Need power for a compact project? Think robots, smart home gadgets, or precision instruments. The N20 gear motor is likely your best bet. Too many models? Don’t worry. This guide breaks down everything. It helps you pick the perfect motor for your needs.

TSL Motor is a leader in micro motor manufacturing. You will benefit from their professional services. They focus on customization. They have strict quality control. They provide solutions for industries like healthcare, automation, and telecommunications.

key takeaways

- N20 Core Function: Converts the motor’s high-speed, low-torque rotation into a slower, high-torque output.

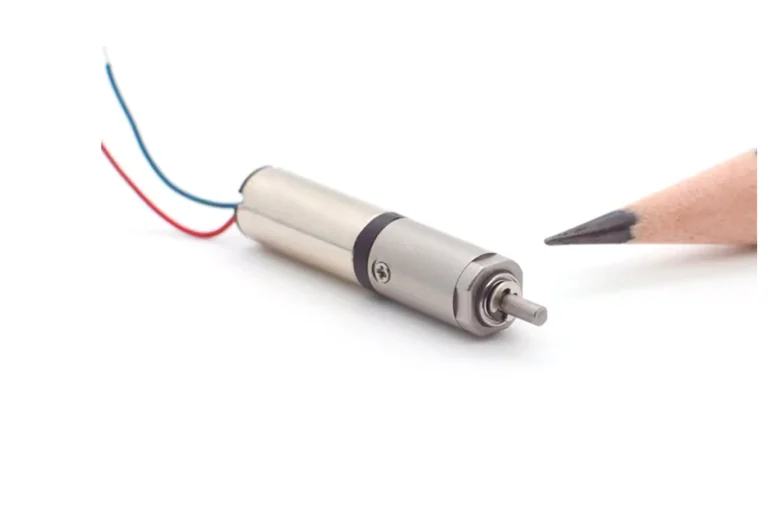

- Standardization: The “N20” term refers to the motor body’s standardized physical size (approx. 15x12x10mm), ensuring interchangeability.

- Torque vs. Speed: A trade-off exists: higher torque at a given voltage results in a lower speed.

- Planetary Gear: Offers the highest torque density and precision (low backlash), ideal for robotic arms and high-precision actuators.

- Worm Gear: Features a unique self-locking function (holds load without power), suitable for smart locks and micro lifters.

- Spur Gear: Is the most economical and highly efficient option for general robots and DIY projects.

- Integrated Encoder: Provides feedback for closed-loop control, essential for precise and repeatable positioning.

- Electric Lead Screw: Converts rotation into accurate linear (push/pull) movement.

- Control Requirement: Motors cannot connect directly to microcontrollers; they require a dedicated motor driver (H-bridge).

Decoding the N20 Gear Motor

What is an N20 Gear Motor?

It’s an integrated system, not just a motor. It combines a small, high-speed brushed DC motor with a gearbox (reducer).

Its main job is conversion. It takes the motor’s raw, high-speed, low-torque spin. Then, it converts it to a much slower, controlled output. This output is significantly more powerful. This is key for moving physical loads.

Why “N20”?

“N20” is not a brand. It’s a standard physical size for the motor body. Typically, it’s 15mm long, 12mm wide, and 10mm high. The gearbox adds to the total length.

This standardization is a huge benefit. It ensures parts from different makers are interchangeable. It has created a vast ecosystem of compatible accessories. The N20 is really a modular platform. You are configuring it, not just picking one.

Therefore, N20 is more of a modular platform than a single product. The core motor serves as the foundation, while additional components such as gearboxes, encoders, or lead screws define its final application. Your selection process is more like a configuration rather than a simple choice.

Core Advantages

The true magic of the N20 gear motor lies in its gearbox. It offers several key advantages, making it indispensable in micro-applications.

- Torque Multiplication: This is the main benefit. The gear ratio directly multiplies torque. This lets a coin-sized motor do the work of a bigger, heavier one.

- Precise Speed Reduction: Raw motor RPM is usually too high. The gearbox tames this speed down (e.g., 15,000 RPM to 100 RPM). This gives you controlled movement for wheels or arms.

- High Power Density: N20 motors offer significant mechanical power. They are tiny and lightweight (about 10-25 grams). Ideal for applications where space and weight are tight limits.

- Better Efficiency: A bare motor might stall or use too much current with a heavy load. The gearbox lets the motor run at its most efficient range while moving the load effectively.

Important Note on Torque:

N20s are often called “high-torque” , but this is relative to their tiny size. Torque, speed, and voltage are linked. At the same voltage, a 50 RPM motor will have much higher torque than a 300 RPM one in the same series. You must understand this trade-off.

N20 Gear Motor Types

The gearbox defines the motor’s suitability for a task.According to different gearboxes, N20 gear motors can be divided into spur gear motors, planetary gear motors, and worm gear motors.

TSL MOTOR not only provide all the aforementioned types of motors, but you can also view relevant customization cases on our product page. We also offer motor customization services, which can be exclusively adapted to your project requirements.

Spur Gear Motor

Working Principle: Spur gears transmit the rotary motion and torque from the driving wheel to the driven wheel by meshing a pair of cylindrical gears with the same tooth profile and parallel axes, achieving power and motion transmission.

Pros and Cons: The advantages and disadvantages of spur gears are distinct. The advantages focus on structure and manufacturing, while the disadvantages are mainly the limitations of transmission performance.

Table 1: Advantages and Disadvantages of Spur Gears

| Advantages | Disadvantages |

| Simple and cheap to make. | High noise and vibration. Gears engage/disengage suddenly. |

| High efficiency (usually over 95%). Friction loss is low. | Limited load capacity. Not for super heavy loads. |

| No axial thrust force. Easier on bearings. | Only for parallel shaft drives. |

| Stable and accurate gear ratio. | Needs high mounting precision for smooth running. |

Spur gears are the most economical choice for efficient and accurate transmission between parallel shafts, especially suitable for low-to-medium speed, light-load applications where noise is not a critical concern (e.g., clocks, simple mechanical devices, and gear pumps).

For high-speed, heavy-load, and low-noise applications, helical or double-helical gears are typically preferred.

Open-Frame N20 Spur Gear Motor

- Pros: lower cost, lighter weight, easy to inspect/modify.

- Cons: vulnerable to dust, debris, physical damage.

- Best for clean environments or internal mounting in larger enclosures.

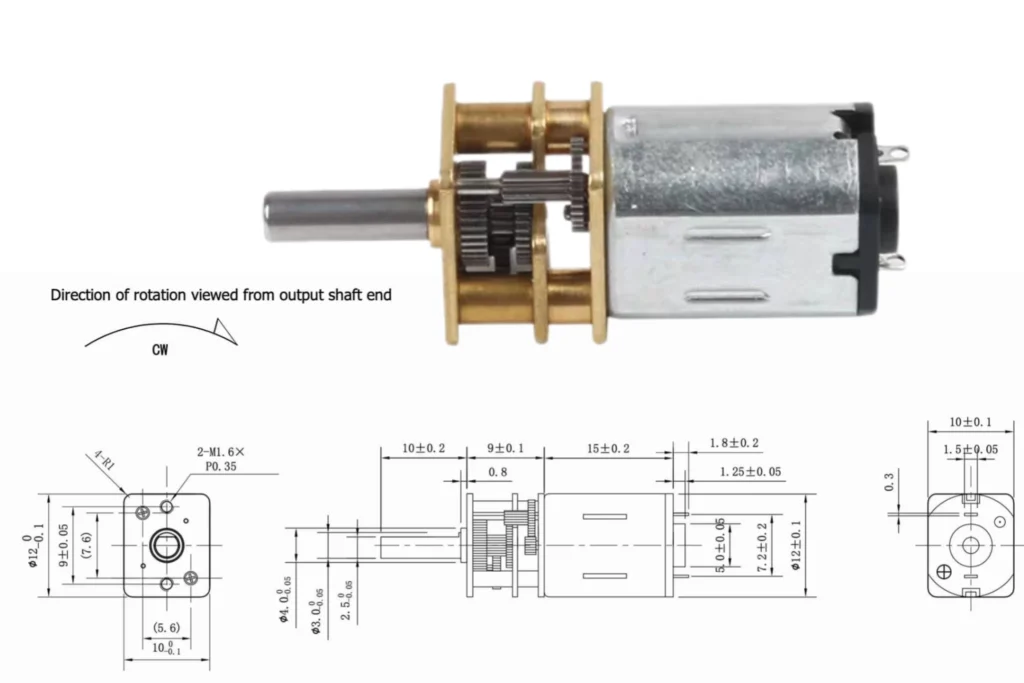

TSL-GM12-N20-KVA Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Spur Gearbox

- Rated Voltage:3V/6V / 12V DC

- Ratio: 10:1 ~1000:1

- No Load Speed:10rpm – 1450rpm

- No Load Current:≤45mA/≤55mA

- Rotation:CW / CCW

- We offer custom solutions upon request

- #More Specifications

TSL-GM12-N20VA-DR Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Spur Gearbox

- Rated Voltage:3V/6V / 12V DC

- Ratio: 10:1 ~380:1

- No Load Speed:28rpm – 2150rpm

- No Load Current:≤0.3A/≤0.50A/≤0.55A/≤0.75A

- Rotation:CW / CCW

- We offer custom solutions upon request

- #More Specifications

Foldback Design N20 Spur Gear Motor

- Layout: This is a special layout where the gear train “folds back” over the motor body.

- Advantage: It saves space, ideal for applications with strict length limits.

- Comparison: A traditional in-line gearbox would be too long for such cases.

TSL-GM1024-N20VA-EN Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Spur Gearbox

- Rated Voltage:3V/6V / 12V DC

- Ratio: 50:1 ~500:1

- No Load Speed:15rpm – 600rpm

- We offer custom solutions upon request

- #More Specifications

- #Outline Drawing

- #Encoder Specifications

Table 2:Table of Different Types of Spur Gear Motors

| Feature | Open-Frame | Closed-Frame | Foldback Design |

| Gearbox Structure | exposed | Gear full-enclosure housing | Gear train "folds back" over the motor body |

| Pros | Lower cost,Lighter weight,Easy to inspect | against dust | Saves space |

| Cons | Less protection | Slightly higher cost and weight. | More complex design. |

| Best Environment | Clean environments | Dusty environments | strict length limits. |

Planetary Gear Motor

How it Works: The central “sun gear” drives “planet gears.” These planets rotate inside a fixed “ring gear.” The “planet carrier” outputs the slow, high-torque, coaxial power.

Pros and Cons: Planetary gear motors have significant advantages due to their unique structure (sun gear, planet gears, internal ring gear), but they also have some inherent drawbacks.

Table 3:Advantages and Disadvantages of N20 Plnetary Gear Motor

| Advantages | Disadvantages |

| 1. High Torque Density and Strong Load Capacity | 1. Higher Cost |

| 2. Compact Structure, Small Size | 2. Difficult to Maintain and Repair |

| 3. Wide Range of Gear Ratios, High Efficiency | 3. Extremely High Requirements for Assembly Accuracy |

| 4. Good Rigidity, High Precision,Lower Noise | 4. Potentially High Bearing Load |

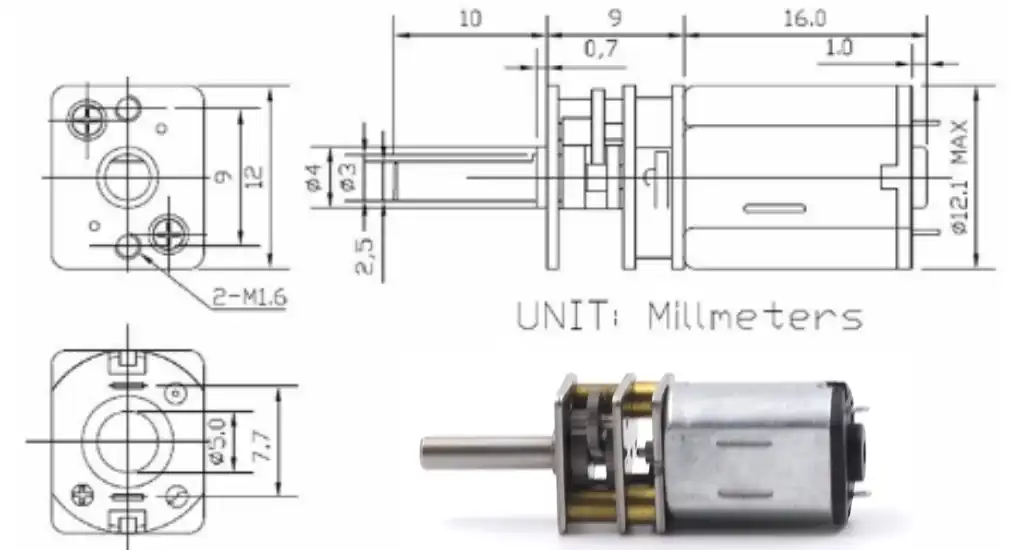

TSL-12GP-N20VA-ME Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Planetary Gearbox

- Rated Voltage:1.5V-12V DC

- Ratio: 120:1

- No Load Speed:65rpm – 250rpm

- We offer custom solutions upon request

- #More Specifications

- #Outline Drawing

Worm Gear Motor

Working Principle: The “worm” (screw-like gear) driven by the motor meshes with the “worm wheel” (toothed disc) via spiral threads, converting the rotation of the perpendicular input shaft into the slow rotation of the worm wheel, while achieving a high gear ratio and a unique self-locking function.

Pros and Cons

The worm gear motor is the best choice for low-speed, high-torque, 90-degree angle transmission, and its self-locking capability is crucial in lifting and positioning applications.

However, its biggest drawbacks are low efficiency and susceptibility to heat and wear, making it unsuitable as a primary transmission mechanism requiring continuous high-speed, high-efficiency operation.

TSL-WG1218S-N20-EN Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Worm Gearbox

- Rated Voltage:3V DC / 6V DC/ 12V DC

- No Load Speed:11RPM – 550RPM

- Rotation:CW/CCW

- We offer custom solutions upon request

To simplify the decision-making process, the table below compares the three main gearbox types, translating abstract engineering concepts into practical decision tools.

Table 4:N20 Gear Motor Types Overview

| Characteristic | Spur Gear Motor | Planetary Gear Motor | Worm Gear Motor |

| Torque Density | Good | Excellent | Very Good |

| Precision/Backlash | Medium | High | Low |

| Noise Level | Medium to High | Low to Medium | Very Low (Quietest) |

| Efficiency | Excellent (Highest) | Very Good | Good (Lower) |

| Self-Locking | No | No | Yes |

| Shaft Alignment | Offset | Co-axial | Right Angle |

| Relative Cost | Low (Most Economical) | High | Medium |

| Best Suited For... | General robotics, wheeled robots, DIY projects | Robotic arms, high-precision actuators, drones | Smart locks, micro lifters, constant load |

Special Types and Customization Options

The N20 platform can be further specialized to meet the needs of advanced applications, extending far beyond simple rotation.

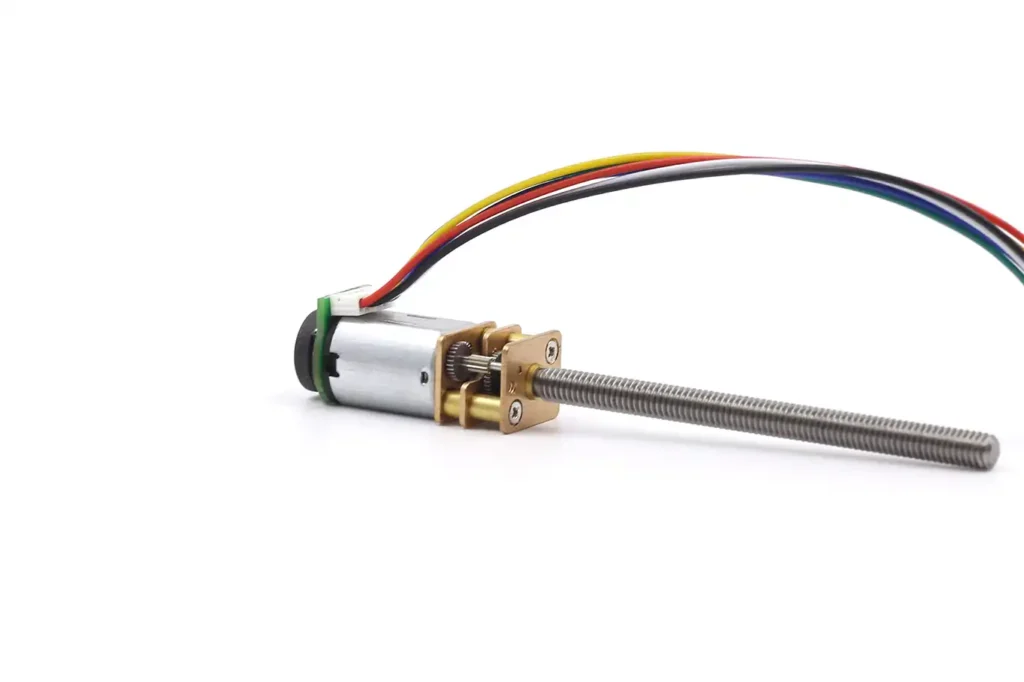

Electric Lead Screw

Converting Rotation into Precise Linear Motion

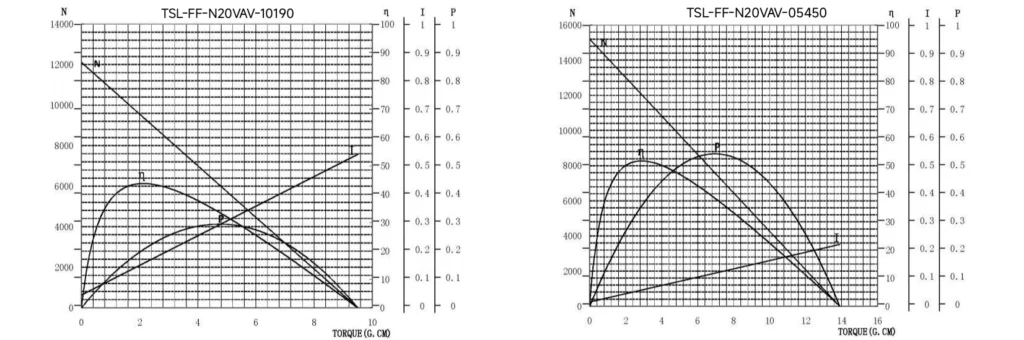

TSL-GM12-N20VA-33M3 Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Spur Gearbox

- Rated Voltage:3V DC / 6V DC/ 12V DC

- No Load Speed:150RPM – 420RPM

- Shaft Diameater:M3

- Shaft Length:33.6mm

- Rotation:CW/CCW

- We offer custom solutions upon request

- #More Specifications

- #Outline Drawing

Function: This variant is an integrated linear actuator. The motor’s rotational output is directly converted into linear push/pull motion via a threaded shaft (lead screw).

Applications: Specific examples include the Z-axis of micro 3D printers, automated camera focus pullers, robotic grippers, lab automation equipment for dose control, and small CNC machines.

Key Advantage: It is a compact, all-in-one linear motion solution that eliminates the need for complex external linkage mechanisms.

Integrated Encoder

Key to Closed-Loop Control

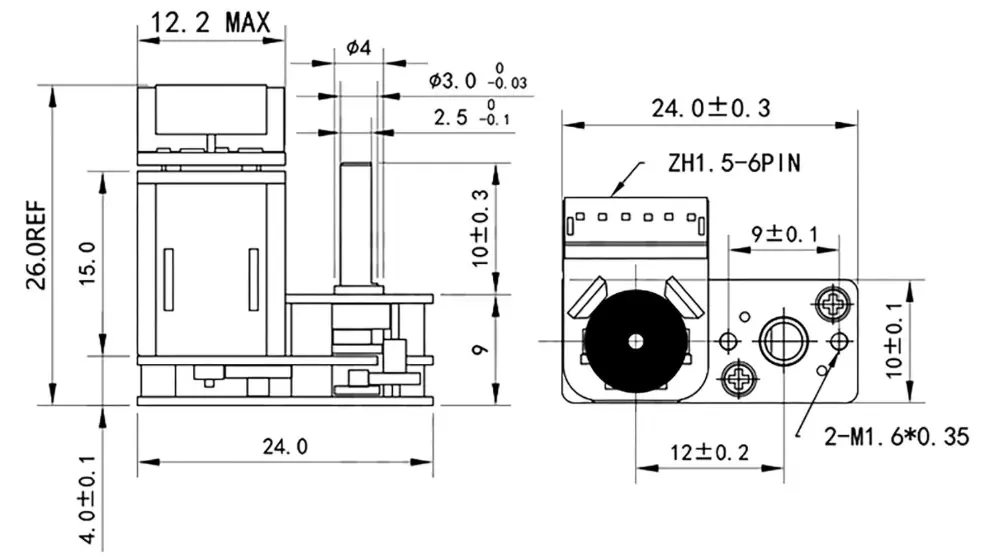

TSL-GM12-N20VA-ABHL Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Spur Gearbox

- Voltage:DC 3-12V/Customizable

- Shaft Diameater:Ф3mm,D thick 2.5mm

- Shaft Length:10mm

- Wiring Specification:ZH1.5-6PIN terminal connector

- Encoder Specification:A B dual phase encoder, 3 line basic signal,voltage 3.3V or 5.0V

- We offer custom solutions upon request

- #More Specifications

- #Outline Drawing

What is an Encoder? An encoder is a sensor mounted on the motor shaft that provides feedback. Most N20 motors use magnetic Hall Effect sensors, which are robust and resistant to dust.

Working Principle: The encoder outputs a series of electrical pulses (e.g., 3 or 7 pulses per revolution, or PPR), which a microcontroller (like Arduino or ESP32) can count. This allows the controller to know the motor’s precise position, speed, and direction of rotation in real-time.

Why is it a Game-Changer? This feedback enables “closed-loop control,” which is essential for precision robotics. Applications include self-balancing robots, robotic arms that need to move to specific coordinates, and any task requiring repeatable, precise motion. This contrasts sharply with “open-loop” control, where power is simply applied with the best result hoped for.

Dual Output Shaft

Synchronized Motion, Simplified Design

TSL-GM12-N20VA-33M3 Datasheet

- DC Motor Type:Brushed DC Motor

- Gearbox Type:Worm Gearbox

- Rated Voltage:6V / 12V DC/Customizable

- No Load Speed:8rpm-380rpm

- Rated Load Speed:6rpm-300rpm

- We offer custom solutions upon request

- #More Specifications

Function: These motors feature output shafts at both the front and rear of the gearbox.

Key Advantage: This allows a single motor to drive two independent mechanisms in perfect synchronization (often in opposite directions, like co-axial counter-rotating propellers). This simplifies the design, reduces weight, and lowers cost compared to using two separate motors.

Applications: Examples include dual-wheel drive systems for small robots, co-axial counter-rotating mechanisms for model boats or drones, and dynamic art installations with complex synchronized movements.

A N20 Gear Motor Tailored for You

Our Capabilities:To match your requirements, TSL MOTOR allows customization of voltage,ratio,speed,shaft shape, and even gear material.

Call to Action: We encourage users with unique requirements to contact us, positioning ourselves as a flexible partner rather than just a standard DC motor manufacturer.

The combination of these features can create highly specialized solutions.

For example, a worm gear motor with a dual output shaft and an encoder is the perfect choice for a smart door lock: the worm gear provides self-locking security, the dual shaft can operate two separate bolts simultaneously, and the encoder confirms the lock status (locked/unlocked).

This synergy demonstrates how function combinations achieve 1+1>2 in application value.

Choose The Right N20 Gear Motor

Defining the core requirements of your project is the primary step in selecting the right motor, which requires focusing on and clarifying five key dimensions: torque, speed, voltage, physical constraints, and control precision.

Step 1: Your Project’s Core Requirements

1.Torque (“How much force is needed?”)

Is it lifting a heavy object, pushing a robot chassis, or rotating a lightweight sensor? This determines the required torque. It is important to distinguish between rated torque (for continuous operation) and stall torque (the absolute maximum before failure, which should be avoided).

2.Speed (“How fast is needed?”)

How quickly does the task need to be completed? This determines the target RPM. Remember the inverse relationship: at a given voltage, higher torque means lower speed.

3.Voltage (“What is the power source?”)

What is the available power source? Is it a 3.7V Li-Po battery? A 5V USB supply? Or a 12V wall adapter? The motor’s rated voltage should match the power supply for optimal performance and lifespan.

Operating at lower voltages is possible but reduces performance, while exceeding the rated voltage may cause damage.

We are a leading DC motor manufacturer in China, and you can customize an N20 Gear Motor adapted to your voltage.

4.Physical Constraints (“How big is the space?”)

Measure the available space. This will determine if a standard in-line motor is suitable, or if a more compact foldback or right-angle worm gear design is necessary.

5.Control and Precision (“How smart does it need to be?”)

Does the project require precise, repeatable positioning? If so, a motor with an encoder is essential. Is the movement linear? Then an electric lead screw is the answer.

Step 2: Selecting Your Power Supply

Power Supply Current: The power supply must not only be able to provide the no-load or rated current but must also be able to cope with the much higher stall current during startup or heavy loads to prevent voltage drops or power failure.

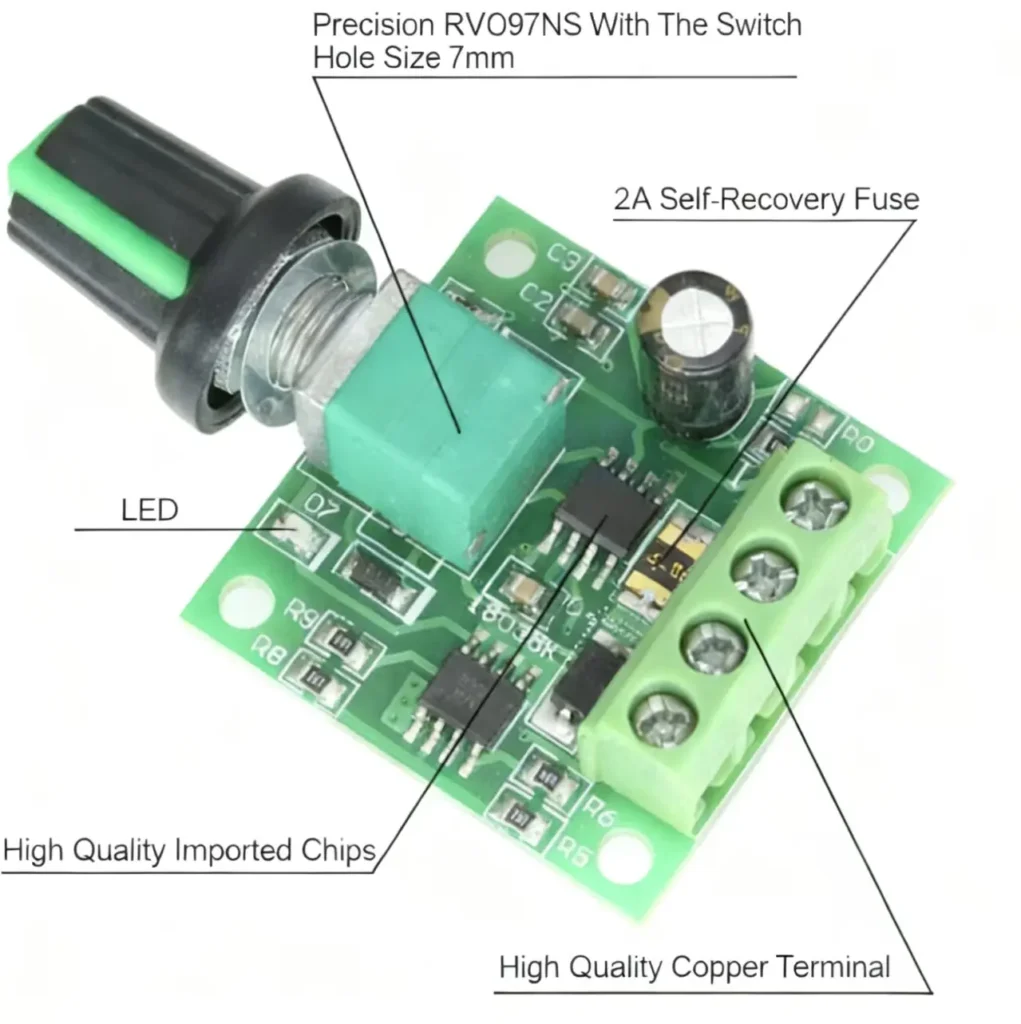

Motor Driver: N20 motors cannot be connected directly to microcontroller pins (like Arduino). They require a dedicated motor driver (e.g., L298N, TB6612FNG) that can handle the motor’s current demands and allows for speed control via PWM and direction control via an H-bridge.

Step 3: Utilizing the Application Matrix

Integrate the previous steps to make the final decision. First, select the most suitable gearbox type based on the application’s core function, then choose the voltage that matches the power supply, and finally, select the gear ratio that provides the best balance of torque and speed.

Table 5: Application and N20 DC Gear Motor Matching Matrix

This table is the ultimate practical tool of this guide. It directly links common user projects with recommended motor configurations from our catalog, removing the last layer of abstraction and barrier.

| Project Example | Recommended Gearbox | Key Feature to Consider |

| Micro Robot Rover (2WD) | Spur Gear | Dual output shaft, closed-frame |

| Small Robotic Arm Joint | Planetary Gear | Integrated Encoder |

| Smart Door Lock/Micro Safe | Worm Gear | None (Self-locking is an inherent feature) |

| Automated Camera Slider | Spur Gear | Electric Lead Screw, Integrated Encoder |

| Dynamic Art Installation | Worm Gear | Dual Output Shaft |

| Self-Balancing Robot | Planetary Gear | Integrated Encoder (High PPR) |

| Length-Constrained Project | Spur Gear | Foldback Design |

Conclusion

The core advantage of the N20 motor lies in its compact size, high power density, and the amazing versatility achieved through a modular gearbox and function platform.

Understanding the trade-offs between torque, speed, gearbox types, and special features is crucial for project success. You are now ready to make an informed decision.

Explore our complete series of spur gear, planetary gear, and worm gear motors to find the ideal power core for your next creation. If you face a unique challenge, TSL MOTOR is ready to help you configure a custom solution.

Frequently Asked Questions (FAQ)

Q1: What is an N20 gear motor?

A1:It is an integrated system that combines a small, high-speed brushed DC motor with a gearbox.

Q2: What does “N20” specifically refer to?

A2: “N20” refers to the standardized physical size of the motor body, typically 15mm long, 12mm wide, and 10mm high. This standardization ensures interchangeability between products from different manufacturers.

Q3:What is the N20 Gear motor’s biggest advantage?

A3:Its high Power Density. The gearbox achieves Torque Multiplication, allowing this tiny motor to handle loads that typically require larger, heavier motors.

Q4: Can TSL MOTOR meet my specific project requirements?

A4: Yes. We offer a diverse selection of N20 Gear Motors (Spur, Planetary, Worm) and provide extensive customization services for non-standard features like specific gear ratios, non-standard shaft lengths, or unique wire harnesses.

TSL Motor: Custom DC Motor Solutions

Established in 2009, Tsinglin Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

N20 Gear Motor

The N20 gear motor is a compact direct current (DC) motor, and the term “N20” indicates its physical size. It usually consists of an N20 motor combined with a spur gear reducer. The gear reducer converts the high speed, low torque output of the N20 motor into low-speed, high-torque output, thus providing greater torque for a wide range of applications.