Introduction

As smart home technology becomes increasingly prevalent, the field of intelligent home robotics is undergoing a profound transformation. Among these advancements, the robotic vacuum cleaner has evolved from a novel tech gadget into an indispensable core cleaning tool for the modern household.

This market maturation has led to elevated consumer expectations; users are no longer satisfied with basic path planning and suction functions but are now demanding a more sophisticated and comprehensive product experience.

Within the complex and precise system of a robotic vacuum, the transmission system—encompassing the drive wheel assemblies and the gearbox assemblies for the main and side brushes—forms the physical foundation upon which all advanced functionalities are realized.

An exceptionally designed transmission system is a prerequisite for achieving a top-tier user experience.

In response to the market’s urgent demand for high-performance, high-reliability robotic vacuums, Tsinglin Motor has introduced its integrated transmission system solution. This solution is the result of systematic engineering optimization aimed at addressing key industry pain points.

Key Takeways

- Integrated Design: Tsinglin Motor provides a complete mechatronic system, not a collection of isolated components.

- Precise Gear Ratios: The gear ratio for each module is precisely calculated to meet its specific functional requirements.

- All-Terrain Capability: High-torque drive wheels ensure superior obstacle-climbing and traversal ability.

- Deep Cleaning: The main brush balances high speed with energy efficiency for powerful cleaning performance.

- Silent Engineering: Helical gears and special grease are used to reduce noise at its source, enhancing the user experience.

- Helical vs. Spur Gears: Innovatively using helical gears instead of traditional spur gears to reduce noise and vibration at the source.

The Complete Robotic Vacuum Transmission System

Tsinglin Motor‘s solution is not a simple assembly of isolated components but a cohesively designed, complete mechatronic system. It provides the core powertrain required for the robotic vacuum to execute all its dynamic functions and is composed of three critical subsystems:

Left/Right Drive Wheel Modules

This is the robot’s mobility hub, responsible for providing power for forward and backward movement, turning, and rotating in place. Its design directly dictates the robot’s maneuverability, the precision of its path execution, and its ability to overcome obstacles in complex home environments.

Main Brush Gearbox

As the core power source of the cleaning system, this module drives the main brush to rotate at high speed. Through powerful agitation and sweeping, it dislodges and lifts dust, hair, and debris from deep within carpets, allowing the vacuum system to capture them. Its performance is a key metric for the robot’s deep cleaning capability.

Left/Right Side Brush Gearboxes

This system drives the side brushes at a precisely controlled speed, responsible for sweeping dust from wall edges, corners, and along furniture. Its function is to gather debris from areas unreachable by the main suction inlet and direct it into the primary cleaning path.

Algorithm-Driven Precision Design: The Science of Optimal Gear Ratios

A Mechatronic Co-Design Philosophy

In modern robotics, mechanical and software engineering are no longer linear, isolated development processes but have entered an era of deep integration and parallel iteration known as “mechatronic co-design”.

The joint R&D between Tsinglin Motor and a leading domestic algorithm company is a perfect embodiment of this advanced philosophy. This collaborative model ensures that mechanical hardware design is no longer based on assumptions but is precisely engineered to meet the stringent demands of advanced algorithms for controlling the physical world.

Every parameter of the transmission system, especially the gear ratio, is a direct physical manifestation of the software’s logic.

Deconstructing the Drive Wheel Gearbox (Gear Ratio: 68.5:1)

Providing High Torque for All-Terrain Traversal

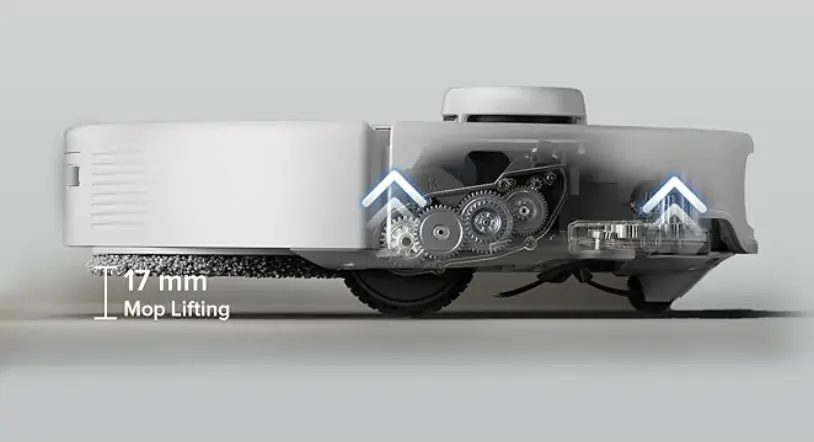

This powerful torque gives the robotic vacuum exceptional obstacle-climbing ability, allowing it to easily mount carpet edges, cross room thresholds, and transition smoothly between different floor types (e.g., from hard floors to high-pile carpets) without getting stuck.

Achieving High-Resolution Motion Control

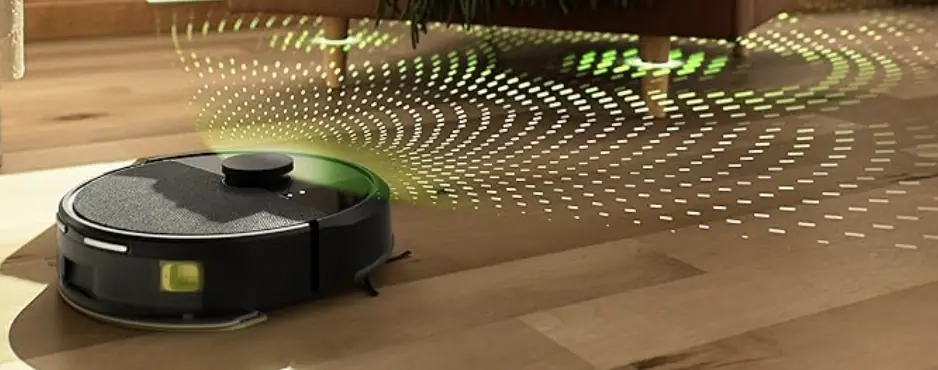

For robots that rely on advanced navigation algorithms like SLAM (Simultaneous Localization and Mapping) or V-SLAM (Visual SLAM), motion control precision is paramount. A high gear ratio means that a tiny rotation of the motor rotor corresponds to an extremely small angular displacement of the wheel.

This provides the algorithm with exceptionally high control resolution. When the algorithm issues a command like “move forward 1 cm” or “rotate 0.5 degrees,” the high-ratio drive system can execute these fine movements with extremely high fidelity. This ensures the accuracy of map building, stability of localization, and perfect replication of the cleaning path, avoiding the “juddering” or “overshooting” common in systems with lower gear ratios.

Analysis of the Main Brush Gearbox (Gear Ratio: 6:1)

In contrast to the drive wheels, the main brush system uses a low gear ratio of 6:1, a design intended to strike the optimal balance between cleaning power and energy efficiency.

Balancing Power and Efficiency

The primary task of the main brush is to agitate and sweep carpet fibers through high-speed rotation to “shake out” deep-seated dirt. Therefore, it needs to maintain a relatively high rotational speed to ensure cleaning efficacy. The 6:1 gear ratio provides the main brush with a sufficiently high speed within a reasonable motor power consumption range, effectively dealing with stubborn dust, debris, and pet hair.

Power Consumption Management

A robotic vacuum’s battery life is a key aspect of the user experience. The main brush is one of the primary power-consuming components. This gear ratio is optimized to ensure that while providing powerful cleaning action, it does not place an excessive load on the motor, thereby keeping current draw within a reasonable range and contributing significantly to the machine’s overall single-charge runtime.

Analysis of the Side Brush Gearbox (Gear Ratio: 23.7:1)

The function of the side brush is finesse, not force. Its medium gear ratio of 23.7:1 perfectly embodies the design principle of “gather, don’t scatter.”

The “Gather, Don’t Scatter” Principle

If the side brush rotates too quickly, it will act like a propeller, scattering dust and debris from corners and edges into already cleaned areas, causing secondary contamination and severely reducing cleaning efficiency. Conversely, if the speed is too slow, it cannot effectively sweep out debris.

The 23.7:1 gear ratio is carefully chosen so that the linear velocity of the brush is sufficient to “flick” debris from corners toward the main brush’s path, yet gentle enough to avoid sending it flying. This is a common flaw in many poorly designed robotic vacuums, a pain point that Tsinglin Motor has solved through precise gear ratio engineering.

Functional Specification Summary

To visually demonstrate the design intent and user benefits of each module, the following table summarizes the core specifications of the Tsinglin Motor transmission system.

| Component Module | Nominal Gear Ratio | Primary Engineering Function | Key End-User & System Advantages |

| Left/Right Drive Wheel | 68.5:1 | High torque generation & high-resolution speed control | Superior obstacle traversal (e.g., carpets, thresholds); enhanced navigation precision; smooth, judder-free motion. |

| Main Brush | 6:1 | High-speed debris agitation | Deep cleaning performance on carpets; efficient collection of heavy debris; optimized for battery life. |

| Left/Right Side Brush | 23.7:1 | Controlled-speed debris gathering | Efficient edge and corner cleaning; prevents scattering of debris, improving single-pass cleaning efficiency. |

The Mechanics of Silence: Advanced Noise Reduction Engineering

Noise is one of the most critical factors affecting the user experience of a robotic vacuum. A noisy device can severely disrupt home life, forcing users to run it only when they are away, which limits its convenience.

The harsh, high-frequency noise of traditional robotic vacuums primarily originates from their internal gearboxes, specifically the impact and vibration generated during gear meshing. Tsinglin Motor’s noise reduction engineering tackles this core source head-on through advanced mechanical design and material science to reshape the robot’s acoustic signature.

Helical Gears vs. Spur Gears: A Technical Comparison

Traditional gearboxes often use spur gears, whose teeth are parallel to the gear’s axis. When a pair of spur gears mesh, their teeth make contact and separate instantaneously across the entire tooth width. This abrupt, linear impact generates significant vibration and pressure waves, which radiate as high-frequency noise and are the primary source of “gear whine.”

Helical Gears

Tsinglin Motor innovatively uses helical gears in the first stage of its gearbox transmission. The teeth of a helical gear are cut at an angle to the gear’s axis. Thanks to this geometry, when a pair of helical gears begin to mesh, the contact starts as a point at one end of the tooth. As the gears rotate, the line of contact sweeps smoothly and gradually across the entire face of the tooth. This “rolling” and gradual engagement dramatically reduces meshing impact, making the power transmission process silky smooth and fundamentally suppressing the generation of vibration and noise.

Managing Axial Thrust

An inherent characteristic of helical gears is the generation of an axial force (Axial Thrust) along the gear’s axis when transmitting torque. This is an engineering challenge that must be properly managed; otherwise, it can increase bearing wear and reduce lifespan.

Tsinglin Motor’s gearbox design fully accounts for this by integrating matching high-performance thrust bearings or deep-groove ball bearings to effectively manage and absorb these axial forces. This not only achieves quiet operation without sacrificing longevity but also highlights the foresight and integrity of the design, ensuring long-term reliable operation.

The Critical Role of Tribology: High-Adhesion Lubrication

The internal lubrication system of the gearbox is the core defense against internal degradation. Here, Tsinglin Motor applies cutting-edge findings from the field of tribology (the science of friction, wear, and lubrication).

The Science of “Specific High-Adhesion Lubricating Grease”:Inside a compact, high-speed gearbox, ordinary grease can be easily slung off the meshing surfaces by centrifugal force, leading to lubrication failure. The specialized grease selected by Tsinglin Motor possesses the following key characteristics

- Forms a Stable Oil Film: This grease forms a tough and durable protective film on the gear surfaces, completely separating the meshing teeth and preventing direct high-pressure contact (whether metal-on-polymer or polymer-on-polymer). This is the most fundamental mechanism for reducing friction, preventing wear, and extending gear life.

- Adhesion and Cohesion: The grease is specially formulated to have an extremely strong ability to “stick” to the gear surfaces (adhesion), while its internal molecular forces are also strong (cohesion), allowing it to resist being thrown off by the immense centrifugal forces of high-speed rotation. This ensures the gears remain effectively lubricated throughout their entire operational lifespan.

- Synergistic Noise Reduction: This viscous oil film also acts as a hydraulic cushion during the moment of gear meshing, absorbing a portion of the impact energy and further reducing noise. It complements the geometric advantages of the helical gears and the damping properties of the polymers, collectively forming Tsinglin Motor’s multi-layered noise reduction system.

The decision to use helical gears and specialized lubricating grease is a profound reflection of the product’s market positioning. The cost of both technologies is higher than that of traditional spur gears and conventional grease.

The company’s deliberate choice of a more expensive component architecture indicates that its strategic goal is not to compete on price in the low-end market. Instead, it aims to vie for the mid-to-high-end market by providing a superior user experience.

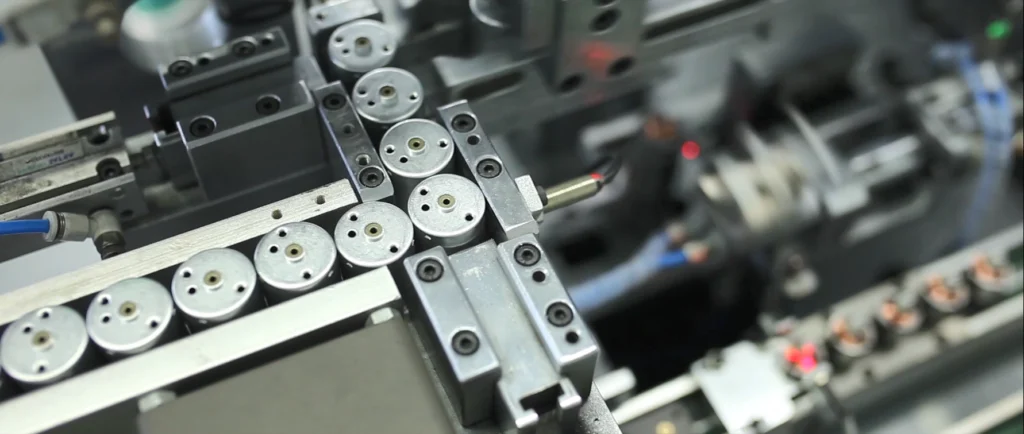

Furthermore, effectively utilizing helical gears requires extremely high manufacturing precision and tighter tolerance control to ensure proper engagement and management of axial forces. This also indirectly proves that Tsinglin Motor possesses advanced manufacturing processes and a rigorous quality control system.

Therefore, its acoustic design is not merely a functional feature; it’s a powerful statement of its high-end market positioning and excellent engineering capabilities.

Summary

Tsinglin Motor’s robotic vacuum transmission system is an integrated mechatronic solution that deeply blends mechanical hardware with software algorithms through a co-design philosophy. This system perfectly meets the demands of modern robotic vacuums for precise motion control, establishing a solid physical foundation for smooth navigation and efficient cleaning.

The core of its superiority lies in function-specific gear ratios. The high gear ratio of the drive wheels provides powerful obstacle-climbing ability and fine movement control. The main brush’s low gear ratio balances cleaning power with energy efficiency, while the side brush’s medium gear ratio solves the common problem of scattering dust, ensuring debris is precisely swept toward the main suction port.

Furthermore, the system makes silence a core design principle. By using helical gears and high-adhesion lubricating grease, it eliminates noise at the source. This technical choice not only significantly enhances the user experience but also clearly shows the company’s strategic positioning to compete in the mid-to-high-end market through superior engineering, rather than just on price.

Frequently Asked Questions (FAQ): Tsinglin Motor’s Robotic Vacuum Transmission System

1. Q:What are the key components of Tsinglin Motor’s transmission system?

A:The system is a complete mechatronic solution composed of three main subsystems: the left/right drive wheel modules, the main brush gearbox, and the left/right side brush gearboxes.

2. Q:Why do the drive wheels use such a high gear ratio (68.5:1)?

A:The high gear ratio serves two primary purposes:

- Provides high torque: This allows the robotic vacuum to easily climb over obstacles like carpet edges and room thresholds, giving it exceptional all-terrain capability.

- Enables high-resolution motion control: A high gear ratio means a tiny rotation of the motor corresponds to a very small wheel displacement. This provides advanced navigation algorithms like SLAM with the precision needed for accurate map building and path execution.

3. Q:Why do the main and side brushes use different gear ratios? What is the purpose of each?

A:The gear ratios are optimized for each brush’s specific cleaning task:

- Main Brush (6:1): A lower gear ratio is used to maintain a high rotational speed. This generates powerful agitation and sweeping force to effectively dislodge deep-seated dirt and hair from carpets. It also helps manage power consumption to extend battery life.

- Side Brush (23.7:1): This medium gear ratio is carefully chosen for the “gather, don’t scatter” principle. If the brush spun too fast, it would scatter dust, causing secondary contamination. This ratio ensures the brush sweeps debris gently from corners toward the main cleaning path without sending it flying.

4. Q:How does Tsinglin Motor reduce the noise of its robotic vacuums?

A:The noise reduction is engineered from the ground up:

- Uses helical gears: Unlike traditional spur gears, which have abrupt, noisy contact, the angled teeth of helical gears engage smoothly and gradually, fundamentally reducing vibration and high-frequency noise.

- Applies high-adhesion lubricating grease: This specialized grease forms a durable film on gear surfaces, acting as a hydraulic cushion that absorbs impact energy during meshing, further dampening noise.

- Advanced Manufacturing: High-precision manufacturing and strict tolerance control ensure proper gear meshing, preventing noise from poor assembly.

5. Q:What are Tsinglin Motor’s main technological advantages?

A:Their advantages include:

- Integrated system design: They provide a complete powertrain solution, not just individual parts.

- Mechatronic co-design philosophy: Hardware is designed in synergy with software algorithms for optimal performance.

- Function-driven engineering: Gear ratios are precisely chosen and optimized for each module’s specific cleaning function.

- High-end materials and processes: The deliberate use of expensive helical gears and specialized grease shows a commitment to superior user experience and high-end market positioning.

6. Q:Do helical gears present any engineering challenges, and how does the company handle them?

A:Yes. Helical gears generate an axial thrust (a force along the gear’s axis). If not managed properly, this can increase bearing wear and reduce lifespan. Tsinglin Motor accounts for this by integrating high-performance thrust bearings or deep-groove ball bearings into their gearbox design, which effectively absorb these forces and ensure long-term durability.

Tsinglin Motor: Custom DC Motor Solutions

Established in 2009, Tsinglin Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

- Custom Micro Motors5 products

- DC Gear Motor139 products

- 6mm Planetary Gear Motor4 products

- 6mm Planetary Metal Gear Motor3 products

- Brushless Gear Motor17 products

- Micro Gear Motor64 products

- Coreless Gear Motor11 products

- N20 Gear Motor26 products

- Plastic Gearbox Motor8 products

- Standard Gear Motor15 products

- Stepper Gear Motor15 products

- Planetary Gear Motor29 products

- Spur Gear Motor63 products

- Worm Gear Motor28 products

- DC Motor78 products

- Brushed DC Motor16 products

- Brushless DC Motor21 products

- Inrunner Rotor BLDC Motor6 products

- Outrunner Rotor BLDC Motor13 products

- Coreless DC Motor13 products

- Micro DC Motor15 products

- Stepper Motor13 products

- Vibration Motors71 products

- Brushless Vibration Motor8 products

- Coin Vibration Motor22 products

- Coreless Vibration Motor3 products

- Encapsulated Vibration Motor6 products

- Linear Resonant Actuator12 products

- Powerful Vibrating Motor17 products

- SMD Vibration Motor4 products

- Sonic Vibration Motor2 products