor8 products -

Coin Vibration Motor22 products

Coin Vibration Motor22 products -

Coreless Vibration Motor3 products

Coreless Vibration Motor3 products -

Encapsulated Vibration Motor6 products

Encapsulated Vibration Motor6 products -

Linear Resonant Actuator12 products

Linear Resonant Actuator12 products -

Powerful Vibrating Motor17 products

Powerful Vibrating Motor17 products -

SMD Vibration Motor4 products

SMD Vibration Motor4 products -

Sonic Vibration Motor2 products

Sonic Vibration Motor2 products

-