When a standard stepper motor cannot meet the high-torque requirements at low speeds, or when finer displacement control is needed, a geared stepper motor becomes the optimal upgrade solution.

By perfectly combining a stepper motor with a gearbox, this geared stepper motor reduces speed while giving the system greater “power” and more precise positioning, effectively addressing the low-speed vibration issue of stepper motors.

Without complex closed-loop control, it can achieve robust and predictable motion at low cost. This guide aims to give you a comprehensive understanding of this configuration and help you make precise selections in real projects.

Key Takeaways

- It integrates a stepper motor and a gearbox. It delivers high torque at low speeds and precise positioning at low cost.

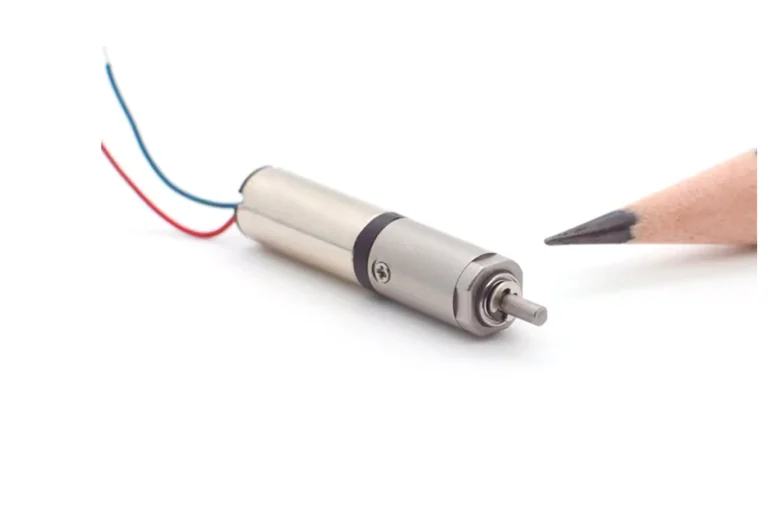

- It amplifies torque proportionally without enlarging the motor size. It saves installation space for heavy-load drives.

- Gear ratio reduces the equivalent step angle. It greatly improves positioning resolution.

- It damps low-speed resonance and jitter. It lowers step loss by cushioning load shocks.

- Various motor and gearbox types match different working conditions.

- Key selection factors: gear ratio, pull-out torque, step angle and installation size.

- It is a cost-effective choice, but has backlash, speed limits and transmission loss.

Why Add a Gearbox to a Stepper Motor?

In many applications, using a stepper motor alone is often not the optimal solution. While stepper motors have advantages such as simple structure, easy control, and precise positioning, they have inherent limitations in low-speed high-torque performance, smooth operation, and high-resolution positioning.

Adding a gearbox to a stepper motor to form a geared stepper motor essentially amplifies the motor’s advantages while compensating for its shortcomings.

Insufficient Torque at Low Speed

The output torque of a stepper motor is closely related to its size. Larger motors generally provide higher torque. Simply increasing the motor size to gain torque not only significantly increases installation space requirements but also makes the overall size and weight much larger.

Compared with adding a gearbox, this approach usually requires a much bigger motor to achieve the same output.

By adding a gearbox, the output torque can be proportionally amplified without changing the motor size, allowing a small stepper motor to drive larger loads stably. This provides better performance and structural layout in space-constrained applications.

Improved Positioning Resolution

Standard small permanent-magnet stepper motors have step angles of 18°, while standard hybrid stepper motors typically have step angles of 1.8°. In certain precision applications, this resolution is insufficient.

Adding a gearbox reduces the effective output step angle according to the gear ratio. For example, an 18° permanent-magnet stepper motor with a 10:1 reduction can achieve an effective step angle of 0.047°, significantly improving positioning accuracy and controllability without relying on complex electronic microstepping.

Reduced Resonance and Vibration

Stepper motors are prone to resonance and vibration at low speeds due to interactions between rotor inertia and the periodic variation of electromagnetic torque. This effect is more pronounced with higher loads or system inertia, resulting in increased vibration and unstable motion.

The mechanical inertia and damping introduced by the gearbox help smooth the rotation at the output shaft, reducing vibration and noise during low-speed operation. This is especially suitable for applications requiring long-term, continuous low-speed operation.

Reduced Risk of Missed Steps

Directly driving a load can cause stepper motors to miss steps when torque is insufficient, which is usually undetected in open-loop systems.

By using a gearbox to reduce the direct load impact on the motor, the motor’s disturbance resistance increases, significantly lowering the risk of missed steps under the same conditions and improving overall system reliability.

Optimized Cost-Performance Balance

For many low-speed high-torque applications, using a servo motor might otherwise be considered. However, servo systems have higher costs, complex tuning, and integration requirements.

A geared stepper motor provides a cost-effective compromise: it simplifies the system while meeting application requirements, offering controllable costs without sacrificing performance.

Geared Stepper Motor Structure

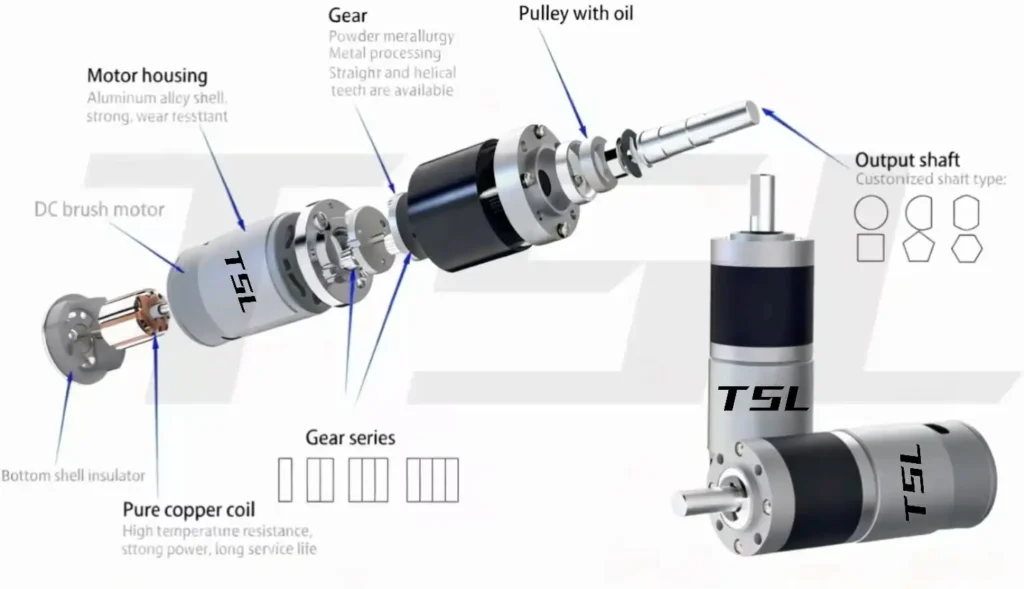

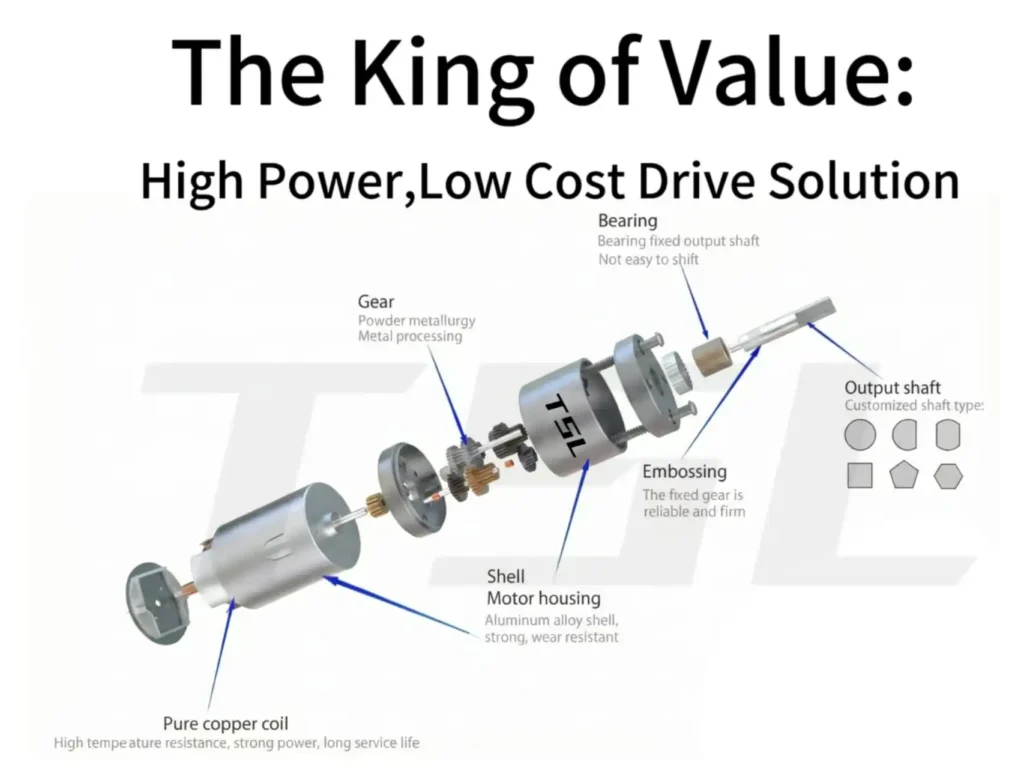

Structurally, a geared stepper motor consists mainly of the stepper motor itself and the gearbox.

Stepper motors generally include permanent-magnet (PM), variable-reluctance (VR), and hybrid types. Gearboxes can be planetary, spur, or worm gear types, with different combinations providing distinct performance characteristics and application scenarios.

Stepper Motor Types

Permanent-Magnet Stepper Motor (PM)

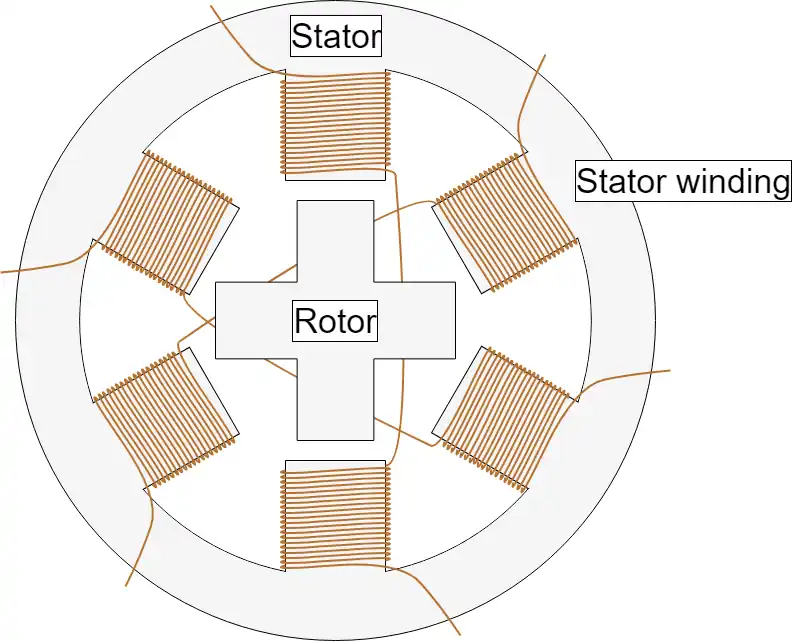

PM stepper motor:The rotor uses permanent magnets, and the stator has a salient-pole winding structure without fine-tooth design. The rotor is driven directly by the magnetic attraction/repulsion between the stator magnetic field and the rotor magnets.

- Step angle: Typically 7.5° or 18°

- Characteristics: Simple structure, low cost, low power consumption, high holding torque, self-locking when powered off; poor high-speed performance, low torque, low precision.

- Typical applications: Low-precision instruments, toys, simple valves, paper feed mechanisms in office equipment, light-load scenarios.

Variable-Reluctance Stepper Motor (VR)

VR stepper motor:The rotor is made of soft magnetic material with a salient-pole structure and no magnets. The stator has a corresponding fine-tooth design. The rotor moves to the position of minimum magnetic reluctance when the stator is energized.

- Step angle: 1.8° or 3.75°

- Characteristics: Simple, low manufacturing cost, low rotor inertia, good high-speed response; no self-locking when powered off, moderate torque, moderate precision, vibration and noise may be noticeable.

- Typical applications: Early automation machines, low-cost machine tool axes, low-speed textile and packaging machines, old office equipment, simple indexing mechanisms; being gradually replaced by hybrid motors.

Hybrid Stepper Motor(HB)

Hybird stepper motor:The rotor combines permanent magnets with fine teeth, and the stator has matching fine teeth. The rotor is driven by both magnetic attraction/repulsion and variable reluctance effects.

- Step angle: Typically 1.8°, further reducible with microstepping

- Characteristics: Moderate-to-high structural complexity, higher cost; high torque, smooth operation, low vibration and noise at low speed, good high-speed performance, high positioning precision, self-locking, compatible with microstepping.

- Typical applications: 3D printers, CNC machines, engraving machines, precision transmission modules, robotic joints, medical testing equipment, surveillance PTZ, semiconductor tooling, precise printing/packaging applications.

Gearbox Types

The gearbox reduces output speed, amplifies torque, and improves positioning accuracy. Common types:

Planetary Gearbox

A planetary gearbox consists of a sun gear, planet gears and an internal ring gear. The planet gears rotate around the sun gear and drive the ring gear for output.

- Advantages: High efficiency, compact, uniform load distribution

- Applications: High-torque, coaxial output, space-constrained industrial automation; most commonly used type.

Spur Gearbox

A spur gearbox is composed of one or more pairs of spur gears, achieving deceleration through gear meshing.

- Advantages: Simple, easy to manufacture, low cost, relatively high efficiency

- Limitations: Limited load capacity, higher noise during engagement

- Applications: Light-load, low-cost devices, non-space-constrained situations.

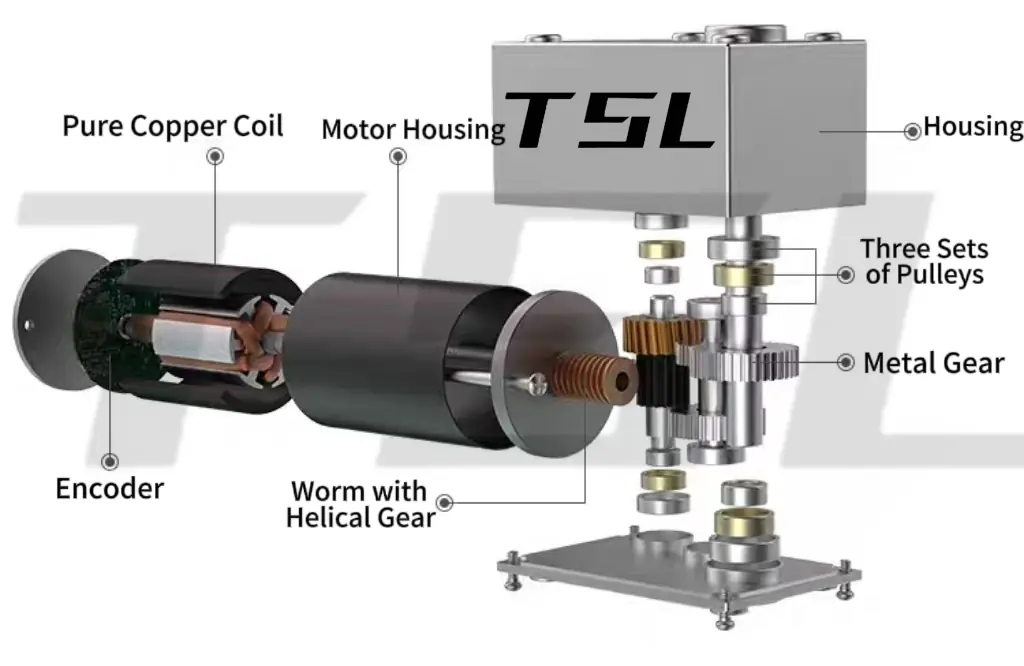

Worm Gearbox

A worm gearbox consists of a worm (helical shaft) and a worm gear. The worm drives the worm gear to rotate for deceleration.

- Advantages: High reduction ratios, self-locking output

- Limitations: Lower efficiency, potential heat generation under long-term heavy load

- Applications: Anti-reverse or holding applications like valve control, lifting mechanisms, precision positioning.

Limitations of Geared Stepper Motors

Despite numerous advantages, the following limitations should be noted when selecting a geared stepper motor:

Backlash

Backlash is an inevitable mechanical meshing clearance inside the gearbox of a geared stepper motor (especially in worm gear and multi-stage planetary gear structures).

Simply put, it is the maximum angle (or displacement) that the output shaft can rotate freely when the input shaft of the gearbox is fixed, essentially the tiny gap between meshing components such as gears and worms.

For high-precision reciprocating positioning or scenarios requiring micron-level repeatability, such clearance may lead to the accumulation of positioning errors.

Engineering suggestions: Low-backlash gearboxes can be selected, or compensation can be performed at the control end combined with closed-loop feedback and microstepping control.

Limited Output Speed

The gearbox reduces the motor output speed, so the maximum output speed is limited under high gear ratios. Geared stepper motors may not meet the requirements for applications requiring high-speed motion or fast response.

Engineering suggestions: Select an appropriate gear ratio according to load and speed requirements, and evaluate the system responsiveness after deceleration.

Transmission Efficiency Loss

Multi-stage gear transmission causes friction and meshing losses, and the efficiency is usually lower than that of direct-drive motors. High gear ratios or worm gear structures have low efficiency, which may lead to heat generation and increased energy consumption under long-term high-power loads.

Engineering suggestions: Design the gear ratio reasonably, and pay attention to lubrication and heat dissipation conditions.

Long-Term Wear

Heavy loads, frequent start-stop operations or high cycle times will accelerate gear wear. Wear will result in increased backlash, torque attenuation and reduced accuracy.

Engineering suggestions: Select high-precision materials, conduct regular lubrication inspections, and make reasonable selections according to load characteristics.

Noise and Vibration

Gear meshing will generate noise and vibration during high-speed or heavy-load operation.

Engineering suggestions: For noise-sensitive occasions, low-noise designed planetary gearboxes or plastic gears can be selected.

Comparison Between Geared Stepper Motors and Other Motor Solutions

Geared stepper motors offer clear advantages over conventional motors. They provide better torque and higher positioning accuracy. They also feature simpler control logic and lower overall costs.

Comparisons with mainstream motor types are elaborated item by item below:

vs. Conventional Open-Loop Stepper Motors

Conventional stepper motors:standard open-loop steppers have low native torque. At low speeds or under heavy loads, they often lose steps or lose positioning accuracy. This makes them unreliable for heavy-duty tasks.

Geared stepper motors:Geared versions use an integrated gearbox to multiply torque. This structural change prevents step loss and ensures stable operation at low speeds. They provide higher precision and reliability for demanding scenarios

vs. Geared DC Motors

Geared DC Motors:Geared DC motors are simple and inexpensive to build. However, they cannot position themselves accurately on their own. To get precise control, you must add encoders or Hall sensors. This makes the system complex, harder to debug, and more expensive to maintain.

Geared Stepper Motors:Geared steppers control speed and position directly via pulse signals. They achieve precision without extra feedback modules. In mid-to-low speed tasks, they are much simpler to implement and more efficient to control.

vs. Servo Motors

Servo Motors:Servo motors offer elite speed and precision. They use closed-loop control for ultra-precise positioning. However, the hardware is expensive. Setting them up requires complex tuning, impedance matching, and high technical expertise.

Geared Stepper Motors:Geared stepper motors are much more affordable and easier to control. While not as fast as servos, they provide stable torque for most mid-range tasks. They are perfect for low-speed, high-torque applications.

The Bottom Line:If your project is cost-sensitive and doesn’t need extreme speed, geared steppers are the best choice. They shorten development cycles and simplify debugging.

Selection of Geared Stepper Motors

When choosing a geared stepper motor, focus on your specific load, accuracy, and installation needs. Proper selection ensures your system runs reliably. It also helps you avoid the high costs of over-designing or the risk of equipment failure from a poor match.

Gear Ratio

The gear ratio is a key parameter in geared stepper motors. It directly affects output speed and torque: a higher ratio increases torque but reduces speed, while a lower ratio decreases torque but increases speed.

When selecting, match the gear ratio precisely to the load’s required speed and torque to ensure sufficient torque and meet speed demands.

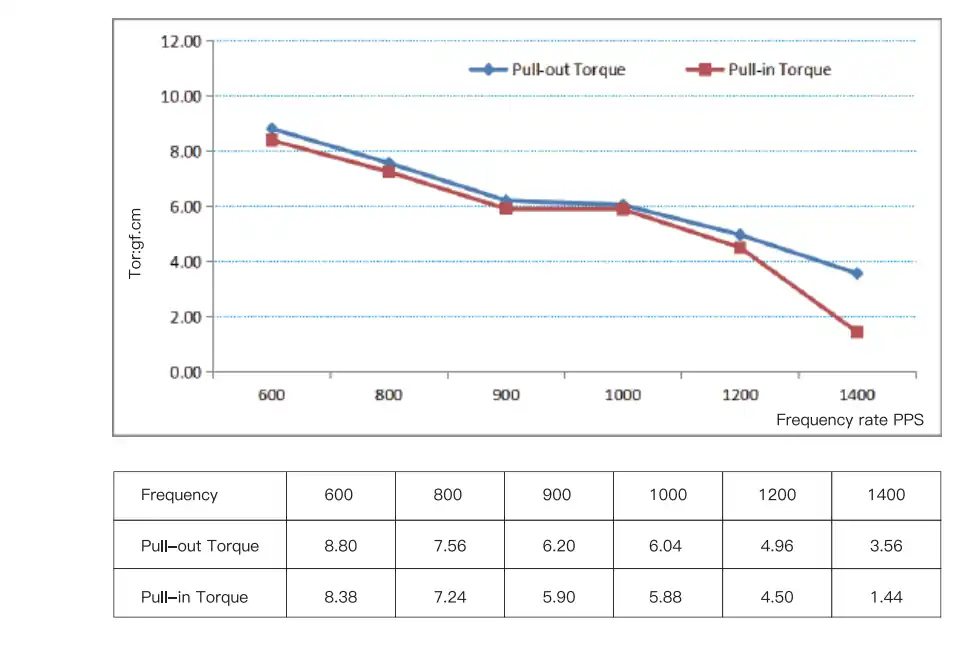

Pull-Out Torque

Pull-out torque is the maximum load torque a motor can stably deliver under rated conditions and serves as the key indicator for determining whether the motor can drive the target load. If the load torque exceeds this value, the motor may lose steps, stall, or suffer positioning errors.

Therefore, during selection, the motor’s pull-out torque must include a reasonable safety margin to handle load fluctuations and sudden impacts.

Step Angle

The step angle is the rotor’s rotation per pulse and determines the motor’s positioning accuracy—the smaller the step angle, the higher the resolution. In a geared stepper motor, the gearbox further enhances positioning accuracy.

During selection, the step angle and gear ratio should be matched to the application’s accuracy requirements to meet the desired positioning error range.

Detent Torque and Holding Torque

Detent torque (or static positioning torque) is the rotor’s inherent holding force when the motor is unpowered, allowing basic positioning after power loss.

Holding torque is the motor’s ability to resist external forces when energized but stationary, ensuring positioning stability under static loads—especially critical for vertical loads or long-term shutdown positioning.

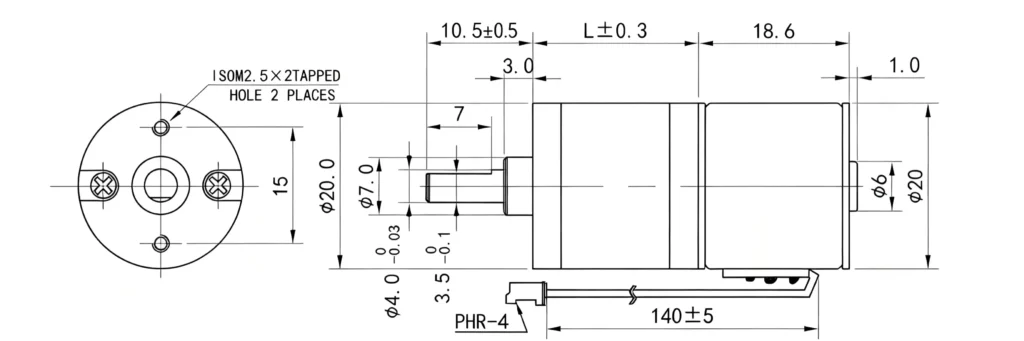

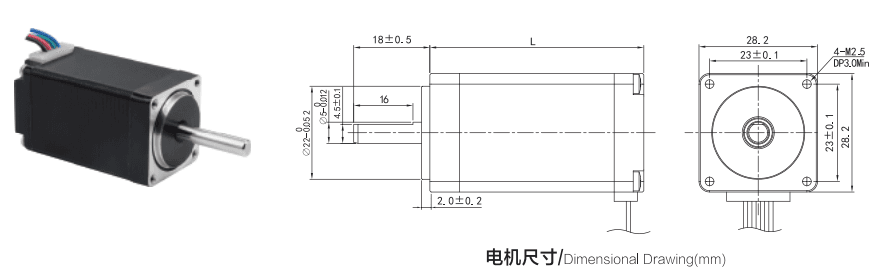

Motor Size and Installation Space

Selection should consider the available space in the equipment assembly cavity and match installation interfaces—such as flange specifications and shaft diameter—to ensure smooth motor installation and allow adequate maintenance clearance.

An oversized motor may not fit, while an undersized one may lack sufficient torque or operate unstably.

Excitation Mode and Insulation Resistance

The excitation mode—such as unipolar or bipolar—directly influences the motor’s torque output, power consumption, and operating noise, and should be chosen based on control performance and energy efficiency requirements.

Insulation resistance affects electrical safety and service life, and must meet the application’s electrical safety standards to prevent faults like short circuits or leakage due to inadequate insulation.

Customization Directions of TSL MOTOR Geared Stepper Motors

TSL MOTOR geared stepper motors offer multi-dimensional customization to meet diverse industry needs. Based on a mature standard platform, they balance performance, accuracy, and cost—ensuring stable quality while controlling expenses. Customization options include:

Core Performance Parameter Customization

Non-standard gear ratios can be customized to match load speed and torque needs. Motor voltage and no-load torque can also be tailored for different power supplies and loads—preventing performance waste or power shortages from mismatched standard specs.

Output Shaft Customization

Output shaft shape (e.g., D-shaft, spline, flat), diameter, and length can be customized to optimize shaft-end connections, enhance motor-equipment compatibility, and reduce the need for extra adapters—saving design effort and cost.

Control Mode Upgrade Customization

Encoders can be integrated to upgrade from open-loop to closed-loop control—eliminating step loss and positioning errors, boosting accuracy and stability for high-precision applications like precision instruments and advanced automation equipment.

Gear Structure Customization

For noise-sensitive and long-life applications, motors can be customized with low-noise gears (e.g., precision-ground or silent gear sets) to reduce operational noise, and with durable gear materials and lubrication systems to extend service life—ideal for continuous-operation environments like assembly lines.

Installation and Housing Customization

Special flanges—like non-standard hole patterns, custom shapes, or varied mounting sizes—can be tailored for tight installation spaces. Housing materials (e.g., corrosion- or heat-resistant), protection ratings, and structural designs can also be customized for harsh environments like high humidity, dust, or extreme temperatures.

In short, TSL MOTOR’s geared stepper motors deliver targeted customization from a proven standard platform—addressing real-world application challenges while balancing performance, reliability, and cost for efficient, stable operation across industries.

Summary

A geared stepper motor combines a stepper motor with a gearbox to deliver low-speed high torque, precise positioning, and smooth operation. It overcomes common issues of standard stepper motors—like low torque, vibration, jitter, and step loss under heavy loads—while offering a cost-effective, easy-to-control solution.

During selection, key parameters—including gear ratio, pull-out torque, step angle, holding torque, and motor size—must be carefully matched to the application for optimal reliability.

With TSL MOTOR’s customization options—such as output shaft shape, gear design, control mode (e.g., open-loop to closed-loop), and installation interface—performance and compatibility can be further enhanced.

Overall, geared stepper motors are ideal for low-speed, high-torque, high-precision applications, delivering stable, efficient, and controllable motion—making them essential for precision industrial automation.

FAQ

Q1: What is a Geared Stepper Motor?

A Geared Stepper Motor combines a stepper motor with a gearbox to reduce speed, increase torque, and improve positioning accuracy.

Q2: Why use a Geared Stepper Motor?

It provides higher torque at low speed, smoother motion, and finer positioning without increasing motor size.

Q3: Does the gearbox improve positioning accuracy?

Yes. The gearbox reduces the effective step angle, significantly increasing output resolution.

Q4: What are the main limitations?

Backlash, lower maximum speed, and efficiency loss at high reduction ratios.

Q5: Can Geared Stepper Motors be customized?

Yes. Gear ratio, shaft design, voltage, gearbox type, and encoders can all be customized.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Stepper Gear Motor

TSL MOTOR designs stepper gear motors with flexibility, allowing customization to suit any equipment need. They offer a range of standard models, including versions with gearboxes and encoders.