22mm Planetary Geared Motor Model TSL-22GP-BL2418

♦ Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TSL-22GP-BL2418

- Voltage range:DC 10V-16V

- Motor Diameter:φ22mm

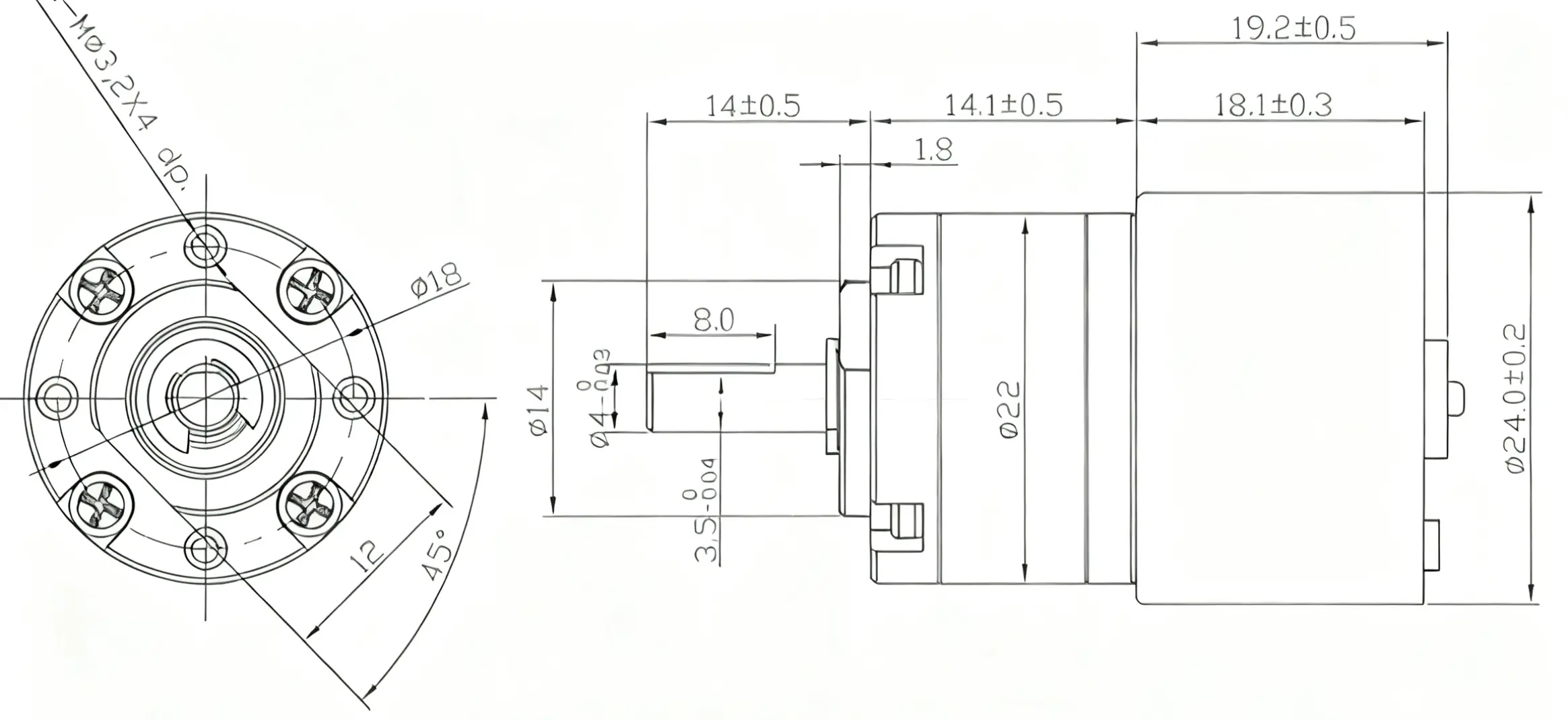

- Shaft length:14mm

- Shaft Diameter:4mm , thick 3.5mm

- #More Specifications

- #Outline Drawing

♦ Typical Applications:7d Ultrasonic Scalpel

High Torque Brushless Electric Motor Planetary Gear Motor Data

Seeking the next-generation drive for your precision devices? Our factory proudly presents the 22mm bldc gear reduction motor. This is a sophisticated blend of a high torque brushless electric motor and a precision gearbox, engineered to deliver exceptional power and control in a compact package.

Our high torque brushless electric motor’s performance is rigorously validated in the medical field. Its most classic application is successfully driving the advanced 7D ultrasonic scalpel. This demonstrates its proven ability to meet extreme demands for smooth, stable power output and precise positioning in critical procedures.

Choose our solution for guaranteed benefits: extended lifespan, superior energy efficiency, and unmatched operational stability. Equip your products with a core component that ensures top-tier performance and reliability, helping you lead the market.

| Motor Model:TSL-22GP-BL2418 | |

| Rated Voltage:DC12.0V | |

| Voltage Range | DC 10-16V |

| No Load Speed | 1300±10%rpm |

| No Load Current | ≤150mA |

| Rated Speed | 1050±10%rpm |

| Rated Current | ≤0.6A |

| Rated Torque | 0.13Kg.cm |

💕The high torque brushless electric motor’s technical specifications are for guidance,we offer custom solutions upon request.

⇒Unit Coversion: 1 g·cm ≈ 0.098 mN·m ≈ 0.014 oz·in;1 mm ≈ 0.039 in;1 g ≈ 0.035 oz

Small High Torque Brushless Electric Motor Mechanical Drawing

Unless otherwise stated, all dimensions are in millimeters. The provided drawings are for illustrative purposes; please contact us to verify precise specifications.

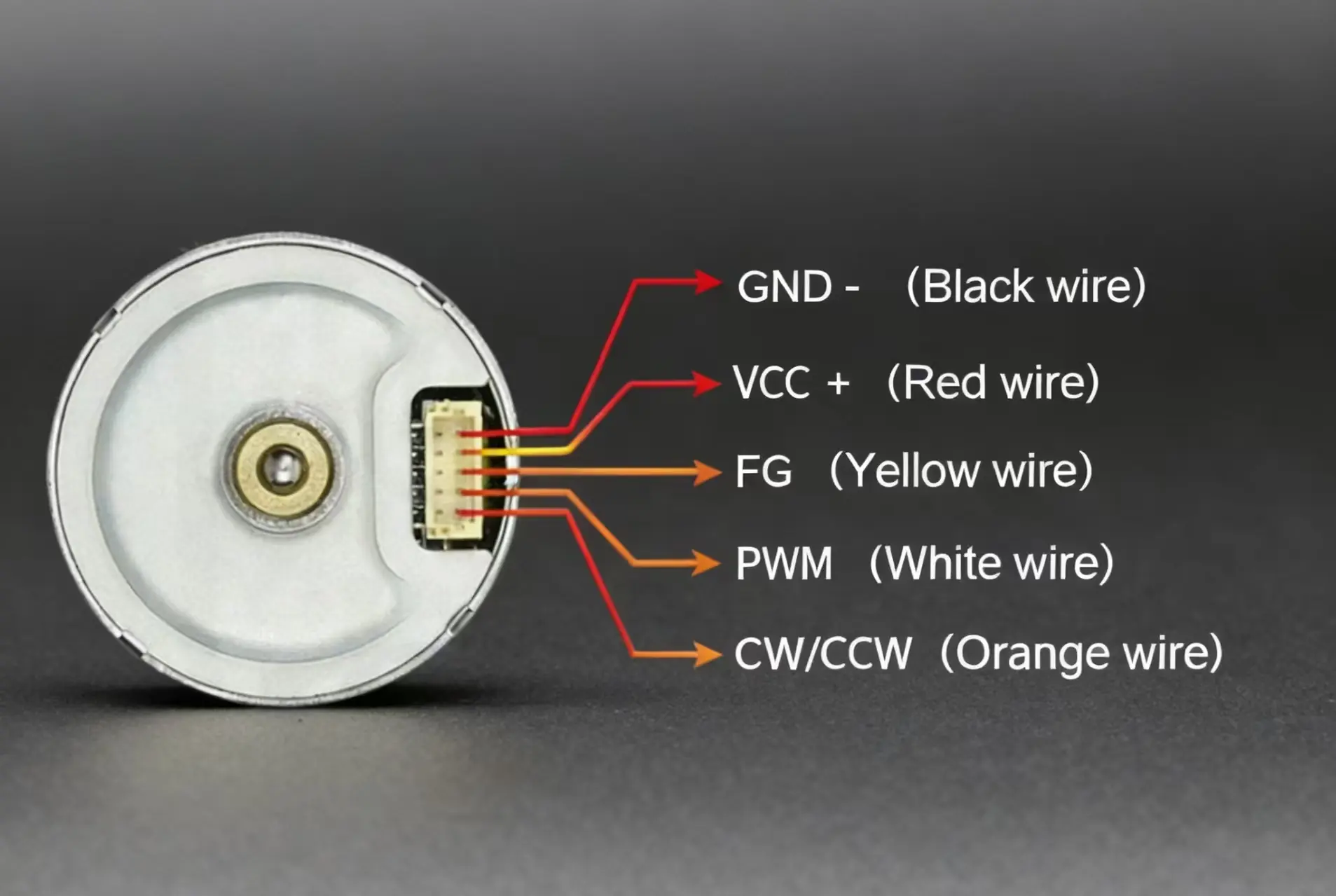

High Torque Brushless Electric Motor BLDC Wiring Method

Wiring instructions:

⚫power –

🔴power +(DC 8-15V)

🟡Speed signal output

⚪Motor induction port: PWM input, duty cycle is inverselyproportional to speed, connected to the negative side of the power supply for the highest speed.

🟠Motor forward and reverse control: when the port is notconnected, the motor CCW;When port is connected to low level (≤0.6v), motor CW.

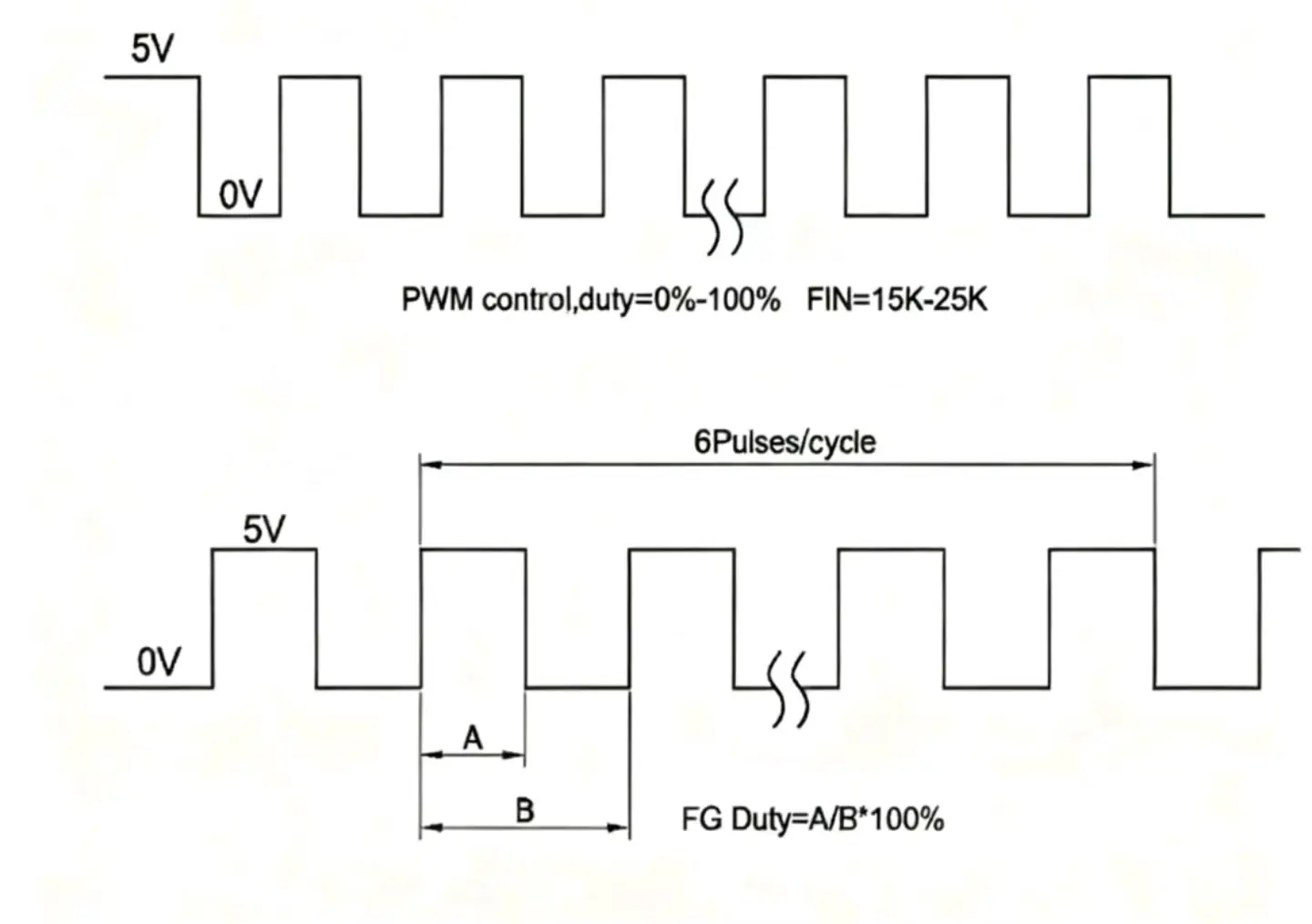

High Torque Brushless Electric Motor Terminations

| NO. | SIGNAL | I/O | SPECIFCATIONS | NOTE |

| 1 | Vm(red wire) | I/N | DC 24VM±10%V | POWER |

| 2 | FG(Green wire) | |||

| VOH | OUT | 5.0V Max | Hall Signal Pulse Outputs | |

| VOL | 0.5V Max | |||

| FG Signal Current | 2mA | |||

| Puise Outputs Of Rotation | 6Pulse/cycle | |||

| 3 | CW/CCW Control(yellow wire) | |||

| Input Voltage Range | IN | 0-5V | High-motor CCW;Low-motor CW | |

| VIH | 2.0V Min.or | |||

| VIL | 0.5V Max | |||

| 4 | GND | IN | Power Ground | Power Ground |

| 5 | PWM Control(blue wire)60K MAX Typical(15K-25K) | |||

| Input Voltage Range | IN | 0-5V(15K-25K) | High-motor OFF;Low-motor ON | |

| VIH | 2.0V Min.or open | |||

| VIL | 0.5V Max | |||

High Torque Brushless Electric Motor Block Diagram

High Torque Brushless Electric Motor Details

Planetary Gearbox Structure

Full planetary gear structure, ensuring excellent wear resistance, high torque capacity, and extended service life. It provides exceptionally smooth and stable operation.

All-Metal Gear Structure

This component utilizes premium metal materials to deliver exceptional wear resistance and an extended operational lifespan.

D-Cut output shaft

The D-Cut output shaft is engineered for effortless, slip-free mounting, significantly reducing assembly time.

Keywords:

high torque brushless dc gear motor,high torque low rpm brushless dc motor,dc brushless motor high torque,high torque dc brushless motor

Development Samples:

If you need samples, please contact us.

Engineering & Manufacturing:

Contact any or the Sales Engineers for a quotation for production or consultation on the integration and customization of your product.

Payment:

1.Payment methods : Paypal, T/T

Shipping:

1.Delivery: DHL/FedEx 3-5 days.

2.Item will be shipped within 1-3 business days after the payment.

3.If you haven’t received the item on the Delivery Time, pls contact us by email if you have any questions. Normally, we will give you a reply within 24 hours, if not, pls check the spam of your email box. We will do our best to help you solve the problems.

4.Please make sure your address is matched with the finally shipping address before you pay.

FAQ for planetary gear motor

Q:What is a planetary gear motor?

A:A planetary gear motor is a type of motor that mimics the movement of a planetary system. The input shaft turns a central gear known as the sun gear, which then drives multiple surrounding planet gears. This setup allows the motor to efficiently increase or reduce speed and is commonly used across various industries due to its compact design and high performance.

If you want a video to explain the principle of planetary gear motor, you can click on this link:https://www.youtube.com/watch?v=Ho4AniHtgxM

Q:Can Planetary Gear Motor Be Customized?

A: Yes,Planetary gear motor can be customized. TSL Motors, a top manufacturer, offers options to adjust torque, speed, and voltage. This ensures the motor meets the specific needs of your application.

Q: How do I place an order?

A: Send us an inquiry and we will send you a quote – make arrangements – confirm the sample – sign the contract/deposit mass production – delivery ready for delivery. Balance/delivery

Q: What about Sample Order?

A: Sample are available to you. Contact us for specifics. If we charge you a cost for the sample, you can take it at ease, as it will be the refund you receive when you make a formal order.

Q: If it is a customized version the information you provide, what should you include?

A: You should give the fundamental specifications of the motor, for example Dimensions Applications, Sizes as well as Voltage, Speed and Torque. It is better to provide an application-specific prototype drawing to us when you can.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration.

Motor Customization Guide

Please tell us your requirements. Our engineers will give you the best solution for your application.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!