In the world of precision mechanics, every millimeter matters.

How to deliver high torque within extremely limited space—while maintaining high efficiency and long-term reliability—often determines whether a product can truly stand out in the market.

This is exactly where custom micro planetary gearboxes create value.

They are not compromises based on standard components, but core power solutions engineered specifically for your application.

With years of deep experience in micro planetary gearbox design and manufacturing, we provide complete customization services—from concept design and engineering validation to mass production.

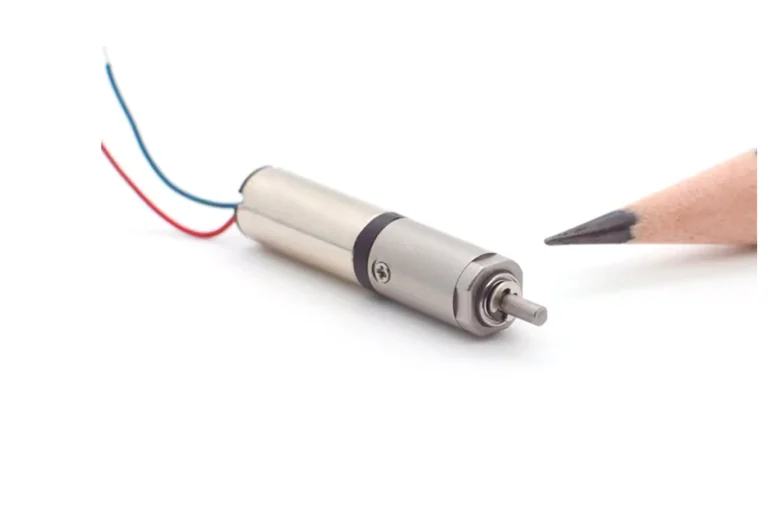

Our product diameters range from 6mm to 52mm, and are widely used in robotics, medical devices, automation systems, and high-precision instruments, helping customers achieve smaller, stronger, and more reliable transmission systems.

Key Takeaways

- Custom design optimized for your application.

- Diameter range from 6mm to 52mm.

- Based on proven platforms, not from scratch.

- No MOQ – supports prototypes and mass production.

- Plastic, metal, or hybrid gears by application.

- Proven in robotics, medical, and precision devices.

- Full system-level support beyond just the gearbox.

Why Choose a Custom Planetary Gearbox

Standard planetary gearboxes often fail to fully match specific application requirements. A custom solution allows optimization of key parameters, including:

- Gear ratio and output torque

- Transmission efficiency and operating noise

- Size, weight, and mounting interface

- Service life and load capacity

With a custom planetary gearbox, the gearbox is no longer a compromise—it becomes a critical guarantee of system performance.

A Real Case: Why a Standard Gearbox Was Not Enough

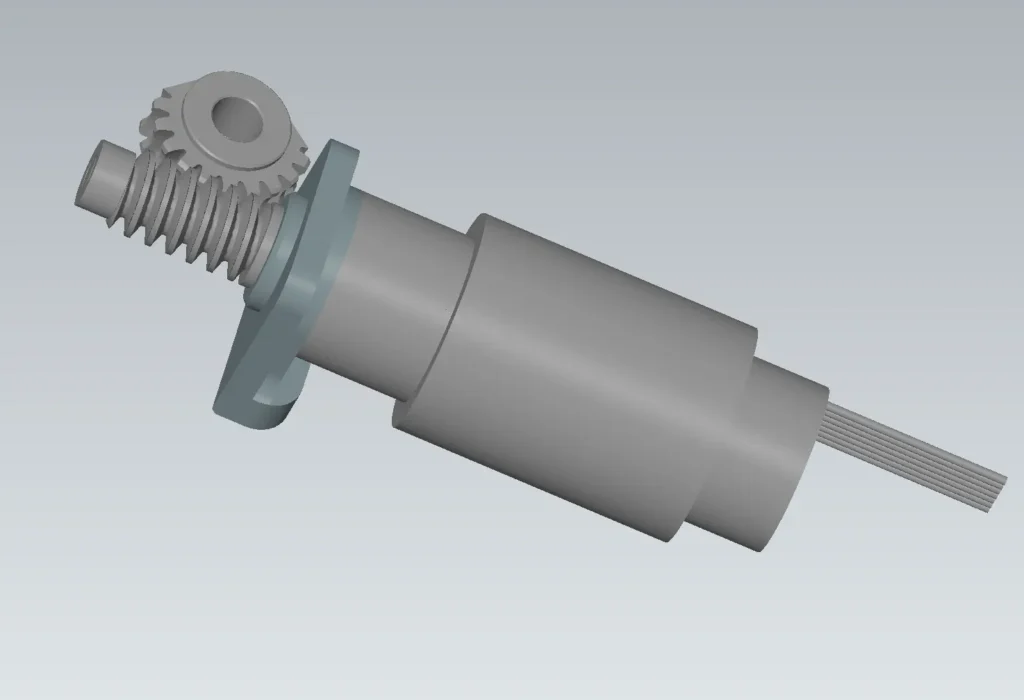

One of our customers originally used a worm gear reducer, but they had two special requirements:

- No self-locking

- When the motor is powered off, the load must not back-drive the motor under a specified torque (Kg·cm)

At first glance, this seems simple. However, standard gearboxes typically cannot satisfy all of the following conditions simultaneously:

- No self-locking

- Ability to withstand a defined back torque when powered off

- Fixed structural dimensions

- No reduction in efficiency

With standard solutions, the result was always a compromise: insufficient torque, inadequate back-torque resistance, or an oversized structure.

The only viable solution was customization.

By adjusting the number of planetary stages, optimizing gear module and materials, and moderately increasing the reduction ratio, we enabled the gearbox to withstand the required back torque in a power-off state—while maintaining non-self-locking behavior.

The final solution fully met the customer’s requirements and significantly improved overall system stability.

6mm–52mm Micro Planetary Gearbox Solutions

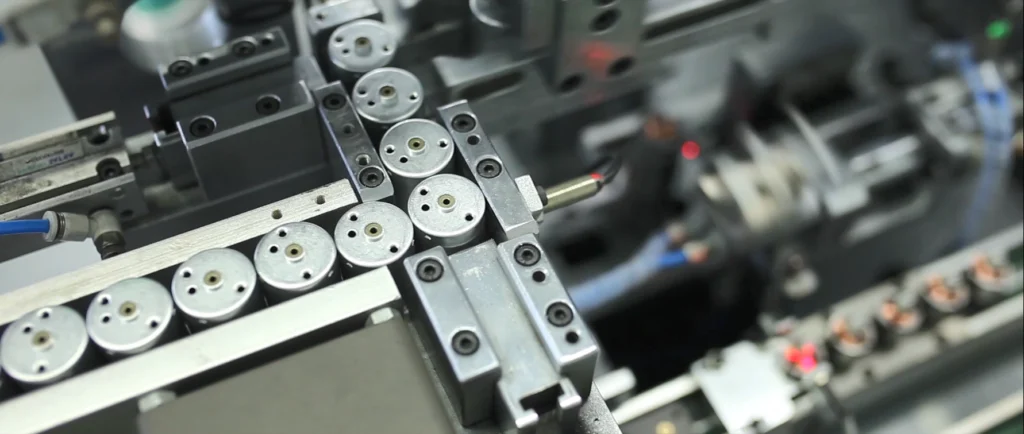

In the micro and small transmission field, we focus on planetary gearbox design and manufacturing. Our products cover diameters from 6mm to 52mm, delivering high torque and stable transmission performance within extremely compact volumes.

This size range is particularly suitable for applications with strict requirements for size, weight, and reliability.

For example, surgical and precision medical instruments demand extremely compact structures. In such cases, we typically recommend 6mm–16mm micro gear motors, achieving both compact integration and high-precision control.

For robotic dexterous hands, our mainstream product diameters include 8mm, 10mm, 12mm, 13mm, and 16mm.

- Five-finger dexterous hands

We usually recommend 13mm planetary gear motors, which provide higher torque within a compact size and are easy to integrate.

Based on our internal testing, our 13mm gear motor can withstand 40 kg load when powered off, and according to customer testing, the maximum load can reach 80 kg. - Four-finger dexterous hands

We typically recommend 16mm planetary gear motors.

Compared to 13mm, the 16mm diameter offers higher torque output and stronger load capacity, enabling greater gripping force and stability within similar structural space.

In general, larger diameters allow higher torque output, making 16mm a better choice for four-finger structures requiring higher load capacity, stronger gripping force, and greater stability.

Customization + Standard Platforms: Lower Cost, Faster Delivery

When customers hear the word “customization”, they often associate it with high development costs, long lead times, and increased technical risk.

Our advantage is that customization does not always start from scratch.

Medical Minimally Invasive Device Case

A customer developing a medical minimally invasive instrument required a 10mm diameter planetary gear motor with:

- Extremely low noise

- Service life exceeding 500 hours

They initially believed a completely new design was unavoidable—raising concerns about cost, lead time, and risk.

After evaluating the requirements, we found that their needs closely matched our existing 10mm standard planetary gear motor, requiring only limited customization:

- Adjusting reduction ratio and gear materials to meet lifetime targets

- Optimizing gear tooth profile and lubrication for noise reduction

- Customizing the output shaft to fit their assembly structure

All modifications were based on a mature, mass-produced platform, rather than a full redesign.

Final Comparison

| Item | From-Scratch Development | Platform-Based Customization |

| Development Cycle | 10–12 weeks | 2–3 weeks |

| Upfront Development Cost | High | Almost zero |

| Technical Risk | High | Low |

| Mass Production Stability | Requires ramp-up | Immediately stable |

Compared to full custom development, platform-based customization significantly reduces cost and risk.

Plastic or Metal Gears — Customized by Application

In custom planetary gearbox design, gear material selection is critical. We support:

Plastic Planetary Gearboxes

- Lightweight and low noise

- Cost-effective for mass production

- Suitable for medium-to-low load applications

Metal Planetary Gearboxes

- Higher torque and load capacity

- Superior wear resistance and structural stability

- Ideal for high-load or long-life applications

Plastic + Metal Hybrid Structures

- Optimal balance between performance and cost

- Common combination: plastic planetary gears + metal sun gear / metal output stage

- Ideal for applications requiring low noise with moderate load capacity

Case Example: Robot Vacuum Drive Module

A customer initially used a full-metal planetary gearbox. While performance was stable, two issues emerged:

- High cost, unfavorable for mass production

- Relatively high operating noise

After evaluating the actual load requirements, we customized a solution based on our standard platform:

- Plastic planetary gears + metal sun gear

- Optimized gear profile and lubrication

- Retained metal output stage for durability

✨ Final Results

- Cost reduced by approximately 30%

- Noise reduced by approximately 40%

- Torque and service life fully met requirements

The product passed system-level testing and successfully entered mass production.

This case clearly shows: material selection is not about choosing the most expensive option, but the most appropriate one.

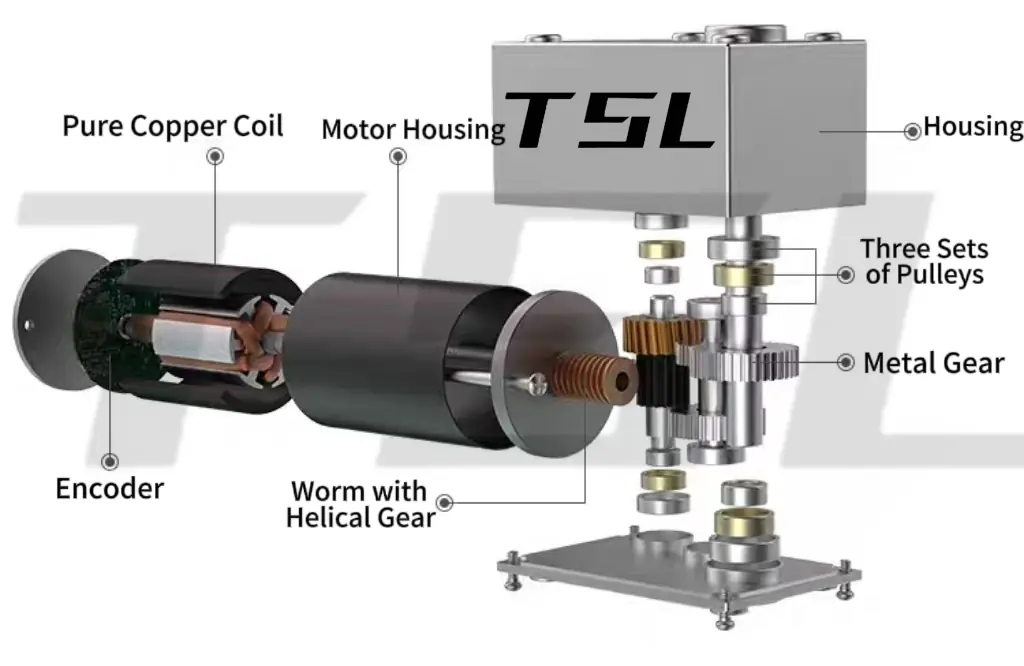

More Than a Gearbox: Complete Transmission System Design

If your requirement goes beyond a planetary gearbox to a complete transmission system, we provide full-system support.

With a senior engineering team having 20+ years of experience, we offer:

- Motor and gearbox matching

- Multi-stage or hybrid transmission designs

(planetary + worm, planetary + parallel shaft, gear transmission systems) - Torque, efficiency, thermal, and lifetime calculations

- System-level optimization from concept to mass production

- Mold development to ensure consistency and production stability

We focus not just on individual components, but on real-world system reliability, efficiency, and consistency.

A Trusted Supplier and Manufacturing Partner: TSL

From prototype validation to large-scale production, we aim to be a long-term, reliable partner.

Our capabilities include:

- Mature gear machining and injection molding

Supporting metal, plastic, and hybrid structures - Consistent quality control system

From incoming materials to final testing - Flexible volume support

From dozens of prototypes to tens of thousands in mass production - Long-term project and platform development

Many customers have cooperated with us across multiple product generations - No MOQ limitation

Ideal for early-stage innovation and validation

We deliver not just products, but sustainable manufacturing capability and long-term technical support.

Conclusion: Choosing the Right Custom Planetary Gearbox Partner

If you are looking for a manufacturer specialized in custom micro planetary gearboxes, we would be honored to be your technical and manufacturing partner.

From 6mm to 52mm, from standard models to customized solutions, from single gearboxes to complete transmission systems—we help you achieve the best balance between performance, cost, and delivery.

FAQ

1. What is a custom planetary gearbox, and how does it differ from a standard one?

A custom planetary gearbox is designed specifically for your application, rather than using a general-purpose standard model.

Key parameters such as gear ratio, output torque, noise level, size, lifetime, and mounting interface can be optimized to match real operating conditions, ensuring better system performance and reliability.

2. Does customization always mean high cost and long development time?

No.

In many cases, customization is based on our proven standard platforms, with targeted adjustments such as gear ratio, materials, or output shaft design.

This approach typically reduces development time to 2–3 weeks, with minimal upfront cost and much lower technical risk compared to full custom development.

3. What size range of micro planetary gearboxes do you offer?

We offer micro and small planetary gearboxes with diameters ranging from 6mm to 52mm, suitable for robotics, medical devices, automation systems, and other high-precision applications.

4. Can a planetary gearbox be non-self-locking while still resisting back torque?

Yes.

Through customized design of planetary stages, gear parameters, materials, and reduction ratio, it is possible to achieve a non-self-locking gearbox that can still withstand a specified back torque when the motor is powered off.

5. Should I choose plastic or metal gears for my application?

The choice depends on load, noise, lifetime, and cost requirements.

- Plastic gears offer lower noise, lighter weight, and cost advantages for medium-to-low load applications.

- Metal gears provide higher torque capacity and durability for high-load or long-life requirements.

- Hybrid structures (plastic + metal) often deliver the best balance between performance and cost.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Planetary Gear Motor

A planetary gear motor combines a micro planetary gearbox with a DC motor, serving as a driving device designed to reduce speed and increase torque. These motors are typically cylindrical and made from materials such as steel or brass. In some cases, plastic components are used to meet specific size and power requirements.