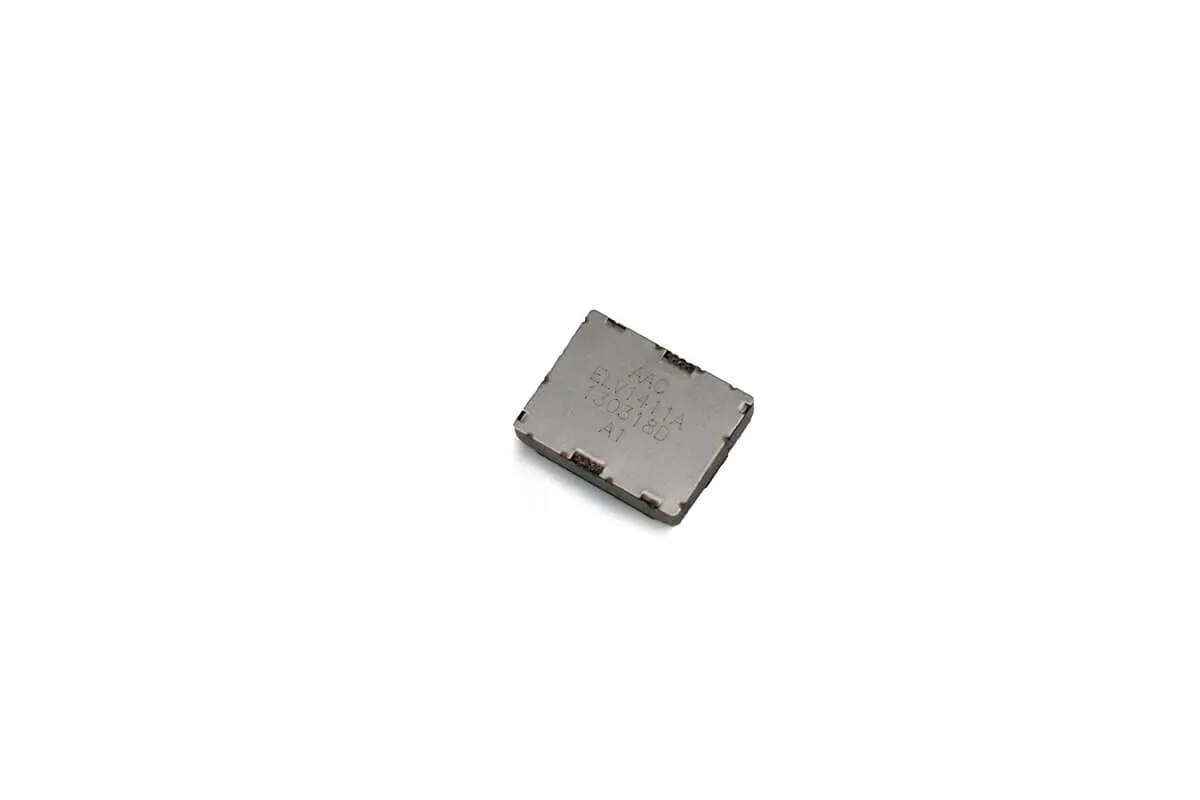

14mm Length LRA Linear Vibration Motor – 11mm Width Model TSL-ELV1411A

♦ Basic Info:

Brand:TSL

Origin:China

Motor Model:TSL-ELV1411A

Certification: ISO9001,ISO14001,IS045001

Green product: ROHS/REACH compliant

Motor Size:14mm x 11mm x 2.5mm

X-Axis LVM-Series LRA Actuator 150Hz Key Features

LRA actuator motor (Also called the lra actuator) can be the one most well-known for applications that use haptics. TSL motors have an internal mass, and the resonance frequency oscillates across the X axis. The design is straightforward and it comes with long life.

The frequency at which the LRA actuator’s stability and the frequency point which corresponds to the peak-topeak value in the curve of acceleration is the most significant.

–Low temperature lra actuator vibrations should be less than 1.5Grms (-10degC conditions and rated voltage), the speed of the motor at the time that the vibration is steady).

–The time of rising is between 0 and 90 percent of normal vibration at 1.5Vrms F0. Falling time ranges from 100 percent to 10 percent of normal frequency at 1.5Vrms F0.

–The value of acceleration that is effective is when the lra motor is stable, and it is vibrating at the rated voltage and frequency.

| Motor Model | TSL-ELV1411A |

| Size | 14mm x 11mm x 2.5mm |

| Motor Weight | 2.5g |

| Vibration Amplitude | 1.5Grms @100g |

| Rated Voltage | AC 2.0Vrms |

| Motor Frequency | 150Hz |

| Nominal Operating Current | 90max |

| Terminal Resistance | 26+/-10% |

| Mechanical Noise | 50dB max |

| Operating Temperature Range | -30℃ ~ +70℃ |

| Storage Temperature Range | -40℃ ~ +80℃ |

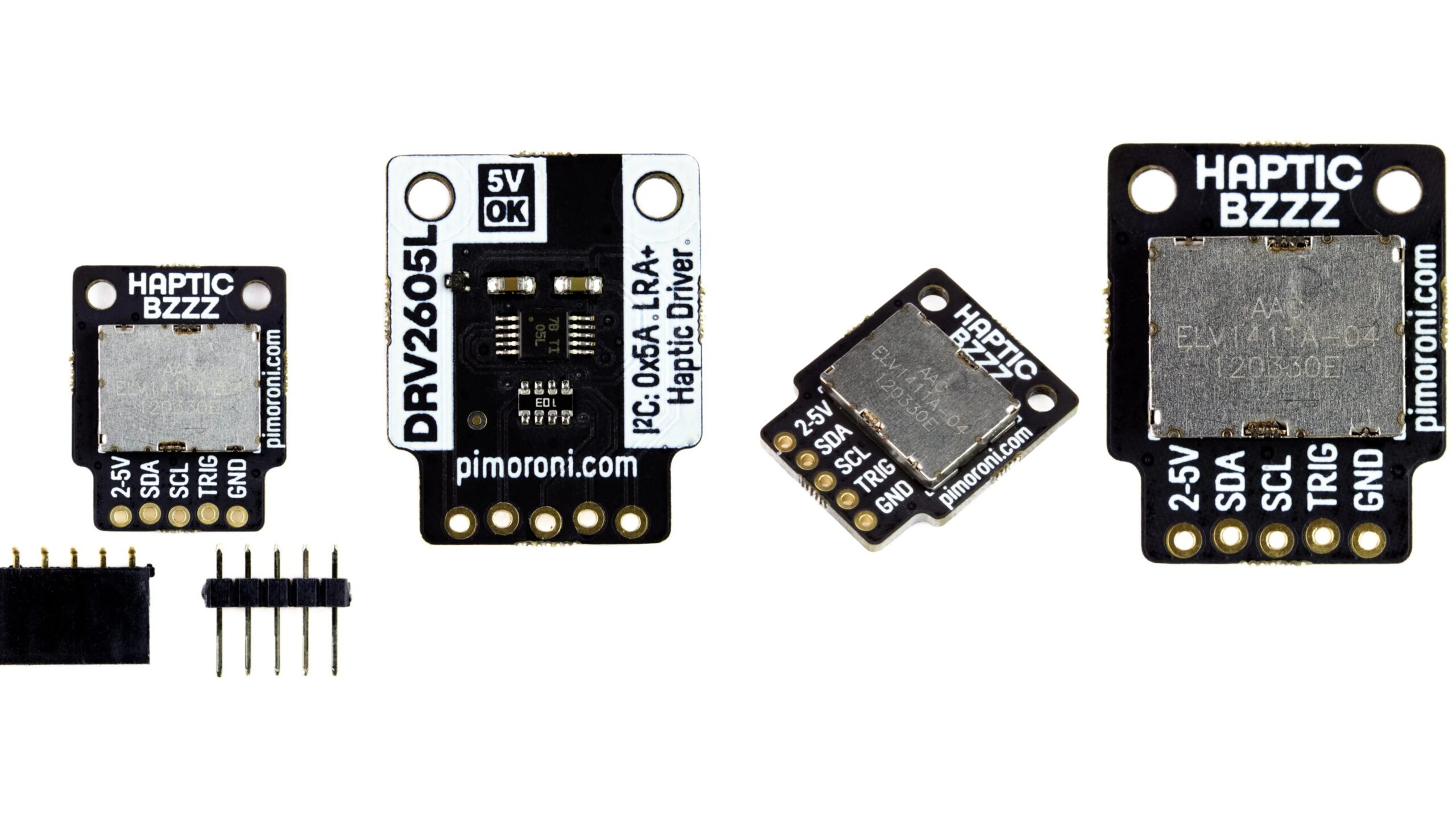

1.5G lra Actuator DRV2605 Driver Kit

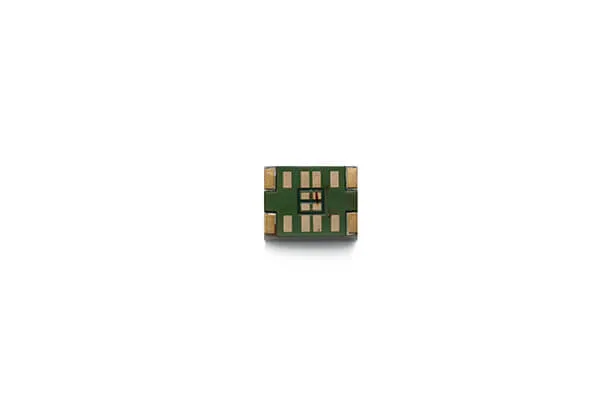

Customized FPCs and SMD connections are both possible.

Reflow temperature recommended for LRA actuator TSL-ELV1411A The ideal reflow temp for the model that uses Pb-Free (Sn/Ag) solder usually ranges between 240-250degC and 40-80 seconds above 220degC. It’s important to know that the guidelines for reflow temperatures for Sn/Pb solder are not as rigid, and allow for minor variations in component and equipment temperatures, without affecting the quality of soldering.

The frequency of vibration in Linear Resonant Actuators (LRAs) is adjusted to match their resonance frequency. For our two LRA actuators their resonance frequency is either Hz, or even 200Hz. Because of the high quality of the factor (Hi-Q) that is present in LRAs using an unrelated frequency to their resonant frequency, whether below or above it the frequency, results in diminished amplitude of vibration. If the frequency applied differs significantly from the frequency of resonance, the LRA actuator could not cause any type of vibration. This is a sign of the significance of synchronizing the operating frequency with the LRA’s resonant frequency to ensure the best performance.

If you need a LRA TSL-ELV1411A driver, you can find from the following link: https://www.amazon.com/Pimoroni-DRV2605L-Linear-Actuator-Breakout/dp/B07RLJFK1S/ref=sr_1_2?keywords=linear+resonant+actuator&qid=1582894146&sr=8-2

If you look up “DRV26” on the Texas Instruments website, you’ll see an array of Integrated Circuits (ICs) specifically designed to drive linear motors. These are part of TI’s DRV26 series: https://www.ti.com/motor-drivers/products.html

Concerning the AWINIC AW8695FCR It’s an IC for motor drivers that is designed to the use of haptic feedback devices. This chip is specifically developed for use with Linear Resonant Actuators (LRAs) and offers features like quick startup and resonance frequency detection and tracking: https://www.awinic.com/en/index/pageview/catid/35/id/5.html

Keywords:

Lra motor, lra Motors micro vibration motor tiny vibration motor x-axis Ira linear resonant actuators Lra haptic, lra vibration

Development Samples:

The quantities of sampling for models that are stocked are available to order directly online from us.

Engineering & Manufacturing:

Contact us via one or the Sales Engineers for a quotation for production or consultation on customizing and integration services.

Payment Method:

Payment methods: Paypal or T/T

Shipping Method:

1.Delivery: DHL door to door within 5-7 days.

2.Item will be delivered within 1-3 days of the payment.

3.If you don’t have the item by the delivery Time please contact us via email with any queries. We usually give you a reply within 24 hours in the event that we don’t, look through your email account. We will try the best we can to assist you with the issues.

4.Please ensure that your address matches the address of your final shipment before you make payment.

5.In order to make sure you get your order tax-free after importation, we’ll declare it at an amount lower than the value you paid for it, please note this in your order, thank you!

FAQ For LRA Actuator

Q:What is the minimum order quantity (MOQ)?

A: There are no minimum order quantity (MOQ) requirements from our side. However, please note that customized components must comply with our material supplier’s established MOQ specifications. For detailed requirements and pricing specifics, kindly refer to the attached quotation document.

Q:How does an LRA vibration motor differ from an ERM vibration motor?

A: An ERM vibration motor uses an unbalanced mass on a DC motor, which generates vibrations as the motor spins. In contrast, an LRA vibration motor uses a voice coil to move the mass, with the springs being the only components at risk of wear or damage.

Q: How do I place an order?

A: Send us an inquiry and we will send you a quote – make arrangements – confirm the sample – sign the contract/deposit mass production – delivery ready for delivery. Balance/delivery

Q: What about Sample Order?

Answer: Sample are available to you. Contact us for specifics. If we charge you a cost for the sample, you can take it at ease, as it will be the refund you receive when you make a formal order.

Q: If it is a customized version the information you provide, what should you include?

A: You should give the fundamental specifications of the motor, for example Dimensions Applications, Sizes as well as Voltage, Speed and Torque. It is better to provide an application-specific prototype drawing to us when you can.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration.

Motor Customization Guide

Please tell us your requirements. Our engineers will give you the best solution for your application.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!