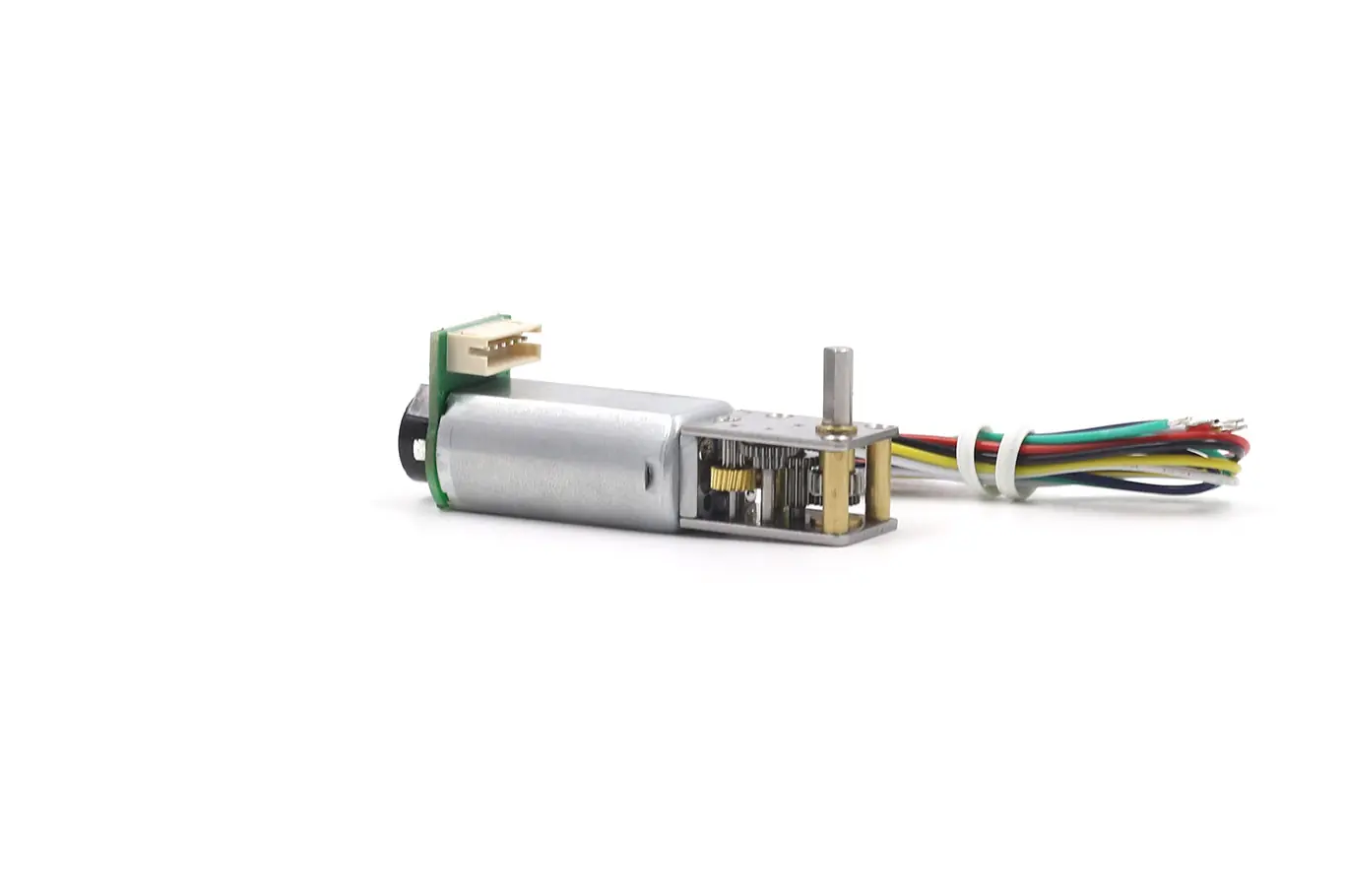

12mm Worm Gear Motor Model TSL-GW1218-050-EN

Basic Info:

- Motor Type:Worm Gear Motor

- Motor Model:TSL-GW1218-050-EN

- Rated Voltage:6V/12V DC/Customizable

- Max No Load Speed:380pm

- Encoder specifications:AB dual phase encoder 7 line basic signal voltage 3.3V or 5.0V

- Product Features:All-metal worm gear and worm wheel structure with power-off self-locking capability.

- #More Specifications

- #Outline Drawing

Typical application:

- Smart selfie stick, smart camera gimbal,

- Intelligent robot camera corner,

- intelligent micro robot, etc.

12V Worm Gear Motor Encodering Datasheet

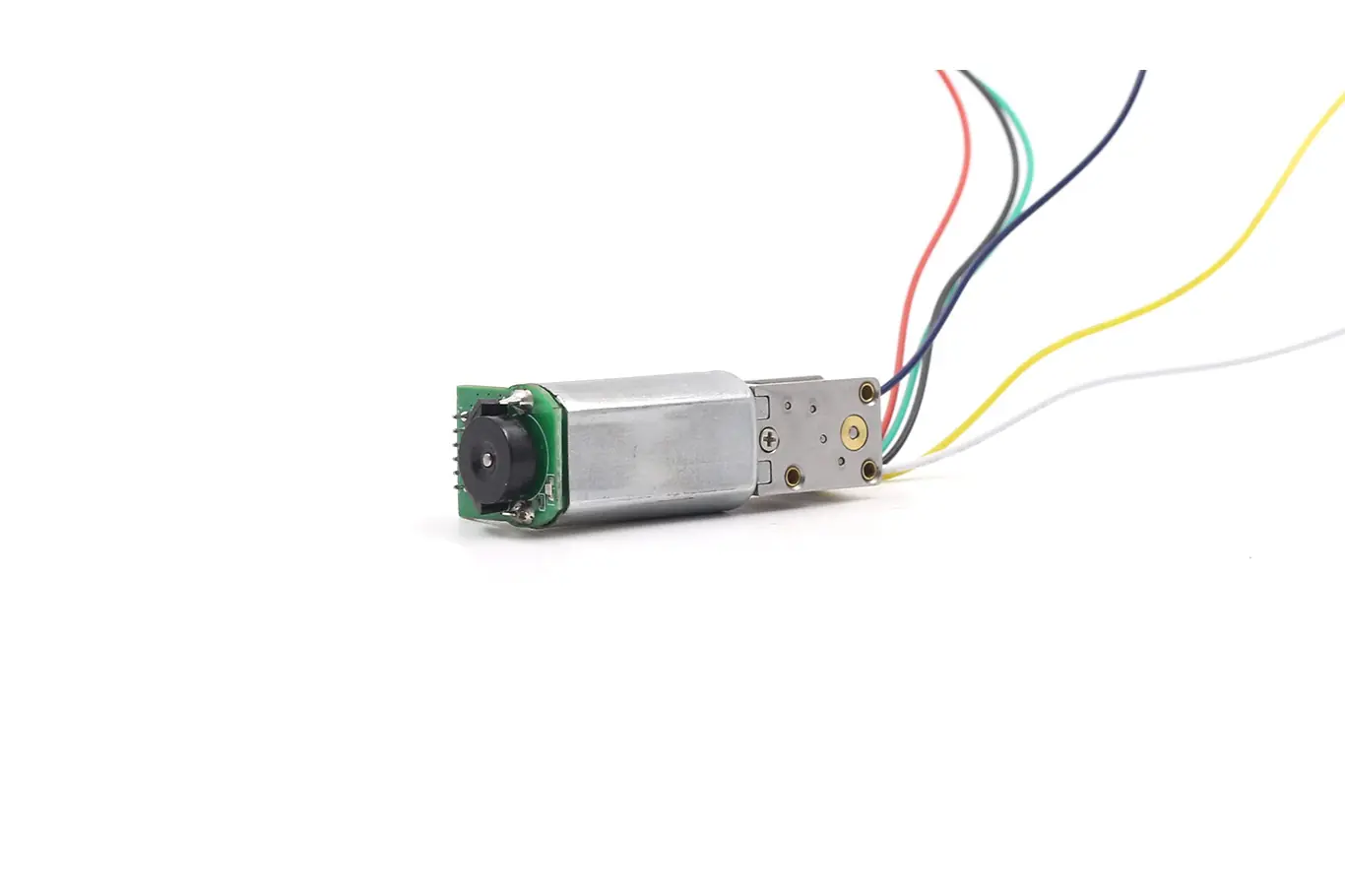

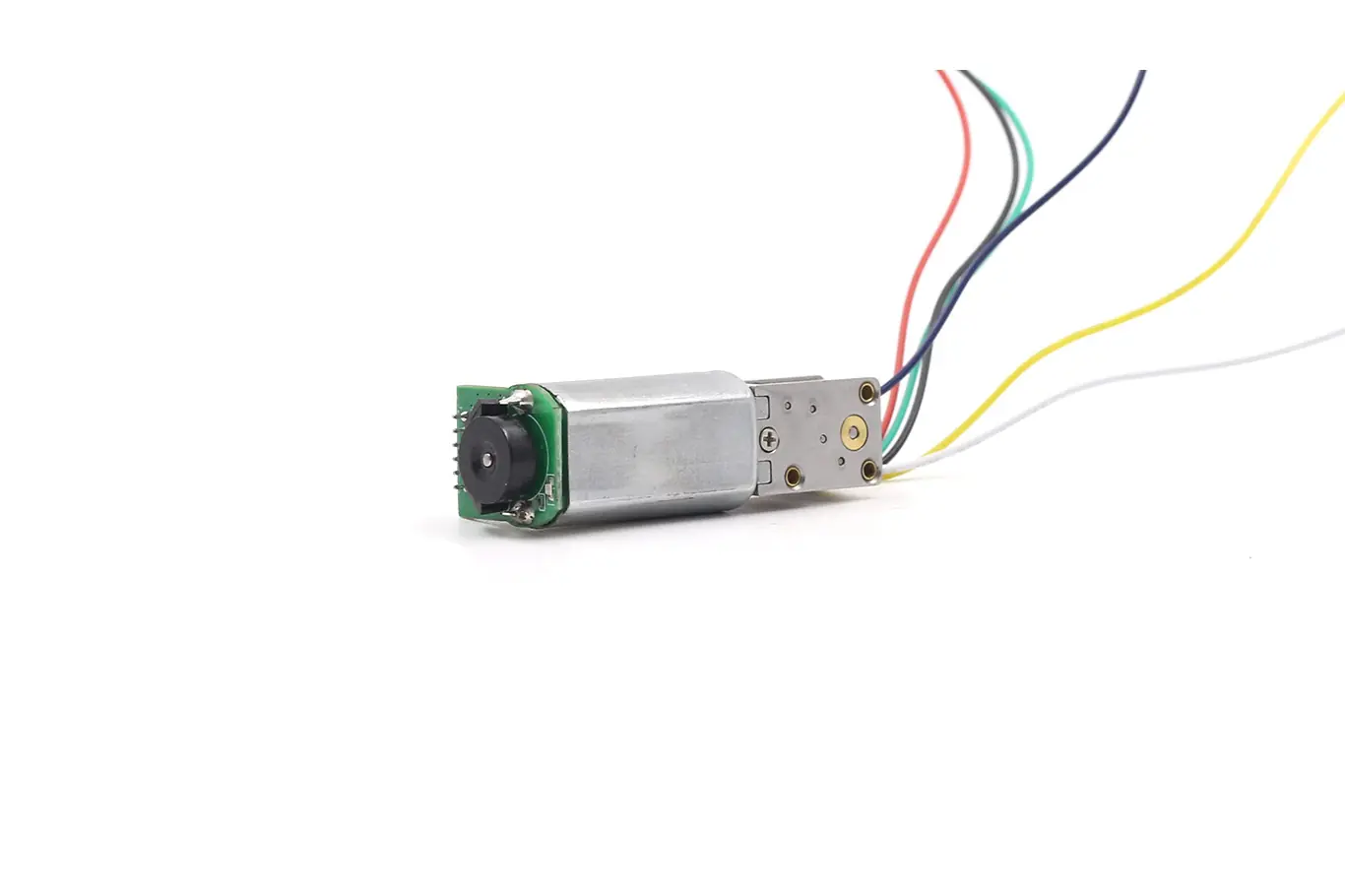

Enhanced Structural Stability

The worm gear motor encodering’s structure achieves exceptional stability using a steel plate frame and a triangular locking pattern. This setup utilizes three ϕ1.4mm pillar holes secured by M1.4 screws to form a rigid support column, which is essential for minimizing motor loosening and shaking after installation. This advanced design significantly outperforms two-pillar copper structures, which are often prone to vibration and potential power imbalance, especially when subjected to high torque loads.

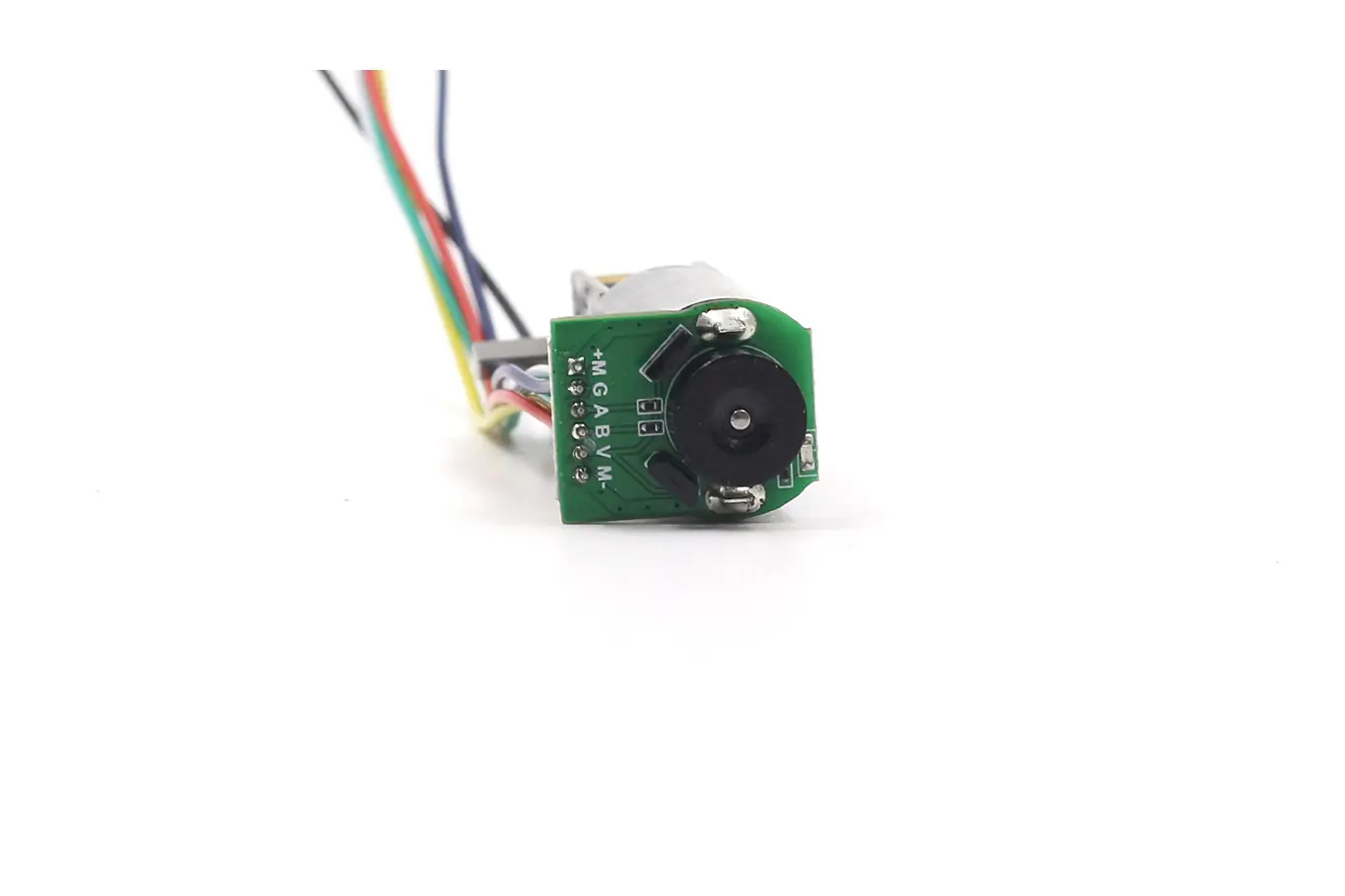

Precision Encoder and Electrical Core

For robust performance, the worm gear motor encodering is wound with pure copper wire and features a pure copper rotor. This configuration guarantees low resistance and strong electrical conductivity, resulting in high torque output. The system includes an AB dual-phase incremental magnetic Hall encoder for precise positioning, providing a base pulse of 7PPR×gear reduction ratio. Additionally, it integrates a built-in DV pressure-sensitive component to ensure EMC compliance.

Gearbox Durability and Longevity

The worm gear motor encodering’s gearbox is engineered for maximum durability and extended service life. By leveraging the strength of the steel plate structure, the reducer’s gear shaft demonstrates enhanced stability and superior resistance to high torque loads. This robust construction not only boosts operational reliability but also effectively extends the overall longevity of the unit.

TSL-GW1218-050-EN,DC12.0V,Max o.55W,11 Tpye

| Ratio | No Load | Rated Load | Stall | ||||

| i : 1 | Speed | Current | Speed | Current | Torque | Torque | Current |

| 42 | 190 rpm | ≤50mA | 140 rpm | ≤0.18A | 0.05 kg.cm | ≤0.17 kg.cm | ≤0.6A |

| 118 | 67 rpm | ≤50mA | 50 rpm | ≤0.18A | 0.15 kg.cm | ≤0.5 kg.cm | ≤0.6A |

| 236 | 33 rpm | ≤50mA | 25 rpm | ≤0.18A | 0.32 kg.cm | ≤1.2 kg.cm | ≤0.6A |

| 302 | 26 rpm | ≤50mA | 20 rpm | ≤0.18A | 0.4 kg.cm | ≤1.5 kg.cm | ≤0.6A |

| 603 | 13 rpm | ≤50mA | 10 rpm | ≤0.18A | 0.8 kg.cm | ≤3 kg.cm | ≤0.6A |

| 1030 | 8 rpm | ≤50mA | 6 rpm | ≤0.18A | 1.2 kg.cm | ≤4.5 kg.cm | ≤0.6A |

⇒Unit Coversion: 1 g·cm ≈ 0.098 mN·m ≈ 0.014 oz·in;1 mm ≈ 0.039 in;1 g ≈ 0.035 oz1

TSL-GW1218-050-EN,DC6.0V,Max o.15W,11 Tpye

| Ratio | No Load | Rated Load | Stall | ||||

| i : 1 | Speed | Current | Speed | Current | Torque | Torque | Current |

| 42 | 380 rpm | ≤65mA | 300 rpm | ≤0.23A | 0.1 kg.cm | ≤0.35 kg.cm | ≤1A |

| 118 | 135 rpm | ≤65mA | 105 rpm | ≤0.23A | 0.3 kg.cm | ≤1 kg.cm | ≤1A |

| 236 | 68 rpm | ≤65mA | 53 rpm | ≤0.23A | 0.65 kg.cm | ≤2.5 kg.cm | ≤1A |

| 302 | 53 rpm | ≤65mA | 41 rpm | ≤0.23A | 0.8 kg.cm | ≤3 kg.cm | ≤1A |

| 603 | 27 rpm | ≤65mA | 20 rpm | ≤0.23A | 1.6 kg.cm | ≤6 kg.cm | ≤1A |

| 1030 | 16 rpm | ≤65mA | 12 rpm | ≤0.23A | 2.4 kg.cm | ≤9 kg.cm | ≤1A |

💕The worm gear motor encodering’s technical specifications are for guidance,we offer custom solutions upon request.

⇒Unit Coversion: 1 g·cm ≈ 0.098 mN·m ≈ 0.014 oz·in;1 mm ≈ 0.039 in;1 g ≈ 0.035 oz1

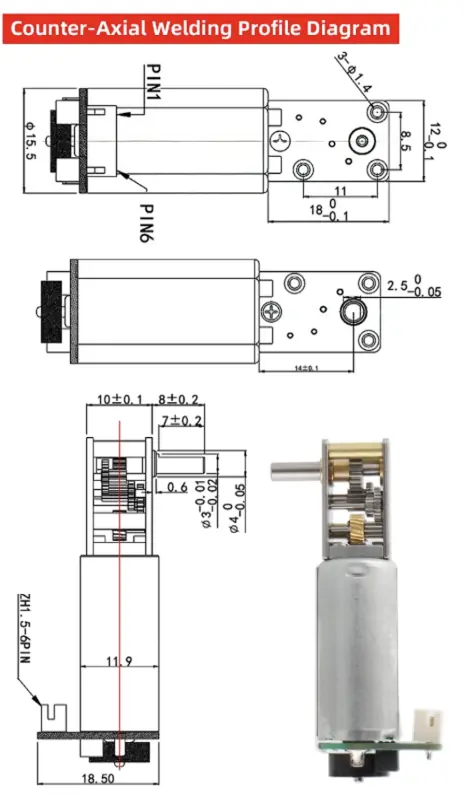

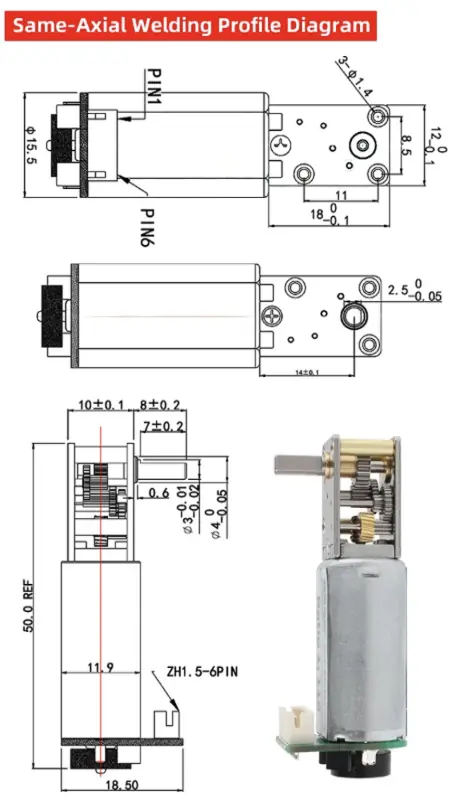

Micro N20 Worm Gear Motor Encodering Mechanical Drawing

Unless otherwise stated, all dimensions are in millimeters. The provided drawings are for illustrative purposes; please contact us to verify precise specifications.

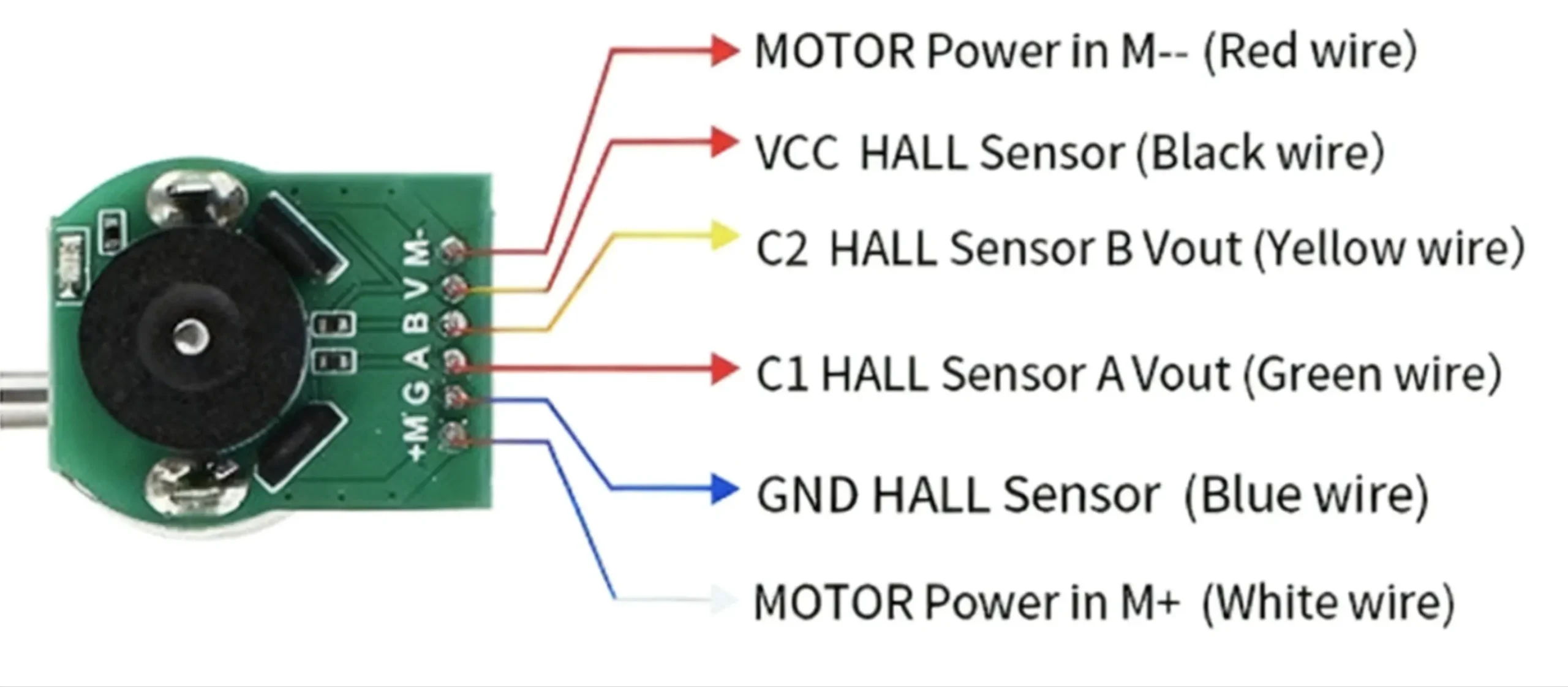

Worm DC Reduction Gear Motor Encodering Wiring Tips

| Encoders Conflg | |

| Type | AB two-phase incremental magnetic Hall encoder |

| Line speed | basic pulse 7PPRx gear reduction ratio |

| Power supply voltage | DC 3.3V / DC5.0 |

| Basic function | built-in pull-up shaping resistor, direct connection to microcontroller |

| Interface type | ZH1.5-6PIN (standard connection line) |

| Output signal type | square wave AB phase |

| Response frequency | 100KHz |

| Basic pulse number | 7 PPR |

Keywords:

motor encodering,encoder motor,sensor motor,dc motor with encoder,worm geared motor

Development Samples:

If you need samples, please contact us.

Engineering & Manufacturing:

Contact any or the Sales Engineers for a quotation for production or consultation on the integration and customization of your product.

Payment:

1.Payment methods : Paypal, T/T

Shipping:

1.Delivery: DHL/FedEx 3-5 days.

2.Item will be shipped within 1-3 business days after the payment.

3.If you haven’t received the item on the Delivery Time, pls contact us by email if you have any questions. Normally, we will give you a reply within 24 hours, if not, pls check the spam of your email box. We will do our best to help you solve the problems.

4.Please make sure your address is matched with the finally shipping address before you pay.

FAQ for worm gear motor

Q:What is a worm gear motor?

A:A worm gear motor is an electric motor integrated with a worm drive mechanism, designed to provide high torque at low speeds, often with a self-locking feature and a right-angle output.

Q:Can worm Gear Motor Be Customized?

A: Yes,worm gear motor can be customized. TSL Motors, a top manufacturer, offers options to adjust torque, speed, and voltage. This ensures the motor meets the specific needs of your application.

Q: How do I place an order?

A: Send us an inquiry and we will send you a quote – make arrangements – confirm the sample – sign the contract/deposit mass production – delivery ready for delivery. Balance/delivery

Q: What about Sample Order?

A: Sample are available to you. Contact us for specifics. If we charge you a cost for the sample, you can take it at ease, as it will be the refund you receive when you make a formal order.

Q: If it is a customized version the information you provide, what should you include?

A: You should give the fundamental specifications of the motor, for example Dimensions Applications, Sizes as well as Voltage, Speed and Torque. It is better to provide an application-specific prototype drawing to us when you can.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration.

Motor Customization Guide

Please tell us your requirements. Our engineers will give you the best solution for your application.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!