In modern automotive engineering, the air-conditioning system is essential for driving comfort.The compressor is the core of this system.Its performance determines cooling efficiency, energy consumption, and noise.

As the power source, the motor must deliver high reliability and long life.The TSL-RS-775 DC motor is designed for these demanding requirements.It offers long life, low noise, and stable operation.Input voltage is electronically controlled.

The system supports multiple intensity modes.This meets various cooling demands and enhances system efficiency.

TSL MOTOR will introduce the technical features and advantages of the TSL-RS-775.We will explain how it improves durability, stability, and user experience.

Key Takeaways

- Application: The TSL-RS-755 is the core, long-life DC drive solution for automotive air-conditioning compressors.

- Control: Precise variable capacity control is achieved by electronically regulating the motor’s input voltage (PWM).

- Durability: Strategic use of custom carbon brushes, high-quality bearings, and robust materials ensures a 10-15 year service life.

- Noise: The motor minimizes NVH through high-precision mechanical balancing and sophisticated electromagnetic noise suppression.

- Architecture: The optimized BDC platform provides significant cost and control simplicity advantages over complex brushless systems.

- Efficiency: The design offers high power density in a compact size, optimizing energy use and packaging flexibility.

- Support: TSL MOTOR provides rapid customization services to perfectly meet unique electrical and mechanical OEM requirements.

Auto Air-conditioning Compressor Basic

The automotive A/C system is a key part of vehicle thermal management.It provides cabin comfort.

In EVs, it also stabilizes battery temperature.The compressor is the “heart” of the refrigeration cycle.It circulates refrigerant and raises its pressure.

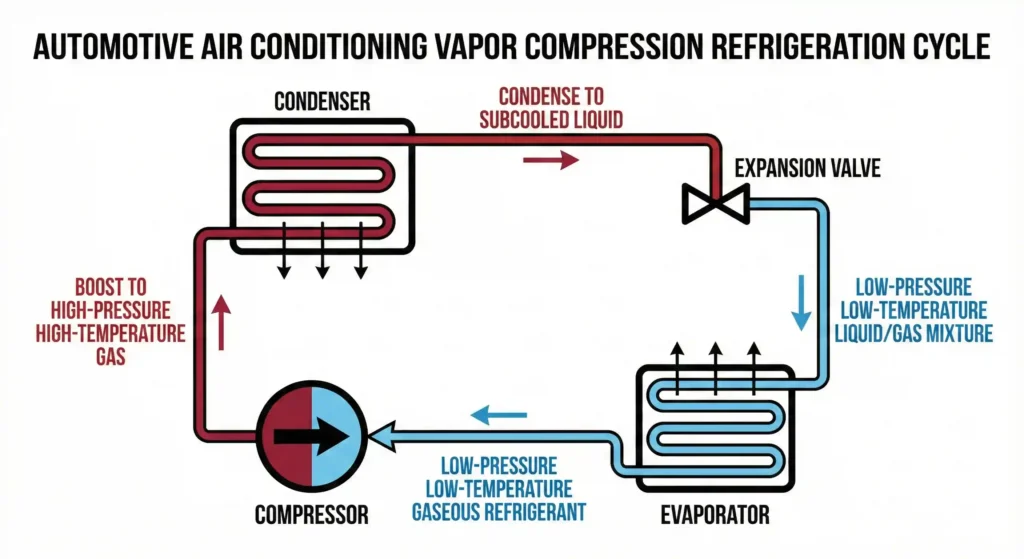

Core Refrigeration Cycle and Component Function

The system uses a vapor compression cycle. The core task is to turn low-pressure, low-temperature gas into high-pressure, high-temperature gas for heat exchange. The compressor is the only power-consuming part in this pressure-boosting process.

After the compressor discharges the hot, high-pressure gas, it goes to the condenser. The condenser releases the heat carried by the refrigerant to the external air. This turns the refrigerant vapor into a supercooled liquid.

The condenser is usually placed in front of the vehicle’s radiator. It uses the cooling fan and airflow from vehicle movement. All system components, including the motor, must be highly durable against high heat and potential corrosion for long-term stable operation.

Auto Air-condition Compressor Architecture Classification

AC compressors are mainly divided into two types: fixed displacement and variable displacement. They are also categorized by operation as reciprocating and rotary.

Capacity Control: Fixed vs. Variable Displacement

Fixed Displacement Compressors (FDC) have refrigerant output proportional to engine speed. They use clutch cycling (start/stop) or secondary throttling for basic capacity control. This often leads to low efficiency and temperature fluctuations.

Variable Displacement Compressors (VDC) automatically adjust power output based on the set temperature.

In mechanical VDCs, a control valve senses system suction pressure (AC demand). It adjusts the crankcase pressure to change the swash plate angle, thus changing displacement.

The drive source changed from the engine belt to an independent motor with the rise of Electric Vehicles (EVs). This shifted variable capacity control from complex mechanical adjustment to high-precision motor speed control.

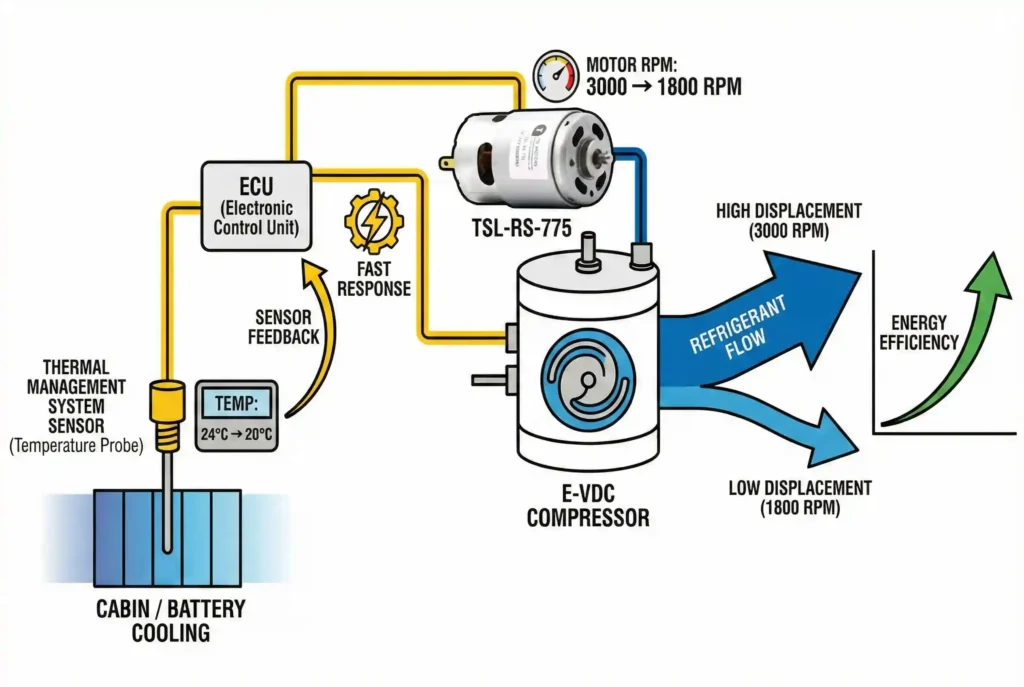

Electric VDC (E-VDC) precisely adjusts the motor RPM based on thermal management needs. This improves system response speed and energy efficiency.

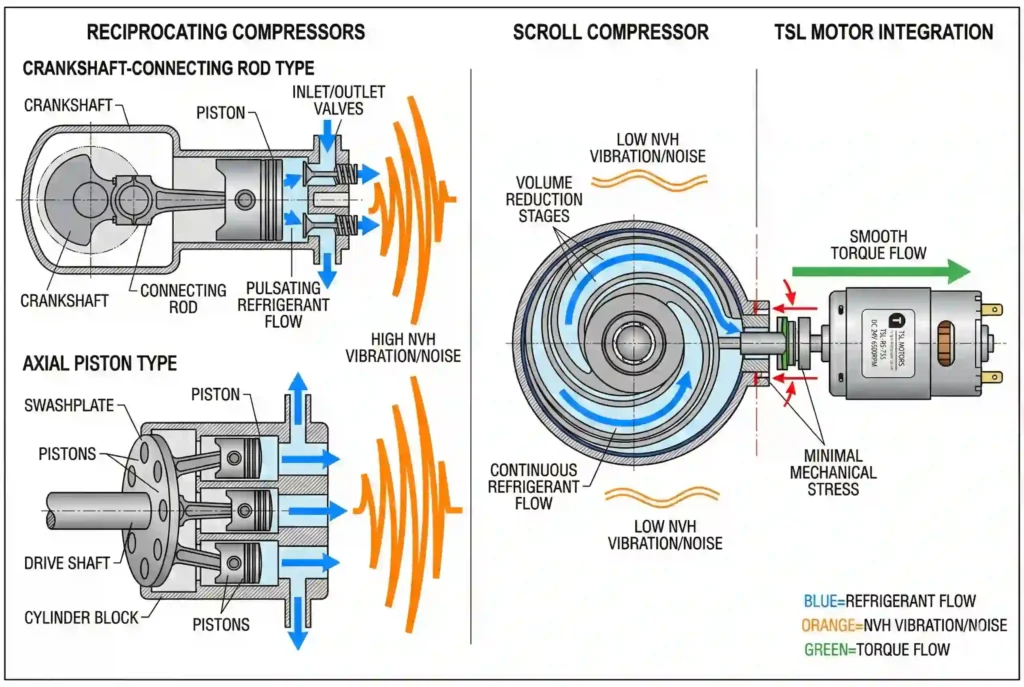

Kinematic Design: Reciprocating vs. Rotary Mechanisms

Reciprocating Types include crank-rod and axial piston designs. These inherently produce pulsed refrigerant flow and high mechanical inertia. This poses NVH (Noise, Vibration, and Harshness) challenges.

Rotary Types, especially the Scroll Compressor, are the mainstream in modern thermal management. A scroll compressor uses an orbiting scroll disk driven by a short-stroke crankshaft around a fixed disk. The refrigerant is trapped in crescent-shaped chambers.

The chamber volume shrinks as the orbiting scroll moves, compressing the refrigerant. Compressed gas exits at the center. The scroll motion is continuous and contactless. This makes the intrinsic mechanical noise significantly lower than reciprocating types.

The stable performance and long-life of the TSL MOTOR solution complement modern scroll compressor design. The smooth, continuous torque demand of a scroll compressor minimizes cyclic mechanical stress and vibration feedback on motor components (brushes, bearings). This provides a favorable environment for the DC motor’s required durability and low-noise characteristics.

Motor as the Core of Variable Capacity Control

In modern car AC systems, the motor is now crucial for precise thermal management and system efficiency. It is beyond a simple driver.

Motor Function and Control Architecture

The motor is the core power source for the compressor. Its main function is to provide torque to pressurize the refrigerant.

In an electric compressor (e-compressor), an integrated Electronic Control Unit (ECU) is involved. This ECU communicates with the vehicle’s main controller and provides precise control of motor operations.

Capacity Modulation via Speed Adjustment

Efficient capacity modulation requires flexible adjustment of refrigerant flow based on thermal load. Controlling capacity by motor speed significantly improves energy efficiency. It avoids energy loss from old throttling valves or cycling strategies. Running the compressor at a lower speed for a longer time improves the overall efficiency of an EV cooling system.

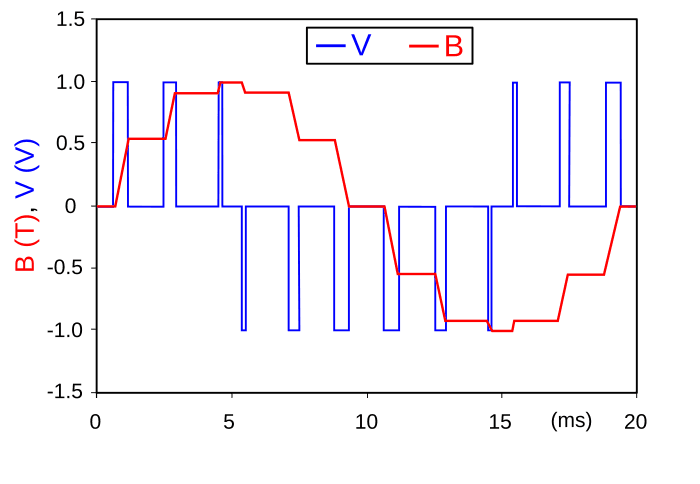

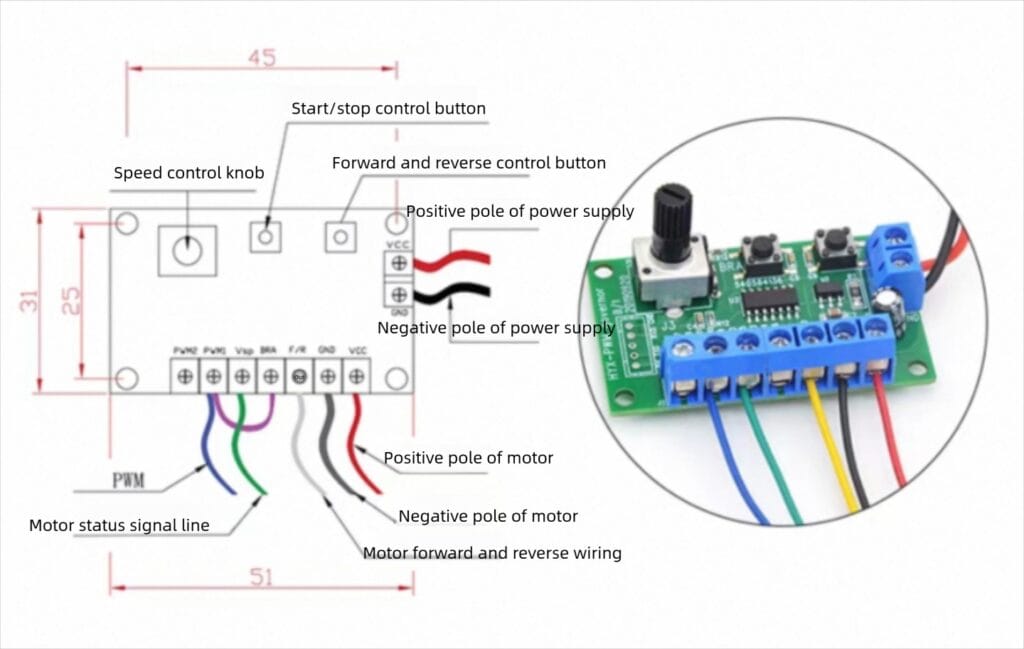

The TSL MOTOR DC motor solution (TSL-RS-775) changes motor intensity by electronically adjusting the input voltage. In a DC motor, speed (RPM) is proportional to the applied armature voltage.

Thus, adjusting the input voltage via a high-precision electronic system (Pulse Width Modulation, PWM) achieves precise, linear, and efficient control of the compressor’s output capacity.

TSL uses a Brushed DC (BDC) motor with voltage regulation. This is a cost-effective system optimization. While Brushless DC (BLDC) systems use complex inverters for the highest efficiency (EER), their electronics are more expensive and complex.

TSL’s BDC architecture only needs a high-frequency PWM driver, not a multi-stage inverter. This greatly reduces the control system’s complexity and initial cost. It makes the TSL solution a competitive choice for 12V/24V auxiliary systems or in vehicles where cost constraint is prioritized over marginal range gains.

Requirements for Stable and Dynamic Speed Control

To effectively control the refrigerant mass flow rate and ensure passenger comfort, the motor speed must be precisely controlled. This requires a motor system with stable and reliable performance.

TSL MOTOR is committed to stable performance throughout the entire operation. This means the motor’s magnetic and mechanical properties must be highly consistent across different voltages and loads.

This ensures the electronic voltage control translates into a stable, predictable RPM and torque output. TSL optimizes the motor’s magnetic circuit and winding design to ensure reliable and repeatable speed control even under dynamic load conditions.

Key Engineering Challenges for Auto AC Compressor Motors

AC compressor motors, especially those under the hood, must meet demanding performance specs while overcoming harsh environmental and durability challenges.

Meeting Noise, Vibration, and Harshness (NVH) Standards

NVH is a core challenge in car design, especially for EVs. Without the masking noise of the combustion engine, any auxiliary system noise becomes more noticeable. Tonal sounds from the AC compressor, if 7-9 dB above ambient noise, will be clearly perceived by passengers.

High-quality silent motor systems aim for below 60 dB, about the level of normal conversation. This requires a multi-layered NVH mitigation strategy:

- Source Noise Reduction: Focuses on the motor’s structural and electromagnetic optimization.

- Isolation and Attenuation: Uses specialized vibration isolators and damping pads to connect the compressor to the vehicle body.

Noise management is complex for TSL MOTOR‘s Brushed DC (BDC) motor. BDC motors inherently generate higher mechanical and electromagnetic noise due to brush friction and arcing during current commutation.

The TSL design team made significant strides with proprietary technology:

- Custom carbon brush formulation to reduce friction noise.

- Integrated precise electrical filtering to suppress high-frequency EMI and humming from sparks.

- High-precision rotor balancing to reduce mechanical vibration during operation.

These modifications ensure compliance with vehicle acoustic comfort standards.

Extended Operating Life and Durability Requirements

Car AC compressors are high-wear components. They are typically expected to match the vehicle’s 10 to 15-year service life.

Under-hood motors must be “lubricated for life.” This means all internal components, especially bearings and lubricants, must maintain performance for the vehicle’s entire service life. These components must also maintain high reliability under harsh environmental conditions: extreme temperature cycling, continuous mechanical vibration, and exposure to a mix of refrigerant and oil.

For TSL’s BDC motor, the “long life” requirement means overcoming the BDC architecture’s inherent weakness: the brush is the main mechanical wear point and often limits service life. TSL must use material engineering beyond standard practices.

This includes selecting robust carbon brush materials for long-term use, using high-quality Japanese imported bearings, and high-performance lubricants. These lubricants have high lubricity, low oil bleeding, chemical inertness, and a wide viscosity range. They damp vibration and maintain stability at extreme temperatures.

Through these optimizations, TSL makes its BDC solution comparable in life expectancy to brushless alternatives, while keeping the cost and control advantages.

Balancing Efficiency and Compact Size (High Power Density)

Modern vehicle drive systems demand extremely high power density. The motor must be compact and highly efficient for smooth operation and flexible vehicle packaging.

The TSL-RS-775 is described as a small, high-efficiency motor. This meets the automotive thermal management need for micro-motors. They must provide power and performance comparable to standard-sized motors, even with space constraints. High efficiency not only reduces battery consumption but also lowers the motor’s self-generated heat load.

To achieve high power density, TSL uses high magnetic energy product permanent magnets and optimized winding design. This ensures maximum torque output within a given volume.

TSL MOTOR’s DC Motor Solution (TSL-RS-775)

The TSL-RS-775 is a strategically engineered platform. It combines the inherent advantages of the Brushed DC (BDC) architecture with the auto industry’s demand for extreme reliability.

| Model | Voltage | No Load | At Maximum Efficiency | Stall Torque | ||||||

| Operation Range | Nomianl(CONSTANT) | Speed | Current | Speed | Current | Torque | Output | EFF | ||

| RPM | A | RPM | A | g.cm | W | % | g.cm | |||

| RS-770-7038 | 3.0-24.0 | 12.0V | 10600 | 1.50 | 9074 | 7.47 | 783 | 72.9 | 81.3 | 5500 |

| RS-770-7529 | 3.0-24.0 | 20.0V | 24500 | 2.50 | 21520 | 17.90 | 1400 | 309.0 | 84.6 | 111500 |

| RS-770-8022 | 3.0-18.0 | 12.0V | 18500 | 3.00 | 16180 | 20.50 | 1250 | 207.5 | 84.3 | 10000 |

| RS770-8025 | 3.0-24.0 | 20.0V | 28500 | 3.50 | 24580 | 21.65 | 1650 | 416.0 | 94.2 | 12000 |

| RS775-29655 | 9.0-36.0 | 24.0V | 6280 | 0.37 | 5010 | 1.87 | 600 | 30.83 | 68.7 | 3640 |

| RS775-4045 | 9.0-36.0 | 12.0V | 4600 | 0.60 | 3500 | 4.30 | 860 | 36.6 | 70.9 | 3600 |

| RS775-4548 | 6.0-36.0 | 12.0V | 4250 | 0.45 | 3664 | 2.35 | 599 | 22.39 | 79.5 | 4200 |

| RS775-6522 | 3.0-30.0 | 18.0V | 15000 | 1.50 | 13125 | 13.75 | 1250 | 168.0 | 68.0 | 10000 |

Strategic Engineering for High-Reliability BDC Platform

While brushless motors (BLDC, PMSM) dominate in high-voltage main drives and some high-efficiency auxiliary systems, BDC motors still offer significant competitive advantages: excellent low-speed torque, lower initial cost, and a minimalist control system.

TSL’s strategy is to optimize components to eliminate the typical limitations of the BDC architecture. This achieves durability and NVH performance comparable to brushless motors.

The TSL-RS-775 platform focuses on strengthening the BDC motor’s most vulnerable parts. It ensures the operating life meets automotive needs. This includes specialized design and selection for the commutation system, bearings, and lubricants. They can withstand the harsh load cycles and environmental stress required for AC compressor driving.

Engineering Design for Extreme Life

To achieve “long life,” the TSL-RS-775 platform uses advanced materials and design to manage mechanical wear and electrical degradation:

Advanced Commutation System:

Life hinges on the durability of the brush and commutator. Using custom carbon brush materials tailored for the application reduces the friction coefficient and extends brush life. TSL uses robust, custom-designed carbon brushes.

Electrical Wear Suppression:

The arcing between the brush and commutator is a noise source and the main cause of electrical erosion and degradation of the commutator surface. The TSL solution addresses this by placing electrical filtering and suppression devices at both ends of the commutator.

These components suppress high-frequency EMI and sparks. This ensures cleaner current commutation and fundamentally mitigates long-term component wear.

Robust Thermal Management:

“Stable performance during operation” relies on efficient heat dissipation and integrated thermal protection. TSL optimizes the winding and stator structure and uses high-thermal conductivity materials. This ensures the motor’s internal temperature remains within a safe range, even under maximum load, preventing degradation from overheating.

Precision Noise Mitigation Technology

To meet NVH requirements without engine noise masking, the motor must use multi-disciplinary noise reduction technologies:

Mechanical Noise Minimization:

Noise comes from mechanical imbalance and component friction. TSL minimizes source noise by using ultra-tight machining tolerances, Japanese imported high-quality bearings, and high-precision rotor dynamic balancing.

Electromagnetic and Winding Optimization:

Electromagnetic noise (especially from cogging torque) is addressed by optimizing the motor’s electromagnetic design. For example, skewed rotor slots or distributed winding designs reduce cogging torque. This ensures smooth, uniform torque output and avoids perceptible magnetic noise.

System-Level NVH Integration:

The physical design of the TSL-RS-775 considers system-level noise reduction. The motor interface is designed to be compatible with vibration isolation pads and elastic mounts. This structure effectively suppresses the transmission of mechanical vibration to the outside.

Variable Intensity Control via Electronic System

TSL MOTOR’s solution of adjusting input voltage electronically offers a cost-effective and precise variable capacity drive for car AC systems.

Detailed Mechanism of Voltage Control for Motor Speed Regulation

The TSL solution uses the linear relationship between DC motor speed and applied armature voltage. By using a PWM driver to dynamically adjust the DC voltage, the compressor speed can be precisely fine-tuned.

Since compressor capacity is directly dependent on speed, this voltage modulation achieves stepless, precise control over the cooling output intensity.

The advantage of voltage control is that it significantly simplifies the drive electronics structure. It reduces the overall complexity and manufacturing cost compared to the complex Variable Frequency Drive (VFD) required for BLDC motors. This control simplicity also streamlines communication and integration with the vehicle’s upper-level controller.

Stable Performance Across a Wide Operating Range

The compressor must operate stably across the entire capacity range, from low intensity (maintaining temperature) to maximum intensity (rapid cooling).

The TSL-RS-775 motor exhibits stable performance during operation. This stability results from a customized DC motor design. It ensures the motor’s mechanical (speed, torque) and electromagnetic characteristics remain highly consistent across different voltage inputs.

To maintain stability at low speeds and avoid pressure pulsation, the motor must be optimized to minimize armature current ripple.

TSL uses comprehensive testing and validation protocols to ensure its motors provide smooth, reliable torque throughout the entire operation envelope. This guarantees continuous and comfortable AC system operation.

Customization as a Performance Accelerator and Supply Chain Value

In the competitive automotive industry, suppliers must offer components that perfectly match specific functions, costs, and platform flexibility. The Design-to-Value (DtV) concept requires that motor parameters be customized for specific cooling cycle needs.

TSL MOTOR, with over 15 years of motor drive solution experience, can quickly customize motor solutions to meet customer requirements. This ability makes TSL a key strategic partner:

- Electrical Performance Customization: TSL can customize voltage and speed based on customer needs. This includes optimizing the input voltage range, rated speed curve, and current consumption.

- Mechanical Integration Customization: TSL provides customization services for drawings, material selection, and prototyping. By customizing shaft geometry, mounting interfaces, and housing dimensions, TSL ensures the motor is perfectly compatible with the specific compressor mechanism and vehicle packaging constraints.

- Material and NVH Customization: Customization extends to core component selection, such as bearing type, brush compound, and sealing method. These choices directly determine the motor’s acoustic output and service life under specific loads.

TSL’s quick customization ability is key to supporting OEM DtV strategies. By precisely tuning parameters, TSL ensures the motor meets specific application needs while optimizing cost, avoiding overly complex or unnecessary components.

This proactive engineering support significantly reduces risks and time-to-market associated with parts procurement. It is a critical factor in managing the cost structure of high-volume automotive supply chains.

Conclusion and Strategic Partnership Summary

TSL MOTOR’s TSL-RS-775 DC drive solution is a strategically optimized platform. It combines the cost-effectiveness and control simplicity of the brushed DC architecture with the strict NVH and long-life requirements of modern car thermal management systems.

This achievement results from TSL’s expertise in: special material selection, high-precision mechanical balancing, and targeted electromagnetic and electronic noise reduction technologies.

These measures collectively ensure the motor has the high durability, high stability, and ultra-low noise operation required for automotive applications. The electronic control of motor intensity via voltage regulation provides a cost-optimized and efficient means of variable capacity control. It is suitable for a wide range of car and commercial vehicle thermal management systems.

We encourage R&D teams and thermal system architects from car OEMs and Tier 1 suppliers to contact TSL MOTOR sales engineers directly.

Through TSL MOTOR’s quick customization service, customers can get fast design evaluation, custom motor configuration, drawings, material selection, and prototyping. This ensures the motor solution fully meets their unique performance and integration requirements.

FAQ

Q1. What is the primary application of the TSL-RS-755 motor?

It is designed specifically for the Automotive Air-Conditioning Compressor as the core power source.

Q2. How does the motor achieve variable capacity (cooling intensity) control?

By using an electronic system to regulate the input voltage (PWM), precisely controlling motor speed.

Q3. What motor architecture does the TSL-RS-755 utilize?

It uses a Brushed DC (BDC) architecture optimized for high reliability.

Q4. How does TSL ensure the long life and durability of its BDC motor?

By using custom carbon brush formulations, imported high-quality bearings, and high-performance lubricants.

Q5. How can automakers collaborate with TSL for a customized solution?

By contacting TSL engineers for electrical performance, mechanical integration, and material customization services.

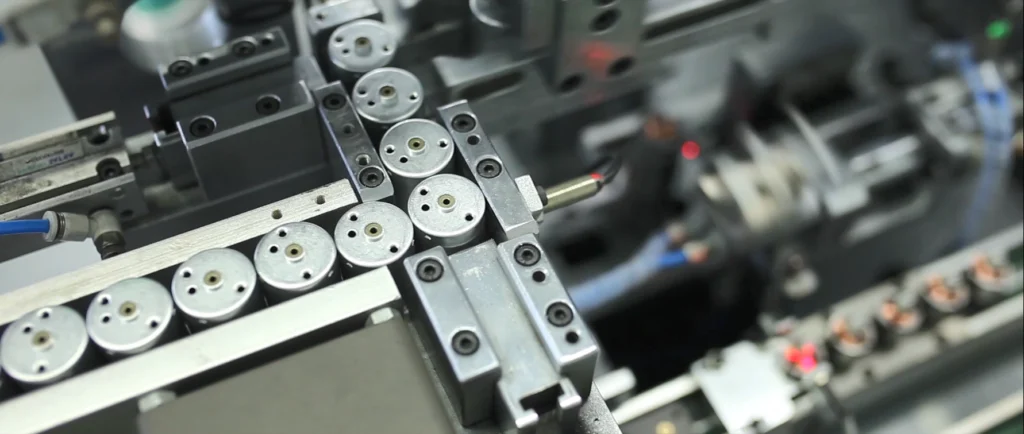

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

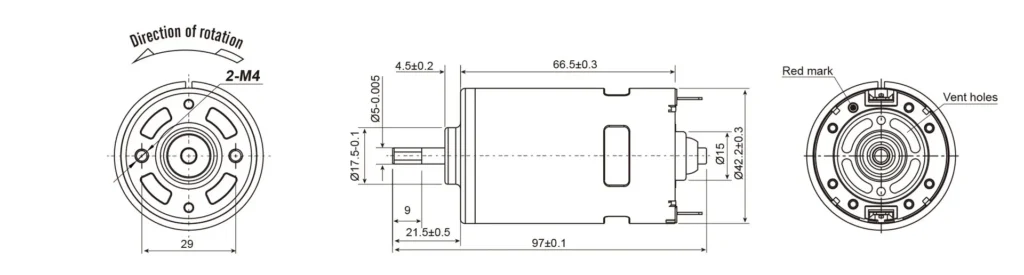

44mm Brushed DC Motor – 66mm Type Model TSL-RS-770/775

♦ Basic Info:

- Brand:TSL

- Origin:China

- Motor Model:TSL-RS-770/775

- #More Specifications

♦ Typical Applications:

Automotive Parts/Valves and Meters/blender machine/coffee machine/Vehicle seat/washing machine