The 7D Ultrasonic Scalpel is leading a profound revolution in aesthetic technology. The core challenge in achieving precise lifting effects lies in ensuring the flawless linear scanning motion of the ultrasonic transducer within the subcutaneous tissue.

This motion must be precise and smooth to form a uniform “Thermal Coagulation Point Array” (TCPs) at the target depth. Any deviation will compromise the therapeutic effect.

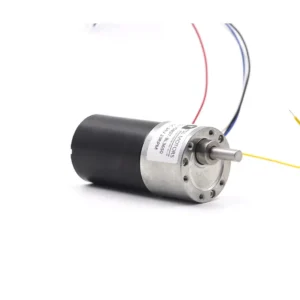

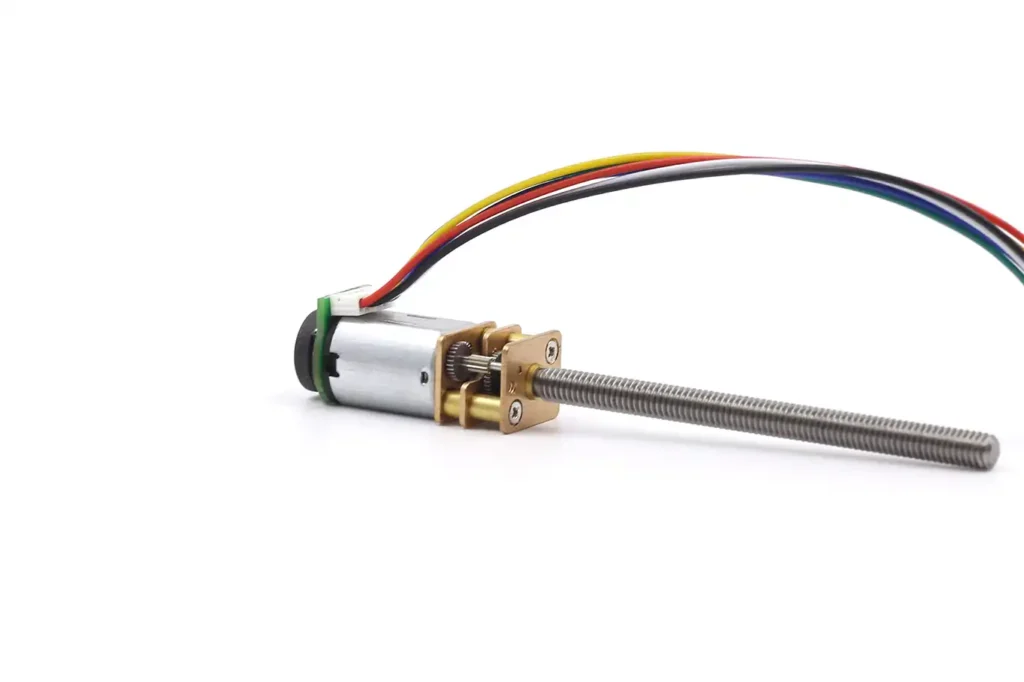

This report will provide an in-depth analysis of how our factory model TSL-22GP-BL2418 micro planetary brushless gear motor is the decisive motion solution that enables the next generation of 7D Ultrasonic Scalpel devices to achieve this precise performance.

Key Takeaways

- Ultimate Precision Drive: The TSL-22GP-BL2418 is the definitive motion solution for the 7D HIFU, ensuring flawless linear scanning to create uniform Thermal Coagulation Points (TCPs).

- Ultra-Quiet Performance: The brushless motor and precision gearbox deliver ultra-low noise and vibration, which is crucial for a premium, comfortable user experience in clinical settings.

- Medical-Grade Reliability: The BLDC motor offers an ultra-long lifespan (over 20,000 hours), making it a highly reliable, permanent component that drastically reduces the Total Cost of Ownership (TCO).

- High Accuracy: The 22GP planetary gearbox maintains a low backlash of under 1.5°, guaranteeing accurate positioning and eliminating slack during motion reversal.

- Simplified Integration: Features an integrated drive and control signals (PWM for speed, FG for feedback) to simplify the control system development and accelerate time-to-market.

- Optimized Torque & Speed: The recommended 5:1 reduction ratio balances torque and speed, enabling efficient and precise execution of rapid linear scanning tasks.

7D Ultrasonic Scalpel (MMFU) Technology Analysis

Working Principle

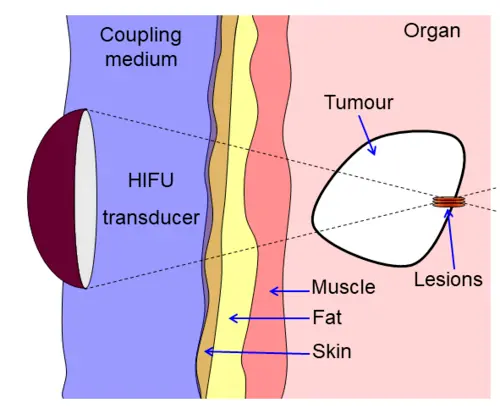

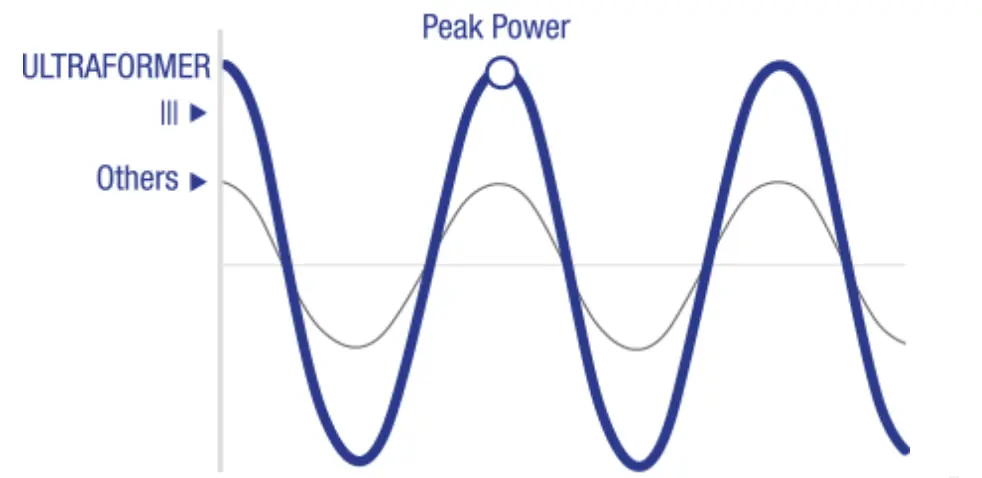

High-Intensity Focused Ultrasound (HIFU) is a non-invasive aesthetic technology that has been widely adopted in the industry. Its core principle is to use the penetrability and focusability of ultrasonic waves to precisely converge energy at a specific depth beneath the skin, achieving therapeutic effects without damaging the epidermis.

The 7D Ultrasonic Scalpel builds on this by employing the more advanced Micro-Macro Focused Ultrasound (MMFU) technology.

This technology can distribute ultrasonic energy more uniformly and precisely to multiple subcutaneous layers, including the dermis and the Superficial Musculoaponeurotic System (SMAS) layer, which is crucial for skin lifting.

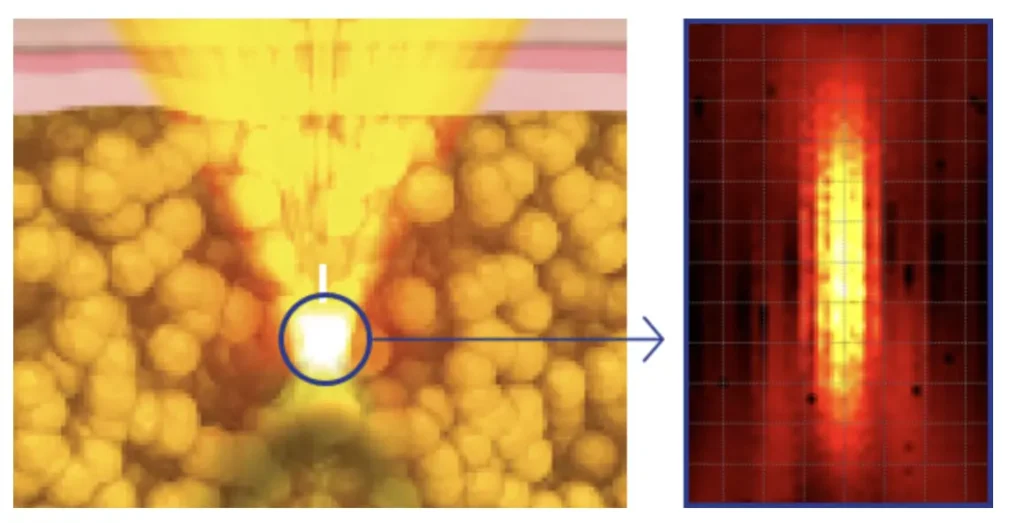

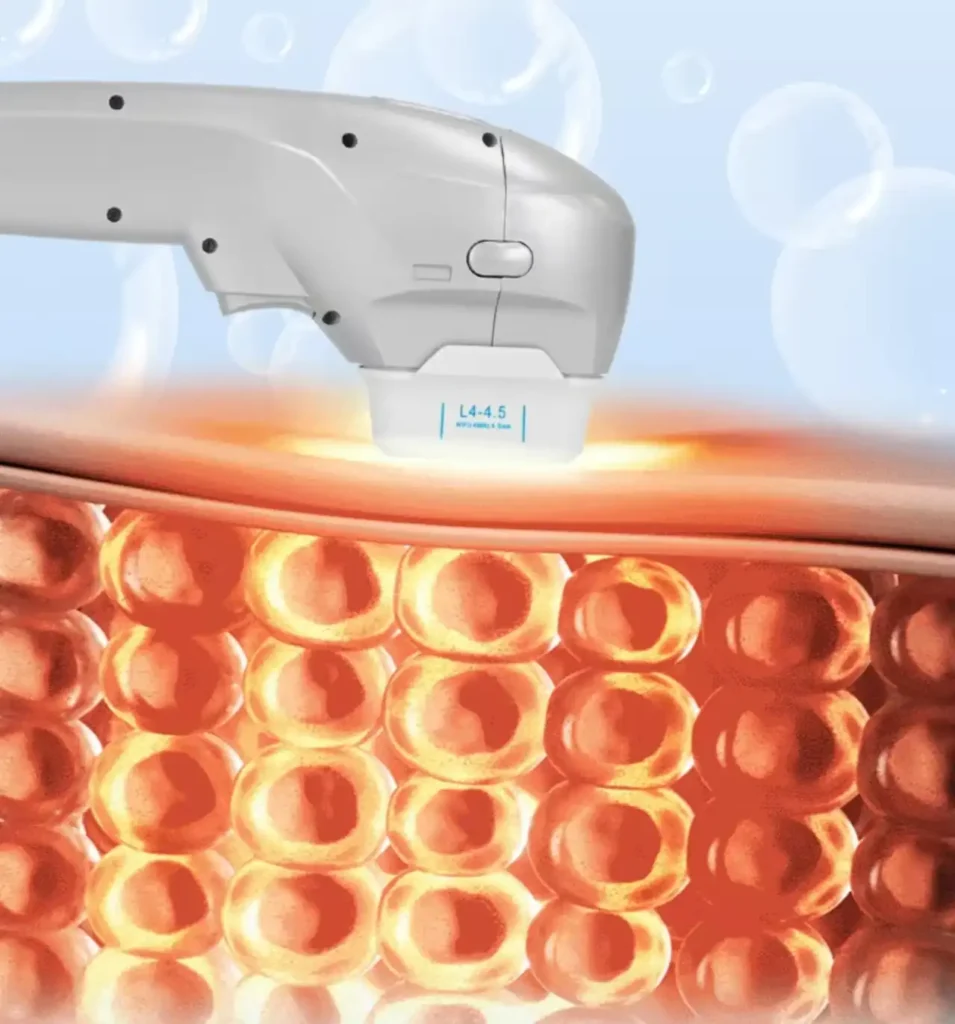

The mechanism of action is the formation of discrete Thermal Coagulation Points (TCPs) within the target tissue, instantly raising the localized temperature to 65-75°C.

This controlled micro-thermal injury initiates the body’s natural wound-healing response, stimulating fibroblasts to produce new collagen (i.e., neocollagenesis), ultimately resulting in skin tightening and lifting effects.

It is important to note that, despite being marketed as an “Ultrasonic Scalpel” in some promotional materials, this is technically a commercial misnomer. Its working principle is fundamentally different from the ultrasonic scalpel used in surgical procedures.

A surgical ultrasonic scalpel uses the high-frequency vibration of its blade (typically in the 20-60 kHz range) to generate frictional heat and cavitation effects, achieving tissue cutting and coagulation hemostasis.

In contrast, the 7D Ultrasonic Scalpel is a non-invasive thermal ablation technology whose energy acts beneath the skin surface to stimulate tissue regeneration, not physical cutting.

This fundamental difference dictates the variation in performance requirements for its drive motor, particularly concerning noise, vibration, and control precision. The operational environment and the user’s experience are far more important considerations than for surgical instruments.

Analysis of the 7D Ultrasonic Scalpel Handpiece

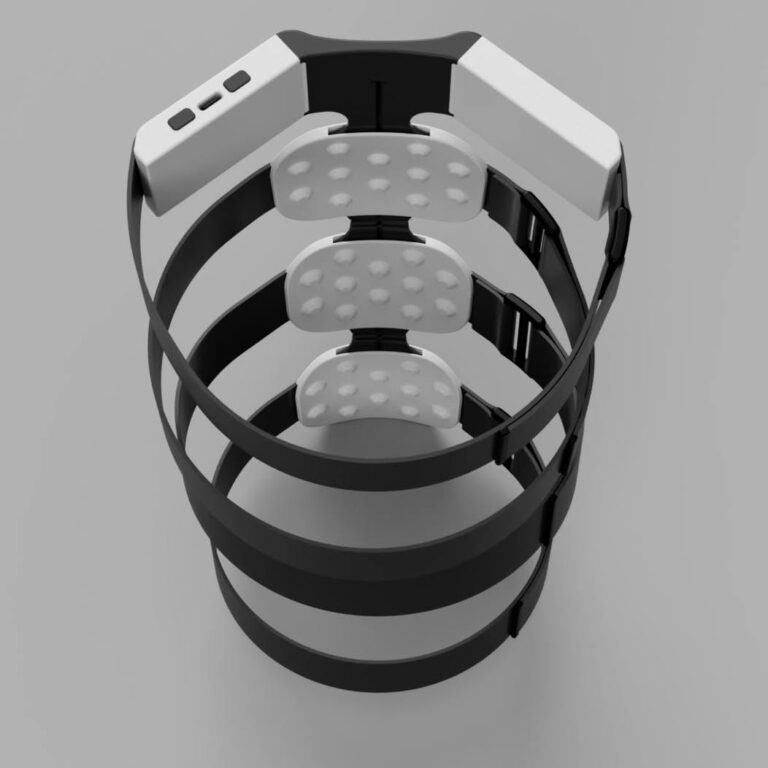

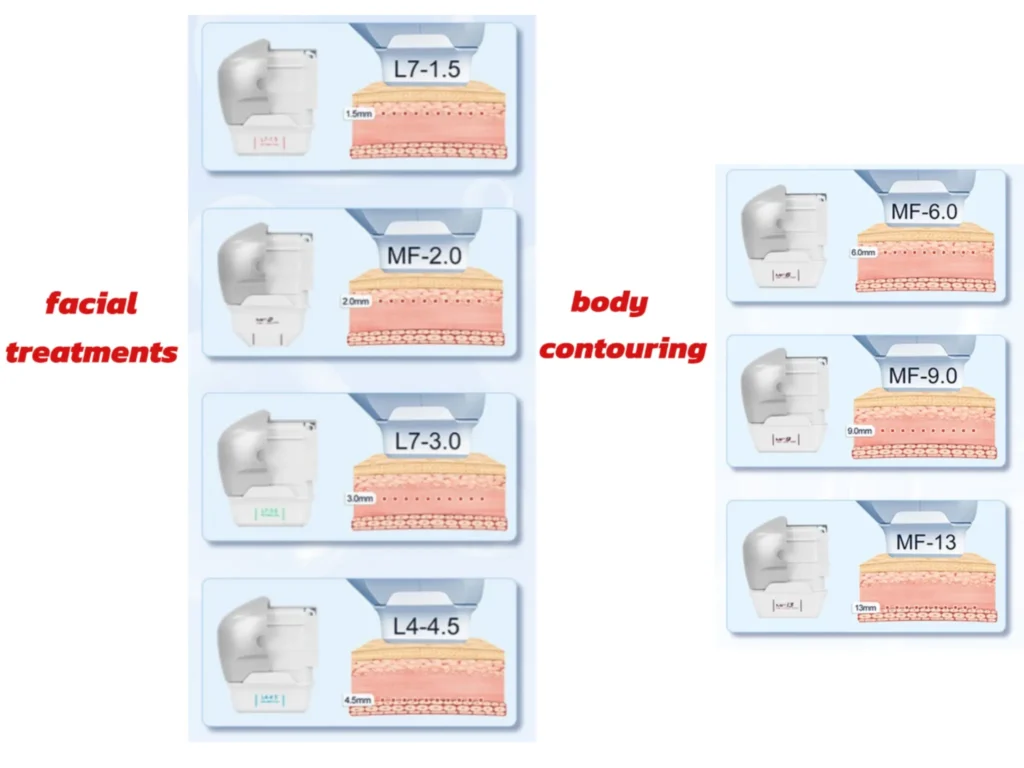

A complete 7D Ultrasonic Scalpel system typically consists of a main control console, a handheld operating handpiece, and a set of interchangeable treatment cartridges.

Each cartridge is precisely designed to focus ultrasonic energy onto a specific subcutaneous depth, such as 1.5mm, 2.0mm, 3.0mm, and 4.5mm commonly used for facial treatments, as well as 6.0mm,9.0mm, and 13.0mm used for body contouring.

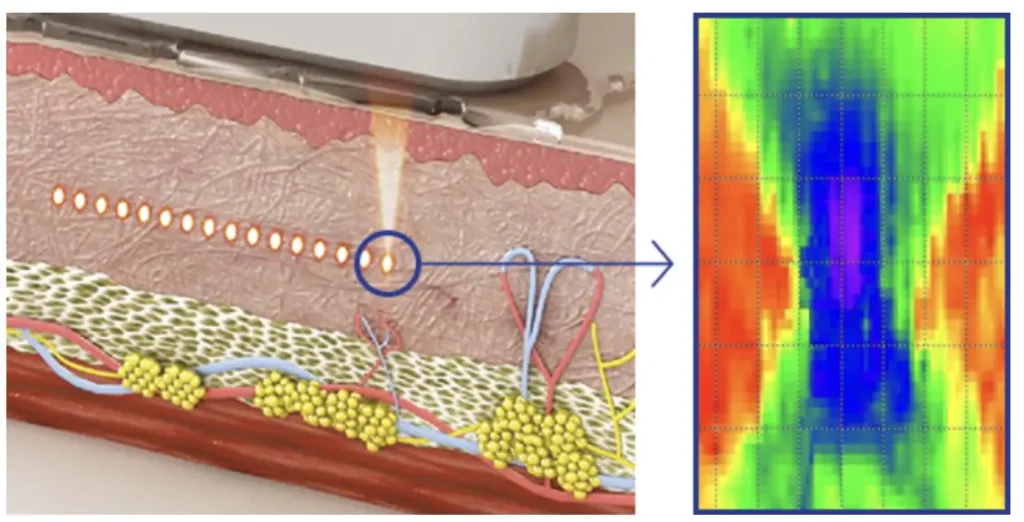

The core mechanical movement occurs inside the handpiece or the cartridge. A piezoelectric transducer generates the high-frequency ultrasonic waves, and to form a linear treatment area composed of multiple TCPs during each “shot,” this transducer must be driven by a motor drive system to perform a precise linear scanning motion.

A single “shot” operation refers to the transducer completing one linear movement over a preset length (e.g., 5-25mm) while emitting a series of focused energy pulses. A complete facial or body treatment typically requires hundreds or even thousands of shot operations.

Challenges of the 7D Ultrasonic Scalpel

Precision and Positioning

To achieve the desired therapeutic effect, the spacing of the TCPs must remain highly consistent to ensure uniform energy delivery to the target tissue. This places extremely high demands on the motion system, which must have minimal mechanical backlash and high-resolution positioning capability.

Since the length of the treatment line can be adjusted between 5mm and 25mm, the motor system must be able to execute the programmed travel distance precisely and maintain consistency over tens of thousands of operations.

Any motion deviation of the motor, such as minor inconsistencies caused by gear backlash or speed fluctuations, will directly translate into imperfections in the treatment line, affecting the final clinical outcome.

Motion Profile

Modern 7D Ultrasonic Scalpel devices often offer “faster shot speeds” and adjustable treatment parameters, meaning their internal drive motors must be capable of precise speed control via methods like Pulse Width Modulation (PWM). The transducer’s motion during scanning must be continuous and smooth, without any jitter or cogging.

Any momentary pause could cause an energy-over-concentrated “hot spot” or an energy-deficient “blind spot” in the tissue. This requires the motor itself to have smooth torque output, typically achieved through a brushless design and a high-quality gearbox. Furthermore, a closed-loop control system with a speed feedback signal (such as an FG signal or encoder) is essential to maintain a constant scanning speed despite minimal changes in friction.

Operating Environment Constraints

7D Ultrasonic Scalpel devices are typically used in quiet clinic or aesthetic center environments, and the handpiece is operated very close to the user’s face and head. Therefore, the operating noise of the drive motor is a critical consideration.

A noisy motor would not only severely affect user comfort and treatment experience but also diminish the device’s premium feel and professionalism. Similarly, the handpiece is held by the operator for extended periods, and excessive vibration can cause operator fatigue and potentially unsettle the user.

A well-designed, smoothly operating brushless motor can minimize noise and vibration, which is key to enhancing overall product value.

In addition, the entire motor and gearbox assembly must be small and lightweight enough to meet the ergonomic design requirements of a handheld device.

Concurrently, the motor must operate efficiently to minimize the heat generated inside the enclosed handpiece, preventing discomfort for both the operator and the user.

Reliability and Long Life

A single 7D Ultrasonic Scalpel treatment involves hundreds of shots, and a busy clinic may perform multiple treatments daily, meaning the motor system must withstand high-intensity, cyclical work.

The lifespan of 7D Ultrasonic Scalpel cartridges, which are consumables, is usually counted in “shots” (e.g., 20,000 to 60,000 shots).

As the core permanent component of the handpiece, the drive motor’s design life must far exceed the total life of multiple cartridges. Therefore, an ultra-long working life measured in thousands of hours (equivalent to millions of cycles) is an indispensable hard requirement for this application scenario.

In summary, the challenge of the 7D Ultrasonic Scalpel lies in the drive system, and the performance of the drive system not only determines the clinical effect of the treatment but also directly shapes the overall experience of the user and the operator.

In the high-end aesthetic device market, “experience” factors such as low noise and low vibration are equally important as “functional” factors like high precision and high reliability.

An excellent motor solution must meet both of these stringent requirements simultaneously to help device manufacturers stand out in fierce market competition.

TSL-22GP-BL2418: A Bespoke Solution for 7D Ultrasonic Scalpel

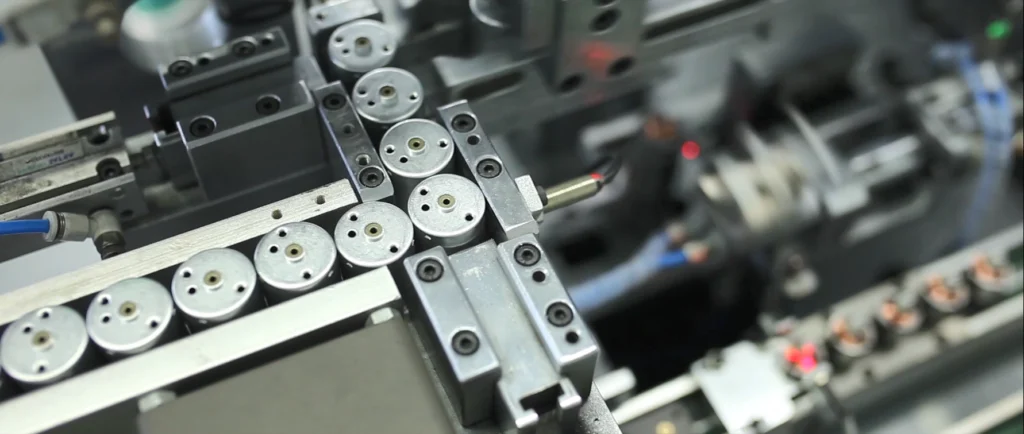

Our product, the TSL-22GP-BL2418, adopts a classic and efficient mechatronic design: combining a high-speed, low-torque BL2418 brushless DC motor with a 22GP planetary gearbox. By reducing speed and increasing torque, it outputs the low-speed, high-torque, high-precision smooth motion required for the application.

The BL2418 Brushless DC Motor

Brushless DC (BLDC) motor technology brings several fundamental advantages to the 7D Ultrasonic Scalpel drive application:

- Ultra-Long Life: Due to the absence of physical brush wear, the theoretical working life of a brushless motor is extremely long, often exceeding 20,000 hours, fully meeting the reliability requirements of medical-grade devices.

- Low Noise and Low Vibration: Electronic commutation technology fundamentally eliminates the frictional noise and spark interference caused by mechanical commutation, making the motor run extremely smoothly and quietly, perfectly matching the pursuit of user experience in high-end aesthetic devices.

- High Efficiency: Compared to brushed motors of the same size, brushless motors have higher energy conversion efficiency, which means lower heat generation and longer battery life (for portable devices).

The inherent characteristics of the BL2418 motor further enhance these advantages:

- Compact Size: Its micro size of 24mmdiameter and18mm length, along with its lightweight design of approximately 30g, allows for easy integration into space-constrained handheld devices.

- Electrical Characteristics: We offer a 12V rated voltage version, and the voltage can be customized according to customer needs. A 12V rated voltage makes it easier to design quiet drivers and minimize heat generation, which can enhance comfort for aesthetic devices that directly contact the user (especially in the sound-sensitive facial area).

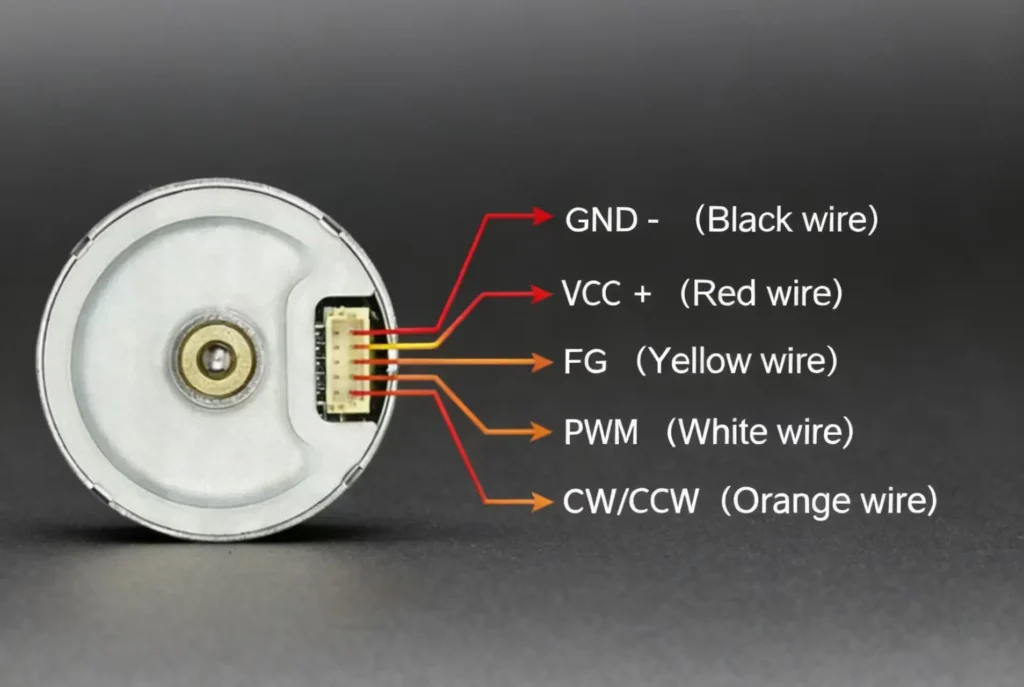

- Integrated Control Functions:The motor features a built-in driver and Hall sensors, offering PWM stepless speed adjustment and FG speed feedback. This integration simplifies the MMFU device manufacturers’ control circuit development, enabling easy closed-loop speed control. This “plug-and-play” design converts complex motion control into simple subsystem integration, greatly reducing R&D costs and time-to-market.

The 22GP Planetary Gearbox

Planetary gearboxes, due to their unique structure, possess several excellent characteristics suitable for precision transmission applications, including high torque density, high transmission efficiency, coaxial output, and a compact structure.

- High-Quality Materials and Construction: The gearbox employs a planetary gear structure. We use all-metal gears and configure ball bearings at the output end to ensure high torque carrying capacity, high rigidity, and long service life.

- Performance Metrics Inference:

- Torque: Our 22mm specification planetary gearbox can provide a continuous output torque of 0.13 Kg.cm, which is sufficient to drive the transducer to perform linear motion on the guide rail and overcome friction.

- Low Backlash: The backlash of our precision planetary gearbox can be controlled to less than 1.5 degrees. This is crucial for ensuring the accurate starting and ending point positioning of the transducer in each scan and eliminating the “slack” during motion reversal.

- Reduction Ratio: We recommend a 5:1 reduction ratio to customers. This ratio maximizes system speed, efficiency, and dynamic response while ensuring the necessary torque gain. This enables the transducer to complete rapid linear scanning tasks with extremely high precision and efficiency, directly supporting the core technical requirements of 7D Ultrasonic Scalpel devices.

The design life of this motor system stands in stark contrast to the life cycle of the device consumables, thereby establishing a strong Total Cost of Ownership (TCO) advantage.

The BL2418 motor‘s working life of over 20,000 hours is hundreds or even thousands of times more durable than the consumable treatment heads, which only have a life of tens of thousands of shots (equivalent to only a dozen or so hours of motor runtime).

This means that the motor is a highly reliable permanent component that virtually requires no maintenance or replacement throughout the device’s entire life cycle.

This not only minimizes equipment downtime and repair costs for end-users such as clinics but also earns the MMFU device manufacturer a reputation for quality and reliability.

Integration and Implementation Recommendations

Mechanical Integration Guide

In the mechanical structure design, the TSL-22GP-BL2418 should be firmly mounted onto the internal support structure of the handpiece via its front flange. Its core task is to convert the rotational motion of the gearbox output shaft into the linear motion of the transducer carriage.

The most common and precise way to achieve this conversion is by using a precision ball screw or a trapezoidal screw mechanism.

The gearbox output shaft is connected to the screw via a coupling, and the transducer carriage is fixed to the screw nut. When the motor rotates, the rotation of the screw drives the nut and carriage to perform smooth linear reciprocating motion.

Electrical Integration and Control Strategy

The high integration of the TSL-22GP-BL2418 motor makes its electrical connection very simple. Below is an explanation of typical wiring and control strategies:

- VCC (Red Wire) / GND (Black Wire): Connects to the DC power supply provided by the system, such as 24V DC.

- FG (Yellow Wire): A simple Interrupt Service Routine (ISR) counts the FG pulses to accurately calculate the motor’s real-time speed. Accumulating these pulses also determines the total revolutions for closed-loop linear displacement monitoring.

- CW/CCW (Orange Wire): Connects to a standard GPIO pin of the MCU. By controlling the logic level (High/Low) of this pin, the motor’s direction of rotation can be conveniently switched to achieve the scanning and rapid return movements of the transducer.

| NO. | SIGNAL | I/O | SPECIFCATIONS | NOTE |

| 1 | Vm(red wire) | I/N | DC 24VM±10%V | POWER |

| 2 | FG(Green wire) | |||

| VOH | OUT | 5.0V Max | Hall Signal Pulse Outputs | |

| VOL | 0.5V Max | |||

| FG Signal Current | 2mA | |||

| Puise Outputs Of Rotation | 6Pulse/cycle | |||

| 3 | CW/CCW Control(yellow wire) | |||

| Input Voltage Range | IN | 0-5V | High-motor CCW;Low-motor CW | |

| VIH | 2.0V Min.or | |||

| VIL | 0.5V Max | |||

| 4 | GND | IN | Power Ground | Power Ground |

| 5 | PWM Control(blue wire)60K MAX Typical(15K-25K) | |||

| Input Voltage Range | IN | 0-5V(15K-25K) | High-motor OFF;Low-motor ON | |

| VIH | 2.0V Min.or open | |||

| VIL | 0.5V Max | |||

In addition to the five-wire brushless motor, we have developed a six-wire version that incorporates a PWM connection. If you require this option, please get in touch with us.

Conclusion

In summary, the TSL-22GP-BL2418 micro planetary brushless gear motor is not merely a simple drive component but a comprehensive mechatronic solution targeting the most critical engineering challenges in 7D Ultrasonic Scalpel handpiece design.

The analysis in this report clearly demonstrates that this motor system perfectly meets the application requirements through its excellent combination of performance.

It provides the medical-grade precision and dynamic control capabilities necessary to achieve optimal clinical results; it ensures the premium user experience expected of high-end equipment through its inherent low-noise and low-vibration characteristics.

And its ultra-long service life and high reliability provide solid long-term value assurance for both device manufacturers and end-users, effectively reducing the total cost of ownership.

Ultimately, by integrating the TSL-22GP-BL2418, 7D HIFU system manufacturers can simplify design, shorten the R&D cycle, and ultimately launch a product that is technically superior and offers a better experience, thus gaining a leading position in the increasingly competitive aesthetic device market.

FAQ

Q1:Why does the 7D Ultrasonic Scalpel require a high-precision motor?

A1:The motor must achieve precise linear scanning motion of the transducer to ensure that the Thermal Coagulation Points (TCPs) formed in the subcutaneous tissue are uniformly spaced

. Any movement deviation can negatively affect the clinical results.

Q2:What is the TSL-22GP-BL2418 motor system designed for?

A2:The TSL-22GP-BL2418 is a micro planetary brushless gear motor specifically designed as the decisive motion solution for driving the 7D Ultrasonic Scalpel (MMFU/HIFU) handpiece

Q3:What is MMFU technology?

MMFU stands for Micro-Macro Focused Ultrasound, an advanced form of HIFU (High-Intensity Focused Ultrasound) that delivers energy more uniformly to multiple subcutaneous layers, including the crucial SMAS layer, to achieve skin tightening and lifting.

Tsinglin Motor: Custom DC Motor Solutions

Established in 2009, Tsinglin Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Tsinglin Motor’s Relevant DC Motor Series

-

Custom Micro Motors5 products

Custom Micro Motors5 products -

DC Gear Motor139 products

DC Gear Motor139 products-

6mm Planetary Gear Motor4 products

6mm Planetary Gear Motor4 products -

6mm Planetary Metal Gear Motor3 products

6mm Planetary Metal Gear Motor3 products -

Brushless Gear Motor17 products

Brushless Gear Motor17 products -

Micro Gear Motor64 products

Micro Gear Motor64 products-

Coreless Gear Motor11 products

Coreless Gear Motor11 products -

N20 Gear Motor26 products

N20 Gear Motor26 products -

Plastic Gearbox Motor8 products

Plastic Gearbox Motor8 products -

Standard Gear Motor15 products

Standard Gear Motor15 products -

Stepper Gear Motor15 products

Stepper Gear Motor15 products

-

-

Planetary Gear Motor29 products

Planetary Gear Motor29 products -

Spur Gear Motor63 products

Spur Gear Motor63 products -

Worm Gear Motor28 products

Worm Gear Motor28 products

-

-

DC Motor78 products

DC Motor78 products-

Brushed DC Motor16 products

Brushed DC Motor16 products -

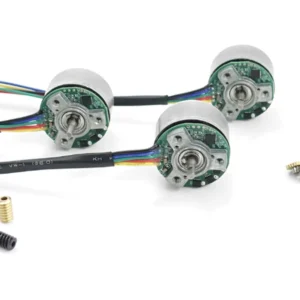

Brushless DC Motor21 products

Brushless DC Motor21 products-

Inrunner Rotor BLDC Motor6 products

Inrunner Rotor BLDC Motor6 products -

Outrunner Rotor BLDC Motor13 products

Outrunner Rotor BLDC Motor13 products

-

-

Coreless DC Motor13 products

Coreless DC Motor13 products -

Micro DC Motor15 products

Micro DC Motor15 products -

Stepper Motor13 products

Stepper Motor13 products

-

-

Vibration Motors71 products

Vibration Motors71 products-

Brushless Vibration Motor8 products

Brushless Vibration Motor8 products -

Coin Vibration Motor22 products

Coin Vibration Motor22 products -

Coreless Vibration Motor3 products

Coreless Vibration Motor3 products -

Encapsulated Vibration Motor6 products

Encapsulated Vibration Motor6 products -

Linear Resonant Actuator12 products

Linear Resonant Actuator12 products -

Powerful Vibrating Motor17 products

Powerful Vibrating Motor17 products -

SMD Vibration Motor4 products

SMD Vibration Motor4 products -

Sonic Vibration Motor2 products

Sonic Vibration Motor2 products

-