20mm Metal Gear Motor Model TSL-GM20-130

♦ Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TSL-GM20-130

- Rated Voltage: 3V/6V/9V DC

- Shaft Diameter:3mm

- Output Shaft Length:10.8mm

- #More Specifications

Miniature Geared Electric Motors Data Sheet

The High Torque Geared Electric Motor Applications for Mining Equipment and custom Gear Motor ,Design with energy efficient features to create compact gear motors are some examples.

| Motor Model | TSL-GM20-130 |

| Rated Voltage | 3V / 6V / 12V DC |

| No Load Speed | 10rpm – 310rpm |

| No Load Current | ≤0.05A / ≤0.11A / ≤0.26A |

| Max Torque | 4kg.cm |

| Rotation | CW / CCW |

| Shaft Diameter | 3mm |

| Shaft Length | 10.8mm |

| Weight | appr. 45g |

TSL-GM20-130, 3V DC

| Ratio | Gearbox | No Load | Rated Load | Stall | ||||

| i : 1 | Length | Current | Speed | Current | Speed | Torque | Current | Torque |

| 25:1 | 16.0mm | ≤0.26A | 310rpm | ≤0.7A | 210rpm | 0.2kg.cm | ≤2.3A | ≥0.6kg.cm |

| 31:1 | 16.0mm | ≤0.26A | 240rpm | ≤0.7A | 170rpm | 0.25kg.cm | ≤2.3A | ≥0.8kg.cm |

| 62.5:1 | 17.5mm | ≤0.26A | 125rpm | ≤0.7A | 85rpm | 0.5kg.cm | ≤2.3A | ≥1.5kg.cm |

| 78:1 | 17.5mm | ≤0.26A | 100rpm | ≤0.7A | 65rpm | 0.6kg.cm | ≤2.3A | ≥1.8kg.cm |

| 100:1 | 19.0mm | ≤0.26A | 78rpm | ≤0.7A | 52rpm | 0.8kg.cm | ≤2.3A | ≥2.0kg.cm |

| 125:1 | 19.0mm | ≤0.26A | 62rpm | ≤0.7A | 40rpm | 1.0kg.cm | ≤2.3A | ≥2.5kg.cm |

| 156:1 | 19.0mm | ≤0.26A | 50rpm | ≤0.7A | 33rpm | 1.2kg.cm | ≤2.3A | ≥3.5kg.cm |

| 195:1 | 19.0mm | ≤0.26A | 40rpm | ≤0.7A | 26rpm | 1.5kg.cm | ≤2.3A | ≥4.5kg.cm |

| 250:1 | 20.5mm | ≤0.26A | 31rpm | ≤0.7A | 20rpm | 2.0kg.cm | ≤2.3A | ≤6.0kg.cm |

| 312:1 | 20.5mm | ≤0.26A | 25rpm | ≤0.7A | 16rpm | 2.5kg.cm | ≤2.3A | ≤6.0kg.cm |

| 390:1 | 20.5mm | ≤0.26A | 20rpm | ≤0.7A | 13rpm | 3.0kg.cm | ≤2.3A | ≤6.0kg.cm |

| 488:1 | 20.5mm | ≤0.26A | 16rpm | ≤0.7A | 10rpm | 4.0kg.cm | ≤2.3A | ≤6.0kg.cm |

TSL-GM20-130, 6V DC

| Ratio | Gearbox | No Load | Rated Load | Stall | ||||

| i : 1 | Length | Current | Speed | Current | Speed | Torque | Current | Torque |

| 25:1 | 16.0mm | ≤0.11A | 280rpm | ≤0.7A | 210rpm | 0.2kg.cm | ≤1.2A | ≥0.6kg.cm |

| 31:1 | 16.0mm | ≤0.11A | 225rpm | ≤0.7A | 170rpm | 0.25kg.cm | ≤1.2A | ≥0.8kg.cm |

| 62.5:1 | 17.5mm | ≤0.11A | 112rpm | ≤0.7A | 85rpm | 0.5kg.cm | ≤1.2A | ≥1.5kg.cm |

| 78:1 | 17.5mm | ≤0.11A | 90rpm | ≤0.7A | 65rpm | 0.6kg.cm | ≤1.2A | ≥1.8kg.cm |

| 100:1 | 19.0mm | ≤0.11A | 70rpm | ≤0.7A | 52rpm | 0.8kg.cm | ≤1.2A | ≥2.0kg.cm |

| 125:1 | 19.0mm | ≤0.11A | 56rpm | ≤0.7A | 40rpm | 1.0kg.cm | ≤1.2A | ≥2.5kg.cm |

| 156:1 | 19.0mm | ≤0.11A | 45rpm | ≤0.7A | 33rpm | 1.2kg.cm | ≤1.2A | ≥3.5kg.cm |

| 195:1 | 19.0mm | ≤0.11A | 36rpm | ≤0.7A | 26rpm | 1.5kg.cm | ≤1.2A | ≥4.5kg.cm |

| 250:1 | 20.5mm | ≤0.11A | 28rpm | ≤0.7A | 20rpm | 2.0kg.cm | ≤1.2A | ≤6.0kg.cm |

| 312:1 | 20.5mm | ≤0.11A | 22rpm | ≤0.7A | 16rpm | 2.5kg.cm | ≤1.2A | ≤6.0kg.cm |

| 390:1 | 20.5mm | ≤0.11A | 18rpm | ≤0.7A | 13rpm | 3.0kg.cm | ≤1.2A | ≤6.0kg.cm |

| 488:1 | 20.5mm | ≤0.11A | 14rpm | ≤0.7A | 10rpm | 4.0kg.cm | ≤1.2A | ≤6.0kg.cm |

TSL-GM20-130, 12V DC

| Ratio | Gearbox | No Load | Rated Load | Stall | ||||

| i : 1 | Length | Current | Speed | Current | Speed | Torque | Current | Torque |

| 25:1 | 16.0mm | ≤0.05A | 190rpm | ≤0.2A | 135rpm | 0.2kg.cm | ≤0.2A | ≥0.6kg.cm |

| 31:1 | 16.0mm | ≤0.05A | 152rpm | ≤0.2A | 110rpm | 0.25kg.cm | ≤0.2A | ≥0.8kg.cm |

| 62.5:1 | 17.5mm | ≤0.05A | 75rpm | ≤0.2A | 55rpm | 0.5kg.cm | ≤0.2A | ≥1.5kg.cm |

| 78:1 | 17.5mm | ≤0.05A | 60rpm | ≤0.2A | 43rpm | 0.6kg.cm | ≤0.2A | ≥1.8kg.cm |

| 100:1 | 19.0mm | ≤0.05A | 47rpm | ≤0.2A | 34rpm | 0.8kg.cm | ≤0.2A | ≥2.0kg.cm |

| 125:1 | 19.0mm | ≤0.05A | 37rpm | ≤0.2A | 27rpm | 1.0kg.cm | ≤0.2A | ≥2.5kg.cm |

| 156:1 | 19.0mm | ≤0.05A | 30rpm | ≤0.2A | 22rpm | 1.2kg.cm | ≤0.2A | ≥3.5kg.cm |

| 195:1 | 19.0mm | ≤0.05A | 24rpm | ≤0.2A | 17rpm | 1.5kg.cm | ≤0.2A | ≥4.5kg.cm |

| 250:1 | 20.5mm | ≤0.05A | 19rpm | ≤0.2A | 13rpm | 2.0kg.cm | ≤0.2A | ≤6.0kg.cm |

| 312:1 | 20.5mm | ≤0.05A | 15rpm | ≤0.2A | 11rpm | 2.5kg.cm | ≤0.2A | ≤6.0kg.cm |

| 390:1 | 20.5mm | ≤0.05A | 12rpm | ≤0.2A | 9rpm | 3.0kg.cm | ≤0.2A | ≤6.0kg.cm |

| 488:1 | 20.5mm | ≤0.05A | 10rpm | ≤0.2A | 7rpm | 4.0kg.cm | ≤0.2A | ≤6.0kg.cm |

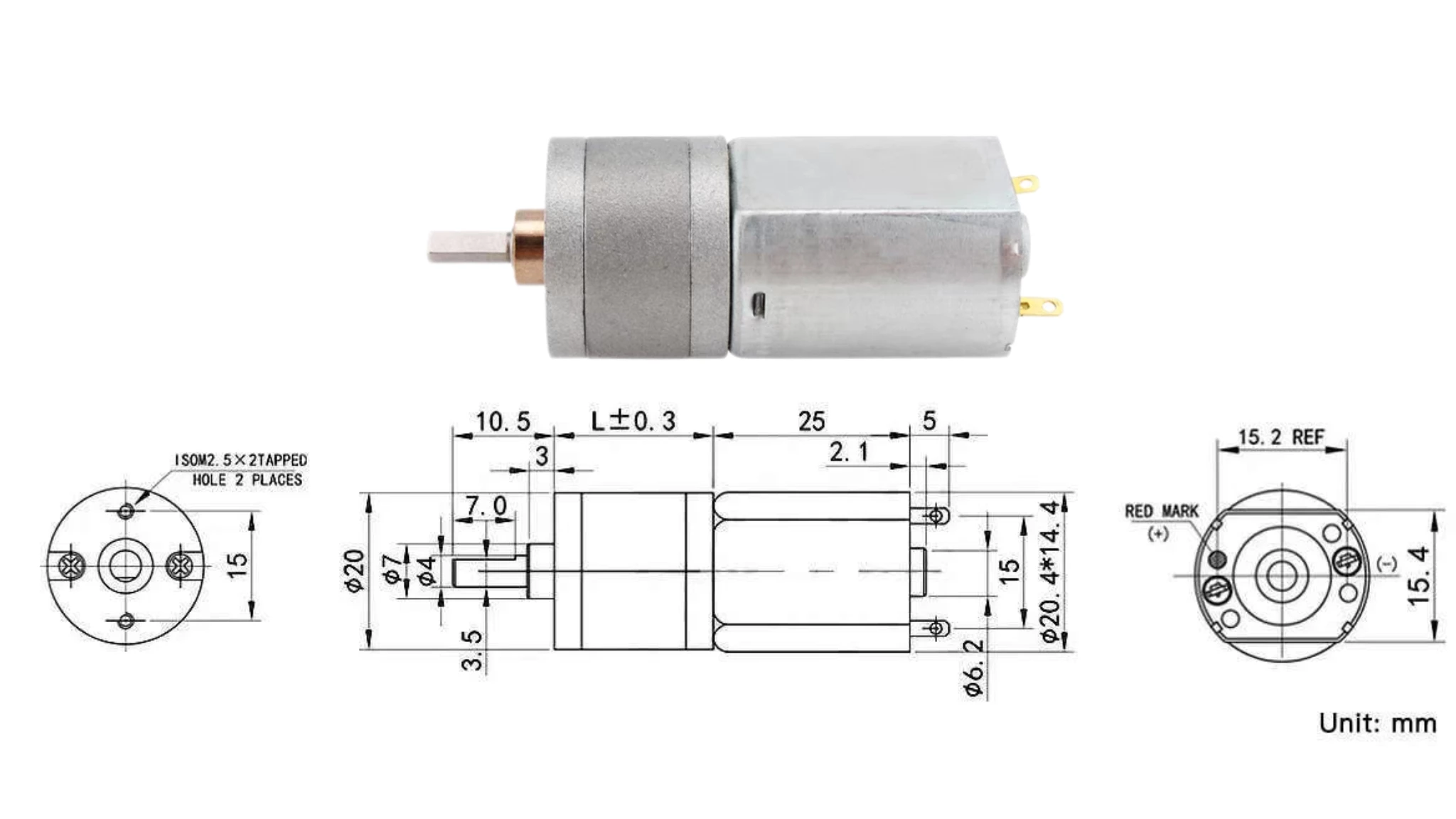

Geared Electric Motor 130 Gear Motors Outline Drawing

Keywords:

speed reduction gear motor, gear motor manufacturer, electric gear motor, high torque gear motor applications, gear motor for mining equipment, custom gear motor design, energy efficient gear motors, compact gear motor,geared electric motor,miniature geared electric motor.

Payment:

Payment options : Paypal T/T

Shipping:

1.Delivery: DHL/FedEx 3-5 days.

2.Item will be delivered within 1-3 days of the payment.

3.If you don’t have the item by the delivery Time Please send us an email with questions. In most cases, we will send you a response within 24 hours. If not, examine the spam in your email inbox. We will try the best we can to assist you with the issues.

4.Please ensure that your address is in line with the final shipping address prior to you make payment.

FAQ for Geared Electric Motor

Q:What is a Spur Gear Motor?

A:A spur gear motor combines a spur gearbox and a motor, typically using a 3-24V voltage. The output shaft is usually eccentric. These motors are precision cylindrical gear motors that transfer motion between two parallel shafts with straight, parallel teeth.

Q: How do I place an order?

A: Send us an inquiry and we will send you a quote – make arrangements – confirm the sample – sign the contract/deposit mass production – delivery ready for delivery. Balance/delivery

Q: What about Sample Order?

Answer: Sample are available to you. Contact us for specifics. If we charge you a cost for the sample, you can take it at ease, as it will be the refund you receive when you make a formal order.

Q: If it is a customized version the information you provide, what should you include?

A: You should give the fundamental specifications of the motor, for example Dimensions Applications, Sizes as well as Voltage, Speed and Torque. It is better to provide an application-specific prototype drawing to us when you can.

Q: What’s one of your main motor?

A: Diameter 4mm~42mm Dc Micro Motor And Gear Motor, Auto Dc Motor, Electric Motor, Gear Motor, Mini Dc Motor, Brush Dc Motor, Brushless Dc Motor, Spur Gear Motor, Micro Motor, Vibration Motor Etc.

Q: What’s the principal use of the microdc motor?

A Mini DC motors are used extensively in home Applications, Office Equipment, Health-Care Application, Sanitation Industry The High-Class Toy Banking System Electronic and Electrical Tools, Automation Industry, Bank Equipments, Payment Equipments, Vending Machines, Power Door Lock, Electric Door Lock.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration. IF you need a torque converter which is used for converting different torques, please click Bossard Online Torque Converter.

Motor Customization Guide

Please tell us your requirements. Our engineers will give you the best solution for your application.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!