In the world of FPV freestyle drones, pilots constantly struggle to balance power, control, and endurance. Traditional motor designs seem unable to achieve all three. This forms a technical bottleneck called the “Impossible Triangle.”

However, TSL Motor’s custom 33mm motor, the TSL-BLDC-3320, redefines FPV motor performance boundaries. It achieves this with engineering breakthroughs: high torque and low energy consumption.

This article will analyze how this motor balances extreme maneuverability and super-long endurance in 5-7 inch airframes. It will reveal the underlying technical logic and application value.

Key Takeaways

Here are the key takeaways for the TSL-BLDC-3320 motor, in single-sentence bullet points:

- Core Dilemma: FPV pilots face an “Impossible Triangle,” struggling to balance power, control, and endurance.

- The Solution: The TSL-BLDC-3320 is a 33mm custom motor designed to solve this trilemma with “High Torque, Low Consumption.”

- Key Performance: It maintains an extremely low current draw of 7.5A even while delivering a high 400gf.cm of load torque.

- Core Advantage: This ultra-low current fundamentally solves motor overheating issues and significantly extends flight endurance.

- Real-World Power: Its high loaded RPM retention rate of 88.75% (14200rpm) proves its massive torque and true power output.

- Versatile Application: The motor acts as a “Torque Monster” for 5-inch freestyle and an “Efficiency Expert” for 7-inch long-range.

- Company Value: This motor demonstrates TSL Motor’s deep custom R&D and mass production capabilities to solve industry pain points.

- Business Model: TSL Motor’s core business is providing clients with one-stop, customized power solutions from concept to production.

The FPV Pilot’s “Impossible Triangle”

FPV Drones represent the ultimate form of flight. Whether racing through obstacles or performing freestyle maneuvers, FPV is a rigorous test of energy conversion and instant response.

The motor is the core power unit. It converts battery energy into thrust. Motor performance dictates speed, agility, control precision, and flight time.

FPV pilots and system designers face an “Impossible Triangle”—an eternal trade-off between Power, Precision, and Endurance.

- Extreme Power: Pilots demand high thrust-to-weight ratios, often 3:1 or 4:1. This is needed for instant acceleration and high-speed maneuvering.

- Precise Control: FPV flying requires millisecond throttle response. Motors must instantly react to flight controller commands for “intuitive” control. This ensures stable attitudes during high-speed flight.

- Long Endurance: Limited flight time is the biggest technical bottleneck for multi-rotor drones, including FPV.

The Inescapable Compromise

In traditional motor design, these three factors are almost mutually exclusive. The industry consensus is that extreme power (e.g., using high KV motors) drastically increases current draw. High current rapidly depletes the battery, severely cutting endurance.

This leads to negative chain reactions:

- Battery Stress: High current causes severe Voltage Sag. Power output weakens during the latter half of the flight.

- Excessive Heat: Per Joule’s Law (Heat ∝ I²R), high current generates massive waste heat. Heat is the “chronic killer” of FPV motors. It wastes energy, further reducing endurance. It also causes irreversible demagnetization of permanent magnets at high temperatures, leading to permanent performance loss or motor burnout.

Therefore, the main conflict in the FPV market is the battle between the “desire for raw power” and the “fear of thermal runaway.” Pilots were forced to accept a compromise: “High performance” meant “high heat” and “short endurance.”

Solving the “Impossible Triangle” requires a fundamental breakthrough in motor energy conversion efficiency.

The Only Solution for FPV: BLDC

The extreme demands of FPV leave only one option: Brushless DC Motors (BLDC).

The fundamental difference from brushed motors is the switching mechanism. Brushed motors use physical brushes for mechanical contact. BLDC motors use an Electronic Speed Controller (ESC) for electronic commutation, driving the permanent magnet rotor.

The revolutionary advantages of BLDC are:

- High Efficiency: BLDC eliminates physical brush friction, resulting in very low energy loss. More electrical energy is converted into useful mechanical work, not wasted heat.

- Long Life & Low Maintenance: No physical wear from brushes or commutators means extremely long operational life with almost no maintenance.

- High Power Density: For the same weight and size, BLDC motors provide far superior power and torque. This is crucial for weight-sensitive FPV drones.

- Precise Control: Multi-rotor attitude control is achieved by precisely controlling each propeller’s RPM. BLDC motors, relying on the ESC to precisely control coil current, are inherently designed for high-frequency control.

This precision is bidirectional. It means the flight controller can control the motor precisely. Crucially, it means the motor must respond precisely and quickly to the flight controller’s signals.

The sought-after “Locked-in” feel in FPV comes from the flight controller’s PID loop. The D term is highly sensitive to angular rate changes (noise and vibration). A sluggish, low-torque, or vibrating motor feeds “dirty” data back to the flight controller.

To suppress oscillations, pilots must lower PID gains. This results in a “soft” control feel and slow response, causing severe “Prop Wash” during high-speed maneuvers.

Conclusion: A high-torque, low-vibration, fast-responding BLDC motor is the physical foundation for “silky smooth” flight and aggressive PID tuning. Not all BLDC motors are suitable for FPV. Evaluating a motor requires examining its engineering “devil in the details.”

TSL-BLDC-3320 Performance Analysis

| Motor Model | Rated Voltage | No Load | Load | Stall | ||||

| Speed | Curremt | Speed | Current | Torque | Torque | Current | ||

| V | RPM | A | RPM | A | g.cm | g.cm | A | |

| TSL-BLDC-3320 | 12V-36V | 16000 | 0.3 | 14200 | 6.5 | 400 | 3565 | 28 |

The specifications of the TSL-BLDC-3320 motor are TSL Motor’s precise “answer” to FPV pain points. We break down four key metrics to translate data into pilot benefits.

Speed and Agility: 16000rpm (No Load), 14200rpm (Loaded)

RPM is the direct source of thrust. While [X] KV ( In the no-load state, for every 1 volt of input voltage, the rotational speed increases by [X] RPM.) estimates theoretical RPM, it’s an ideal, no-load metric.

In real flight, propeller drag causes RPM to drop significantly—the “Bog down” issue common in high-KV motors.

TSL-BLDC-3320 provides two core figures: 16000rpm (no load) and 14200rpm (loaded). This means its loaded RPM retention rate is an outstanding 88.75% (14200 \16000). This value confirms strong torque: the motor maintains high RPM even under heavy load, providing sustained high speed and strong climb power.

Control and Response: 400gf.cm (Load Torque), > 2500gf.cm(Stall Torque)

High RPM retention is supported by massive torque, which TSL-BLDC-3320 provides with “dual insurance”:

Load Torque (400gf.cm)

Defines “Control Precision.”This is the continuous rotational force at 14200rpm under load. FPV freestyle demands quick stops, flips, and S-turns. The flight controller orders instant RPM changes to fight prop wash.

A 400gf.cm load torque means the motor has enough power to instantly overcome propeller inertia and air resistance to execute the RPM change command. This is the physical source of the sought-after “locked-in feel” and “precise control.”

Stall Torque (> 2500gf.cm)

Defines “Burst Limit.”Stall Torque is the maximum instantaneous torque at zero speed (or when locked). This is the motor’s “ultimate reserve” and “final trump card.”

When executing a “Punch-out” or recovering from a stall (like the bottom of a Power Loop), the motor needs burst power far beyond cruising torque.

The > 2500gf.cm stall torque (over 6 times the load torque) ensures massive instantaneous power for extreme maneuvers and emergency avoidance, providing ample safety redundancy.

Efficiency and Durability: 2.5A(No Load), 7.5A(Load)

If high speed and torque are FPV “must-haves,” the TSL-BLDC-3320’s current consumption is its revolutionary highlight.

While delivering 14200rpm and 400gf.cm torque, the load current is no more than 7.5A.

In FPV, high thrust usually means high current draw. High current is the biggest enemy of endurance. Traditional motors might require 15A or 20A to achieve 400gf.cm of torque.

The TSL Motor achieves this with 7.5A. This indicates an exceptionally high electromagnetic conversion efficiency (thrust per Watt).

This “High Torque, Low Consumption” characteristic successfully solves the FPV “Impossible Triangle.” It creates three decisive knock-on effects:

- Longer Endurance: At the same battery capacity (e.g., 1500mAh), a ≤7.5A cruise current means significantly extended flight time.

- Lower Heat: Per Joule’s Law (Heat = I²R), with constant resistance, halving the current reduces heat generation to one-quarter. This low load current resolves the heat problem at its source. The motor remains cool, and performance is consistent from takeoff to landing, without performance decay due to thermal fade.

- Lighter System: Due to its high efficiency, pilots can use smaller (lighter) batteries or carry more capacity for the same takeoff weight, further boosting thrust-to-weight ratio and agility.

The core competitiveness of the TSL-BLDC-3320 is not “raw speed” in one metric, but the “efficiency balance” under high power output.

Differentiated Advantage in 5-7 Inch Airframes

The name TSL-BLDC-3320 reveals its physical size: 33mm diameter. This is a very large stator diameter in FPV. For comparison, mainstream 5-inch freestyle/racing motors use 22xx or 23xx series (e.g., 2207, 2306). 7-inch long-range motors often use 28xx series (e.g., 2806.5).

Motor physics shows that for brushless outer rotor motors, a larger rotor diameter and higher-grade magnetic steel typically result in stronger torque output.

The TSL-BLDC-3320’s massive 33mm body is the physical basis for its superior performance (high torque, high efficiency).

This unique data combination allows the motor to “cross over” and excel in both 5-inch and 7-inch platforms, demonstrating distinct advantages in both fields.

5-inch Freestyle Application

- Demand: Extreme “locked-in feel,” powerful “Punch-outs,” and “heat resistance” during continuous high-intensity maneuvers.

- TSL-3320 Match:

- Torque Dominance: The massive 400gf.cm torque from the 33mm body is a “Torque Monster” on a 5-inch frame. It drives high-pitch 5-inch props “effortlessly.” Pilots will experience unprecedented “swift response.” PID tuning can be more aggressive, and prop wash suppression is superior.

- Efficiency Durability: Freestyle is power-hungry. The 7.5A low current draw means pilots can execute more difficult maneuvers on a single battery. The motor performance remains at its peak, as it will not degrade due to overheating during continuous flight.

7-inch Mid/Long-Range Application

- Demand: The core requirement for 7-inch platforms is “efficiency” and “endurance.” They need motors to drive large (7-inch) propellers smoothly and efficiently at the lowest possible power consumption.

- TSL-3320 Match:

- Perfect Efficiency Fit: The motor’s “High Torque, Low Consumption” trait is the perfect solution for 7-inch long-range flight. The 7.5A cruise current is the key to achieving super-long endurance.

- Torque Stability: 7-inch propellers are heavier and have greater inertia. The 400gf.cm load torque ensures the motor can stably and precisely control these large props. It provides smooth, vibration-free thrust even when adjusting heading in windy conditions, which is vital for cinematic camera work.

TSL Motor’s Custom R&D and Production Capability

The TSL-BLDC-3320 is more than just a high-performance FPV option. It is a case study proving TSL Motor’s deep R&D capability in solving complex industry pain points.

In the drone industry, “Off-the-shelf” components often mean compromise.

Professional applications (surveying, agriculture, logistics, defense) have unique, strict power system requirements: reliability at high altitude, peak efficiency at specific loads, or ultra-long durability in extreme temperatures.

These needs cannot be met by standard motors; they require “tailor-made” solutions.

TSL Motor’s core value proposition comes from this capability. The balance in electromagnetic design, material science, and thermal management shown by the TSL-BLDC-3320 is just the tip of the iceberg of TSL Motor’s engineering team’s capacity.

- Deep Custom R&D Capability: TSL Motor has already developed numerous custom brushless motor models for clients. This means TSL is an engineering partner with deep R&D ability, capable of developing power systems based on specific client needs (load, endurance, cost, environment).

- Mass Production Capability: TSL Motor “simultaneously possesses the conditions for mass-producing brushless motors.” This is critical. Bridging the gap between an excellent prototype and stable, reliable, cost-competitive high-volume production is a huge hurdle in the drone industry. TSL’s mass production capability makes it a reliable partner for stable supply chains and scaled deployment.

TSL Motor‘s true product is not just the “motor,” but the “ability to solve propulsion system problems.” The TSL-BLDC-3320 is a microcosm of how our engineering team solved the FPV market’s “high consumption and high heat” pain point.

Whether your drone project requires ultimate agility, ultra-long endurance, or absolute reliability in harsh environments, TSL Motor’s custom R&D and mass production lines offer a one-stop power solution from concept to volume.

Is your drone facing a power bottleneck? Contact TSL Motor today. Let’s define the performance boundaries of your next-generation product together.

FAQ

Q1: What exactly is the TSL-BLDC-3320?

A1: The TSL-BLDC-3320 is a custom 33mm brushless motor from TSL Motor. It is designed to solve the “Impossible Triangle” that FPV pilots have long faced—the inability to balance Extreme Power, Precise Control, and Long Endurance simultaneously. This motor achieves all three through its breakthrough “High Torque, Low Consumption” engineering.

Q2: What are the specific specs for “High Torque, Low Consumption”?

A2: The motor’s core advantage is its efficiency:

- High Torque: It provides 400gf.cm of load torque (ensuring “locked-in” feel and control) and over 2500gf.cm of stall torque (ensuring extreme burst power).

- Low Consumption: While delivering this immense torque, its load current is no more than 7.5A.

Q3: Is this motor for 5-inch or 7-inch drones?

A3: It excels in both, offering distinct advantages for each platform:

- For 5-inch Freestyle: It’s a “torque monster.” The massive 400gf.cm torque delivers an extreme “locked-in” feel and powerful punch-outs, easily fighting off prop wash. Its low heat generation lets you fly harder for longer.

- For 7-inch Long-Range: It’s an “efficiency expert.” The “High Torque, Low Consumption” characteristic is a perfect match for long-range needs. The 7.5A cruise current is the key to achieving super-long endurance.

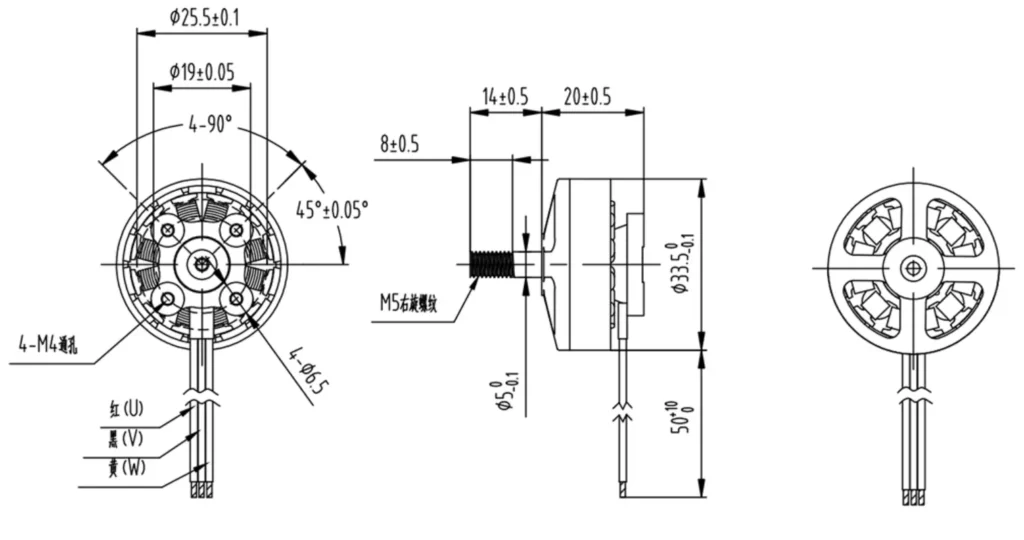

33mm Outrunner Rotor BLDC Motor TSL-BLDC-3320

♦ Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TSL-BLDC-3320

- Voltage:12V-36V

- No-Load Speed : 16000RPM

- Load Speed: 14200RPM

- Stall Torque:3565g.cm

- Stall Current: 28A

- #More Specifications

- #Outline Drawing

♦ Typical Applications:Drone

- racing-oriented

- acrobatic

- long-range

- ducted fan