From Industry 4.0 smart factories to sub-millimeter surgical robots, modern engineering faces one challenge: high torque in tiny spaces.As systems shrink and become smarter, the need for compact and powerful actuators is exploding.

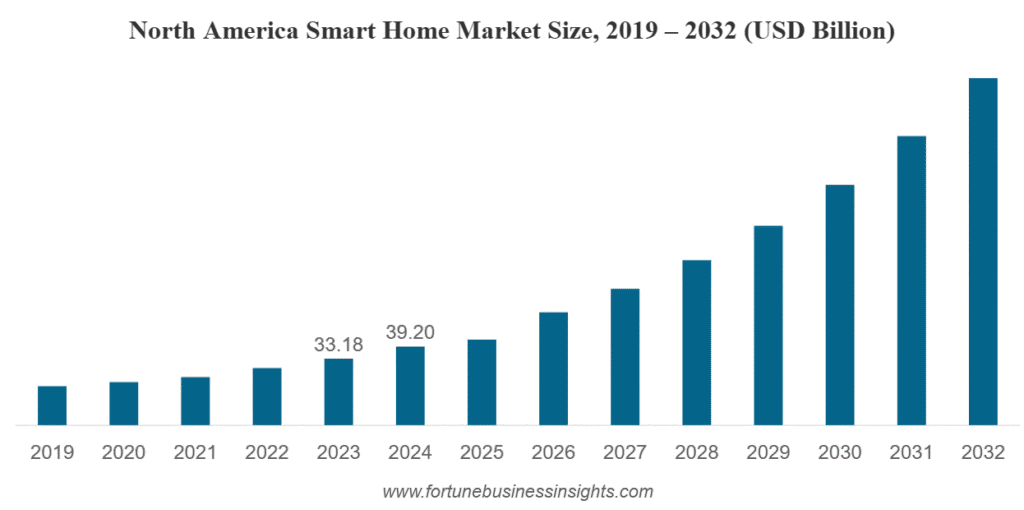

In 2024, the global smart-home market exceeded USD 121 billion.By 2032, it is projected to soar past USD 633 billion.Behind this explosive growth lies one essential force: devices that must be silent, invisible, and powerful.

With years of R&D and manufacturing experience, we have seen how it balances the demands for smaller size, higher strength, and smarter control.Its coaxial compact structure and outstanding power density give it clear advantages over traditional gearboxes.Its transmission efficiency can exceed 95%.

Drawing from our manufacturing practice, this article explains how ultra-low heat loss and precise control make micro planetary gear motors exceptionally durable and highly efficient — for medical devices, robotics, and smart home applications.

Key Takeaways

- A planetary gear system is a mechanism where multiple planet gears rotate around a central sun gear inside a ring gear.

- Its primary advantages include high torque density, compact size, excellent efficiency, and balanced load distribution.

- Planetary gearboxes can be categorized by material (plastic, powder-metal, steel), stage count (single or multi-stage), and gear manufacturing method.

- They are widely used in medical devices, smart locks, robotics, industrial automation, and other compact high-torque applications.

- Global standards such as gear accuracy grades, noise requirements, material specifications, and lifetime testing govern their quality and performance.

- Selecting a planetary gear motor requires defining torque, speed, voltage, duty cycle, environmental conditions, and expected lifetime.

What is a Planetary Gear Motor?

The planetary gear system (or epicyclic gear train) is named for its resemblance to solar system orbital mechanics.

Internal Architecture and Load Distribution

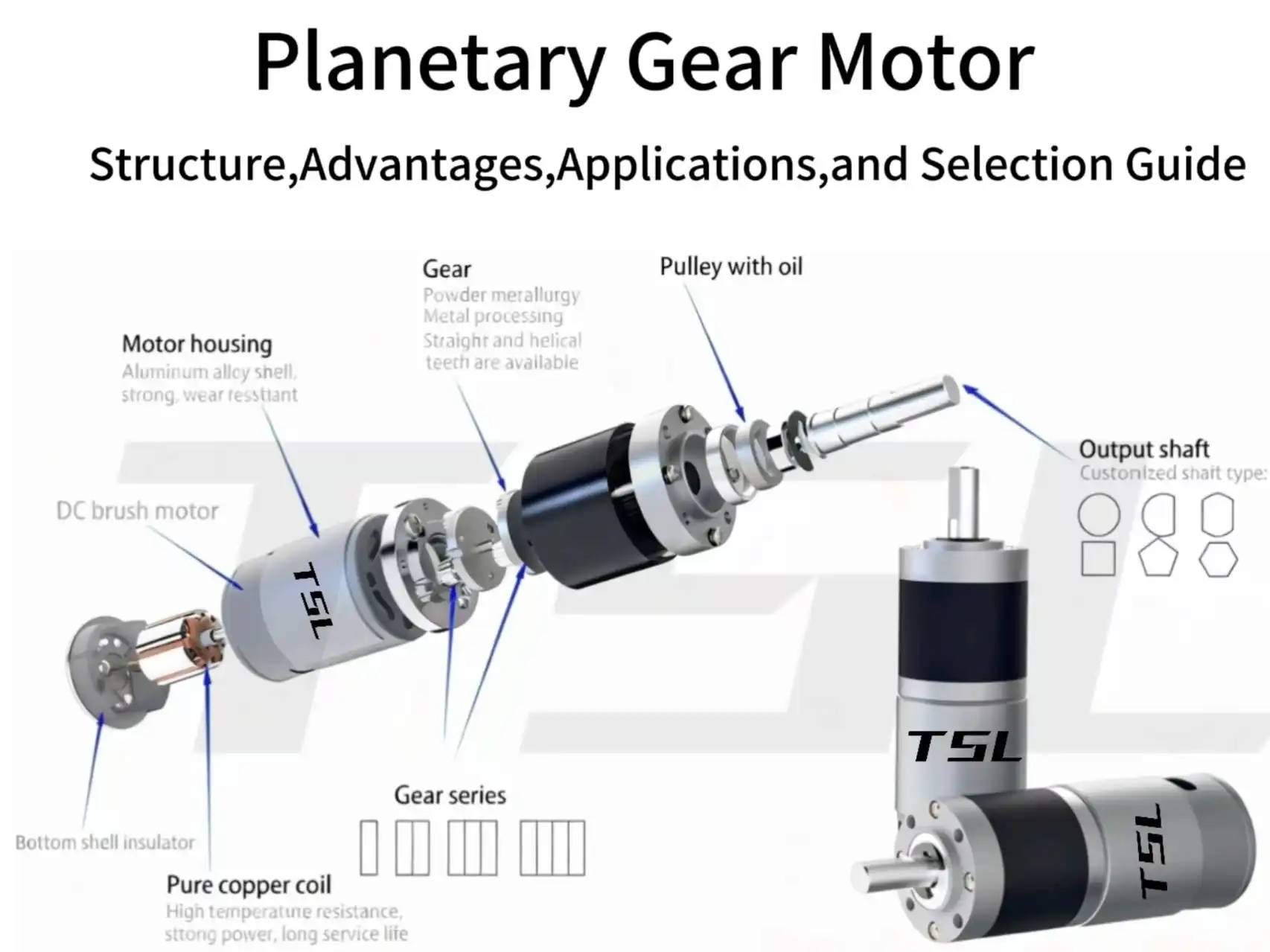

A micro planetary gearbox consists of three core coaxial mechanical elements:

- Sun Gear (Input): This is the central gear. It is typically machined or pressed onto the motor shaft, serving as the power source.

- Planet Gears (Idlers): A set of gears (usually 3 to 5) that orbit the Sun Gear. They are mounted on a rigid Planet Carrier.

- Ring Gear (Housing): The internally toothed gear that encloses the planet gears. In most standard configurations, the Ring Gear is fixed to the motor housing and remains stationary.

The genius of this design lies in Load Distribution. In standard spur gear systems, all torque load passes through a single point of contact.

This causes stress concentration and limits torque capacity. In a planetary system, the input torque from the Sun Gear is simultaneously distributed to three or more planet gears.

How It Works

If the structure is the skeleton, the kinematic principle is the soul of the micro planetary gear motor. Its operation is like a precisely choreographed cosmic run. It converts the high-speed kinetic energy of the DC motor into the powerful potential energy required by industry:

Input (Sun Gear Drive): The DC motor shaft at the core rotates at high speed, driving the central Sun Gear. This is the source of power: high speed, low torque.

Transmission (Planet Gear Orbit): The Planet Gears mesh with the Sun Gear. Since the outer Ring Gear is fixed (part of the casing), the Planet Gears cannot spin in place. They are forced to orbit the Sun Gear while rotating around their own axis.

Output (Carrier Transfer): This orbiting motion directly drives the Planet Carrier. The carrier acts as the output shaft. Its rotation speed is much lower than the Sun Gear’s, but the output torque is multiplied.

Multi-Stage Transmission

For high-end applications like medical pumps or robotic joints, a single-stage reduction (typically 3:1 to 5:1) is often insufficient. This is where the engineering beauty of multi-stage planetary transmission comes into play.

The Cascading Principle: This mechanism is like a relay race. The output of the first stage (the planet carrier) is physically connected directly to the Sun Gear of the second stage. The “finish line” of one stage becomes the “start” of the next.

The Exponential Effect: The total reduction ratio is calculated by multiplying the ratios of all stages, not adding them. For example, two 4:1 stages in series yield a 16:1 ratio. Adding a third stage increases this to 64:1. This allows for huge torque multiplication without needing a larger motor.

The Space Miracle: This is the most valuable advantage for our clients. This method of increasing the ratio by extending the length of the motor allows us to maintain a constant diameter (the Micro size, e.g., 16mm, 22mm) while boosting output torque by tens or even hundreds of times. Engineers do not need to redesign the device casing; they only need to allow a slight increase in motor length.

The Role of Rolling Contact in Efficiency

Efficiency in gear trains is a function of friction.

Sliding vs. Rolling: Worm gears rely on sliding contact, where the worm screw slides across the wheel teeth, generating significant heat and wear. Planetary gears primarily utilize rolling contact.

Tribology: The rolling action facilitates the formation of an elastohydrodynamic lubrication (EHL) film between the gear teeth. This film separates the metal surfaces, reducing wear and friction. This is why planetary gears maintain efficiencies of 95-98% per stage, whereas sliding-contact worm gears may drop below 50%.

Types of Planetary Gear Motors

The main types of planetary gear motors is categorized by motor type and gearbox structure, so engineers can choose the right model for their application.

Classification by Motor Type

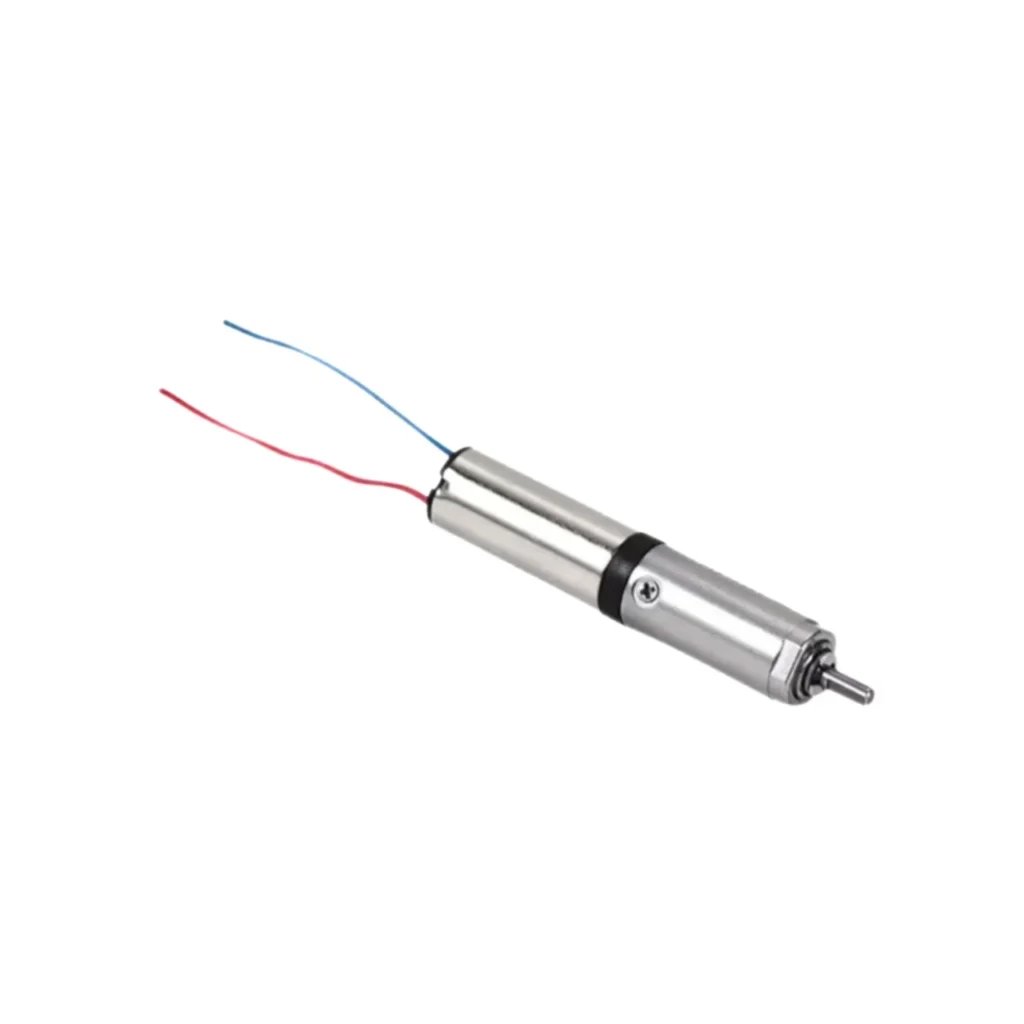

1) Brushed DC Planetary Gear Motor

brushed dc motor+planetary gearbox

Brushed DC motors remain the most widely used power source for planetary gearboxes.The brushed dc motor Provides rotational power using brushes and a commutator.

Advantages

- Ease of Control: Just apply voltage; no need for complex drivers.

- Low Cost: Brushed DC motors are cheaper than BLDC or servo motors.

- Compact Size: Planetary gearbox allows high torque in small packages.

- Stable Output: Reliable for continuous low-to-medium duty cycles.

- Versatility: Works across consumer electronics, automation, and light robotics.

Limitations

- Brush Wear: Brushes degrade over time, reducing lifespan compared to BLDC.

- Electrical Noise: Sparks from brushes can cause EMI (electromagnetic interference).

- Lower Efficiency: More losses compared to brushless systems.

- Maintenance: Requires occasional replacement of brushes.

Applications

- Smart Locks → Compact motor + gearbox fits inside lock housing, providing torque to turn bolts.

- Micro Robots → Low-cost drive solution for small mobile robots.

- Vending Machines → Used to rotate dispensing mechanisms.

- Mini Tools → Electric screwdrivers or cosmetic devices where torque is needed but cost must stay low.

- Actuators → Linear actuators in automation systems, where precision isn’t as critical as cost.

Brushless DC Planetary Gear Motor

bldc motor+planetary gearbox

BLDC motors upgrade planetary gearboxes with longer life and higher efficiency.A BLDC motor works by using electronic commutation with permanent magnets and sensors instead of brushes, producing smooth, efficient rotation with no mechanical wear.

Key Features:

- Extremely long lifetime — no brush wear

- High speed and high efficiency

- Low heat generation, better thermal management

- Suitable for continuous and demanding operation

Typical Applications:

- Medical devices

- Drones

- AGV/AMR (autonomous mobile robots)

- Industrial sensors

- Precision automation systems

Coreless Planetary Gear Motor

coreless dc motor+planetary gearbox

A coreless motor combined with a planetary gearbox is one of the most advanced solutions for ultra‑compact, high‑precision motion systems. Its unique design eliminates the traditional iron core, resulting in exceptional responsiveness and smoothness.

Key Features

- Instant Acceleration: The absence of an iron core reduces inertia, allowing the motor to reach target speed almost immediately.

- High Sensitivity: Even tiny voltage changes produce a quick response, making it ideal for delicate control tasks.

- Ultra‑Smooth Startup: No cogging torque means startup is seamless, with minimal vibration.

- Whisper‑Quiet Operation: Noise levels are significantly lower than conventional brushed or cored motors.

- Compact & Lightweight: Coreless motors are smaller and lighter, perfect for portable or miniaturized devices.

- Energy Efficiency: Lower losses during startup and operation extend battery life in handheld or mobile systems.

Applications

- Precision Instruments: Optical zoom systems, microscopes, and measurement devices where smooth motion is critical.

- Micro Robotics: Tiny robots or actuators that require fast, precise movements without excess weight.

- Optical Systems: Camera gimbals, laser alignment tools, and medical imaging equipment.

- Handheld Devices: Portable pumps, smart tools, and consumer gadgets where quietness and responsiveness matter.

- Medical Devices: Infusion pumps, surgical instruments, and diagnostic tools requiring ultra‑low vibration.

- Wearables: Smartwatches or haptic feedback systems where compactness and efficiency are essential.

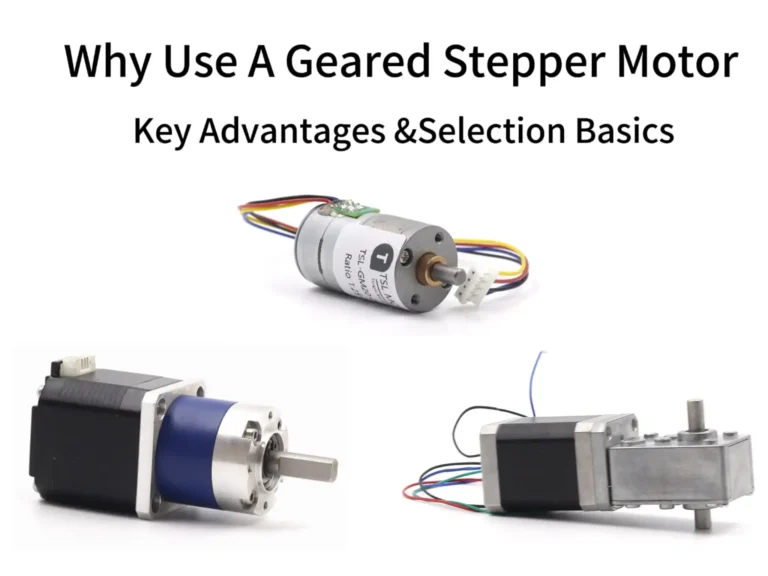

Stepper Planetary Gear Motor

stepper motor+planetary gearbox

A Stepper Planetary Gear Motor combines the precise step‑by‑step motion of a stepper motor with the torque multiplication of a planetary gearbox. This pairing makes it ideal for applications where accuracy and controlled movement are critical.

Key Features

- High positioning accuracy — each step translates into predictable motion.

- Open‑loop control — simple driver electronics, no feedback required.

- Excellent low‑speed torque — planetary gears boost torque at slow speeds.

- Smooth motion — reduced vibration compared to direct‑drive steppers.

Typical Applications

- Camera gimbal systems and pan/tilt units

- Medical infusion pumps and dosing devices

- Laboratory automation (sample handling, pipetting)

- XY stages and precision positioning tables

- 3D printers (extruder drives, Z‑axis lifts)

Advantages

- Cost‑effective compared to servo planetary motors

- Easy to control with basic stepper drivers

- High repeatability for positioning tasks

- Compact design with strong torque density

Limitations

- Lower efficiency than brushless planetary motors

- Limited speed range — best suited for low to medium speeds

- Open‑loop control can lose steps under heavy load (unless upgraded with closed‑loop drivers)

Servo Planetary Gear Motor

The most advanced type — motor + gearbox + encoder + controller,forming a complete closed‑loop drive system.

Features

- Closed‑loop control — real‑time feedback ensures accuracy and prevents step loss.

- High positioning accuracy — encoder feedback allows precise motion control.

- High stability under load — maintains performance even with sudden torque changes.

- Smooth motion — ideal for industrial automation and robotics tasks.

Typical Applications

- Robotic joints and collaborative robots

- CNC automation and precision machining

- Industrial machinery and servo actuators

- High‑end medical and laboratory equipment

Advantages

- Superior precision compared to stepper planetary motors

- Reliable under heavy loads and frequent start‑stop cycles

- Long service life with optimized efficiency

- Integrated system reduces need for external components

Limitations

- Higher cost than brushed or stepper planetary motors

- More complex setup (requires encoder + controller tuning)

- Larger size compared to simpler planetary gear motors

Classification by Gearbox Structure

Planetary gearboxes can also be classified by the material and construction of the gear set.

Plastic Planetary Gearbox Motor

Lightweight and quiet, ideal for consumer products where torque demands are moderate.

Key Features

- Very low noise — perfect for quiet environments

- Lightweight structure — reduces overall device weight

- Low cost — economical for mass production

- Suitable for light-load applications — not designed for heavy torque

Typical Applications

- Electric locks and smart home actuators

- Toys and hobby devices

- Cosmetic and personal care tools

- Small consumer gadgets where silence matters

Advantages

- Quiet operation — ideal for home or office use

- Lower power consumption — extends battery life

- Easy to integrate into compact devices

- Cost-effective for large-scale consumer products

Limitations

- Shorter lifespan compared to metal gearboxes in demanding environmentsstance.

- Lower torque capacity — not suitable for heavy-duty tasks

- Reduced impact resistance — gears may wear faster under shock loads

Metal Planetary Gearbox Motor

Steel or brass gears dramatically increase torque capability and durability.

Key Features

- High torque output — handles demanding loads with ease

- Strong, impact-resistant structure — resists wear and shock

- Capable of heavy-duty operation — suitable for industrial use

- Long mechanical life — durable under continuous stress

Typical Applications

- Robotics actuators and robotic arms

- Electric tools (drills, grinders, cutters)

- Industrial automation equipment

- Servo actuators and CNC machinery

- AGV/AMR drive systems

Advantages

- Excellent performance under high load conditions

- Reliable during frequent start-stop cycles

- Superior durability compared to plastic gearboxes

- Stable operation in harsh environments

- Longer service life — reduces maintenance costs

Limitations

- Higher noise level compared to plastic gearboxes

- Increased cost due to material and machining

- Heavier weight — less suitable for ultra-light devices

- Requires lubrication and maintenance for optimal life

Hybrid Planetary Gearbox Motor

Plastic first stage + metal later stages or plastic gears +metal output shaft

Why This Design Exists

- Plastic first stage → runs at high speed, low torque. Plastic gears reduce noise, vibration, and cost.

- Metal later stages → handle higher torque loads. Steel or brass gears provide strength, durability, and impact resistance.

- Result → a gearbox that combines the quietness and affordability of plastic with the torque and durability of metal.

Key Features

- Balanced cost and performance — ideal for mid‑range applications

- Lower noise than all‑metal gearboxes — smoother operation

- Higher torque than all‑plastic gearboxes — stronger output capability

- Very good durability — withstands moderate shock and long use

Typical Applications

- Micro pumps and fluid control systems

- Medical devices (infusion pumps, diagnostic tools)

- Smart locks and home automation actuators

- Robotics actuators and micro‑robotics joints

- Consumer devices where silence and strength both matter

Advantages

- Cost efficiency — cheaper than full‑metal gearboxes, stronger than full‑plastic ones

- Noise control — plastic first stage absorbs vibration and reduces sound

- Torque output — metal stages ensure reliable power delivery

- Durability — hybrid design extends lifespan compared to all‑plastic gearboxes

Limitations

- Not as strong as full‑metal gearboxes under extreme loads

- Slightly noisier than all‑plastic gearboxes

- Requires careful design to balance wear between plastic and metal stages

Different Types Planetary Gear Motor Comparison Table

| Classification | Type | Torque Capacity | Noise | Cost | Lifetime | Precision |

| Classification by motor type | Brushed DC Planetary Gear Motor | ⭐⭐ Medium | ⭐⭐ Medium | ⭐ Low | ⭐⭐ Medium | ⭐⭐ Medium |

| BLDC Planetary Gear Motor | ⭐⭐ Medium–High | ⭐⭐ Medium | ⭐⭐ Medium–High | ⭐⭐⭐ Very Long | ⭐⭐⭐ High | |

| Coreless Planetary Gear Motor | ⭐ Medium | ⭐⭐⭐ Very Low | ⭐⭐ Medium | ⭐⭐ Medium | ⭐⭐⭐ High | |

| Stepper Planetary Gear Motor | ⭐⭐ Medium | ⭐⭐⭐ Low | ⭐⭐ Medium | ⭐⭐ Medium | ⭐⭐⭐⭐ Very High | |

| Servo Planetary Gear Motor | ⭐⭐⭐ High | ⭐⭐ Medium | ⭐⭐⭐ High | ⭐⭐⭐ Long | ⭐⭐⭐⭐ Very High | |

| Classification by gearbox type | Plastic Planetary Gearbox Motor | ⭐ Low | ⭐⭐⭐ Very Low | ⭐ Very Low | ⭐⭐ Medium | ⭐ Medium |

| Metal Planetary Gearbox Motor | ⭐⭐⭐ High | ⭐⭐ Medium | ⭐⭐ Medium | ⭐⭐⭐ High | ⭐⭐ Medium | |

| Hybrid Planetary Gearbox Motor | ⭐⭐⭐ High | ⭐⭐ Low | ⭐⭐ Medium | ⭐⭐⭐ High | ⭐⭐ Medium |

The Advantages of Planetary Gear Motors

Planetary gear motors are the top choice for compact, high-precision devices. Their design overcomes the limits of traditional gearboxes. For engineers, the advantages below are key.

Superior Torque Density

Structural Principle:

A planetary gear system shares the load across 3 to 5 planet gears that mesh simultaneously. This distributes torque among multiple gear pairs, greatly reducing the stress on any single gear.

Practical Value:

Compared with spur gearboxes of the same size, planetary gear motors can deliver several times—or even tens of times—higher torque without increasing volume. This is the key to achieving “power in the palm of your hand”, enabling miniaturized, high-torque actuation.

Coaxial Design

Structural Principle:

The sun gear, planet gears, and ring gear are all arranged around the same central axis. The input and output shafts naturally remain coaxial.

Practical Value:

This cylindrical, coaxial layout achieves the highest possible space utilization. It is ideal for narrow tubular spaces (such as motorized blinds or endoscopic robotic arms) or applications where the actuator must be integrated into the center of a rotating joint.

High Efficiency and Thermal Management

Kinematic Principle:

Planetary gears primarily transmit motion through rolling contact, rather than the sliding friction found in spur or worm gears.

Practical Value:

A single stage typically exceeds 95% efficiency, with very low energy loss. For battery-powered devices (such as AMRs or power tools), high efficiency directly translates into longer operating time. Reduced losses also mean lower heat generation, unlocking better durability and longer service life under harsh environments or heavy loads.

Low Backlash and High Precision

Manufacturing Principle:

Planet gears are evenly distributed inside the ring gear, forming a symmetrical structure that balances radial forces and ensures smooth transmission. With precision machining and proper preloading, gear clearance can be significantly minimized.

Practical Value:

Low backlash is essential in robotics, medical imaging systems, and laboratory automation. It ensures that tiny motor movements are accurately translated into output shaft motion, preventing positioning errors.

Outstanding Reliability and Shock Resistance

Design Principle:

Multi-point meshing not only transmits torque but also distributes external impacts.

Practical Value:

Planetary gearboxes exhibit superior rigidity and shock resistance. In applications involving frequent start-stop cycles, rapid acceleration/deceleration, or accidental drops (such as industrial robots and handheld tools), planetary gear systems remain more stable and durable than single-mesh spur gear systems.

Comparative Analysis: Planetary vs. Worm vs. Spur Gears

While the planetary gear motor is often the superior choice for high-performance applications, the market offers distinct alternatives. A nuanced selection process requires understanding the specific trade-offs of Spur Gear Motors and Worm Gear Motors.

The Spur Gear Motor: Simplicity and Cost-Effectiveness

The spur gear motor represents the simplest form of gearing, consisting of straight-toothed gears mounted on parallel shafts.

- Architecture: The drive train is a cascade of gear pairs (pinion driving gear).

- Performance: Torque is transferred through a single line of contact. This limits load capacity and makes the teeth susceptible to shock loading.

- Acoustics: The sudden engagement of the full tooth width creates impact noise, making spur gears louder, especially at high speeds.

- Primary Advantage: Low manufacturing cost and ease of maintenance. For non-critical, low-torque applications like simple toy actuation or basic vending machines, spur gears provide a functional, economical solution.

The Worm Gear Motor: The Self-Locking Specialist

Distinct from the coaxial planetary design, the worm gear motor employs a screw-and-wheel configuration.

- Architecture: The input shaft drives a spiral worm (screw), which meshes with a worm wheel. This creates a 90-degree right-angle output.

- Self-Locking Mechanism: A unique feature is its ability to be self-locking. Due to the friction angles, the wheel generally cannot drive the worm. This provides a passive braking effect, ensuring that a lifted load does not drift downward when power is cut—a critical safety feature in hoists and elevators.

- Efficiency Penalty: The reliance on sliding contact results in low efficiency (30-60%). High ratios lead to significant energy loss as heat.

- Wear and Backlash: The sliding action wears the softer bronze wheel, leading to increased backlash over time, making them less suitable for precision positioning.

Detailed Technical Comparison Table

The following table synthesizes the operational characteristics, providing a decision framework for engineers.

| Feature | Planetary Gear Motor | Worm Gear Motor | Spur Gear Motor |

| Transmission Geometry | Coaxial (In-Line) | Right Angle (90°) | Parallel Shaft (Offset) |

| Torque Density | High (Load shared by 3+ planets) | Medium | Low (Single contact point) |

| Efficiency | High (90% - 98% per stage) | Low (30% - 60%) | Medium-High (85% - 90%) |

| Backlash (Precision) | Low (< 5 arcmin available) | High | Medium |

| Noise Level | Low (Balanced forces) | Low (at low speeds) | High (Tooth impact) |

| Backdrivability | High (allows compliance) | Zero (Self-locking) | High |

| Heat Generation | Low | High (Sliding friction) | Moderate |

| Cost | Moderate to High | Moderate | Low |

| Typical Application | Robotics, Medical, Smart Locks | Hoists, Conveyors, Lifts | Toys, Simple Automation |

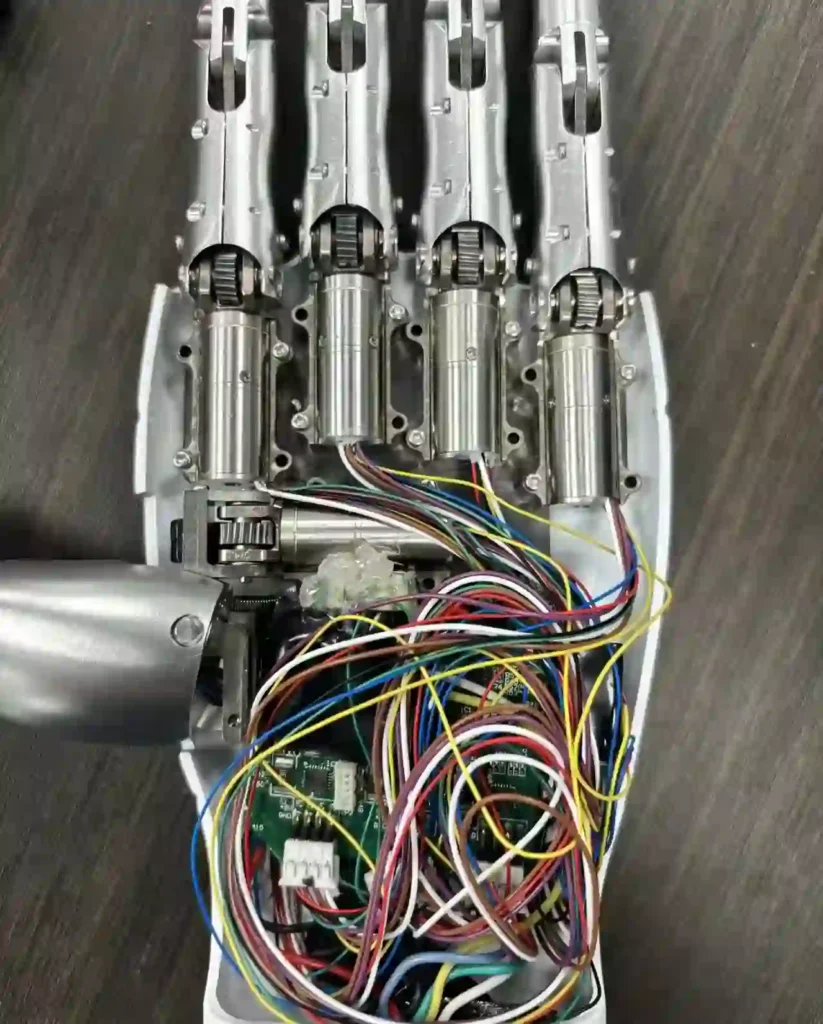

Insight: The “Hybrid” Approach

Recent trends in robotic dexterity have led to hybrid designs. For example, anthropomorphic robotic hands may utilize a worm gear stage for the proximal joints (to provide self-locking holding capability without power) coupled with a planetary gear stage for the distal joints (to provide speed and efficiency).

This highlights that while planetary motors are generally superior, the specific physics of the application (e.g., the need for passive holding torque) may dictate a mixed approach.

Planetary Gear Motor Applications

Sector Analysis I: Advanced Robotics and Industrial Automation

Robotics is one of the strongest drivers behind innovations in high-torque, low-backlash actuation technologies. The shift from rigid industrial robots to collaborative and dexterous systems places planetary gear motors at the center of robotic design.

Collaborative Robots (Cobots) & Backdrivability

Unlike traditional fenced robots, collaborative robots work directly alongside humans. This interaction requires a safety property known as compliance or backdrivability—the ability for the robot arm to yield when pushed by an external force (e.g., a collision with a person).

While larger joints tend to use higher-power actuators, micro planetary gear motors are ideal for end-effectors (electric grippers, tool modules) and precision wrist joints. They are essential for achieving dexterous motion and fine control.

Backdrivability challenge:

High reduction gearboxes typically have high friction and resist backdriving. Worm gears are inherently non-backdrivable.

Planetary advantage:

Because of their high efficiency and rolling contact, planetary gear motors provide excellent backdrivability.

This allows the motor controller to detect external torque peaks (via current feedback) and actively reverse or stop motion to prevent injury. Their low inertia design minimizes the reflected inertia defined as:J_ref = J_load / N²,making the robot feel lighter and safer during human interaction.

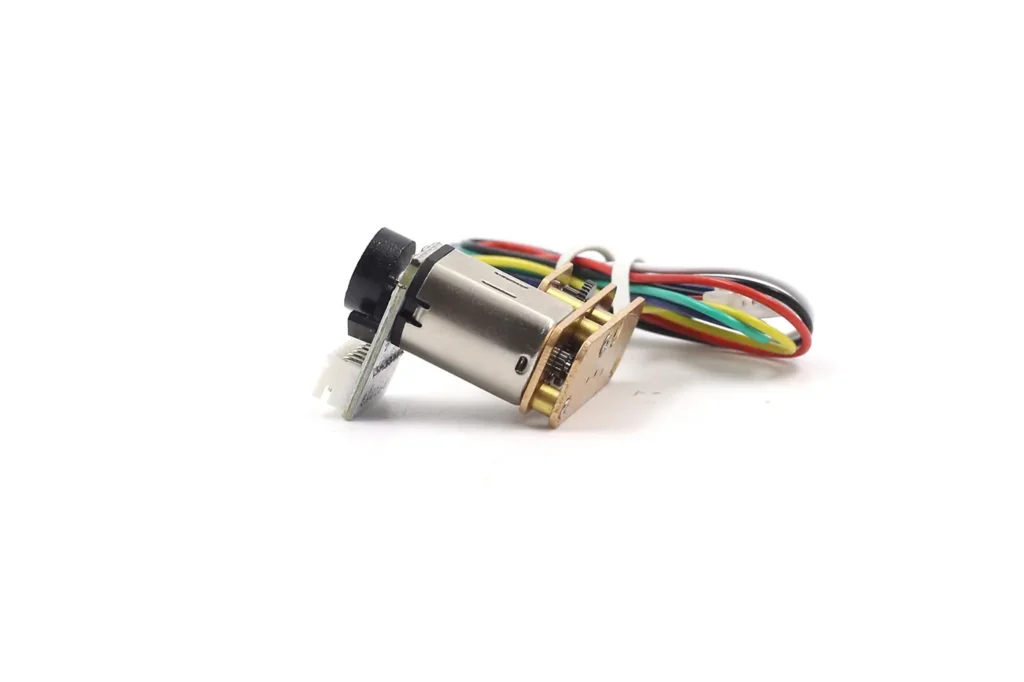

Dexterous Manipulation: A Micro Planetary Revolution

Replicating human hand function requires actuators small enough to fit inside the geometry of finger phalanges.

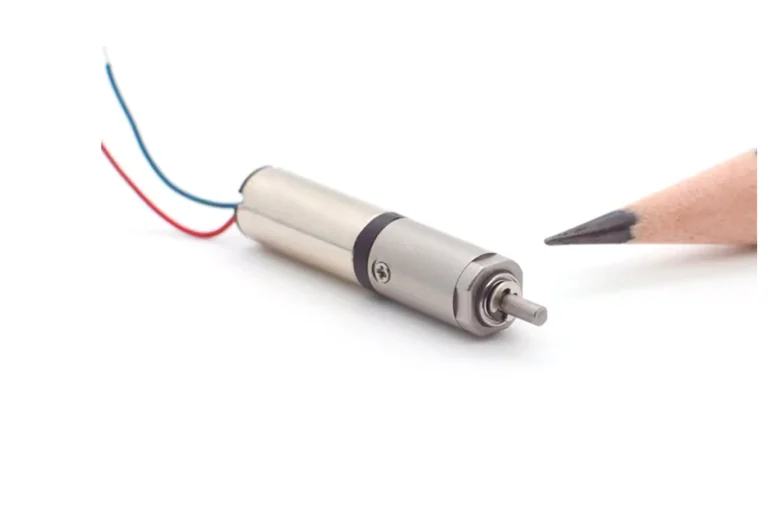

Miniaturization:

Our smallest planetary gear motors are as small as 6 mm in diameter.

Application:

In robotic hands, a 6 mm planetary gearbox paired with a coreless or brushless motor provides gripping force. The coaxial structure allows the actuator to be embedded directly inside the finger linkage.

Torque requirement:

A typical robotic finger joint may require 1–3 Nm of torque. Multi-stage micro planetary gearboxes convert the high speed of a 6 mm motor (e.g., 20,000 RPM) into the low-speed, high-torque output needed for grasping. Compact multi-stage configurations can achieve 100:1 or higher ratios within <30 mm total length.

Electric Grippers vs. Pneumatics

Industrial automation is rapidly shifting from pneumatic grippers (noisy, inefficient, poor force control) toward electric grippers.

Precision control:

Electric grippers driven by planetary gear motors enable precise control of gripping force (via current) and position (via encoder). With only software adjustment, the same gripper can handle fragile eggs or heavy steel components.

Self-locking in grippers:

Some electric grippers integrate high-ratio planetary gearboxes or specially designed lead screws to hold force during power loss—achieving worm-gear-like safety while maintaining higher efficiency.

Sector Analysis II: Medical Technology and Surgical Precision

Medical applications demand the perfect blend of reliability, sterility, and low noise. These systems are often life-critical, placing extremely rigorous performance requirements on motors.

Powered Surgical Staplers: The High-Torque Challenge

Modern surgery increasingly relies on powered staplers that cut and seal tissue simultaneously.

The Physics of Stapling:

Driving titanium staples through varying tissue densities requires a massive, instantaneous burst of torque—often up to 30 Newton-centimeters (N.cm).

The Planetary Solution:

Handheld staplers must be lightweight to prevent surgeon fatigue. A 16mm or 22mm planetary gear motor is the standard solution. It can deliver the required peak torque from a compact battery-powered unit. The high efficiency ensures the battery lasts through lengthy procedures.

Sterilization:

These motors must often withstand autoclave cycles (steam sterilization at 134°C). Manufacturers use specialized high-temperature windings, magnets, and lubricants, along with sealed planetary gearheads, to survive repeated sterilization without degrading performance.

Insulin Pumps and Control Theory

Portable insulin pumps deliver precise micro-doses continuously, 24/7.

Control challenge:

The motor must overcome static friction to dispense tiny amounts of insulin and then stop instantly. Traditional PID controllers struggle with nonlinear friction behavior at extremely low speeds in miniature geartrains.

Advanced control (LQG):

Research shows that Linear Quadratic Gaussian (LQG) control with a Kalman filter performs better for insulin pump motors. It estimates motor states more accurately, compensates gearbox noise and friction, reduces rise/settling time, and ensures precise drug delivery.

Acoustics & patient anxiety:

Noise affects user comfort. Loud pumps can cause anxiety or disturb sleep. Planetary gearboxes offer smoother acoustic characteristics than spur gears.

Noise levels must typically remain below 30–40 dBA. We often use hybrid gear trains—plastic in early stages (for low noise) and metal in final stages (for torque strength).

Laboratory Automation

In automated blood analyzers, HTS systems, and DNA sequencers, throughput determines economic viability. High-speed planetary motors drive pipetting gantries and robotic samplers through thousands of rapid accelerations and positioning cycles.

Speed & durability

High-speed operation demands excellent efficiency and thermal performance. Planetary gearbox efficiency keeps temperature rise low—critical inside sealed analyzer enclosures. Multi-point load sharing ensures durability during 24/7 operation.

Precision barrier: Eliminating repeatability errors

This is a zero-tolerance domain.

Risk amplification:

Even sub-millimeter positioning errors can cause pipette tips to strike tube walls at high speed, resulting in splashing, sample loss, or cross-contamination that ruins entire batches.

Planetary solution:

Planetary gear motors offer low backlash and excellent repeatability. Their rigid structure and precise machining minimize settling time and ensure accurate homing—critical for accuracy and throughput.

We commonly supply customized 12 mm to 22 mm actuators optimized for smoothness to prevent bubbles or overflow during high-speed liquid handling. For these applications, low backlash is not optional—it is a mandatory safety requirement.

Sector Analysis III: The Invisible Home – Smart Automation

The “smart home” movement is built on the idea of invisible actuation, where intelligence is embedded seamlessly into everyday objects.

Smart Door Locks & Teardown Insights

Modern smart locks (August, Yale, Schlage) must fit existing door hardware.

Torque requirement:

Door locks often require 1.5–2.0 Nm of torque to turn the latch, especially when misalignment or weathered seals increase friction.

Teardown observations:

Inside mainstream smart locks, 10–16 mm full-metal planetary gear motors are ubiquitous. The coaxial shape allows them to fit inside round lock bodies or knobs.

Mechanism:

The motor drives the planetary gearbox, which turns the output shaft connected to the latch tailpiece. Sensors monitor position, and if jamming is detected via current spike, the motor reverses to avoid damage.

Curtain & Shade Tubular Motors

Automatic blinds rely on tubular motors housed inside roller tubes.

Geometry is destiny:

Planetary gearboxes have a cylindrical, coaxial form factor, making tube-integration feasible. Worm gears protrude too much to fit into the tube.

Internal structure:

These motors use long, multi-stage gearboxes (3–4 stages) to achieve high ratios (e.g., 64:1 or higher) required to lift heavy blackout curtains.

DIY & solar-powered shades:

High gearbox efficiency (up to 95%) enables solar-powered cordless blinds. A small solar panel can fully support daily up/down cycles due to the motor’s low energy consumption.

Sector Analysis IV: Automotive Mobility and ISO Standards

As vehicles shift toward software-defined architectures, mechanical linkages are being replaced by precise by-wire electromechanical actuators.

Electronic Parking Brake (EPB)

Mechanical handbrakes are obsolete.

Application:

EPB systems mount a motor directly on the brake caliper. Pressing a button activates the motor and leadscrew to clamp the brake pads.

Planetary requirement:

The system needs high torque to secure the vehicle on slopes. Planetary gears amplify torque from compact 12V DC motors. High efficiency ensures fast braking response in milliseconds.

LiDAR & Sensor Cleaning

Autonomous vehicles rely on LiDAR sensors spinning at constant, precise speeds.

Stability:

Planetary motors provide the smooth, low-vibration rotation required. Any gearbox jitter appears in the LiDAR point cloud as noise or blurring.

Cleaning actuators:

Retractable nozzles for cleaning cameras and sensors also use small planetary actuators for extension/retraction under harsh conditions.

Automotive Noise Standards

Automotive applications follow strict acoustic regulations.

ISO 16750:

Defines environmental testing for vehicle electrical equipment, including sinusoidal and random vibration—to ensure gearboxes survive harsh road conditions.

ISO 10844:

Specifies standardized road surfaces for vehicle pass-by noise measurements. For EVs, actuator noise becomes more significant. Planetary gears are quieter than spur gears, helping manufacturers meet low-noise requirements.

Engineering-Based Selection

Selecting the correct planetary gear motor is a multidimensional optimization problem. It requires physics-based modeling—not just choosing a voltage.

Torque Calculation & Motion Physics

Proper motor selection begins with calculating the required torque. For mobile robots, torque depends on friction and acceleration.

Friction load:

F_friction = μ × N

where μ is the friction coefficient (e.g., 0.7 for carpet) and N is the normal force (weight).

Acceleration load:

F_acceleration = m × a

where m is mass and a is the desired acceleration.

Total required torque (T):

T = (F_friction + F_acceleration) × r_wheel

where r_wheel is the wheel radius.

Example

A 20 kg robot, on carpet (μ = 0.7), accelerates at 0.2 m/s² with a wheel diameter of 10 cm (r = 0.05 m).

F_f = 0.7 × 20 kg × 9.8 m/s² = 137.2 N

F_a = 20 kg × 0.2 m/s² = 4 N

Total force = 141.2 N

Torque = 141.2 N × 0.05 m = 7.06 Nm

Selection conclusion:

This application likely requires a high-speed DC motor paired with a high-ratio planetary gearbox (e.g., 50:1).

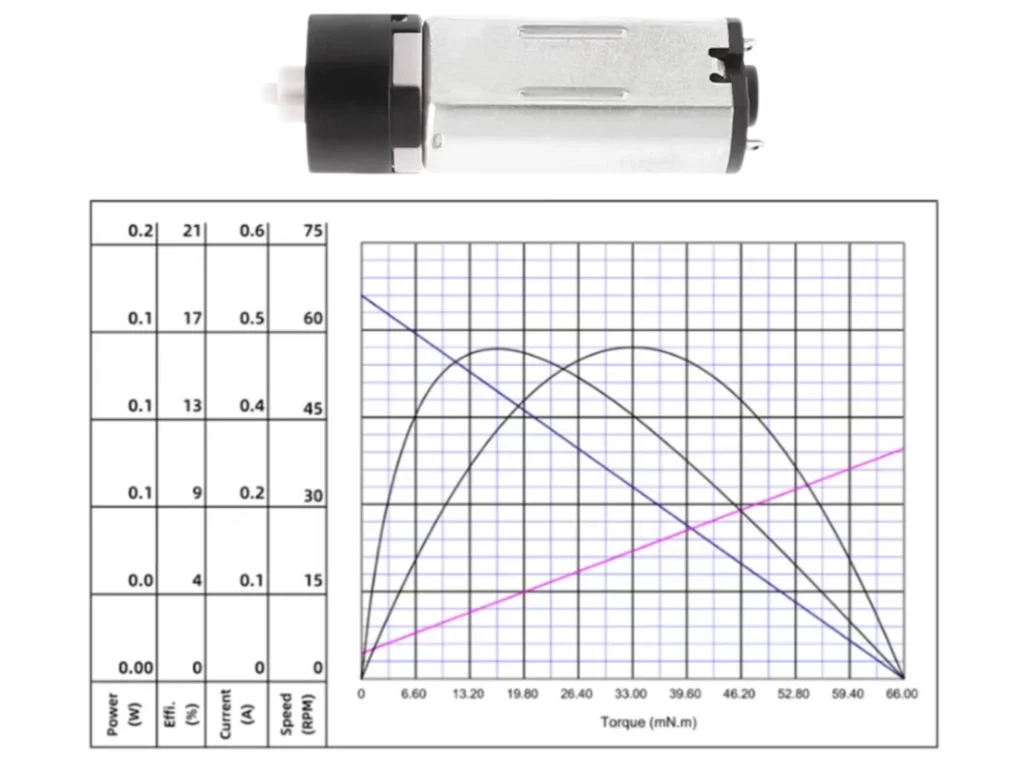

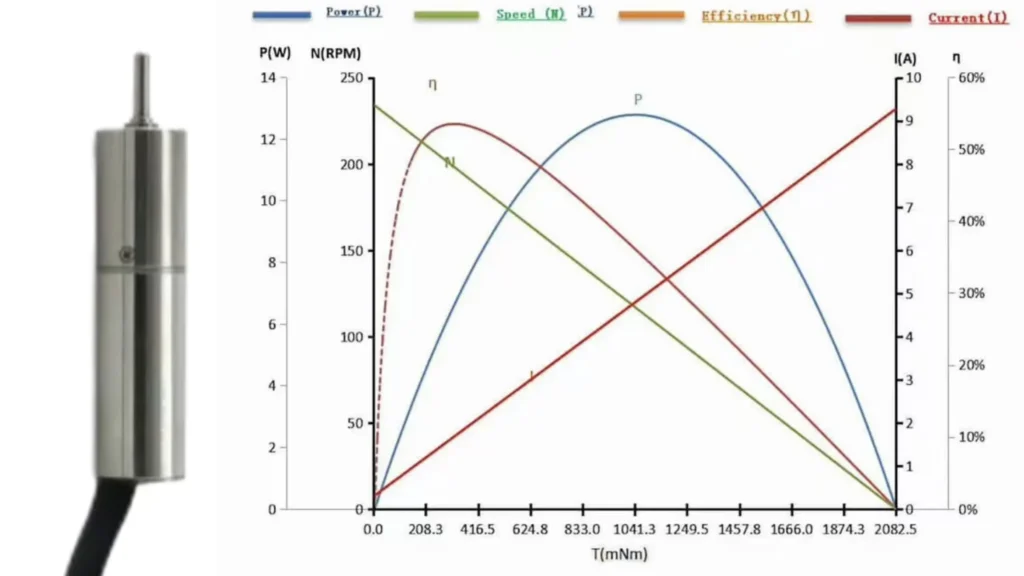

Load Curves: Continuous vs. Peak

Engineers must distinguish between:

Continuous torque:

The torque a motor can deliver indefinitely without exceeding thermal limits. Planetary gearboxes perform well here due to load sharing among multiple teeth.

Peak / stall torque:

The maximum torque needed to start moving the load. Planetary gearboxes can typically withstand 2–3× the rated torque during brief impact events because of their robust multi-tooth engagement.

Inertia Matching

n high-dynamic applications such as robotics, the motor rotor inertia (J_m) should be matched to the reflected load inertia (J_reflected).

Reflected inertia:

The gearbox reduces the apparent load inertia by the square of the reduction ratio N.

J_reflected = J_load / N²

Optimization:

Planetary gearboxes allow high reduction ratios, significantly lowering reflected inertia, improving controllability, and enhancing dynamic response.

Manufacturing, Quality, and Global Standards

In a globalized supply chain, the origin and process of gearbox manufacturing influence reliability just as much as the design itself. The manufacturing method determines the “grade” of the gear.

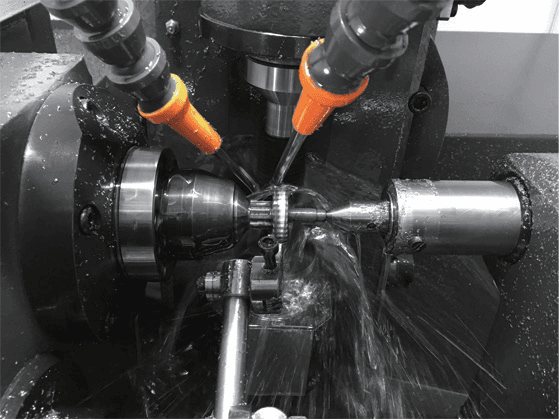

Manufacturing Processes: Skiving vs. Hobbing vs. Powder Metallurgy

Power Skiving

A modern machining method suitable for 5-axis CNC machines. It can rapidly and precisely produce internal ring gears, which are critical components of planetary systems. Skiving is faster than shaping and more precise than broaching, enabling high-quality planetary gear rings to be mass-produced.

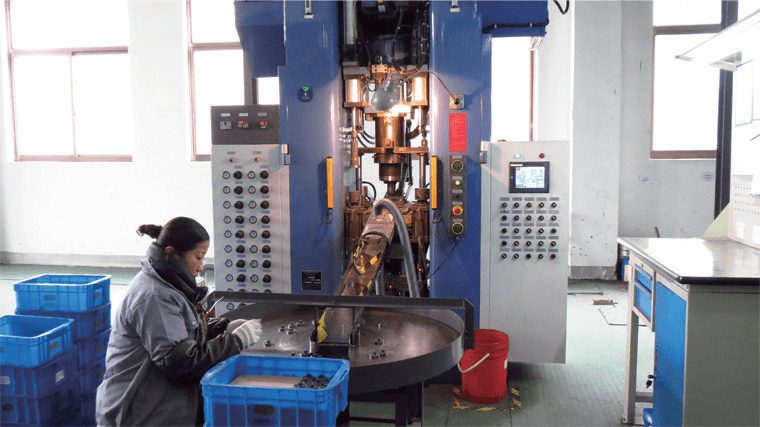

Powder Metallurgy (Sintering)

Metal powder is pressed into a mold and then sintered at high temperature. This allows low-cost production of geometrically complex gears. Widely used in automotive and consumer-grade planetary gearboxes. Cost-effective, but impact strength is lower than machined steel gears.

Injection Molding

Plastic gears (POM/nylon) are used where low noise and low cost are priorities. In medical planetary gearboxes, the first stage is often plastic for quiet operation, while later stages use sintered or machined steel for torque handling.

Quality Standards: AGMA and ISO

Gear quality is not subjective—it’s defined by engineering standards.

AGMA (American Gear Manufacturers Association)

AGMA standards (e.g., AGMA 2001, AGMA 2015) classify gears by precision. High-precision aerospace gears may reach AGMA Class 12, while commercial gears are typically Class 8.

ISO 1328

The international equivalent. In ISO standards, a lower number indicates higher precision (the opposite of older AGMA scales). High-performance planetary gears for robotics typically reach ISO Class 6 or 7.

Meaning:

ISO Class 6 gears have tighter tolerances in tooth profile and pitch error, resulting in lower transmission error, less vibration, and significantly reduced noise.

coustic Testing Methodology

To meet medical and automotive requirements, TSL MOTOR perform strict noise testing.

Setup:

Tests are conducted inside an anechoic chamber to eliminate background noise.

Procedure:

Microphones are placed at a fixed distance (e.g., 10 cm or 1 m). The motor runs at various speeds and loads.

Analysis:

Engineers look for frequency peaks that indicate gear meshing issues such as eccentricity or damage. Overall sound pressure level (dBA) is measured. High-quality planetary motors intended for medical devices often need to stay below 45 dBA.

Conclusion: The Precision Imperative

The planetary gear motor stands as a testament to the elegance of mechanical engineering. By mimicking the orbital dynamics of the cosmos, it achieves a terrestrial feat: packing immense power into a microscopic footprint.

While spur gears remain relevant for cost-sensitive, low-impact applications, and worm gears retain a niche in self-locking vertical lifts, the planetary gear motor is the undisputed driver of the high-tech economy.

From the 6mm motor securing a smart home to the high-torque actuator powering a cobot’s elbow, this technology bridges the gap between digital commands and physical action.

As industries continue to push the boundaries of miniaturization and efficiency—demanding motors that are quieter, stronger, and smarter—the planetary gear motor will remain the beating heart of automation.

For the global engineer, the choice is clear: when performance cannot be compromised, the planetary system is the standard.

FAQ

Q1.What is a planetary gear motor?

A1:A planetary gear motor is a gear system where multiple planet gears rotate around a central sun gear inside a ring gear. This structure provides high torque density, compact size, and excellent efficiency.

Q2:Why are planetary gear motors used in compact or high-load applications?

A2:Because the load is shared across multiple planet gears, the system can deliver high torque within a very small volume. This makes them ideal for medical devices, smart locks, robotics, and precision instruments.

Q3:How do planetary gear motors compare with spur gear motors?

A3:Planetary gears generally offer higher torque, better efficiency, and more uniform load distribution. Spur gear motors are simpler and cheaper but cannot match the compact torque density of a planetary system.

Q4:What materials are commonly used for planetary gearboxes?

A4:

- Plastic gears: quiet, economical, suitable for light loads

- Metal gears: durable, high torque, suitable for demanding applications

- Powder-metal gears: balanced cost and strength

- Cut gears (machined steel/bronze): highest precision and durability

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Planetary Gear Motor

A planetary gear motor combines a micro planetary gearbox with a DC motor, serving as a driving device designed to reduce speed and increase torque. These motors are typically cylindrical and made from materials such as steel or brass. In some cases, plastic components are used to meet specific size and power requirements.