In an era of miniaturization and precision, devices demand powerful yet compact motors.From miniature medical instruments to robotic bionic hands, size, efficiency, and reliability are critical.

The micro brushless planetary geared electric motor offers a high-performance solution.It merges brushless technology with planetary gear transmission in a tiny package.This combination pushes the boundaries of what small motors can achieve.

Whether you are designing robotic dexterous hands, industrial automation equipment, or medical devices, the micro brushless planetary geared electric motor is quickly becoming the top choice for engineers and product developers worldwide.

Key Takeaways

- 1. It integrates a brushless DC motor and a planetary gearbox.

- 2. It features compact size and strong torque in small spaces.

- 3. Brushless design ensures long life and low maintenance.

- 4. It runs quietly, smoothly and with high efficiency.

- 5. It suits medical, robotics, smart lock and optical applications.

- 6. TSL mass-produces 8–13mm models with zero MOQ.

- 7. It supports flexible customization for diverse needs.

What Is a Micro Brushless Planetary Geared Electric Motor?

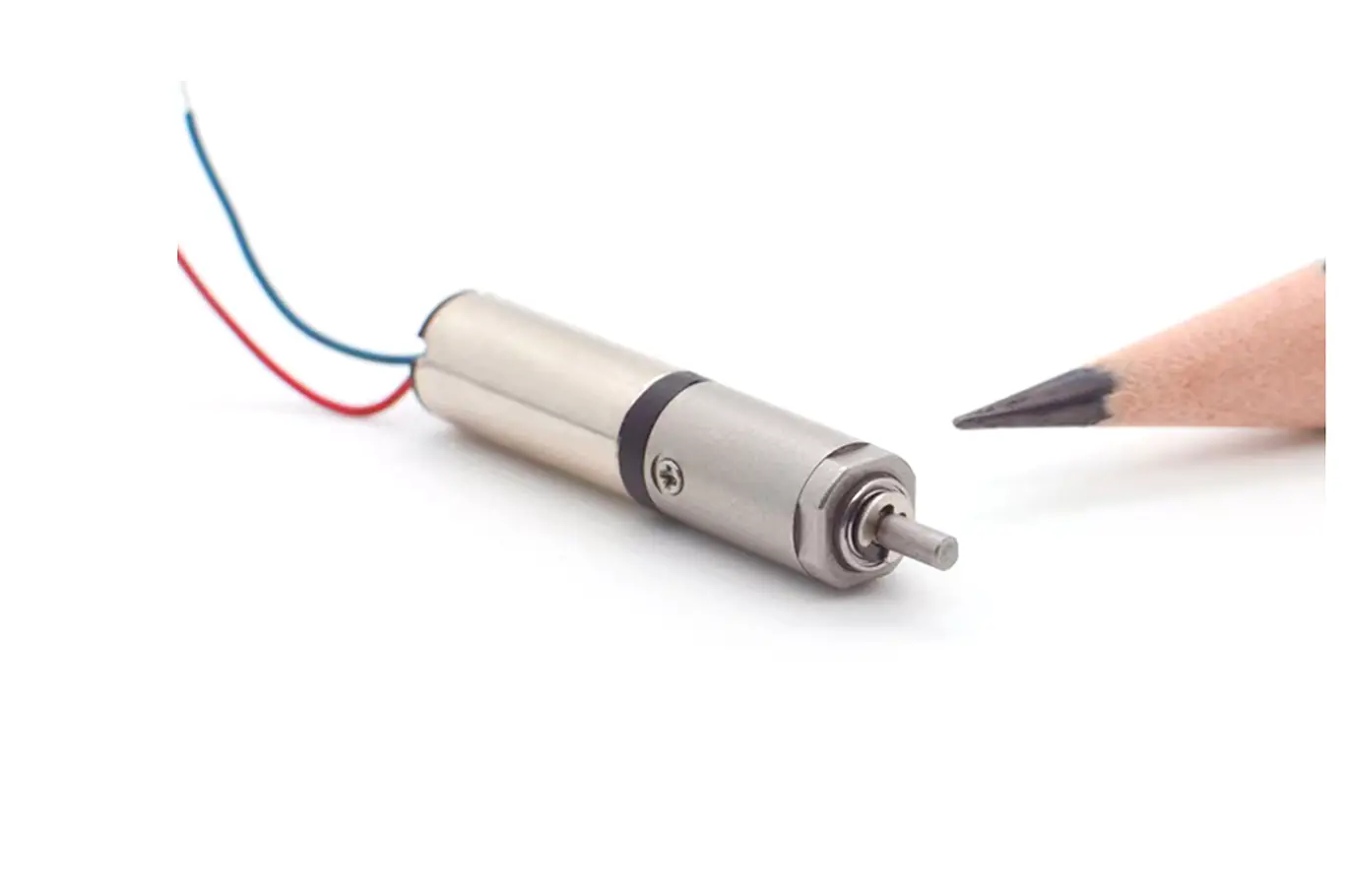

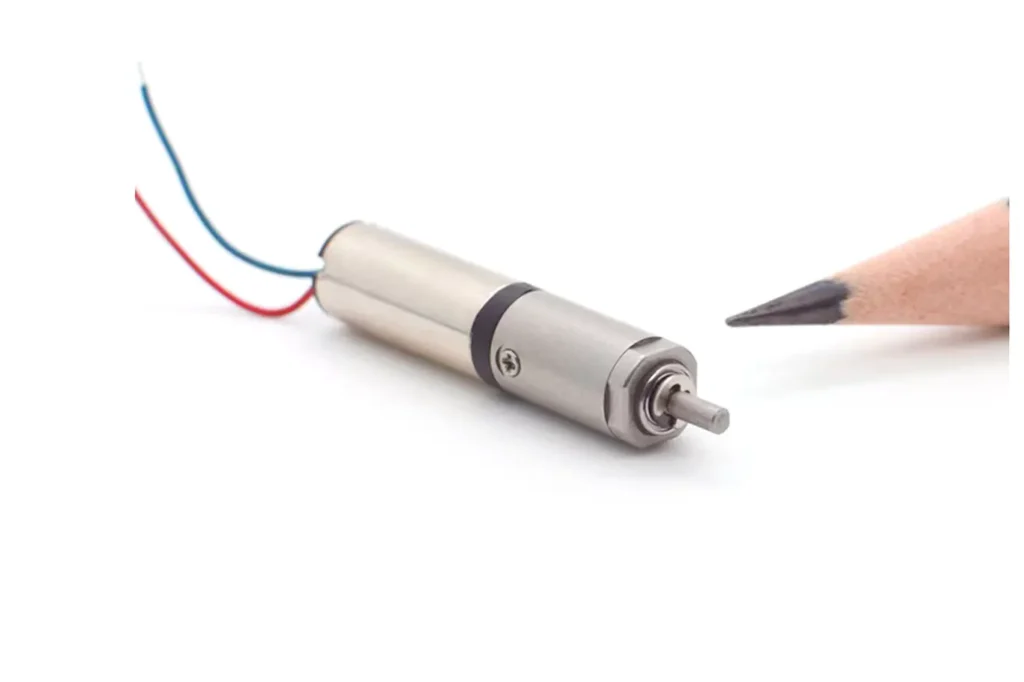

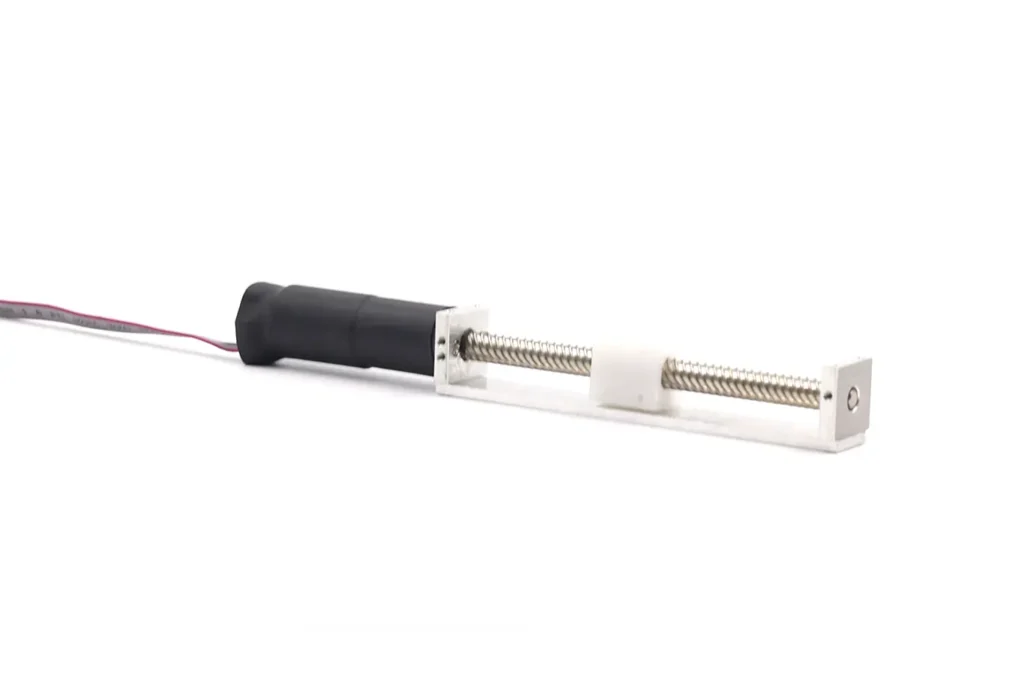

It is a compact power unit that integrates a brushless DC motor with a planetary gearbox.For example, TSL’s smallest model has a diameter of 6 mm. Maxon and Zhaowei’s smallest models reach 4 mm.

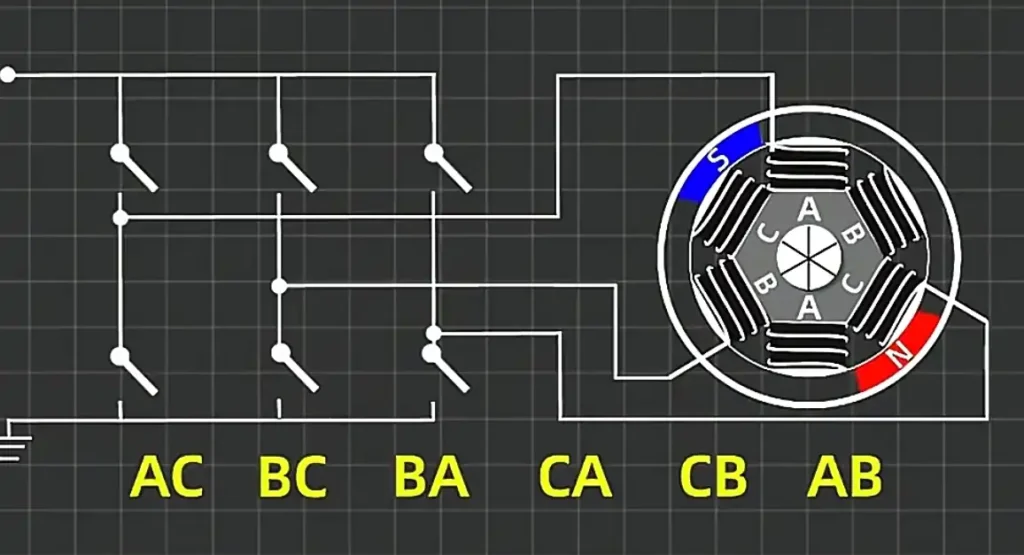

Brushless DC Motor

Brushless DC motors use electronic commutation.They do not rely on brushes for commutation like traditional brushed DC motors.This eliminates brush wear.The motor runs without brush friction, sparks, or long-term wear.

It fundamentally solves the core pain points of brushed motors.

For DC geared motor manufacturers, brushless DC motors are the trend for high-precision, miniaturized scenarios.

Take our dexterous hand client as an example.

Their original brushed motors suffered from slow response and magnetic leakage interference.After switching to our micro brushless planetary geared motor, response speed improved significantly.Signal shielding issues were completely resolved.

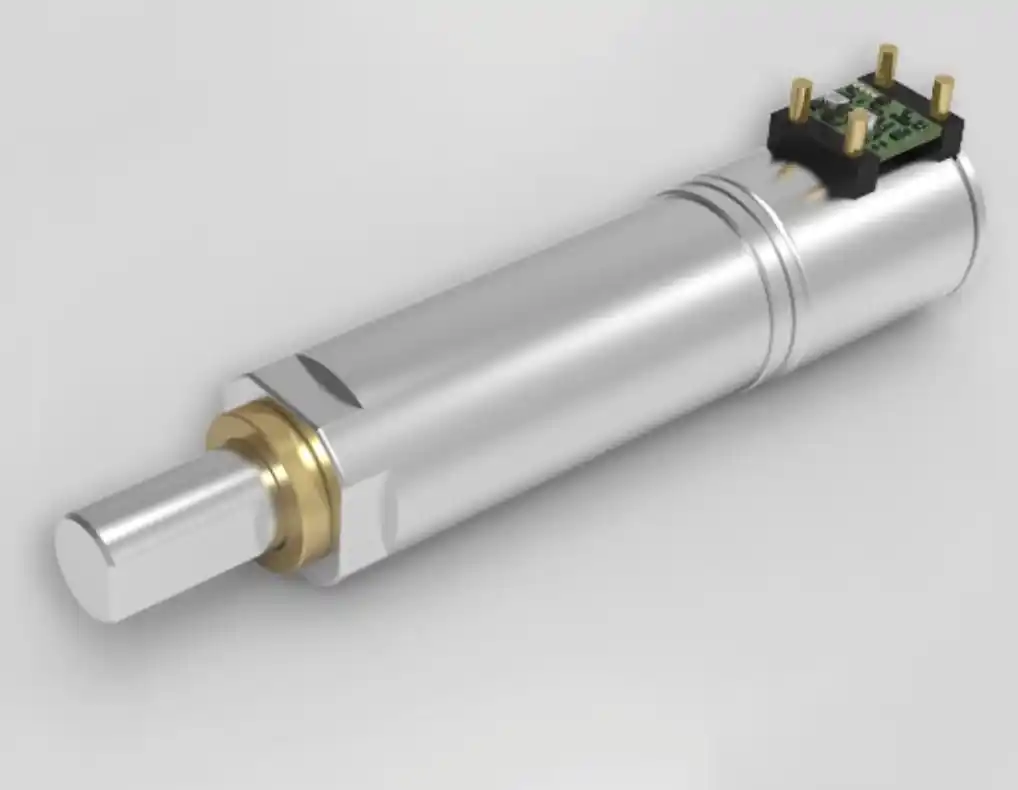

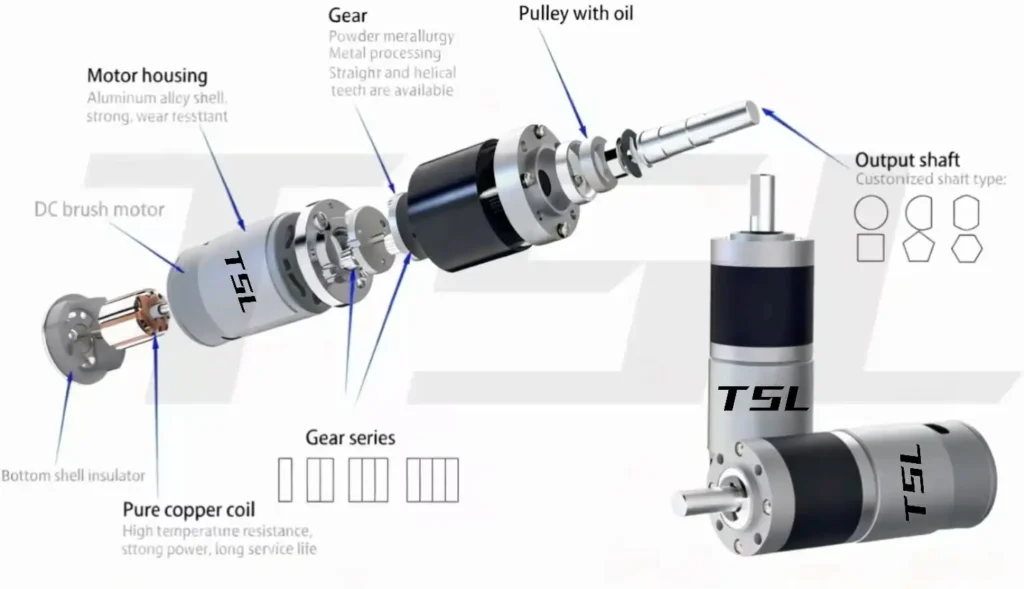

Planetary Gearbox

A planetary gearbox (also called planetary reducer or epicyclic gearbox) consists of three parts:a central sun gear, multiple planet gears that revolve and rotate around it, and an outer ring gear.

Unlike traditional gearboxes that transmit torque through a single pair of meshing gears,planetary gearboxes share loads across multiple planet gears.

All gears mesh at the same time.This greatly amplifies torque.The load-sharing design delivers extremely high torque in an ultra-small size.With multi-tooth meshing, even load distribution, and high meshing stiffness,

planetary gearboxes run smoother, with less vibration and lower noise than standard spur gearboxes.They efficiently boost torque and reduce speed.They provide stable, precise power transmission.

All these functions fit in an extremely compact space.They are an ideal choice for high-performance transmission systems.

Advantages of the Micro Brushless Planetary Geared Electric Motor

The micro brushless planetary geared motor stands out in demanding, space-constrained applications.It is a leader among similar motors thanks to its unique strengths.

Compact Size, Strong Torque

Planetary gearboxes are known for high torque density.They output more torque per unit volume than spur or worm gearboxes.

Paired with a miniaturized brushless DC motor, the finished motor fits easily into tight spaces.These spaces include smart watch components, tiny mechanical joints, and medical implants.It still outputs enough torque to drive the load.

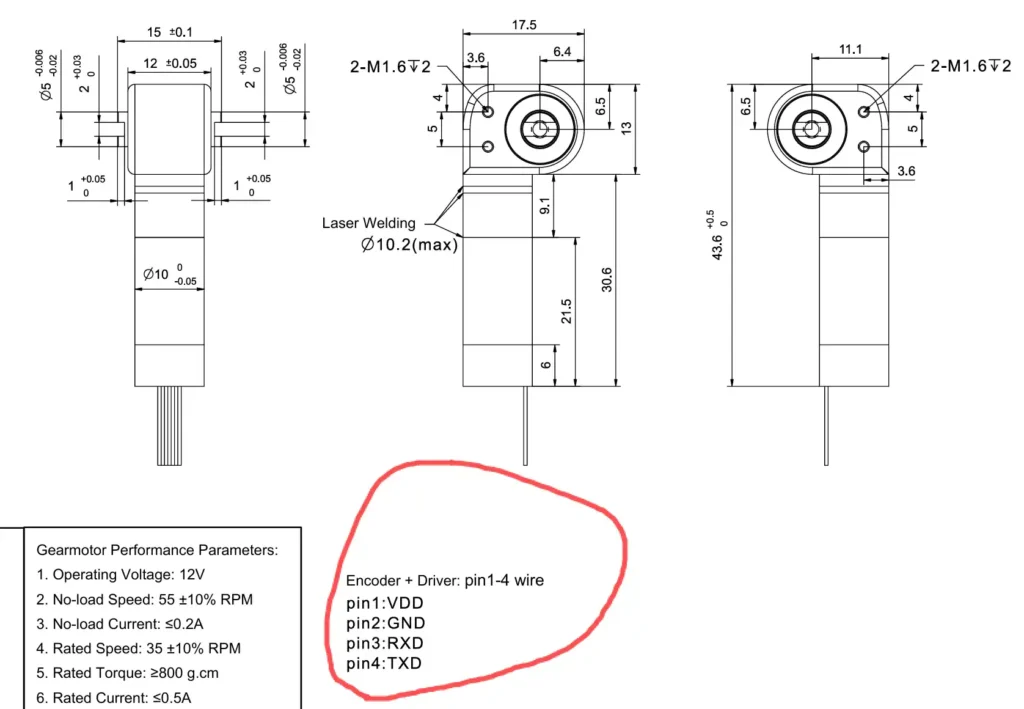

For instance, our 13 mm-diameter micro brushless planetary geared motor has a rated torque of up to 2 kg·cm.It can drive small actuators or precision pumps.

If the total motor length is shortened from 45 mm to 30 mm and a worm structure is added to the output shaft,the rated torque rises to ≥2.5 kg·cm.

Long Service Life, Low Maintenance Costs

The brushless design completely removes brush wear.Brush wear is the main failure cause of traditional micro motors.No brush replacement or frequent maintenance is needed.

These micro brushless planetary geared motors have a service life of over 10,000 hours.This far exceeds that of brushed motors.They are ideal for hard-to-maintain or non-serviceable applications.

Examples include sealed medical devices, industrial automation equipment, and remote sensors.No brush friction also reduces heat and electromagnetic interference.This further extends component life and improves operational reliability.

High Efficiency, Low Energy Consumption

Brushless motors are inherently more efficient than brushed motors.Brushless motors typically reach 80%–90% efficiency.

Brushed motors only hit 60%–70%.Brushless motors avoid energy loss from brush friction and commutator resistance.Paired with a planetary gearbox with up to 90% transmission efficiency,the overall efficiency of the micro brushless planetary geared motor rises sharply.

This cuts power consumption and extends battery life for portable devices.It also lowers energy costs in industrial applications.

Quiet, Smooth, and Precise Operation

The brushless design greatly reduces operating noise.Noise is ≤45 dB at a 30 cm distance.

It suits noise-sensitive environments such as hospitals, offices, and consumer electronics (massagers, smart home products).The multi-tooth meshing of the planetary gearbox ensures vibration-free power delivery.

Electronic commutation enables precise speed and position control.This is critical for dexterous hands, 3D printers, medical pumps, and other precision-motion devices.

Many of our models have integrated encoders.They detect position and direction in real time, boosting control accuracy.

For customer convenience, we offer optional built-in drivers.The motor can be driven with only 4 wires.

High Versatility and Customization

These motors are highly versatile.They come with rich customization options to match specific application needs.

Manufacturers offer a wide range of specifications:

- Voltage: 3–24 V DC

- Gear ratio: 1:3 to 1:1296

- Speed: 4–7500 rpm

- Size: 6 mm to 56 mm

At TSL, we have a full product lineup.We are the only domestic manufacturer capable of mass-producing 8–13 mm micro brushless planetary geared motors.

We support optional encoders, built-in drivers, protective casings, and flexible mounting (brackets, threaded installation).We also provide drip-proof and other protective features for harsh environments.

This flexibility makes the motor widely applicable to consumer electronics, industrial machinery, and more.

Gear Life Determines System Life, Not the Motor

Brushless DC motors can last tens of thousands of hours.In real engineering applications, especially under high loads, high cycles, or shock loads,the mechanical life of the planetary gearbox often becomes the system’s first bottleneck.

Materials and Craftsmanship

Micro gears require ultra-high dimensional accuracy and surface hardness.Their tiny size makes heat treatment and reinforcement extremely difficult.Many manufacturers can make large planetary gearboxes.

Few can produce 4–13 mm gearboxes.Only Maxon and Zhaowei can achieve this at a high level.TSL cannot manufacture 4 mm gearboxes.But we mass-produce 6–16 mm micro planetary gearboxes.

To extend gearbox life, we use solid steel machined gears.These gears last longer than powder metallurgy gears.

Load Concentration in Multi-Stage Reduction

The first gear stage (high-speed stage) bears the highest cycle counts.Its main failure modes are tooth surface wear and fatigue pitting.

The last gear stage (low-speed stage) bears the maximum torque.It is prone to root bending fatigue or overload damage.

Failure in any stage disables the entire system.Balancing strength design across stages to achieve “equal strength life” is key.

Inevitable Wear and Performance Degradation

Even without catastrophic failure, long-term gear wear causes:

- Increased backlash: lost positioning accuracy and unstable control

- Lower efficiency: more friction, higher temperatures, accelerated lubricant aging and material fatigue

- Higher noise: an early warning sign of malfunction

Lubrication is vital in enclosed micro spaces.Grease selection (base oil viscosity, thickener, additives) and filling volume directly affect wear rate and low-temperature startup performance.

Applications of the Micro Brushless Planetary Geared Electric Motor

The micro brushless planetary geared motor has evolved from a basic power component.It is now a core motion module that enables intelligence, precision, and user-friendliness in high-end equipment.

Medical Devices and Precision Instruments

Medical actuators demand high reliability, ultra-low noise, dust-free operation, precise control, and long continuous running.

Technical Matches

- Long life and maintenance-free operation : Brushless motors eliminate brush wear, the main failure source.High-quality planetary gearboxes ensure stable long-term output.They reduce maintenance and prevent downtime of critical medical devices.

- Excellent low-speed smoothness : The motor runs continuously and jitter-free at ultra-low speeds.This fits micron-level motion control in surgical robots and precise dosing in micro pumps.

- Compact structure and high power density : It delivers stable, sufficient drive in extremely space-limited systems.Examples include endoscopes and CT slip rings.

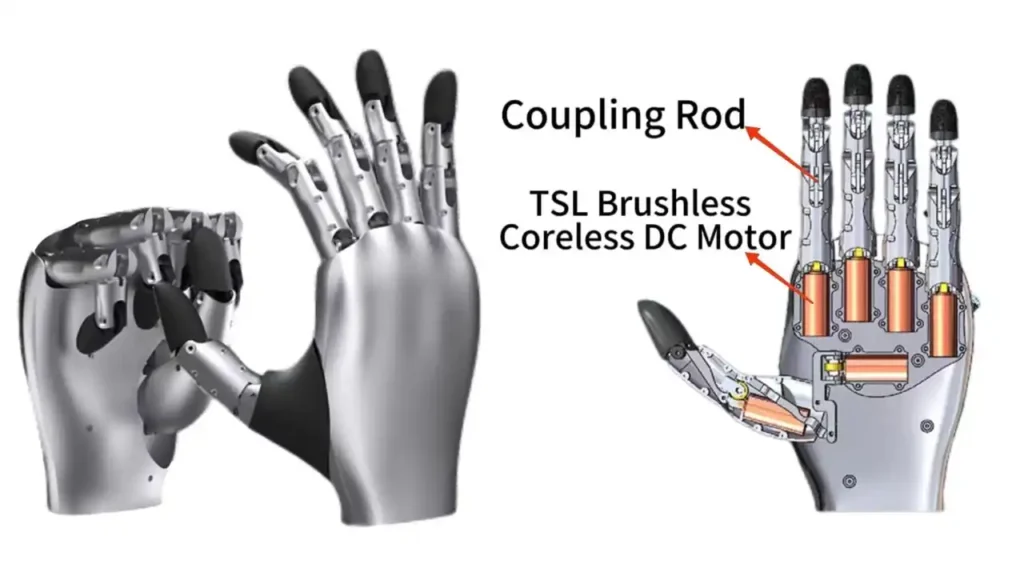

Robotic Dexterous Hands

Robotic dexterous hands need motors with ultra-high power density, ultra-compact structure, fine torque and position control, low-speed smoothness, and fast dynamic response.These support complex grasping and human-machine interaction.

Technical Matches

- System-level integration : The motor, gearbox, sensing, and drive integrate into one finger joint or palm.It forms a highly modular actuator unit.This integration greatly simplifies wiring and reduces structural redundancy.It enables multi-DOF, high-density joint layouts.

- Direct drive from high reduction ratio : It delivers high output torque in a limited size.Finger joints can drive loads or phalanges directly.It reduces backlash, friction, and control uncertainty from secondary transmissions (cables, links).This is key for precise control of fingertip force and displacement in grasping tasks.

- High rigidity and predictable backlash : Planetary gearboxes have natural advantages in torsional rigidity and consistency.They ensure consistent joint response in multi-finger coordination.Predictable, modelable backlash matters more than ultra-low backlash.It directly stabilizes force control algorithms and repeatability.

- Low-speed smoothness and fine force control : Most dexterous hand motions run at low or quasi-static speeds.The brushless motor and planetary gearbox deliver smooth, continuous output at ultra-low speeds.This supports fine grasping, compliant control, and safe human-machine interaction.

Smart Locks and Electric Actuators

Smart locks and electric actuators need quiet operation, high energy efficiency, high reliability, and controllable costs.

Technical Matches

- Efficient brushless drive : Brushless motors consume almost no power at standstill.They only use power during movement.This greatly extends battery life for long-standby smart terminals.

- Self-locking capability : High-ratio planetary gear structures have certain back-drive self-locking.They maintain lock status even when powered off.No extra electromagnetic or mechanical limiters are needed.

- Smooth and silent operation : The combination of planetary gears and brushless drive ensures quiet start-stop.It removes the “click” noise of traditional motors.It improves the feel and user experience of high-end smart locks and actuators.

Optical and Precision Adjustment Mechanisms

Optical and precision positioning systems need high resolution, long-term stability, and continuous smooth low-speed motion.

Technical Matches

- Ultra-low-speed smooth operationIt suits laser beam steering, telescope tracking, optical correction platforms, and other micro-motion applications.

- Low-backlash or preloaded planetary gear designSpecial design and preloading greatly reduce backlash impact on pointing accuracy.

- Cost-effective alternative to direct driveFor medium-precision applications, it is a cheaper, more compact alternative to direct-drive motors.

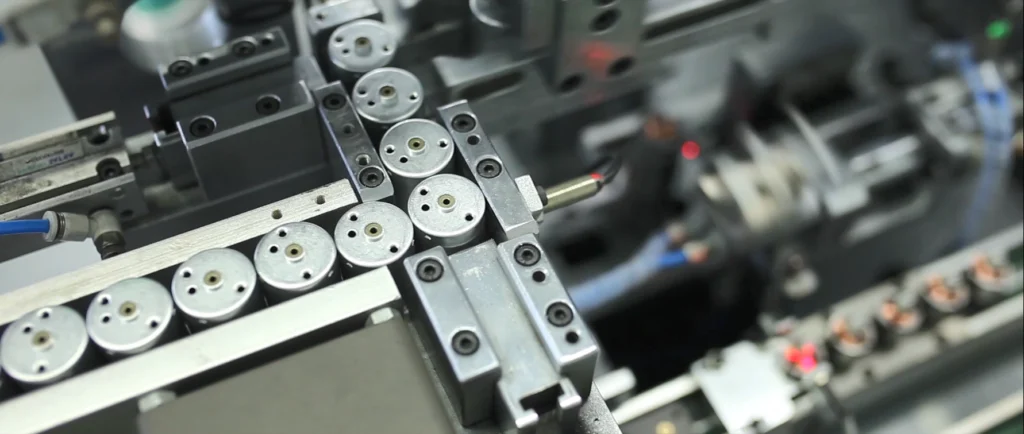

TSL Customization and Mass Production

In actual procurement, engineers and buyers focus on three core points:customization flexibility, on-time delivery, and cost control.TSL’s micro brushless planetary geared motor solutions cover all three.

- Minor customization based on mature platforms : Adjust parameters, dimensions, or interfaces to meet diverse needs.Lower development risks at the same time.

- Zero MOQ threshold : Support small-batch trial production and fast prototyping for design verification.

- Controllable lead time and consistency : Mature production systems ensure batch consistency and stable delivery.

- Exclusive mass production capacity : We are the only domestic manufacturer mass-producing 8–13 mm micro planetary geared motors.We balance standardization and customization.

- Mature FPC wiring solution: Thin, flexible, and easy to route in compact spaces.Ideal for micro devices and complex mechanical structures.

- Optional integrated sensors : Support Hall sensors or encoders.Enable closed-loop control of position, speed, and torque.

- Built-in driver module : Optional integrated drive highly combines motor and controller.Simplify system design and improve overall reliability.

This modular, customizable solution helps customers complete the full process from design verification to mass production quickly.This is especially true for size-limited, high-precision applications.

Conclusion

The micro brushless planetary geared motor is more than an upgrade of traditional power components.It is a core motion module for precise, intelligent, and high-efficiency equipment.

By combining brushless technology and planetary gear transmission,it achieves high torque, high efficiency, low noise, and long-term stable operation in a compact size.

It meets strict requirements for medical instruments, dexterous hands, smart locks, portable devices, and optical precision mechanisms.

With mass production capacity for 8–13 mm micro motors, zero MOQ, and rich customization (Hall, encoder, built-in driver, wiring),TSL provides end-to-end solutions for engineers from design verification to mass production.

This helps customers stay competitive in cutting-edge miniaturized, precise, and highly reliable technologies.Choosing a micro brushless planetary geared motor is not just selecting a drive solution.It is embracing a future-oriented design philosophy: compact, efficient, intelligent, and reliable.

FAQ

Q1: What is a micro brushless planetary geared electric motor?

A: A compact power unit integrating a brushless DC motor and a planetary gearbox.

Q2: What’s its main advantage over brushed motors?

A: No brush wear, longer life and lower electromagnetic interference.

Q3: What’s the smallest diameter of this motor?

A: 4 mm (Maxon, Zhaowei) and 6 mm (TSL).

Q4: What fields is it mainly used in?

A: Medical devices, robotic dexterous hands, smart locks, etc.

Q5: Can TSL customize this motor?

A: Yes, with flexible customization and zero MOQ threshold.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Brushless Gear Motor

A brushless gear motor is an excellent choice for devices that require long-lasting performance. These motors, paired with spur, planetary, or worm gearboxes, are offered by leading manufacturers of miniature geared motors. Known as brushless gear motors, they provide a longer lifespan and lower maintenance costs due to the lack of brushes in the DC motor.