Robotics, medical devices, and automation all face the same challenge: high precision and high torque in limited space.

The 28mm planetary gearbox 27:1 is a proven compact solution. It is efficient, stable, and widely used.

This article pairs it with the TSL-28GP-365 DC motor to help you quickly judge whether this setup fits your project.

Key Takeaways

- The 28mm planetary gearbox offers high torque density in a compact size.

- Planetary gear structures provide higher efficiency and smoother operation than spur or worm gearboxes.

- The 27:1 reduction ratio balances speed, torque, efficiency, and control performance.

- Compared with very high ratios, 27:1 maintains better dynamic response and back-drivability.

- Final output speed and torque depend on the motor, voltage, and load, not only the ratio.

- The 28mm 27:1 gearbox supports multiple motor types, including DC, BLDC, stepper, and coreless motors.

- 27:1 is a proven starting point, but ratio and motor can be adjusted if space allows.

Why Use a Planetary Gearbox?

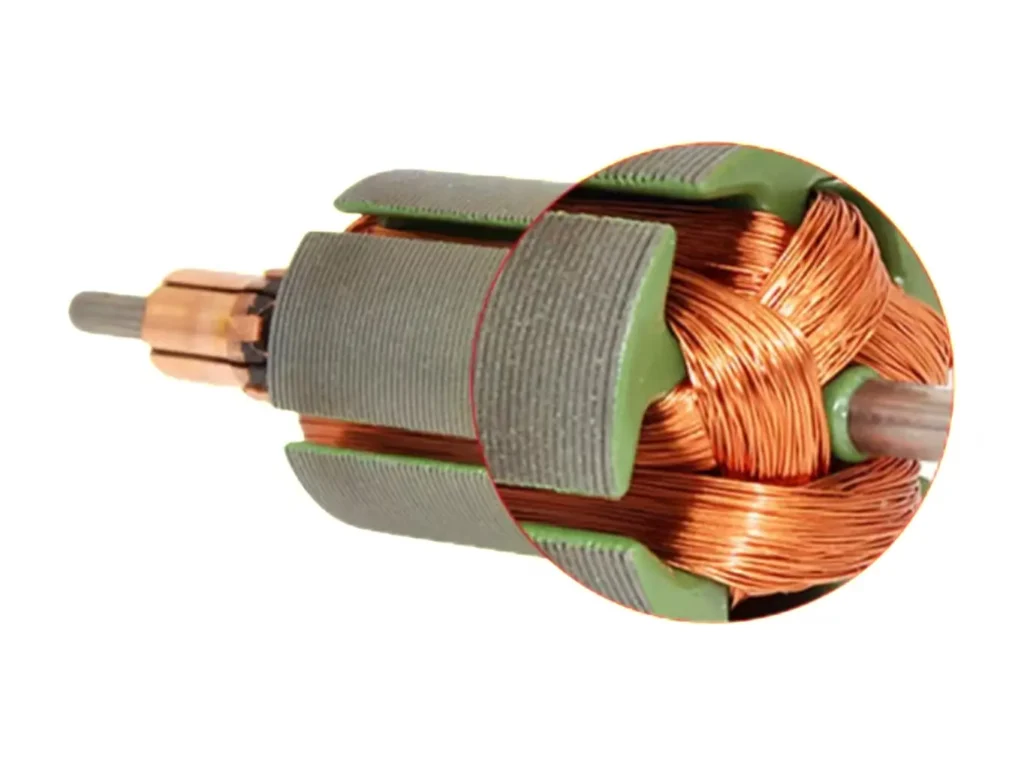

The name “planetary gearbox” comes from its unique gear layout.Multiple planet gears rotate around a central sun gear.The structure is similar to planets orbiting a star.

In micro and small-to-medium power drive systems, common reduction structures include spur gearboxes, worm gearboxes, and planetary gearboxes.

Among them, planetary gearboxes are widely used.The main reasons are as follows:

Higher Torque

The reason why a 28mm planetary gearbox has much higher torque density than a traditional spur gear structure lies in its load-sharing mechanism.

In a spur gearbox, all torque is carried by a single gear pair.Under high load, gear teeth are more likely to suffer fatigue or breakage.

A planetary gearbox usually contains 3–4 planet gears.Torque is evenly distributed across multiple meshing points.This greatly reduces the load on each tooth surface.

For the 28mm size, this multi-point meshing feature allows several times the stall torque of a traditional structure without increasing volume.For example, the stall torque of TSL-28GP-365 is at least 40 kg·cm.

Higher Transmission Efficiency

Planetary gearboxes mainly use rolling contact during meshing.Sliding friction between tooth surfaces is very small.

Mechanical efficiency usually exceeds 90%.This is much higher than the 50%–70% efficiency common in worm gearboxes.

Worm gear structures involve large amounts of sliding friction.This generates significant heat.

It not only reduces efficiency but also accelerates lubricant aging.It limits reliability in long-term continuous operation.

By comparison, the high efficiency of planetary gearboxes means lower heat generation, more stable torque output, and higher energy efficiency.

Smoother Operation

The force distribution of a planetary gear structure is symmetrical.Multiple planet gears are evenly arranged around the sun gear.

With many meshing points evenly distributed, the system maintains good dynamic balance during operation.

This means that planetary gearboxes have lower vibration, lower noise, and easier backlash control.

- Multi-point meshing makes gear meshing forces more continuous.It avoids the periodic impact seen in single gear-pair meshing.

- Tooth surface loads are evenly distributed.Meshing noise is significantly lower than in spur gear structures.

- Backlash accumulation error is naturally smaller in planetary structures.They are suitable for applications requiring precise positioning.

For applications that require “feel” and “precision,” planetary gearboxes offer clear advantages in stability, responsiveness, and repeat positioning accuracy.

Why Choose a 27:1 Reduction Ratio?

In actual selection, a higher reduction ratio is not always better.For 28mm planetary gearboxes, 27:1 has become the most common and well-balanced option.

The core reason is that it achieves an excellent balance among speed, torque, efficiency, size, and control performance.

Moderate Output Speed

The higher the reduction ratio, the lower the output speed.In the 28mm size range, motor platforms such as 365, 385, or brushless motors typically have no-load speeds between 3000 and 12000 rpm.

For example, under 6V with TSL-28GP-365:

- At a 100:1 reduction ratio, the rated output speed is 33 rpm.System response becomes noticeably slower.Dynamic performance is limited.

- At a 27:1 reduction ratio, the rated output speed is 120 rpm.It provides sufficient torque.It also maintains good dynamic response.

For systems requiring fast start, stop, and adjustment, such as robot joints, medical pumps, and actuators, this speed range is especially important.

More Sufficient Torque Margin

In 28mm planetary gearboxes, 5.2:1, 14:1, and 19:1 are high-speed ratios.Torque amplification is limited.They are suitable for light loads or high-speed transmission.

The 27:1 ratio provides higher torque multiplication.

For example, TSL-28GP-365 27:1 at 24V achieves a stall torque of at least 3.5 kg·cm.

This is sufficient for most small and medium robot and automation mechanisms.

In other words, 27:1 is a middle point.It avoids insufficient torque.It also avoids excessive speed sacrifice.

Higher Efficiency

A higher reduction ratio means more gear stages.Typically, a single planetary stage provides ratios from 3:1 to 10:1.Higher ratios require multiple stages.

A 27:1 ratio is usually implemented with a two-stage planetary gear system.

For TSL 28mm planetary gearboxes:

- Single-stage efficiency is about 90%

- Two-stage efficiency is about 80%

- Three-stage efficiency is about 70%

- Four-stage efficiency drops to about 60%

This efficiency advantage means that, under the same battery power consumption, the 27:1 configuration provides longer endurance and lower heat generation.

27:1 Is Only a Ratio, Not the Final Performance Answer

It should be clarified that 27:1 is only a reduction ratio.It does not directly equal final output speed or torque.

Actual output performance is determined by multiple factors:

- Motor rated speed and power

- Selected reduction ratio

- Operating voltage

- Actual load and working conditions

If you have clear speed or torque targets, 27:1 can be used as a reference.It is not the only option.

If space allows, the reduction ratio can be adjusted.This is easier than replacing the motor.

Remember:

Increasing the reduction ratio lowers speed and increases torque.

Reducing the reduction ratio increases speed and reduces torque.

Typical Applications of 28mm Planetary Gearbox 27:1

The reason why 28mm planetary gear motors are used across robotics, medical, smart home, and financial equipment lies in their balanced engineering solution.They achieve balance among size, torque capability, efficiency, noise, and cost.

The 27:1 ratio falls into a “golden range.”Speed is not too slow.Torque is not too weak.Efficiency is not too low.Back-drivability is acceptable.

Robotics and Collaborative Automation

In educational robots and light industrial robotic arms, 28mm motors are often used to drive wrist joints or grippers.

Robot joints usually need to provide high torque at low speed to maintain posture or grip objects.

Collaborative robots place special importance on back-drivability.A 27:1 ratio provides sufficient torque amplification.With fewer stages, it still allows manual movement when power is off.

This enables hand-guiding and teaching.High reduction ratios such as 500:1 cannot achieve this.

Medical Technology and Laboratory Automation

Medical pumps, such as infusion pumps and syringe pumps, are key application scenarios for 28mm gear motors.

In these devices, the motor must drive the pump shaft at an extremely constant speed.Using a 27:1 reduction ratio with 16mm or 28mm motors ensures flow accuracy.

The multi-tooth meshing of planetary gears significantly reduces operating noise.This meets the strict low-noise requirements of medical environments.

Smart Home and Building Automation

In automatic curtains, smart door locks, and electric actuators, the size of a 28mm planetary gear motor fits well into narrow installation spaces.

For example, the 120 rpm speed of TSL-28GP-365 27:1 matches the visual rhythm of curtain pulling or door lock operation.

It is not too fast to cause impact.It is not too slow to make users wait.

The long service life of metal planetary gears ensures years of maintenance-free operation.

This greatly reduces total ownership cost.

Financial and Office Automation

ATM machines, coin sorters, and high-speed scanners require frequent start, stop, and reversal.

28mm planetary gear motors use robust alloy steel gear sets.They can withstand inertial shock caused by frequent direction changes.

The 27:1 configuration provides enough power to handle thick stacks of banknotes.It also maintains processing speed.This ensures operational efficiency of financial equipment.

TSL-28GP-365 Performance Parameter Table

TSL-28GP-365,DC 12.0 V

| Ratio | Gearbox | No Load | Rated Load | Stall | ||||

| i : 1 | Length | Current | Speed | Current | Speed | Torque | Current | Torque |

| 3.7:1 | 27.5mm | ≤0.15A | 1,200rpm | ≤0.25A | 890rpm | 0.1kg.cm | ≤0.7A | ≥0.3kg.cm |

| 5.2:1 | 27.5mm | ≤0.15A | 860rpm | ≤0.25A | 600rpm | 0.14kg.cm | ≤0.7A | ≥0.4kg.cm |

| 14:1 | 35.5mm | ≤0.15A | 320rpm | ≤0.25A | 235rpm | 0.35kg.cm | ≤0.7A | ≥1.0kg.cm |

| 19:1 | 35.5mm | ≤0.15A | 235rpm | ≤0.25A | 170rpm | 0.50kg.cm | ≤0.7A | ≥1.3kg.cm |

| 27:1 | 35.5mm | ≤0.15A | 165rpm | ≤0.25A | 120rpm | 0.65kg.cm | ≤0.7A | ≥1.8kg.cm |

| 51:1 | 43.5mm | ≤0.15A | 88rpm | ≤0.25A | 64rpm | 1.2kg.cm | ≤0.7A | ≥2.2kg.cm |

| 71:1 | 43.5mm | ≤0.15A | 63rpm | ≤0.25A | 46rpm | 1.7kg.cm | ≤0.7A | ≥4.5kg.cm |

| 100:1 | 43.5mm | ≤0.15A | 45rpm | ≤0.25A | 33rpm | 2.5kg.cm | ≤0.7A | ≥9.0kg.cm |

| 139:1 | 43.5mm | ≤0.15A | 32rpm | ≤0.25A | 23rpm | 3.5kg.cm | ≤0.7A | ≥10.0kg.cm |

| 264:1 | 51.5mm | ≤0.15A | 17rpm | ≤0.25A | 12rpm | 6.5kg.cm | ≤0.7A | ≥20.0kg.cm |

| 369:1 | 51.5mm | ≤0.15A | 12rpm | ≤0.25A | 8rpm | 9.0kg.cm | ≤0.7A | ≥28.0kg.cm |

| 515:1 | 51.5mm | ≤0.15A | 8.7rpm | ≤0.25A | 6rpm | 12.0kg.cm | ≤0.7A | ≥40.0kg.cm |

TSL-28GP-365,DC 24.0 V

| Ratio | Gearbox | No Load | Rated Load | Stall | ||||

| i : 1 | Length | Current | Speed | Current | Speed | Torque | Current | Torque |

| 3.7:1 | 27.5mm | ≤0.2A | 2,350rpm | ≤0.5A | 1,780rpm | 0.2kg.cm | ≤1.4A | ≥0.5kg.cm |

| 5.2:1 | 27.5mm | ≤0.2A | 1,700rpm | ≤0.5A | 1,200rpm | 0.26kg.cm | ≤1.4A | ≥0.8kg.cm |

| 14:1 | 35.5mm | ≤0.2A | 640rpm | ≤0.5A | 470rpm | 0.70kg.cm | ≤1.4A | ≥2.0kg.cm |

| 19:1 | 35.5mm | ≤0.2A | 470rpm | ≤0.5A | 340rpm | 1.0kg.cm | ≤1.4A | ≥2.5kg.cm |

| 27:1 | 35.5mm | ≤0.2A | 330rpm | ≤0.5A | 240rpm | 1.3kg.cm | ≤1.4A | ≥3.5kg.cm |

| 51:1 | 43.5mm | ≤0.2A | 176rpm | ≤0.5A | 128rpm | 2.4kg.cm | ≤1.4A | ≥4.3kg.cm |

| 71:1 | 43.5mm | ≤0.2A | 125rpm | ≤0.5A | 90rpm | 3.4kg.cm | ≤1.4A | ≥9.0kg.cm |

| 100:1 | 43.5mm | ≤0.2A | 90rpm | ≤0.5A | 66rpm | 5.0kg.cm | ≤1.4A | ≥20.0kg.cm |

| 139:1 | 43.5mm | ≤0.2A | 64rpm | ≤0.5A | 46rpm | 7.0kg.cm | ≤1.4A | ≥35.0kg.cm |

| 264:1 | 51.5mm | ≤0.2A | 34rpm | ≤0.5A | 24rpm | 13.0kg.cm | ≤1.4A | ≤40.0kg.cm |

| 369:1 | 51.5mm | ≤0.2A | 24rpm | ≤0.5A | 16rpm | 18.0kg.cm | ≤1.4A | ≤40.0kg.cm |

| 515:1 | 51.5mm | ≤0.2A | 17rpm | ≤0.5A | 12rpm | 24.0kg.cm | ≤1.4A | ≤40.0kg.cm |

DC Motor with 28mm Planetary Gearbox 27:1 – TSL-28GP-365 Overview

TSL-28GP-365 is a high-performance planetary gear motor with a 28mm diameter.It supports DC 12V / 24V and allows voltage customization.

It is suitable for automation, robotics, and medical equipment.

Its 27:1 reduction ratio achieves a good balance among speed, torque, and efficiency.It is one of the most commonly used configurations on the 28mm platform.

Key Features

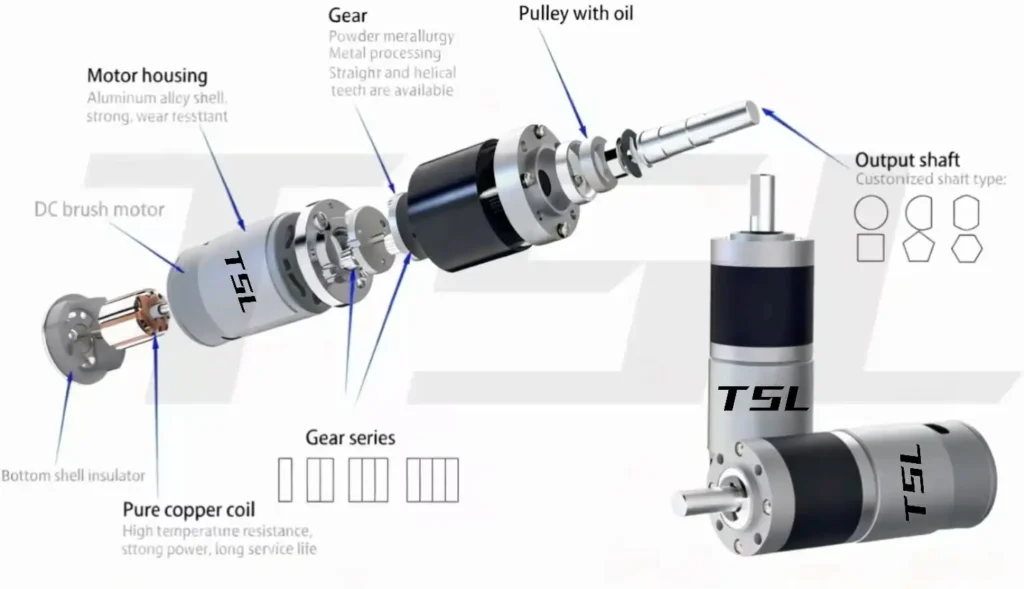

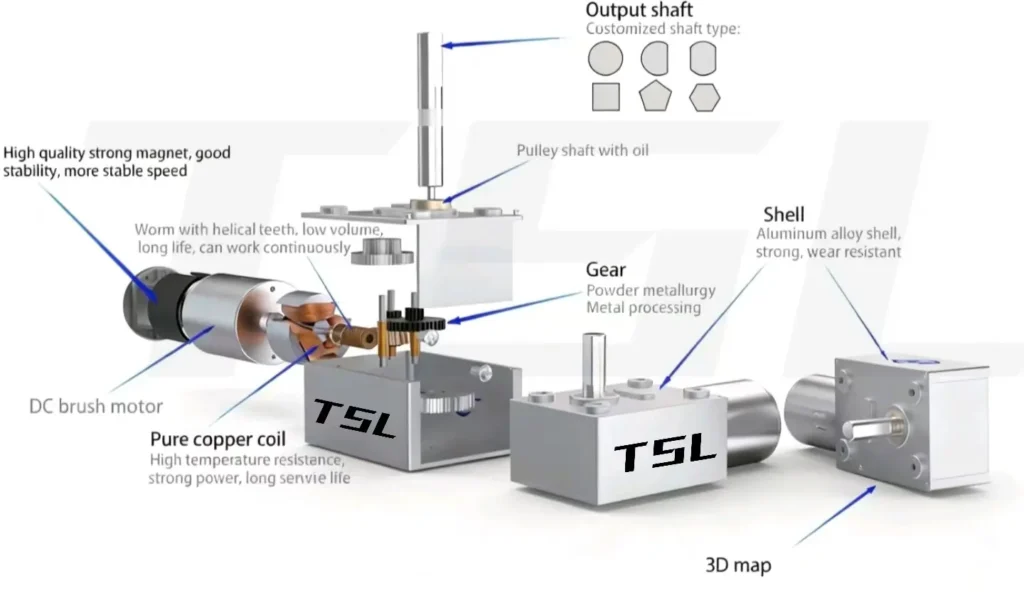

All-Metal Gear Structure

All gears in the 28mm planetary gearbox are made of high-strength metal materials.

The sun gear is made of brass.The planet gears are made of steel.The sun gear rotates at the highest speed and has the highest meshing frequency.It requires low friction and low noise materials.

Brass is softer than steel.It has a lower friction coefficient and self-lubricating properties.

This allows smoother high-speed meshing and reduces noise.

As a “soft gear,” brass also protects steel planet gears.It avoids accelerated wear caused by hard-to-hard meshing.

The TSL-28GP-365 has three planet gears.They carry the main torque output.

Steel has high hardness, high strength, and excellent wear resistance.It can withstand high contact stress and long-term fatigue loads.This makes it ideal for planet gears.If planet gears were made of brass, service life would be greatly reduced.

Pure Copper Windings

The motor rotor uses pure copper windings.Compared with copper-clad aluminum or inferior conductors, pure copper has lower resistivity and better conductivity.

Under the same voltage and size, pure copper windings allow more current to flow.This generates stronger electromagnetic force.

This significantly increases output torque.It also reduces copper loss and heat generation.Overall efficiency and continuous operating capability are improved.

Pure copper wire is also more stable under high temperature and heavy load.This helps extend motor service life.

Ball Bearing Structure

This low-speed, high-torque motor uses a high-quality ball bearing structure.Compared with sleeve bearings, ball bearings have lower friction resistance.

They maintain higher mechanical efficiency during startup, low-speed operation, and frequent start-stop cycles.Ball bearings provide stable support at high speed.They significantly reduce vibration and noise.They also reduce energy loss caused by friction.

TSL MOTOR uses high-quality ball bearings imported from Japan.

This further improves wear resistance, smooth operation, and long-term reliability.These bearings have stronger radial and axial load capacity.They also offer better heat dissipation.

This allows stable output and long service life under continuous operation or high-load conditions.

More Than TSL-28GP-365:27:1 Planetary Gearbox with Multiple Motor Options

Although this article focuses on TSL-28GP-365 (27:1), the gearbox is only part of the drive system.

Different applications have different requirements for speed, torque, lifespan, noise, and control.

Keeping the 28mm planetary gearbox + 27:1 reduction ratio unchanged, we can match multiple motor types to better fit your application.

Brushed DC Motor

Brushed DC motors use brushes and commutators for mechanical commutation.They have a simple structure and easy control.They are the most common and cost-effective solution.

They are suitable for:

- Cost-sensitive projects

- Simple control systems

- Medium and low-speed continuous operation

TSL-28GP-365 belongs to this category.

Brushless DC Motor

Brushless DC motors use electronic commutation.They provide higher efficiency and no mechanical wear.They are suitable when higher requirements are placed on lifespan, efficiency, noise, and reliability.

They offer:

- Long service life

- High efficiency

- Low noise

- Suitability for long-term continuous operation

Combined with a 27:1 planetary gearbox, they are ideal for service robots, medical equipment, and high-reliability industrial applications.

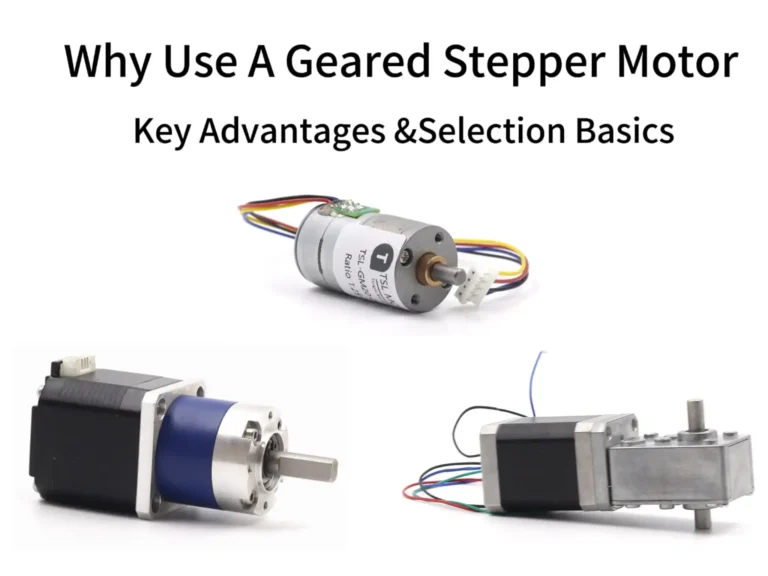

Hybrid Stepper Motor

Hybrid stepper motors combine permanent magnet and variable reluctance structures.

They improve positioning accuracy and holding torque through toothed magnetic paths.

They offer:

- Higher holding torque

- Finer micro-stepping control

- Suitability for semi-closed-loop or light servo systems

Combined with a 27:1 planetary gearbox, they are suitable for laboratory instruments, optical platforms, and micro-positioning mechanisms.

We also provide hybrid stepper motor and 27:1 planetary gearbox combination solutions.

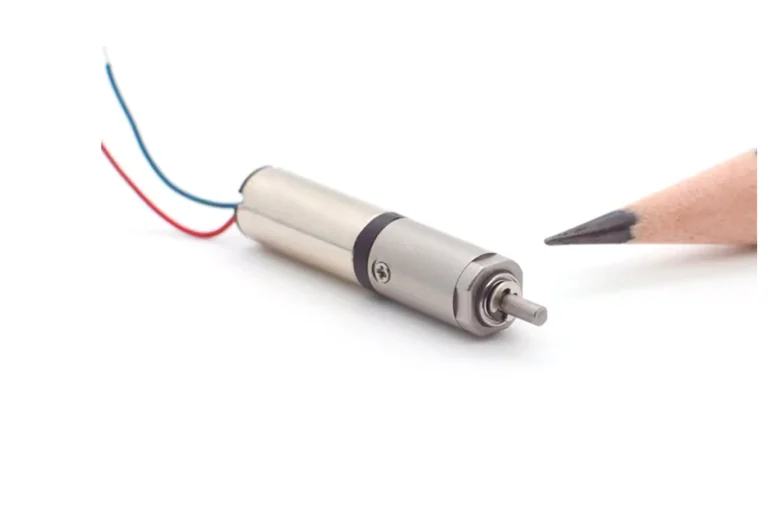

Coreless Motor

Coreless motors use an ironless hollow winding structure.Rotor inertia is extremely low.They provide very fast response and cogging-free operation.

They are suitable for applications requiring:

- Fast response

- Lightweight design

- Very low noise

Combined with a 27:1 planetary gearbox, they are ideal for medical pumps, precision instruments, and micro-robots.

Customization Support

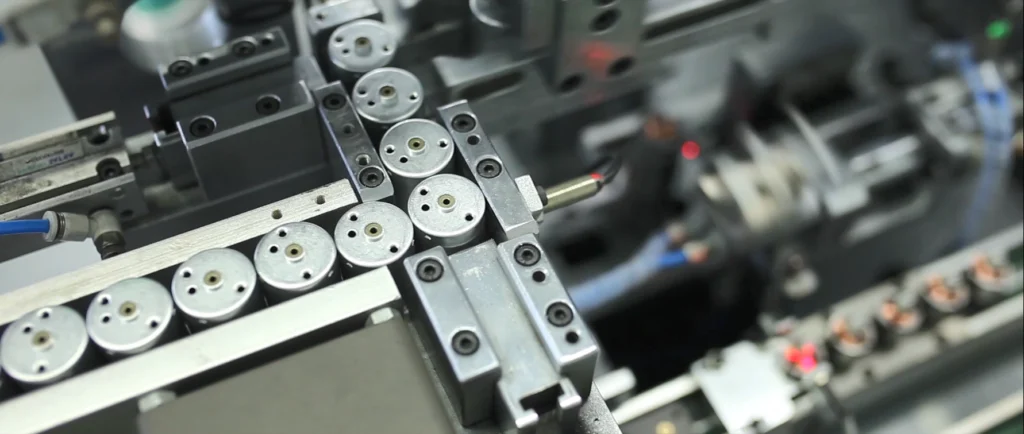

In addition to the standard TSL-28GP-365, TSL MOTOR can match different DC motor specifications on the same gearbox platform.System-level customization is available.

Motor Performance Parameters

- Operating voltage

- No-load speed

- Maximum output torque

- Startup and stall characteristics

- Noise and efficiency optimization

Environment and Reliability

- High or low temperature operation

- Long-term continuous operation

- Lifetime ratings such as 500h / 1000h / 3000h

- Dustproof, moisture-proof, and corrosion-resistant treatment

Structure and Dimensions

- Motor diameter and length

- Output shaft diameter, length, D-shaft, spline, or special structures

- Mounting flange and hole positions

- Custom layouts for limited space

Functions and Interfaces

- Encoders (Hall, magnetic, optical)

- Cable length, wiring order, sheath material

- Connector types such as JST or Molex

TSL MOTOR has focused on DC motors for more than 15 years.It is a leading DC motor manufacturer in China.

ou may directly present specific application requirements or special needs.

The TSL MOTOR engineering team will evaluate feasibility, structural limits, and performance targets.We will provide the most suitable solution.

Conclusion: 27:1 Is a Starting Point, Not a Limitation

In the 28mm size class, planetary gearboxes dominate because they balance torque density, efficiency, stability, and lifespan exceptionally well.

Among them, 27:1 is the most proven and widely used ratio—strong under load, responsive in motion, and suitable for robotics, medical devices, smart home systems, and financial automation.

But 27:1 is not the limit. Actual output depends on the motor, ratio, voltage, and load. With the same 28mm platform, adjusting the ratio or motor type can deliver more precise performance.

That’s why TSL MOTOR offers more than one model. Whether brushed, brushless, stepper, or coreless, we can match the best motor–gearbox combination for your application.

If you already know your speed or torque targets, 27:1 is a solid starting point. If you want to reduce trial‑and‑error, our engineering team can help with professional selection.

Choosing the right platform matters more than fixating on a single number.

FAQ

Q1: Why is the 27:1 ratio commonly used in 28mm planetary gearboxes?

A: It offers a balanced combination of speed, torque, efficiency, and control performance.

Q2: What output speed can be expected with a 28mm 27:1 planetary gear motor?

Output speed depends on motor speed and voltage.At 6V, Rated speed is around 120 rpm with a 365 motor.

Q3:Can the 28mm 27:1 planetary gearbox be combined with different motors?

It can be matched with brushed DC, brushless DC, hybrid stepper, or coreless motors depending on application needs.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

28mm Planetary Gear Motor Model TSL-28GP-365

♦ Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TTSL-28GP-365

- Voltage range:DC12V/24V

- Motor Diameter:φ28mm

- Shaft length:12mm

- Shaft Diameter:6mm , thick 4mm

- #More Specifications

- #Outline Drawing

♦ Typical Applications:

- Smart Robot, Electric Curtains

- Smart Balancing Car, Smart Robotic Arm