In modern automobiles, the windshield washer pump system has become an indispensable component for ensuring driving safety.

With the continuous upgrading of automotive functions, the washer pump is not only used on the front and rear windshields, but some vehicle models are even equipped with headlamp cleaning pumps to ensure optimal lighting performance in complex weather and night driving conditions.

The motor is the core driving force within this system. The washer pump usually employs a DC gear motor, characterized by its small size, high efficiency, and strong durability. By regulating the input voltage through the electronic system, the motor can flexibly switch between different intensity modes, meeting the requirements for low-speed, intermittent, or high-speed cleaning.

As an experienced motor supplier, TSL MOTOR offers a durable and long-lasting gear motor (TSL-GM16-030) for this application. This motor not only maintains stable performance in various environments but also allows for customized design based on client needs, providing a more reliable and intelligent solution for automobile manufacturers.

Leveraging advanced manufacturing processes and stringent quality control, TSL MOTOR‘s motor solution brings a safer and more comfortable driving experience to global users.

Key Takeaways

- Core Application and Safety Assurance. This motor is specifically designed for automotive washer pump systems, acting as the core drive for clear visibility and driving safety. It supports cleaning for front/rear windshields and high-end headlamps.

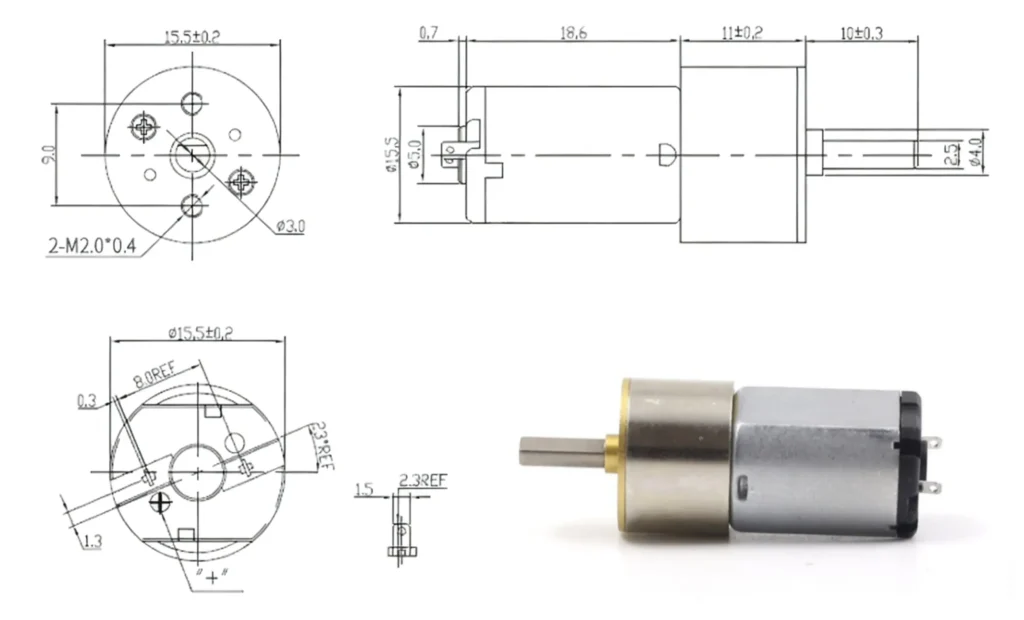

- Motor Type and Size Advantage. It is a high-efficiency DC Gear Motor known for its compact size and high power density. Its 15.5 mm diameter is ideal for the tight installation spaces in modern vehicles.

- High Durability and Environmental Adaptability. The motor utilizes an all-metal gearbox and a reinforced sealing structure. It maintains stable performance across extreme temperatures from -40°C to +85°C.

- Exceptional Torque Output Capability. Through high-energy product materials and optimized design, the motor achieves high torque density. This ensures powerful starting force when dealing with high-resistance conditions like ice or mud.

- Low Noise (NVH) Operation. TSL MOTOR employs low-backlash design and precision dynamic balancing technology. This significantly reduces vibration and noise, enhancing cabin comfort.

- Intelligent Control Compatibility. The motor is fully compatible with vehicle electronic control systems (ECU/BCM). It supports PWM speed control for seamless, stepless switching between different cleaning modes.

- Flexible Customization Service. TSL MOTOR offers comprehensive customization of electrical and mechanical characteristics. This ensures the motor’s performance precisely matches the specific requirements of various vehicle models.

Automobile Wash Pump

Core Function and Safety Significance

In modern vehicles, the windshield cleaning and wiper system is a vital part of ensuring driving safety. Its core function is to handle the dirt, dust, insect residue, and winter road grime and salt that accumulate on the windshield during driving, thereby ensuring the driver always has a clear field of vision.

The power source for this system is a battery-operated electric wiper water pump, typically a miniature electric centrifugal pump. The pump’s role is to draw cleaning fluid from the reservoir and transport it through tubing to the spray nozzles, which then propel it onto the windshield surface at high pressure.

The fluid reservoir is generally made of corrosion-resistant plastic, with a capacity of 1.5 to 2 liters, sufficient for daily use.

After the cleaning fluid is sprayed, it spreads as fine streams or a mist over the glass surface. The wiper then immediately activates, effectively sweeping the mixture of liquid and contaminants to the side, completing the cleaning process.

To avoid exposure to heat and impact, the wiper water pump is usually installed in a hidden location, such as under the vehicle’s front hood or behind the wheel arch liner. The specific layout may vary among different vehicle models.

Structure of the Cleaning System

With the evolution of automotive technology, the wiper cleaning system has expanded from single front-windshield application to multi-area service, enhancing all-around visibility.

Modern vehicles commonly feature more than one washer pump: one dedicated to the front windshield, providing greater flow and pressure, and another serving the rear windshield, especially common in hatchbacks, station wagons, and SUVs, to ensure safety when reversing and maintaining rear visibility.

In high-end models or vehicles equipped with high-performance lighting systems, a specialized cleaning pump is also provided for the front headlamps.

These pumps typically require higher operating pressure to spray a high-pressure jet of water to remove dirt from the headlamp lenses, preventing impact on beam quality, while meeting regulatory requirements and driving safety standards. Due to the more demanding operating environment, these components must have a robust structure and a high degree of waterproofing.

Operation and Control in the Cockpit

Inside the cockpit, the cleaning and wiper system controls are designed to be within easy reach of the driver, usually located on the combination switch stalk next to the steering wheel.

Drivers can select one of the three basic wiper modes using a knob or lever: low-speed for light rain or drizzle; high-speed for moderate to heavy rain to quickly clear large amounts of water; and intermittent mode, which allows the wipers to operate at set intervals, suitable for light rain or mist, while extending wiper blade life and conserving energy.

A wash button is usually located at the top of the stalk. When the driver presses or pulls this button, the water pump instantly activates, the nozzles spray cleaning fluid, and the wipers automatically sweep a few times, achieving synchronous cleaning.

Some premium models also feature intelligent rain sensors that automatically adjust the wiper speed based on the amount of rain, and can even trigger the wash function, further enhancing driving convenience and safety.

Overall, the automobile windshield cleaning and wiper system is a complete electromechanical safety assurance device. From the reservoir, pump, tubing, and nozzles, to the wipers and cockpit controls, it forms a complete closed-loop system.

As demands for intelligence, environmental friendliness, and regulatory compliance continue to increase, the system is evolving towards greater efficiency, durability, and intelligence, promising even more reliable visibility for drivers in the future.

How the Automobile Wash Pump Works

The Role of the Washer Pump

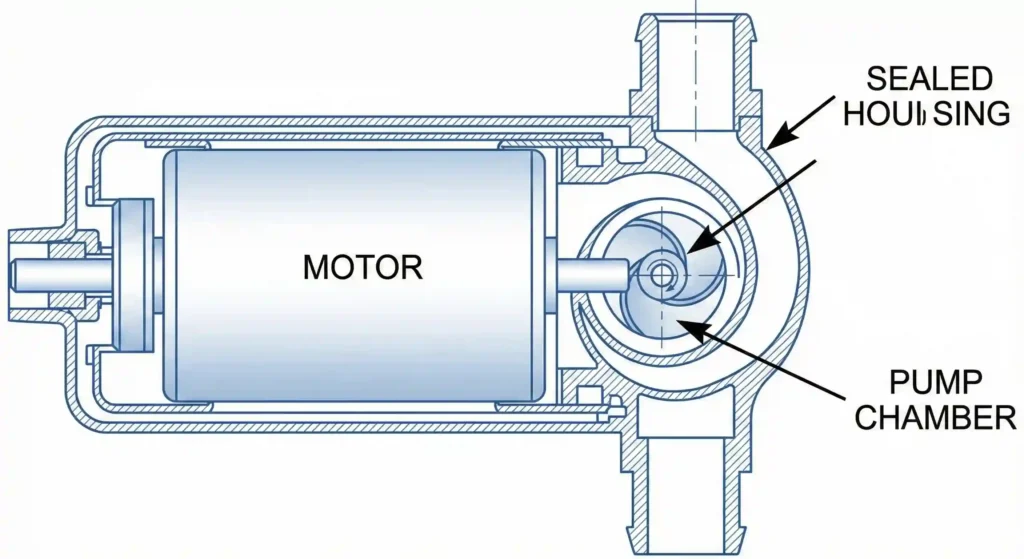

Within the entire windshield cleaning system, the washer pump is the key core component. Its function is to extract washer fluid from the reservoir, pressurize it, and send it through the hoses to the spray nozzles so that the fluid can reach the surface of the windshield, headlamps, or rear glass.

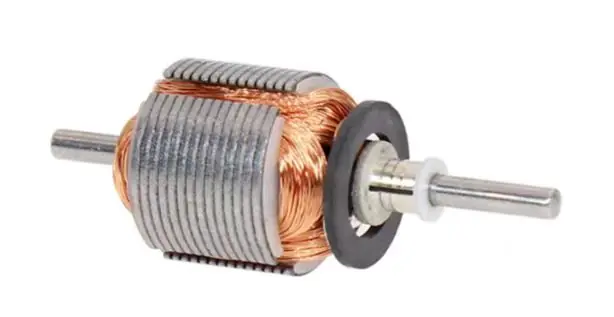

Modern vehicles generally use miniature DC-motor-driven centrifugal pumps. The motor rotates the impeller at high speed to generate centrifugal force, providing stable pressure and flow.

Unlike the wiper blades, which can only wipe mechanically, the washer pump determines the washing force, spray coverage and overall cleaning effect—making it the true leading functional component in the cleaning system.

Structural Features and Installation Position of the Wiper Pump

The wiper pump has four main parts. Motor, impeller, pump chamber, and sealed housing.

The design is compact, stable, durable, and low-cost. It is installed near the reservoir in hidden areas. Common positions are the lower edge of the engine bay or inside the fender liner. This avoids heat, vibration, and external impact.

The reservoir is made of corrosion-resistant plastic. Capacity is usually 1.5 to 2 liters. This size meets long-term usage needs.

Automotive technology has advanced. The system evolved from single-pump to multi-pump design. Vehicles often use a front windshield pump.

They also use a rear windshield pump. Premium models add a high-pressure headlamp cleaning pump. Each pump provides different pressure and flow rates. They meet the cleaning needs of different areas.

The Auxiliary Role of the Wiper in the Cleaning Process

The wiper plays an auxiliary role. It cannot clean on its own. It wipes away loosened dirt after fluid is sprayed. It pushes dirty liquid toward the glass edge.

The pump sprays and washes. The wiper wipes clean. Both work together in synergy. The pump provides the power and fluid delivery.

The driver controls pump and wiper with a switch near the steering wheel. Pressing the wash button activates the pump. Fluid sprays instantly. The wiper sweeps several times to finish cleaning.

High-end models use rain sensors. Sensors adjust wiper speed automatically. They can trigger the wash function when dirt is detected. This improves convenience and safety.

Key Challenges Facing the Wiper System

In modern automobiles, the wiper cleaning system is critical for visibility and safety. Its core actuators—the wiper pump and motor—must run stably in harsh environments.

The system faces challenges in durability, mechanical load, electronic control, NVH, and smart functions.

Durability Challenges in Extreme Environments

The wiper system endures severe cold, extreme heat, humidity, rain, and snow. It is exposed to road salt, mud, and chemicals in the cleaning fluid. The pump and motor, near the engine bay or wheel arch, need strong sealing. They must resist corrosion and meet strict IP ratings. Materials, seals, and insulation face high demands from long-term erosion.

High Mechanical Load and Instantaneous Starting Torque

Rain, mud, insects, and ice increase friction between wiper and glass. Start-up and high-speed wiping require strong torque. The motor must deliver stable high-torque output. It needs efficient speed reduction and torque boosting. The pump must perform reliably under cold start and high-pressure spray.

NVH Control Challenges

Comfort standards demand low noise and vibration. Motor, gearbox, and pump housing create vibration and resonance. Noise can reach the cabin if not suppressed. The motor must run smoothly. The gearbox needs low-noise design. Control logic must optimize start-up and speed changes.

Electronic Control and Intelligent Adjustment

Smart rain sensors and ADAS increase control complexity. The system is no longer simple on/off. It requires precise electronic control. Functions include rain sensing, automatic washing, and speed-adjusted wiping. Pump and motor must be highly controllable. They need fast response and stable linear output. They must adapt to complex software strategies.

Electromagnetic Compatibility (EMC)

Pump and motor generate inrush current and EMI. This can affect cameras, radar, HUDs, and CAN/LIN systems. The system must meet strict EMC standards. Motors, drivers, and wiring layouts face higher requirements.

Longevity and Wear Challenges

The wiper system is used frequently. Motors perform hundreds of thousands of motions. Pumps undergo countless starts, stops, and high-pressure cycles. Common issues include brush wear, gearbox fatigue, lubricant loss, pump dry running, and seal aging. Design must balance durability, material quality, and reliability.

Miniaturization, Lightweighting, and Energy Efficiency

Space in the engine bay is tight. Miniaturization is inevitable. Smaller size creates thermal, vibration, and torque challenges. Electric and hybrid vehicles monitor energy strictly. Motors and pumps must be more efficient to save battery power.

Consistency in Cleaning and Spray Performance

Spray pressure and nozzle design decide cleaning quality. At high speeds, aerodynamic drag alters spray trajectory. Fluid may not cover the windshield effectively. The system must ensure stable pressure. Nozzles must resist clogging. Spray angles must adapt to speed and wind. It must also handle freezing and blocked lines.

Regulations, Materials, and Cost Pressure

Regions impose rules on noise, materials, and performance. Headlamp cleaning requires specific spray pressure. Materials must meet RoHS and REACH standards. Noise limits are stricter. As a mass-produced part, the system must balance cost and reliability. Supply chain stability is essential.

How TSL MOTOR Addresses the Challenges

Automotive wiper pump systems face many engineering challenges. These include environment, high load, EMC, NVH, and longevity. The design and manufacture of the gear motor are critical.

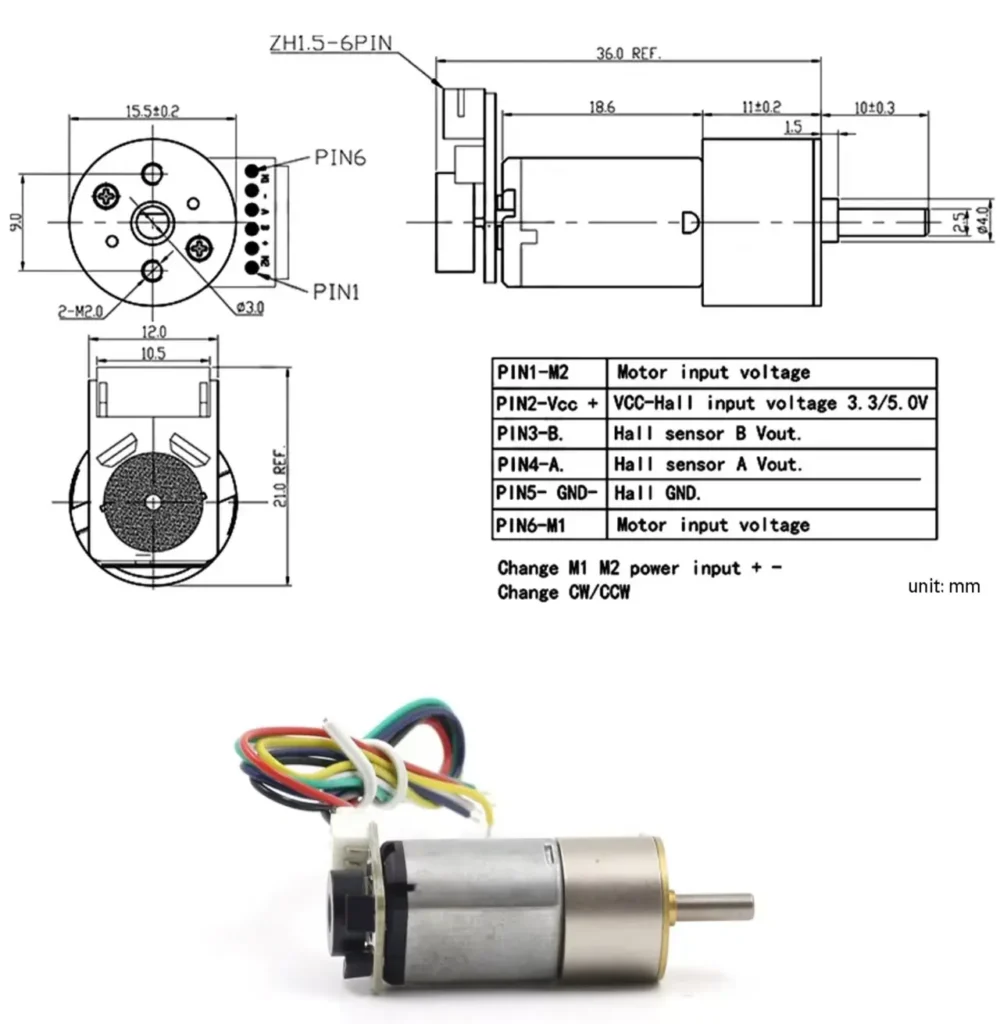

TSL MOTOR is a leading producer of miniature precision motors. We have expertise in design, materials, electrical performance, and intelligent control. Our TSL-GM16 series motors offer five core advantages.

Compact Size and High Power Density

The motor is compact and tightly designed. Diameter is only 15.5 mm. This fits tight spaces in modern automobiles. It gives manufacturers more flexibility in engine bay layout. High-energy permanent magnets and optimized winding design are used.

Efficient magnetic circuits deliver high torque density. Strong output is achieved without increasing size. This meets high starting torque needs in ice, snow, and mud.

High Reliability and Environmental Adaptability

The motor is rugged, durable, and long-lasting. It works in extreme conditions from -40°C to +85°C. TSL MOTOR uses all-metal gearboxes for wear resistance. Japanese bearings reduce friction and load. Sealed structures resist water, dust, and salt spray.

Motors undergo strict reliability tests. Tests include temperature cycling, salt spray, and endurance. Stable output is ensured under long-term high load. This reliability is vital for frequent start-stop operation.

Customized Electrical Characteristics

The motor can be customized for voltage, speed, torque, and load. Different vehicles need different flow, pressure, and response. TSL MOTOR offers custom winding parameters. We adjust magnetic circuits, speed, voltage, and stall torque.

After evaluation, we design the best performance curve. Efficiency is maximized in all modes. Modes include high-pressure spray and low-flow energy saving. Customization gives precise cleaning, lower energy use, and longer life.

Smooth Operation and Excellent NVH Performance

The motor runs smoothly with minimal vibration. Noise and vibration control are critical for comfort. TSL MOTOR uses low backlash gear design. Dynamic balancing reduces vibration at high speed. Optimized tooth profile lowers meshing noise.

Low-noise carbon brushes reduce electromagnetic noise. The motor stays quiet and smooth in all conditions. This improves cabin comfort and meets strict NVH standards.

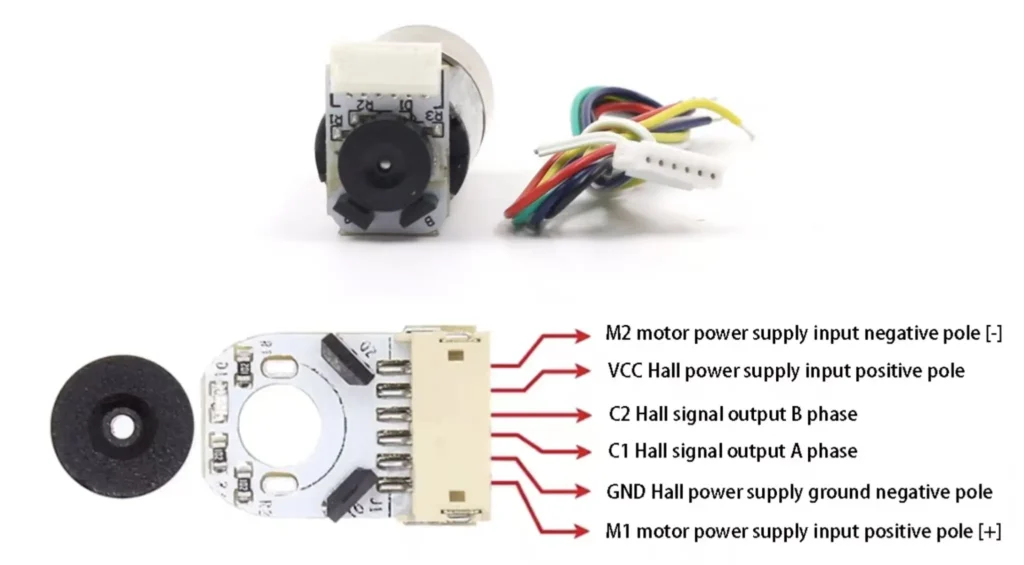

Intelligent Speed Control and Intensity Management

The motor supports voltage regulation and multi-mode operation. It is compatible with ECU, BCM, and rain sensors. Functions include PWM speed control and duty cycle control. Modes include low speed, high speed, and intermittent. Intelligent sensing mode is supported.

Input voltage or PWM duty cycle adjusts output intensity. Cleaning becomes more efficient. Energy use is reduced. Action is smoother. System response is faster. This meets future needs of EVs and smart cars.

Conclusion

The wiper cleaning system is vital for safety and comfort. It is no longer just an auxiliary device. Performance depends on reliable and precise gear motors. Challenges include extreme temperatures, humidity, frequent start-stops, high torque, EMC, and NVH. Weak motors reduce cleaning effectiveness and safety.

TSL-GM16-030 gear motors meet automotive-grade standards. They offer high power density, durability, low noise, controllability, and customization. They fit different vehicles, regions, and cleaning scenarios.

In the future, vehicles will be smarter, more efficient, and more compact.

TSL MOTOR will continue to deliver advanced wiper pump motor solutions. We provide reliable and flexible products for global manufacturers and suppliers. Our strengths are high-precision manufacturing, innovative materials, and deep expertise in miniature drive systems.

We have over 15 years of experience in motor drive technology. We customize motor solutions quickly to meet client requirements. We also provide design drawings, material selection, and sample prototyping support.

For more information on automobile wiper motor solutions, please contact our sales engineers.

FAQ

Q1: How does TSL MOTOR address harsh environmental challenges in the auto industry?

A1: It features all-metal gearboxes and reinforced sealing to withstand extreme temperatures (from -40°C to +85°C) and resist corrosion.

Q2: What measures are taken in the TSL-GM16 series for Noise, Vibration, and Harshness (NVH) control?

A2: Measures include low-backlash gear design, precision dynamic balancing, and low-noise carbon brush materials for smooth and quiet operation.

Q3: Does TSL MOTOR offer customization for this motor series?

A3: Yes, we provide specialized customization for parameters such as windings, magnetic circuits, speed, voltage, and current to perfectly match specific vehicle requirements.

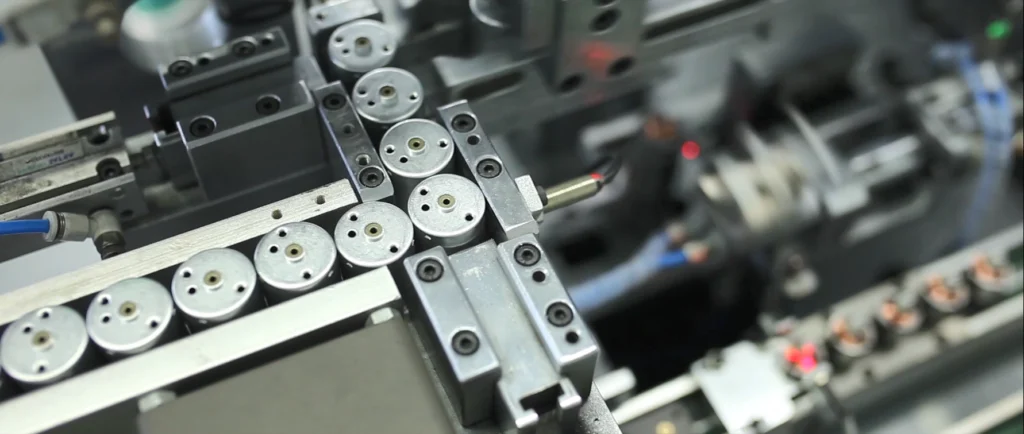

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

16mm Metal Gear Motor Model TSL-GM16-030

Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TSL-GM16-030

- Voltage:DC 3-12V/Customizable

- Shaft Diameater:3mm D2.5mm

- Shaft Length:10mm

- #More Specifications

- #Outline Drawing

♦ Typical Applications:

- Smart robots, intelligent robotic arms

- smart home, smart focusing systems

- miniature pan-tilt heads