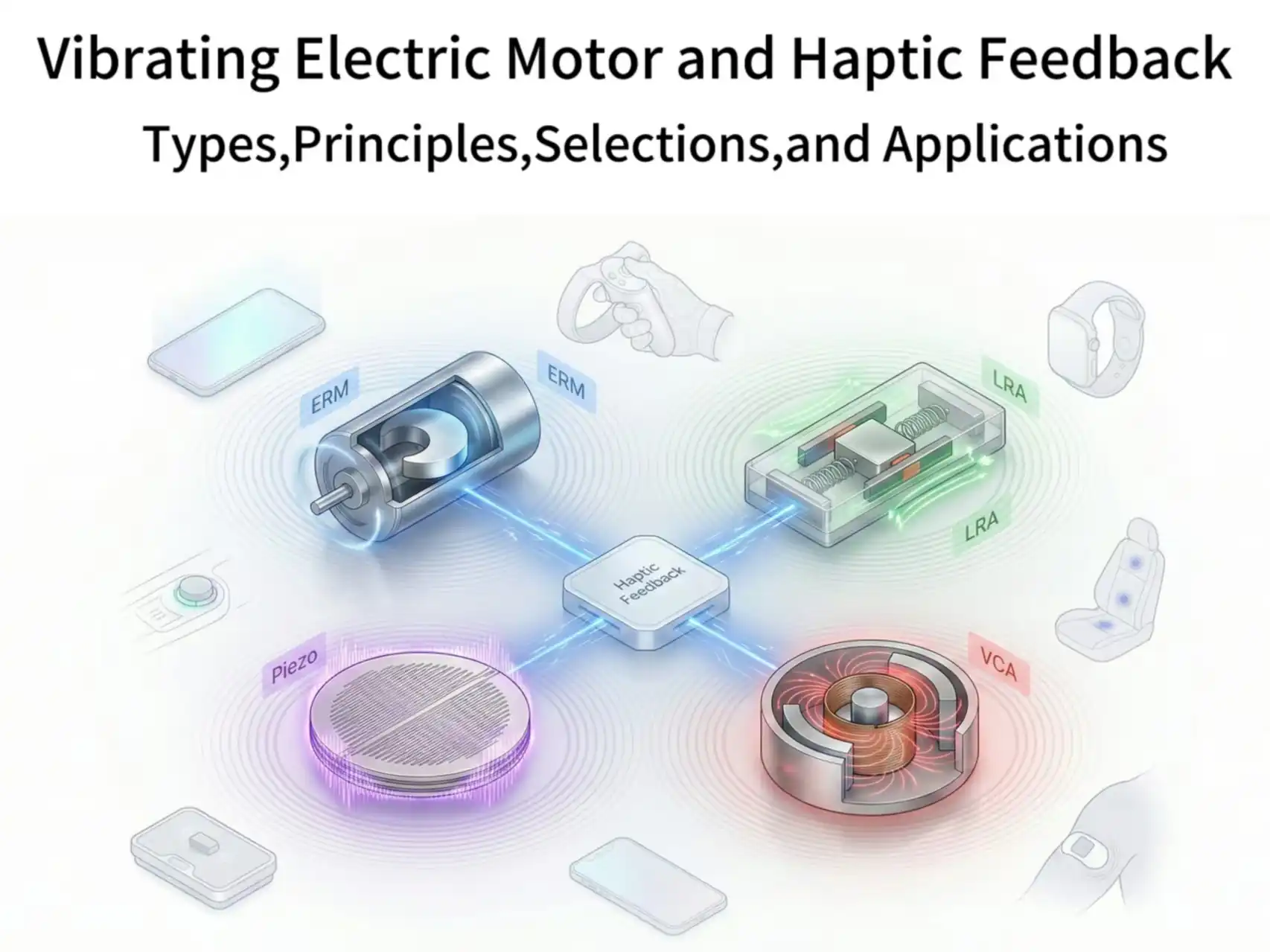

In Human-Machine Interface(HMI), vision and hearing dominate. Touch (Haptics) is rising as the most direct channel. Breakthroughs in vibrating motors drive this revival. Haptic Actuators evolved from silent alerts to key bridges between digital and human perception.

This report reviews ERM, LRA, Piezoelectric Actuators, and Voice Coil Actuators. We explore applications in consumer electronics, automotive safety, medical robotics, and VR. With 15+ years of experience, TSL MOTOR provides selection advice and market insights.

Key Takeaways

- Core Technology Types Vibrating motors are mainly ERM and LRA, with Piezo and VCA used for precision control.

- ERM vs. LRA ERM motors are low-cost and simple to drive but slower in response. LRA motors deliver faster, crisper haptic feedback, common in premium devices.

- Lifespan & Reliability Brushless ERM motors provide long life and high reliability. Brushed motors wear quickly and are unsuitable for frequent or prolonged use.

- Space-Constrained Design Coin or pancake motors save thickness space, making them ideal for ultra-thin wearables, though vibration strength is weaker.

- Precision Control Piezo and VCA actuators offer ultra-fast response and high resolution, suitable for complex haptic waveform simulation.

- Automotive Requirements Automotive vibration feedback must be reliable, temperature-resistant, and fast. LRA motors are widely used in seat alerts and haptic dashboards.

- Selection Metrics Engineers must evaluate voltage, G-force, RPM, power, size, lifespan, and noise. There is no universal best motor—only the right fit for each application.

Vibrating Electric Motor Basic

What Are Vibrating Electric Motors?

A Vibrating Electric Motor, also known as a vibration motor or Haptic Actuator, is a specialized motor designed to generate mechanical vibration. It converts electrical energy into periodic mechanical motion, typically by using an eccentric mass on the rotor or other specific vibration mechanisms.

How Vibrating Electric Motors Work?

The core function of a vibrating motor is to convert electrical energy into periodic mechanical vibration. Different motor types employ distinct physical mechanisms:

ERM Vibration Motor

Core Principle: Imbalance = Vibration.

The ERM motor is a DC motor characterized by an eccentric mass fixed to the rotor shaft.

The asymmetric mass distribution generates continuous centrifugal force when rotating. This force causes the motor and its mounted device to vibrate.

Operating Process:

- Power On: DC current enters the stator coils, generating a magnetic field.

- Rotor Rotation: The magnetic field drives the rotor and shaft to spin at high speed.

- Centrifugal Force: The off-center mass generates a centrifugal force that constantly changes direction.

- Vibration: This force transfers to the motor casing and then to the device, creating periodic vibration.

LRA (Linear Resonant Actuator)

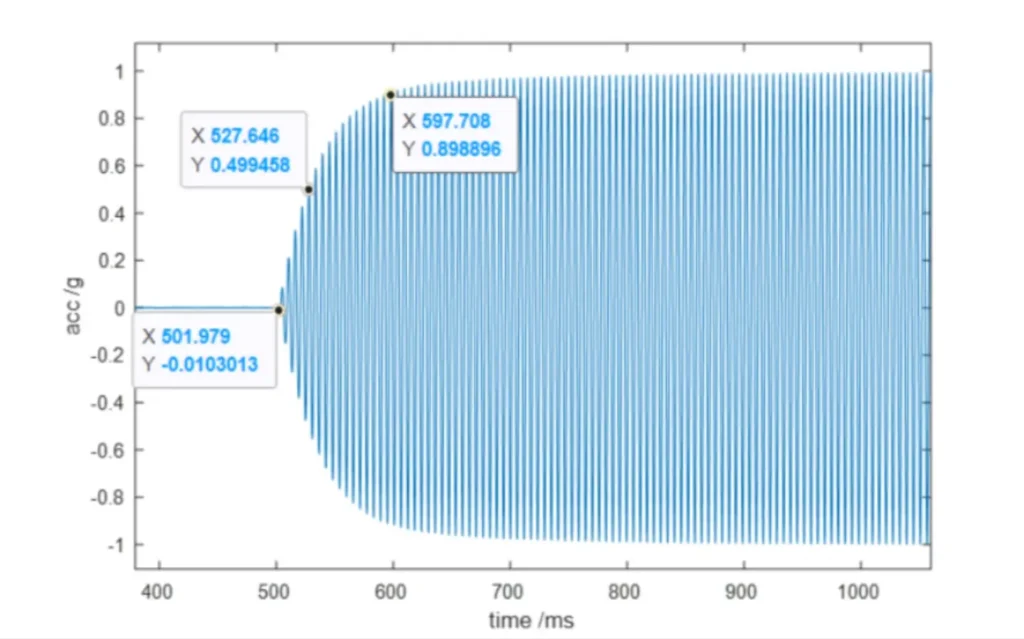

The LRA is a vibrating motor that generates precise haptic feedback. It oscillates back and forth at a resonant frequency using a spring-mass system. Unlike traditional ERM motors, the LRA relies on linear, non-rotational vibration.

Driving Process:

- AC Drive: AC current passing through the coil generates an alternating magnetic field.

- Magnetic Interaction: The alternating field interacts with the permanent magnet’s field. This pushes the magnet to oscillate along a single axis.

- Resonance Effect: When the drive frequency matches the system’s natural resonant frequency, the amplitude is maximized, achieving peak efficiency.

- Haptic Feedback: This linear vibration transfers through the casing, delivering clear and rapid haptic feedback.

Piezoelectric Actuator

Piezoelectric Actuator:When an electric field is applied across a piezoelectric material (e.g., ceramic or crystal), the material undergoes a minute mechanical deformation (expansion or contraction).

This deformation is directly converted into displacement or vibration. It drives external structures or creates haptic feedback.

Conversely, the material generates an electric charge when subjected to mechanical stress. Thus, it can function as both an actuator and a sensor.

Driving Process:

- Voltage is applied across the piezoelectric material.

- The material produces a tiny but rapid expansion or bending.

- This deformation is either amplified or directly transmitted to the device, achieving displacement or vibration.

Voice Coil Actuator (VCA)

The VCA is a precision drive component based on the principle of electromagnetic induction. It operates similarly to a loudspeaker. It generates straight-line motion or vibration through the interaction between a coil and a permanent magnet. Unlike rotary motors, VCA directly achieves single-axis linear displacement, making it widely used in haptics and precision control.

Driving Process:

- When current passes through the coil, a Lorentz Force is generated between the coil and the magnet.

- This force pushes the coil or magnet to move linearly along a single axis.

- Current direction determines the motion direction. Current magnitude determines the displacement or vibration intensity.

Vibrating Electric Motor Types

Vibrating motors can be categorized into four types based on their core drive mechanism: Voice Coil Actuator (VCA), Piezo Actuator, Linear Resonant Actuator (LRA), and Eccentric Rotating Mass Motor (ERM).

They rely on different physics principles to generate periodic vibration. Each offers distinct advantages in response speed, energy efficiency, frequency characteristics, and haptic performance.

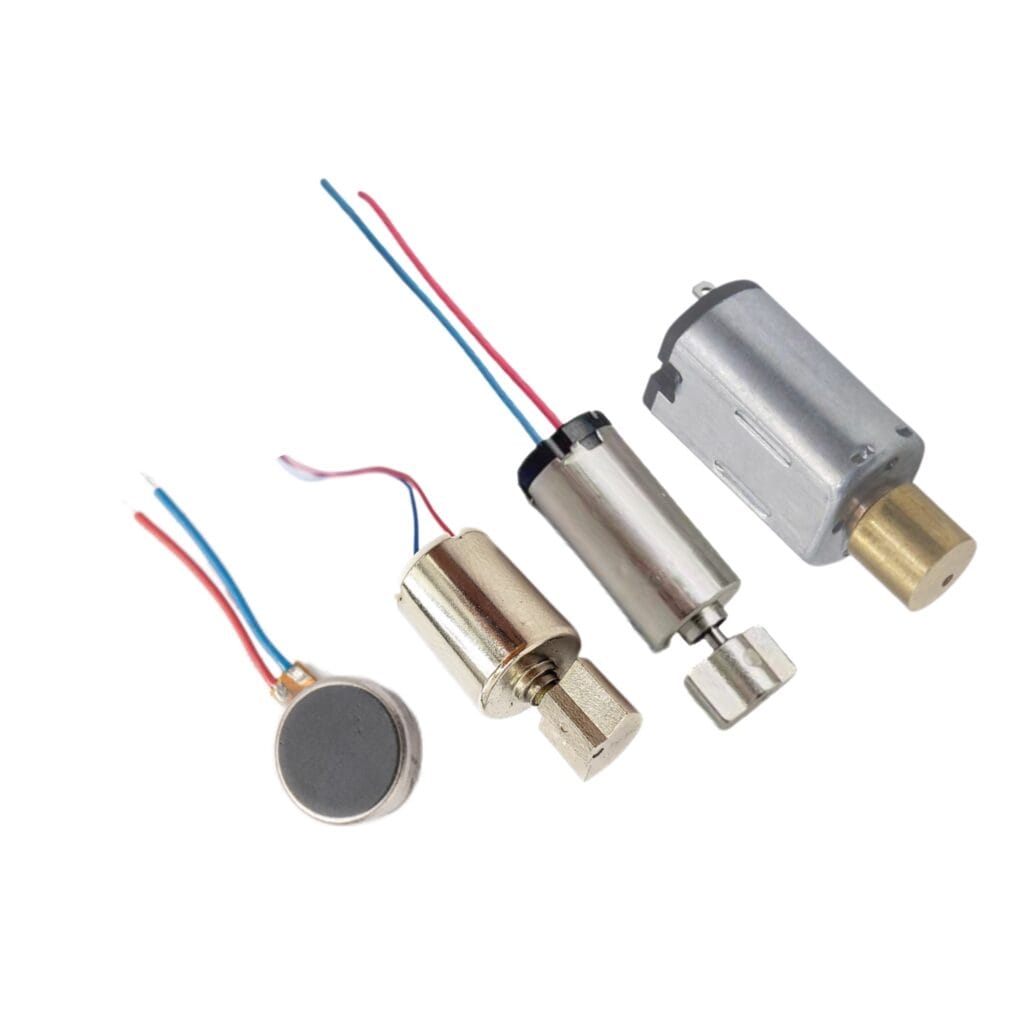

The ERM vibrating electric motor, as the most common type, is further subdivided into: brushed, brushless, SMD, coreless/cylindrical, coin/pancake, encapsulated, and sonic vibration motors.

Precision/Controllable Vibrating Electric Motors

These motors are typically used in scenarios requiring high precision, fast response, or specific waveform control. Examples include haptic feedback, optical focusing, and active vibration cancellation.

Voice Coil Actuator (VCA)

Key features: Linear motion, continuous, high response speed.Displacement is proportional to input current.Theoretically infinite resolution.Precise control of position, speed, and force.

Advantages: Very fast response (milliseconds), high precision, long lifetime (no contact wear).

Disadvantages: Needs closed-loop sensors (grating, magnetic scale) for accuracy. High cost. No self-locking.

Applications: High-end haptics (force feedback wheels, VR controllers), optical positioning, vibration tables, hard disk head drives.

Piezoelectric Actuator

Key features: Nanometer resolution, high output force, high stiffness, ultra-fast response (microseconds).

Advantages: Extremely high resolution, strong output force, fastest response, no electromagnetic interference.

Disadvantages: Very small travel (less than 0.1% of size). Shows hysteresis and creep. Needs high voltage (tens to hundreds of volts). High cost.

Applications: Nano-positioning platforms, precision optics adjustment, inkjet printer heads, active vibration control, ultrasonic motors.

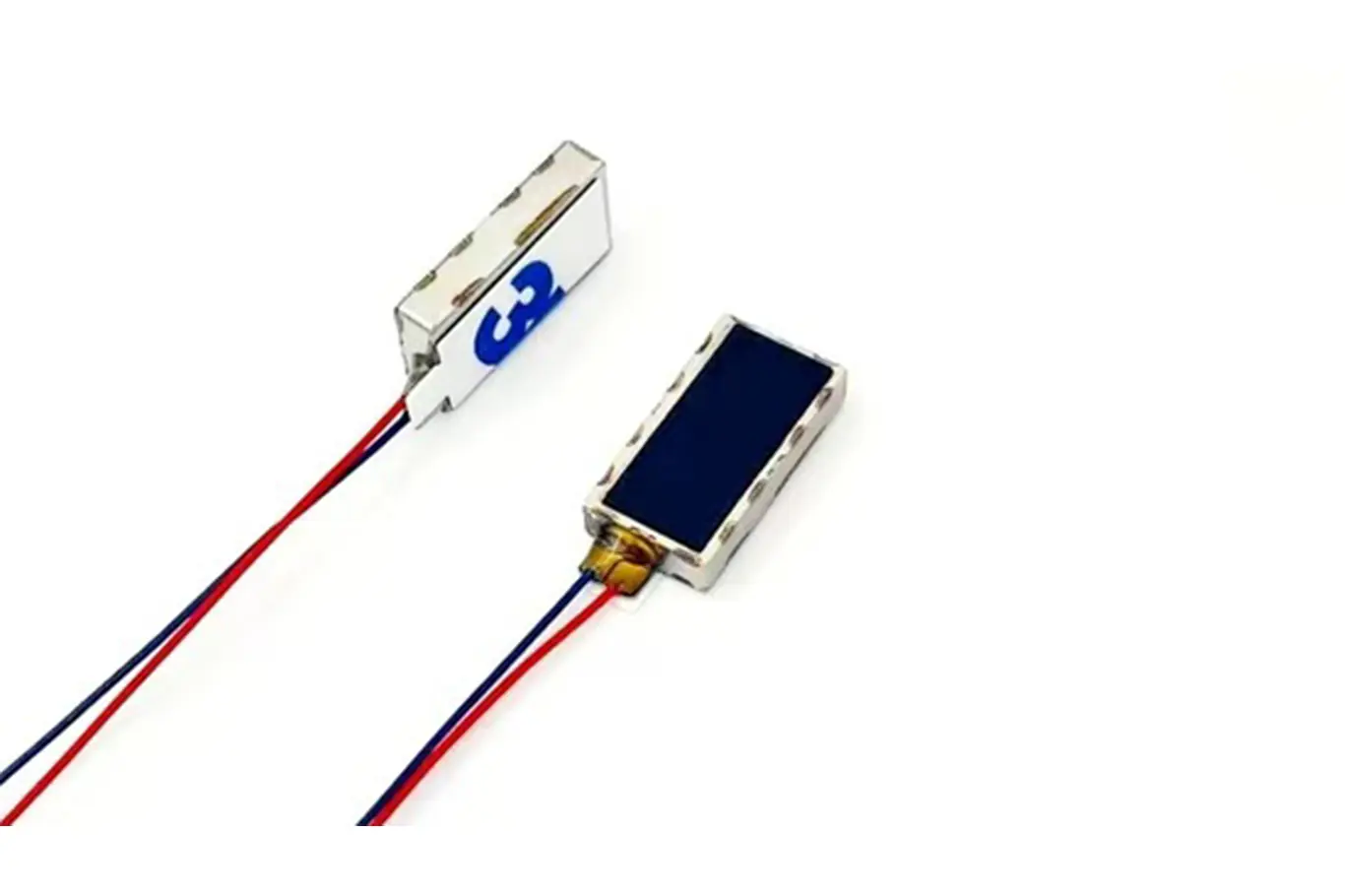

Linear Resonant Actuator (LRA)

Key features: Operates at narrow resonance band. Highest efficiency and amplitude at resonance.

Advantages: Fast start and stop (slower than VCA). Low energy use at resonance. Cleaner, crisper feel than ERM.

Disadvantages: Frequency fixed by structure. Narrow bandwidth. Amplitude sensitive to frequency changes.

Applications: Smartphones, smartwatches for haptic feedback. Provides finer vibration than ERM.

Eccentric Rotating Mass Vibrating Electric Motor (ERM)

The ERM motor is the most classic and widely applied type.All variants are based on this mechanism, differing only in motor form, structural design, and packaging.

Brushed ERM Motor

Working principle: Traditional DC brushed motor + eccentric weight. Carbon brushes and commutator supply power to rotor coils.

Features: Simple structure, lowest cost, easy to drive with DC voltage.

Advantages :High low-speed torque, stable and controllable vibration.

Disadvantages: Brush wear, shorter lifetime, electrical noise, electromagnetic interference.

Applications:Small vibrating feeders, handheld vibrating tools, low-cost screening equipment.

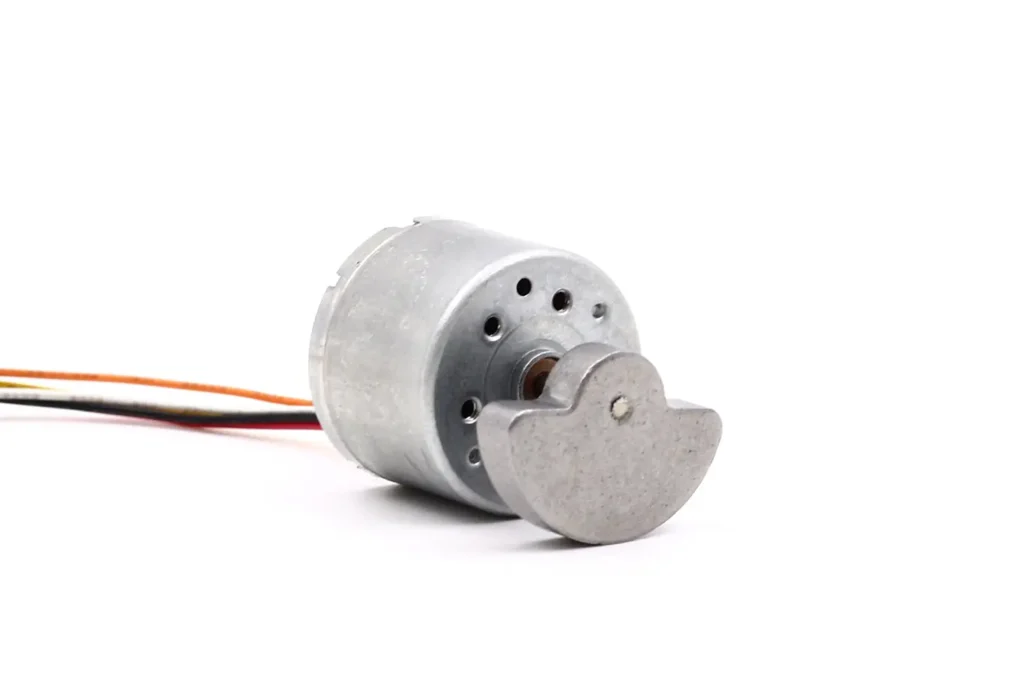

Brushless ERM Motor

Working principle: Uses BLDC technology with electronic commutation.

Features: Very long lifetime (no wear parts), higher efficiency, quieter operation, high reliability.

Disadvantages: Needs complex drive circuits (three-phase driver). Higher cost than brushed motors.

Applications: Products requiring long life and high reliability, such as automotive electronics and high-end power tools.

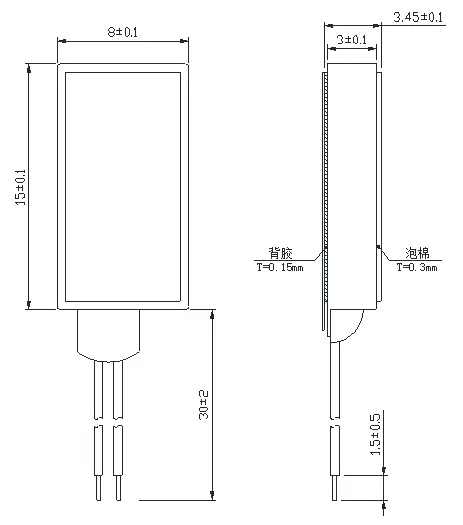

SMD ERM Motor

Features: Designed for Surface Mount Technology (SMT). Flat housing with solder pads. Supports automated PCB assembly.

Applications: Mass production consumer electronics, such as TWS earbuds and ultra-thin smartphones.

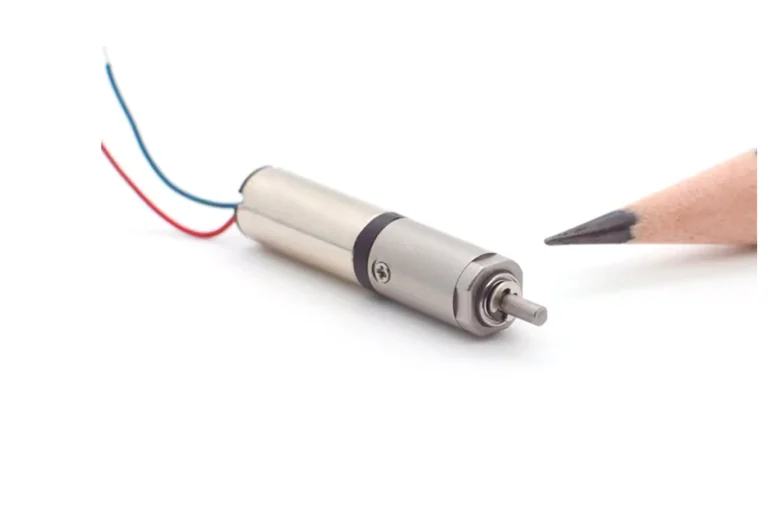

Coreless / Cylindrical ERM Motor

Working principle: Rotor uses ironless “coreless cup” coil winding.

Features: Very low inertia, ultra-fast response (10–20 ms start/stop), high efficiency, smooth operation.

Applications: Devices requiring fast response, such as high-end game controllers and medical instruments (e.g., insulin pumps).

Encapsulated Vibration Motor

Features: Entire ERM motor sealed with epoxy resin or metal shell.

Advantages: Waterproof, dustproof, corrosion-resistant. Provides mechanical protection and insulation.

Applications: Outdoor devices, wearables, products exposed to moisture or harsh environments.

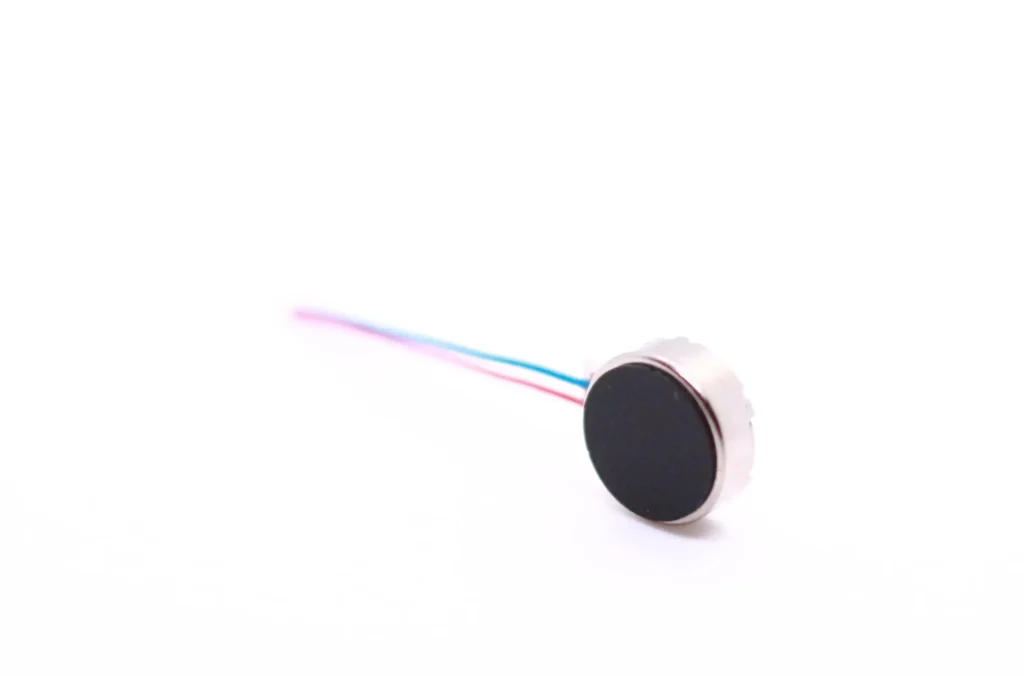

Coin / Pancake Vibration Motor

Structure: Flat design. Eccentric weight rotates in a plane. Diameter larger than thickness.

Advantages: Saves thickness space. Ideal for ultra-thin devices.

Disadvantages: Weaker vibration compared to cylindrical motors of same diameter.

Applications: Smartphones, smart cards, ultra-thin wearables.

Sonic Vibration Motor

Disadvantages: Weaker vibration strength. Faster mechanical wear. Lower lifetime and efficiency than low-speed ERM.

Working principle: High RPM (>15,000) generates high-frequency vibration (>250 Hz).

Advantages: Produces light, delicate “buzz-like” haptic feel.

Benefits of Vibrating Electric Motors

Small size + strong force

Vibration motors are very compact, often just a few millimeters to a few centimeters.

Despite their size, they deliver enough vibration force for practical use. This makes them ideal for space‑constrained devices such as smartwatches, earbuds, and medical patches.

The combination of small footprint and strong output is perfect for ultra‑thin electronics.

Low cost

The design is simple, manufacturing is mature, and supply chains are stable. Brushed ERM motors are especially inexpensive, making them suitable for mass‑market consumer products. Cost advantages drive adoption in toys, entry‑level electronics, and disposable devices.

Simple driving requirements

Most vibration motors run directly from a DC power source. No complex control is needed. Vibration strength can be adjusted easily with PWM signals. This lowers development barriers and shortens design cycles for engineers.

Fast response speed

Types such as LRA and coreless ERM can start and stop within milliseconds. Fast response ensures crisp haptic feedback and improves user experience. This is critical in game controllers and VR devices where timing must match user actions.

High reliability

Brushless and encapsulated designs can last tens of thousands of hours. Encapsulation also provides water, dust, and sweat protection, making them suitable for harsh environments. Reliability is a key requirement in medical and industrial applications.

Low power consumption

Coin motors and piezo actuators consume very little power. This makes them ideal for battery‑powered devices. Efficient designs extend the runtime of wearables and mobile products. In IoT devices, low‑power vibration motors are essential for long‑term operation.

Applications of Vibrating Electric Motors

Vibrating motors are used in a vast range of applications. Different sectors have varied requirements for vibration intensity, frequency, lifespan, and noise. Here is an in-depth look at four major application categories:

Consumer Electronics & Wearables

Typical Devices: Smartphones, smartwatches, VR/AR controllers, gamepads, fitness trackers.

Design Considerations:

- Space Constraint: Devices are often very thin, necessitating Coin Motors, SMD Motors, or LRA.

- Haptic Experience: Vibration must be clear but not jarring, emphasizing a “click” feel rather than a strong shake.

- Power Control: Battery-powered devices must select low-power models to ensure battery life.

Case Studies:

- iPhone’s Taptic Engine uses LRA for precise haptic feedback.

- Some phones use ultra-thin Coin Motors for silent alerts.

Health & Beauty Devices

Typical Devices: Facial massagers, handheld therapy devices, muscle stimulators, portable massage guns.

Design Considerations:

- Vibration Intensity: Directly impacts user experience. Massage guns need strong vibration; facial beauty devices require soft, high-frequency vibration.

- Noise Control: Beauty and medical equipment must be quiet for user comfort.

- Reliability: Devices may run for long periods. Long-lifespan brushless motors or Sonic Motors are required.

Case Studies:

- Sonic facial brush uses a Sonic Motor for high-frequency, delicate vibration.

- Portable massage guns use high-power cylindrical ERM Motors for strong muscle stimulation.

Industrial Applications

Typical Devices: Material feeders, concrete vibrators, industrial shakers, small vibration platforms, precision dosing systems.

Design Considerations:

- High Strength & Long Life: Industrial equipment often runs continuously. Brushless ERM or high-power motors are essential.

- Environmental Adaptability: Equipment may operate in dusty, damp, or high-temperature environments. Encapsulated motors are required.

- Power/Size Matching: Feeders need high-power motors; precision dosing systems require small but stable vibration sources.

Case Studies:

- Concrete vibrating rods use high-power ERM Motors on construction sites.

- Precision feeders in the pharmaceutical industry use Encapsulated ERM Motors to ensure reliability and hygiene.

Automotive Applications

Typical Devices: Feedback buttons, haptic dashboards, seat vibration alerts.

Design Considerations:

- Safety: Haptic feedback must be clear and reliable, used for driver assistance and warnings.

- Environmental Resilience: Car interior temperatures fluctuate widely. Motors need high-temperature resistance and anti-vibration performance.

- Low Noise & Fast Response: Driving environments require quiet operation. Vibration must start and stop quickly.

Case Studies:

- High-end car seat safety alert systems use LRA Motors for precise haptic warnings.

- Haptic dashboard buttons use Coin Motors to simulate the feel of physical button clicks.

Key Specifications and Selection Guidelines for Vibrating Electric Motors

In real-world projects, motor selection involves far more than simply asking “Can it vibrate?”. Engineers must evaluate electrical parameters, mechanical structure, lifespan, and application environment. The following specifications and practical guidelines form the basis of reliable design decisions:

Rated Voltage / Operating Voltage

Common values: 3V, 3.7V, 5V, 12V.

Higher voltage → stronger vibration output, but also higher power consumption and stricter drive requirements.

For battery-powered devices, voltage must balance performance with battery life.

Vibration Force / Acceleration (G-force)

Determines perceived vibration strength.

Expressed in G.

In wearables, excessive force reduces comfort; in industrial feeders, insufficient force fails to meet process needs.

Speed (RPM)

Higher RPM → greater centrifugal force → stronger vibration.

But high speed increases noise and mechanical wear.

Engineers must balance performance with reliability.

Current and Power Consumption

Critical for battery-powered products.

Excessive current draw shortens battery life.

Engineers budget power consumption to prevent the motor from becoming the system’s “power hog.”

Motor Size and Mounting Method

Coin vs. cylindrical designs affect device thickness and layout.

Mounting options: SMT, wire soldering, or mounting holes.

SMD or Coin Motors suit ultra-thin devices; cylindrical motors are common in industrial equipment.

Lifespan and Reliability

Medical and industrial products require long-lifespan designs, such as brushless motors.

Brushed motors are cheaper but wear quickly, unsuitable for frequent start/stop or long operation.

MTBF (Mean Time Between Failures) data guides selection.

Noise and Vibration Smoothness

In precision devices (massagers, wearables), noise and jerkiness directly affect user experience.

Smooth, low-noise vibration requires high manufacturing precision and optimized motor structure.

Practical Selection Guidelines

Based on these specifications, engineers typically follow these rules of thumb:

- Strong Vibration → Choose High RPM + Large Eccentric Mass. Best for massage guns and industrial feeders requiring high force.

- Ultra-Long Lifespan → Choose Brushless Vibration Motor. Lifespan up to tens of thousands of hours. Ideal for medical equipment and industrial tools.

- Advanced Haptic Feedback → Choose LRA Vibrator. Clear vibration, fast response. Common in smartphones and VR/AR controllers.

- Low Cost & Fast Integration → Choose ERM Cylindrical Motor. Simple structure, mature supply chain. Suitable for standard consumer electronics.

- Extremely Small Space / Lightweight → Choose Coin/Pancake Vibration Motor. Thickness only 2–5 mm. Ideal for smartwatches and ultra-thin wearables.

Beyond standard models, TSL MOTOR offers one-stop customization. Parameters such as eccentric mass weight, output voltage, wire length, and connector type can be tailored to specific applications. This ensures engineers achieve the optimal match between performance, reliability, and design constraints.

Conclusion

Vibrating electric motors, as the core drive components for haptic feedback, are playing an increasingly vital role. This spans consumer electronics, industrial, medical, and automotive sectors. Different motor types offer unique advantages in structure, performance, and application. Engineers must balance intensity, lifespan, power consumption, and space constraints during selection.

With over 15 years of industry experience, TSL MOTOR provides not only standardized ERM and LRA products. We also offer customization for eccentric mass, output voltage, wire length, and connector solutions. This helps you create the best haptic solution.

✅ If you are looking for reliable, efficient, and customizable vibrating motors and haptic feedback solutions, TSL MOTOR is your trustworthy one-stop partner.

FAQ

Q1:What is the main difference between an ERM and an LRA motor?

ERM motors use a rotating eccentric mass to create vibration, offering low cost and easy driving. LRA motors use linear oscillation at a resonant frequency, providing crisper, faster, and more precise haptic feedback.

Q2:Why do smartphones and smartwatches often use LRA instead of ERM?

LRA motors offer faster start/stop times and a cleaner, more defined vibration experience, which is essential for high-quality tactile feedback in modern mobile and wearable devices.

Q3:What is a Piezo Actuator and where is it typically used?

A Piezo Actuator converts electrical voltage into mechanical deformation. It is used in applications requiring the highest precision and speed, such as nanometer-level positioning and high-resolution haptic surfaces, due to its microscopic stroke.

Q4:Which motor type is best for applications requiring a long lifespan and high reliability?

The Brushless ERM Motor is the best choice. It has no carbon brushes to wear out, resulting in an extremely long service life and high reliability, suitable for automotive and medical devices.

Vibration Motors

TSL MOTORS designs and manufactures a wide range of high-quality, and cost-effective vibration motors. If you request high-quality micro vibration motors, this is the right place, the quality is guaranteed, and we can provide specifications, datasheets, test reports, performance, and related certifications. Various connection interfaces to choose from. All types of vibration motors can be highly customized for applications. Please contact us freely for samples and detailed quotations.