In modern motor systems, the brushless outrunner motor is widely used. It’s found in drones, robotics, automation, model power systems, and light power transmission. This is due to its high torque output, stable operation, and high customizability.

Its unique “outrunner structure” offers significant advantages in power density and efficiency. It is an ideal choice for engineers and equipment manufacturers.

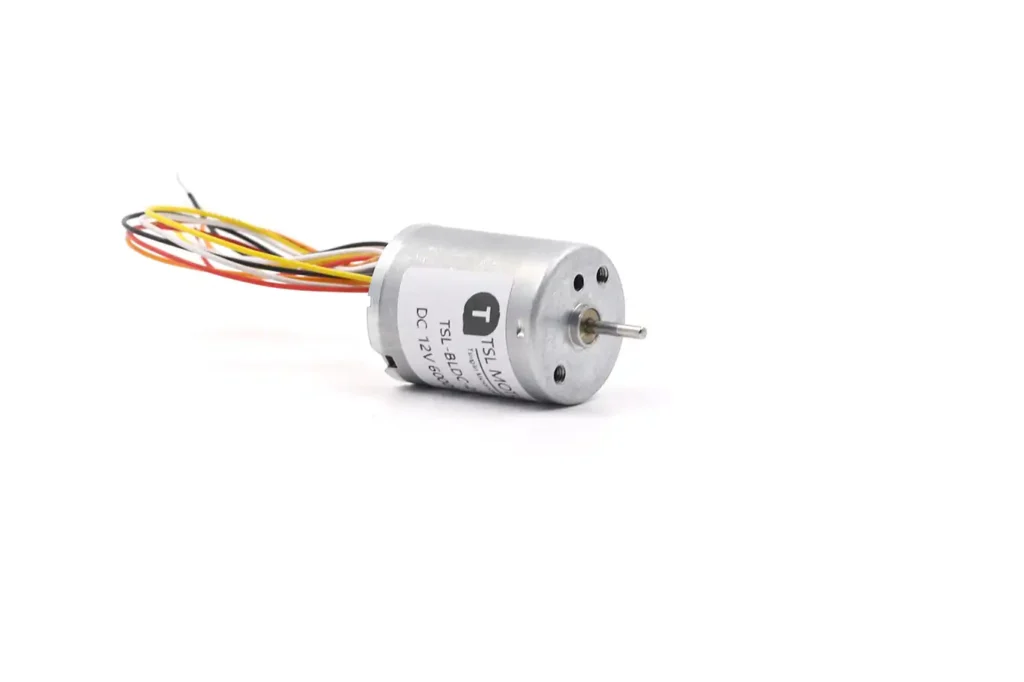

As an enterprise specializing in DC motor R&D and manufacturing, TSL MOTOR will systematically analyze the brushless outrunner motor. This analysis draws from years of engineering practice. It covers the working principle, advantages, limitations, common pain points, application analysis, and selection logic.

Our goal is to help readers understand the engineering value of these motors more clearly. They will be able to select the right solution based on their application needs.

Key Takeaways

- High Torque Direct Drive Advantage The outrunner has a larger rotor diameter, increasing the torque lever arm. This allows for high torque output at low speeds, ideal for direct-drive applications.

- Heat Dissipation is the Main Constraint The stator (heat source) is enclosed inside, resulting in a long heat path. Therefore, it is unsuitable for 24/7 continuous high-power industrial use.

- The Top Choice for Drones Its high instantaneous torque perfectly meets the drone’s high-thrust requirement. Airflow during flight also provides the necessary cooling.

- Fast Dynamic Response and Quiet The elimination of motor inertia and the gearbox leads to smoother, quieter operation. This is especially crucial for gimbals and medical devices.

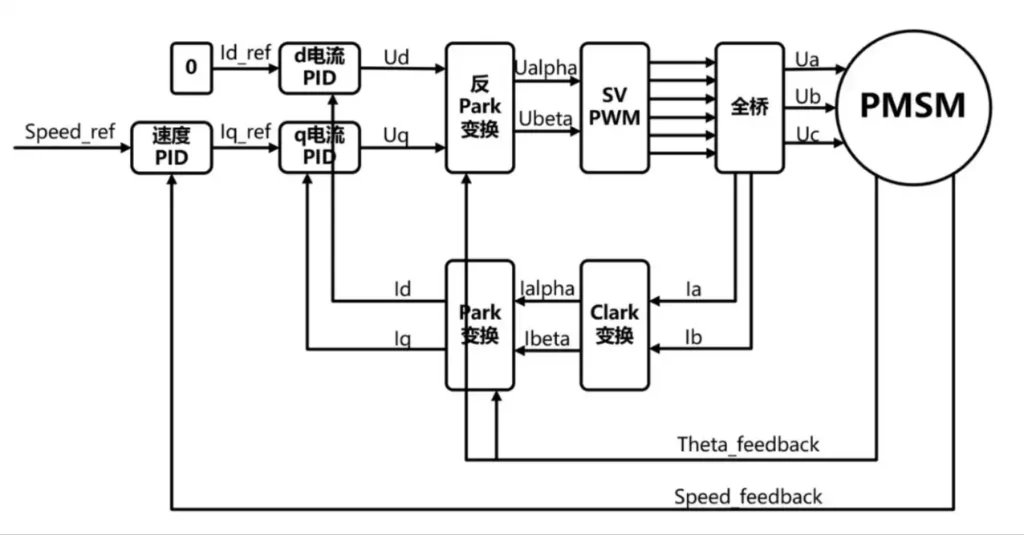

- High Demands on the ESC Controller Outrunners usually have more pole pairs, making startup and low-speed control more difficult. They require high-computing or FOC algorithm controllers.

- Limited Impact Resistance The casing (which is the rotor) is exposed externally and is susceptible to impact or foreign objects. Extra protection is needed in outdoor or dusty environments.

- Selection Must Match Application Do not focus only on peak power; consider continuous power and thermal conditions. The motor and ESC must be matched as a complete system.

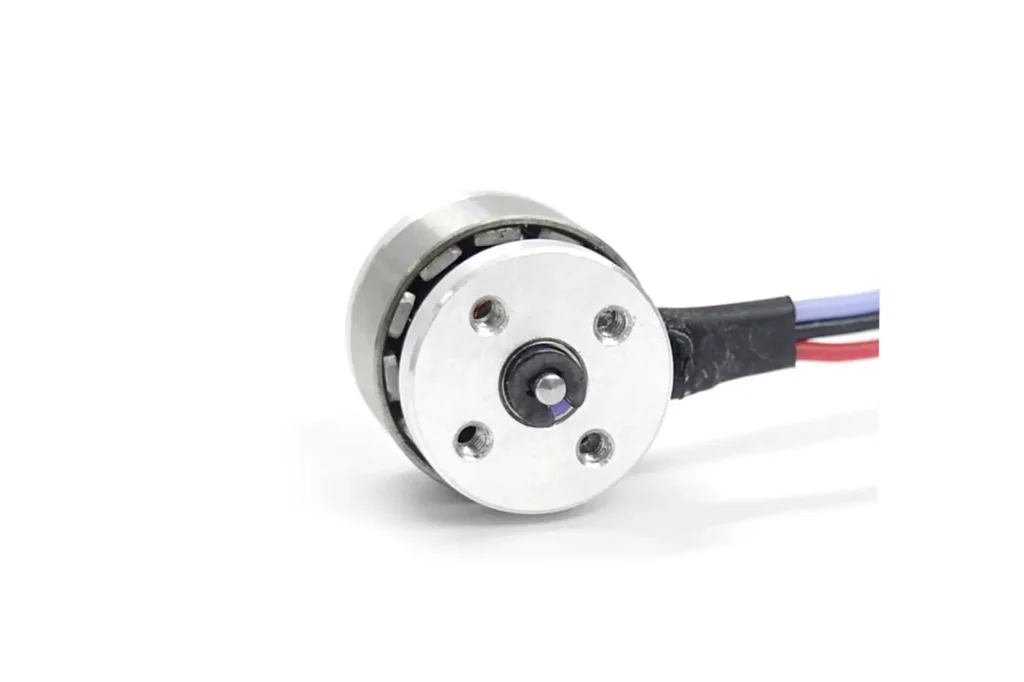

What is a Brushless Outrunner Motor?

Unlike traditional inrunner brushless motors, the rotor of an outrunner motor is on the outside. This outer ring (rotor) is like a cup enclosing the stator.

A standard outrunner structure includes the stator, rotor, bearing system, and Electronic Speed Controller (ESC).

Stator

The stator of an brushless outrunner motor is essentially a winding of energized wires on silicon steel laminations.

- Silicon Steel Laminations: These form the main magnetic path. They offer good magnetic permeability. Lamination and insulation coating reduce eddy current losses.

- Windings: These are made of Enameled Copper Wire. An insulating lacquer layer prevents short circuits. TSL MOTOR uses pure copper wire for high conductivity and stable high-temperature performance.

Rotor

The brushless outrunner motor rotor is simply the magnets plus the outer casing.

- Casing (Outer Shell): This is usually cup- or cylinder-shaped. It encloses the stator. Its top often has bolt holes, threads, or a hub. These features allow direct mounting of propellers, wheels, gears, or gimbal brackets, enabling “direct drive”.

- Magnets (Magnetic Tiles): The magnets are tightly bonded to the inner wall of the casing. They must be distributed uniformly. This ensures a symmetrical magnetic field.

- Uneven arrangement leads to an unbalanced air-gap magnetic field. This causes vibration and reduced efficiency during operation. Neodymium Iron Boron (NdFeB), grades like N35–N52, are commonly used.

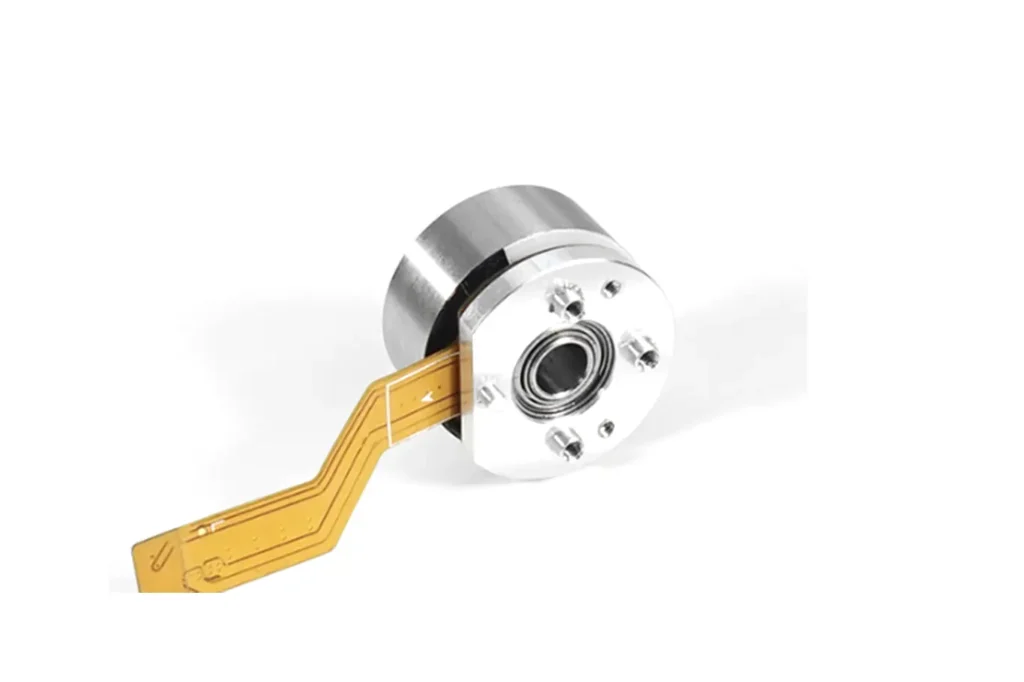

Bearings

The bearings must handle both radial and axial loads. TSL MOTOR uses imported Japanese bearings. This ensures long motor life, high precision, and low noise.

ESC (Electronic Speed Controller)

The ESC is the “brain” of the brushless motor. It converts DC power from the battery into three-phase AC power. This drives the stator windings to produce a rotating magnetic field. This field, in turn, spins the rotor.

How Does a Brushless Outrunner Motor Work?

The principle of the brushless outrunner motor is the same as all brushless motors. The key difference is the rotor is on the outside. The stator is inside, enclosed by the rotor. This is how the outrunner motor gets its name.

Step 1: Powering and Initial Position Detection

When the motor starts, the controller uses Hall sensors or a sensorless algorithm to determine the initial position of the rotor poles.

- Example: If the rotor’s N pole is near winding phase A, the controller powers phases A and B. This generates a magnetic field. The field is oriented to pull the rotor and produce maximum torque.

Step 2: Generating a Rotating Magnetic Field

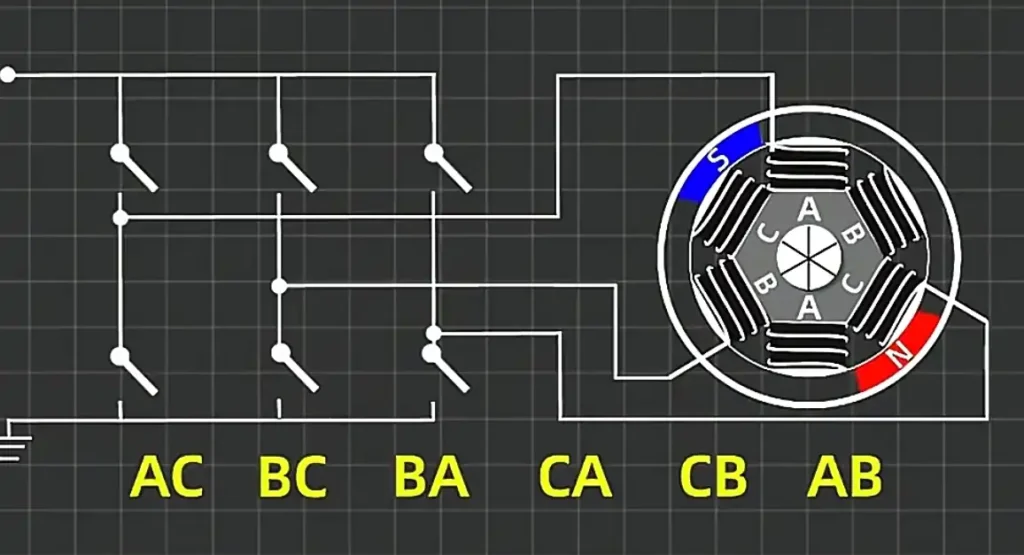

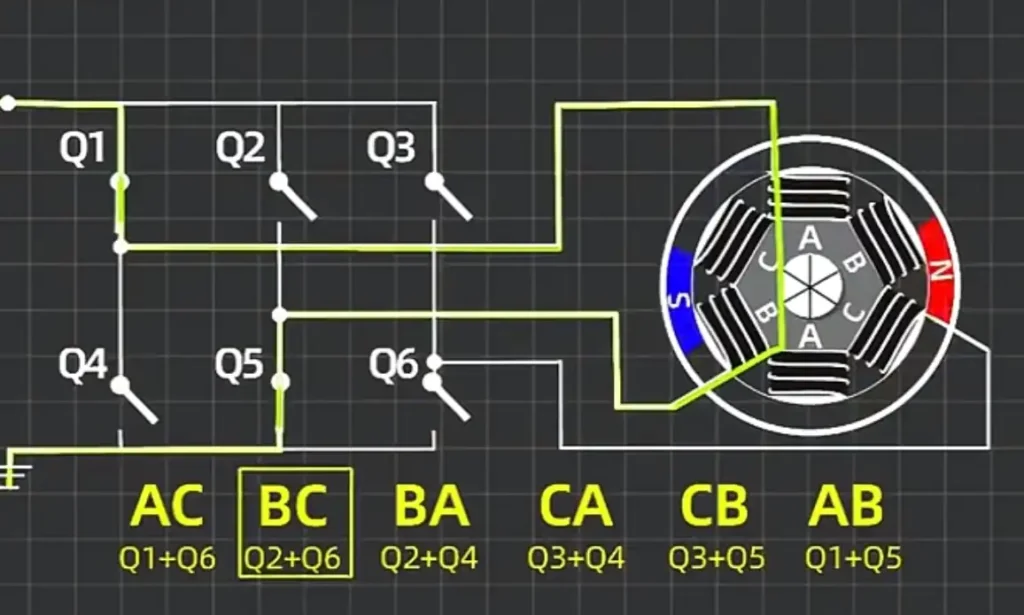

The controller uses an inverter circuit. It converts DC power into three-phase AC (square or sine wave). It then energizes the stator windings in a fixed sequence.

- Taking a three-phase star connection and the typical six-step commutation (switching every 60° electrical angle):

- AC Phase Powering: (Q1+Q6 switches closed). Current flows from A to C. A magnetic field is generated in a specific direction.

- BC Phase Powering: (Q2+Q6 switches closed). Switches to B and C. The magnetic field rotates 60°.

- BA, CA, CB, AB Phase Powering: The sequence continues, changing current direction to maintain rotation.

Step 3: Magnetic Force Drives the Rotor

The stator’s rotating magnetic field interacts with the rotor’s static magnetic field (permanent magnets):

- Attraction occurs when the stator’s N pole aligns with the rotor’s S pole.

- Repulsion occurs when the stator’s N pole approaches the rotor’s N pole.

- These forces combine to drive the outer rotor (casing) in continuous rotation.

Step 4: Real-time Commutation and Closed-Loop Control

Hall sensors continuously detect the rotor’s position. This feedback goes to the controller.

- The controller precisely adjusts the winding power timing based on the position signal. This ensures the magnetic field is always “pulling” the rotor forward.

- Sensorless schemes estimate the position. They do this by detecting the zero-crossing point of the Back EMF (Electromotive Force) generated by the windings.

Step 5: Speed and Torque Regulation

- Speed Control: The controller adjusts the average voltage applied to the windings via PWM (Pulse Width Modulation). This changes the current magnitude, thereby adjusting the speed.

- Torque Control: Higher current leads to a stronger magnetic field. This results in a greater output torque (within the magnetic saturation limit).

Advantages of Brushless Outrunner Motors

The outrunner structure enables the motor to output high torque directly at low speeds. It is also highly efficient and operates quietly. It eliminates the need for a gearbox.

The structure is light and compact. This makes it especially suitable for drones, gimbals, and light equipment. Its fast response and excellent dynamic performance are notable in scenarios with frequent transient changes.

High Torque

Motor output torque is a product of Magnetic Force × Lever Arm.

The outrunner places the rotor outside, on a larger diameter. This effectively increases the “lever arm” for torque generation.

For the same magnetic flux and current, it produces more torque than an inrunner motor of the same size.

This provides an inherent “high-torque-at-low-speed” characteristic.

In many applications (drones, hub motors, gimbals), this eliminates or simplifies the reduction gearbox. This improves efficiency and reduces system complexity, noise, and weight.

Low Speed, High Efficiency

Traditional inrunners often need a gearbox for high torque. Gear transmission involves friction, heat, and energy loss.

The brushless outrunner motor directly outputs the required torque at the target low speed (e.g., hundreds to a few thousand RPM). This eliminates gearbox losses.

| Motor Model | Rated Voltage | No Load | Load | Stall | ||||

| Speed | Curremt | Speed | Current | Torque | Torque | Current | ||

| V | RPM | A | RPM | A | g.cm | g.cm | A | |

| TSL-BLDC-6132N-01A | 12.0 | 3000 | 0.08 | 2700 | 0.35 | 200 | 2029 | 5.4 |

Key Applications: Power tools, small wind turbines, fans, automation equipment.

Low Noise Operation

First, the outrunner’s high output torque eliminates the need for a gearbox. This removes the meshing noise of gears.

Second, the outrunner has a large mass and high rotational inertia. This strongly dampens speed fluctuations and electromagnetic torque ripple. The speed is smoother, reducing periodic noise from speed variation and commutation.

Key Applications: Cinema equipment, medical instruments, smart home devices.

Simple Structure and Light Weight

The outer casing (the rotor) of a brushless outrunner motor is often the mounting platform for the load (e.g., propeller, fan blade). This creates a highly integrated structure. The gearbox structure is also eliminated.

Key Applications: Drones, RC models, portable devices.

Fast Response, Excellent Dynamic Performance

The outrunner motor has low inertia for its power. Magnetic field changes directly drive the rotor. Response time is short.

When combined with FOC (Field-Oriented Control) algorithms, it can achieve millisecond-level dynamic adjustment.

Key Applications: Gimbals, drones, mechanical grippers.

Limitations of Brushless Outrunner Motors

While the brushless outrunner motor excels in torque density, efficiency, and response speed, it has structural and control limitations. These must be fully considered during design and selection.

Relatively Weak Heat Dissipation Capability

The heat sources (stator copper and iron losses) are enclosed inside the motor.Heat must travel a long path to dissipate: Stator → Stator Bracket → Motor Shaft/End Cap → Outer Casing. The thermal resistance is high, and the path is long.

Continuous power/torque is limited by the temperature rise. Its strong instantaneous overload capacity cannot be sustained as long as a similarly sized inrunner motor.

This is the primary reason it is unsuitable for continuous, heavy-duty industrial work. (Drones use forced air cooling during flight, which helps mitigate this).

Exposed Structure, Limited Impact Resistance

The outer rotor is the rotating casing and is directly exposed to the environment. Any external force or foreign object directly impacts the rotor.

In dusty environments, debris can enter the stator/rotor gap, causing rubbing or seizing.

If the casing is impacted, magnets can detach or shift, leading to motor imbalance. Engineers usually need to add protective covers or seals, increasing weight and cost.

Limited Continuous Torque

The stator is the “heat source.” Its limited space means limited winding cross-section and iron core volume. This lowers the continuous current carrying capacity (thermal limit).

The brushless outrunner motor is an excellent “sprinter,” but not a “marathon runner.”

Large Dynamic Inertia

The brushless outrunner motor’s mass is distributed at the outer periphery. Its rotational inertia is larger than an inrunner of the same size.

While this provides smooth running, it requires greater instantaneous power to overcome inertia in scenarios requiring frequent starts/stops or rapid acceleration/deceleration.

For high-speed dispensing machines or precision positioning equipment, the brushless outrunner motor may not be as responsive as a lightweight inrunner.

Higher ESC (Controller) Requirements

Outrunner motors typically have a higher number of pole pairs. This is for better low-speed smoothness and torque density.

However, the back EMF waveform is complex. Startup and low-speed control become more difficult.

If the controller parameters are mismatched, it can cause starting jitter, step loss, or failure to start.

Using FOC (Field-Oriented Control) significantly improves performance, but requires a higher-spec controller, increasing cost. The quality of the ESC algorithm is critical for stable low-end operation.

Difficulty in Integrating High-Precision Feedback

In applications requiring high-precision position control (e.g., industrial servos, CNC machines), the outrunner struggles to match the precision and stability of inrunner servo motors.

Engineers usually choose an inrunner + encoder combination. The outrunner is better suited for low-precision, high-torque direct drive.

Applications of Brushless Outrunner Motors

The brushless outrunner motor’s high torque density, light weight, and fast response make it valuable in various fields.

Drone / UAV / FPV Power Systems

Drones need high thrust with limited weight. The outrunner’s “long lever arm” structure outputs high torque at low speeds. It can directly drive large-diameter propellers.

Its direct torque output quickly responds to flight control commands. This achieves precise attitude control.

The motor’s heat dissipation limit is solved by forced air cooling during flight. Its intermittent peak load characteristic perfectly matches its design.

Gimbals and Stabilizers

Gimbals require the motor to maintain stable torque at very low speeds to prevent image shake.

Outrunners have many pole pairs. This allows for fine magnetic field changes and smooth torque output.

The motor itself can be part of the gimbal axis, resulting in high integration.

Gimbal motors typically work at low speeds and small angles. The low load and temperature rise perfectly avoid the outrunner’s weakness in heat dissipation and continuous torque.

Robot Joints and Collaborative Arms

The motor can serve as the direct rotary joint of a robot. This enables highly integrated modular design. It is ideal for the light weight, compactness, and safety (no protruding gearbox) required by collaborative robots.

Direct drive eliminates gear elasticity and non-linearity. This improves the bandwidth for force and position control.

Power Tools

Tools like electric drills and wrenches need huge instantaneous torque (“impact” or “drilling” torque).

The brushless outrunner motor can provide peak torque far exceeding its continuous rating in a very short time. This suits this “pulsed” work requirement.

The motor casing can directly integrate fan blades or a transmission interface, making the entire machine compact for handheld use.

The short working cycle (e.g., tightening one screw) allows enough intermittent cooling time. Its strong instantaneous overload capacity fits this condition well. Protection design against debris is crucial.

Small Wind Power Generation and Electric Thrusters

As a generator, a high pole-pair outrunner can produce a higher AC voltage frequency at low rotational speeds (light wind). This improves wind energy capture efficiency and startup performance in low wind.

In underwater drones or small boats, the propeller is mounted directly on the outrunner. This creates a highly integrated, shaft-less propulsion module with good sealing and high efficiency.

How to Select the Right Brushless Outrunner Motor?

Motor selection is a systematic matching process, not just reading a parameter table. It requires combining application, load characteristics, control strategy, thermal conditions, and mounting. The goal is to find a motor that meets performance and runs reliably in real-world conditions.

Clarify the Application Scenario

Understanding your application scenario is crucial for parameter selection.

- Drone → Needs to be light, high KV, fast response.

- Robot Joint → Needs high torque, fine control, good heat dissipation.

- Fan / Pump → Needs long-term stable operation, focus on continuous power.

The application dictates the parameter range. Avoid getting lost in a “parameter sea” initially.

Determine Core Parameters

KV Value: Determines speed and torque characteristics.

- Low KV → High torque, suitable for heavy loads.

- High KV → High speed, suitable for light loads.

Supply Voltage: First check the system’s power supply capacity, then select the motor.

- Example: Do not select a 12V-only motor for a 24V system.

Current / Power: The motor’s maximum current must match the limits of the power supply and ESC.

- Otherwise, it will burn out quickly.

Select Motor Size and Mounting Method

Size

- The outer diameter and length determine if the motor fits in your equipment.

- Engineers often use CAD to place the motor model for fitting checks.

Mounting Method

- Flange Mount → Common in precision equipment, ensures accurate positioning.

- Base Mount → Common in industrial equipment, easy to install.

- Custom Bracket → Common in drones and robots. Engineers design their own brackets to integrate the motor with the gearbox or heat sink.

Key Point:Mounting must be considered as part of the overall machine structure, not an afterthought.

Control Compatibility

ESC Matching:Motor parameters must be consistent with the controller’s drive range.

Control Strategy:

- Square Wave Drive → Simple and cheap, but less efficient.

- FOC → Preferred by engineers; high efficiency, low noise, especially in robotics and EVs.

Heat Dissipation and Reliability

The poor heat dissipation of the internal windings is a major concern for engineers.

- Consider:

- Temperature rise during continuous operation.

- Risk of magnet demagnetization.

- Need for air/water cooling assistance.

Engineers often add temperature sensors and run tests. This confirms the motor won’t overheat under extreme conditions.

Common Pain Points of Brushless Outrunner DC Motors

Startup Jitter / Startup Failure

Typical symptom: Motor just “shakes” once and doesn’t rotate. Fails to start at low speed, accompanied by squeaking or vibration.

Engineering Reasons:

- High pole count → Difficult for ESC to identify magnetic pole position.

- Mismatched startup parameters (timing, startup power, PWM frequency).

- High winding resistance → Back EMF is too low at low speed.

Engineer’s Insight: Adjusting ESC parameters is the first step. Many do not realize this initially.

Overheating During Continuous Load

Customer complaint: Drone is scalding hot after 5 minutes of flight. Temperature easily exceeds 80°C–100°C during long runs.

Reasons:

- Suboptimal outrunner heat dissipation path.

- High-frequency, high-current operation.

- Small size + High KV → Large current, severe copper loss.

Engineer’s Insight: Don’t just look at peak power; continuous power is the key.

Magnet Demagnetization / Unbonding

Common in cheap motors:

- High temperature → Magnet performance drops.

- Adhesive softens → Magnet shifts.

Consequence: Thrust drops suddenly, severely degrading flight performance.

Engineer’s Insight: Our TSL MOTOR industrial-grade motors use high-temperature resistant magnets and glue. Customers don’t need to worry about this.

Short Bearing Life / Noise

Common feedback: Noise appears after a few hours of use. Slight wobble exacerbates vibration.

Reasons:

- High radial load on the outrunner.

- Insufficient lubrication.

- Low-grade bearing material.

Engineer’s Insight: Bearings are the first component to fail. Pay attention to life and lubrication during selection. TSL MOTOR uses imported Japanese precision bearings, so our customers have not encountered problems here.

Vibration Due to Poor Concentricity

Symptoms: High-speed vibration, slapping sound, “jello effect” in drone videos.

Reasons:

- Uneven weight distribution between casing and magnets.

- Poor dynamic balancing.

- Propeller mounting eccentricity.

Engineer’s Insight: Dynamic balancing is a science often overlooked by DIY users. TSL MOTOR motors undergo dynamic balancing and runout testing.

ESC Compatibility Issues

Typical Problems: Unstable speed, low-speed jitter, sudden power drop.

Reasons:

- High pole-count outrunners are better suited for FOC or high-frequency PWM.

- Simple algorithms in cheap ESCs.

- Improper timing settings.

Engineer’s Insight: The motor and ESC are a system. Don’t evaluate components individually.

Inaccurate KV or Poor Batch Consistency

User Complaint: Labelled KV1000, measured 900–1200. Large variation between batches.

Reason: Poor quality control from non-industrial-grade suppliers.

Engineer’s Insight: Don’t blindly trust labelled parameters. Actual testing is reliable. TSL MOTOR tests the parameters of every motor, and each prototype includes a test report.

Conclusion

The brushless outrunner motor is a motor technology highly optimized for specific applications. Its external rotor structure provides high torque density, light weight, and fast response. These advantages make it irreplaceable in drones, gimbals, robot joints, power tools, and light power transmission systems.

However, it also has limitations: limited heat dissipation, bearing life challenges, high dynamic balancing requirements, and controller matching difficulty. These pain points are frequently discussed in the engineering community. They remind engineers to fully evaluate the motor against actual working conditions during selection.

From an engineering perspective, the key to successful outrunner motor application is:

- Clearly defining the application scenario; avoid blindly pursuing parameters.

- Matching electrical and control strategies; ensure the motor and ESC work together.

- Focusing on heat dissipation and reliability, especially in continuous load scenarios.

- Emphasizing manufacturing quality and material selection (high-temp magnets, imported bearings, dynamic balancing).

TSL MOTOR provides more stable and durable outrunner solutions. We achieve this by using high-temperature resistant magnets, imported Japanese precision bearings, strict dynamic balancing, and consistent parameter control.

💡 Overall: The outrunner brushless motor is the best choice for “lightweight, high-efficiency direct drive.” However, for 24/7 heavy load, extreme precision, or industrial-grade protection, the inrunner motor remains more suitable. Engineers should combine application needs, advantages, and limitations to harness its true engineering value during selection.

FAQ

Q1:Why does an outrunner motor have more torque than an inrunner of the same size?

Answer: The outrunner structure places the permanent magnets on the outside. This increases the rotating diameter which acts as a lever arm. Based on the principle of torque Force times Radius a larger lever arm allows for higher torque output with the same electromagnetic force.

Q2: What is the main limitation of outrunner motors?

Answer: The primary limitation is relatively weak heat dissipation ability. The heat source the stator windings is enclosed by the outer casing. This long heat path makes it unsuitable for high power industrial applications that require continuous 24/7 heavy loading.

Q3:What is the advantage of outrunner motors in drone applications?

Answer: The advantages are high torque at low speed and light weight. It can directly drive large diameter propellers to provide high thrust. Its operation mode is intermittent peak load which perfectly suits its strong instantaneous overload capacity.

Q4:What does the KV value mean when selecting a motor

Answer: The KV value speed constant in RPM V represents how many revolutions per minute the motor will increase when 1 volt of voltage is applied at no load. A low KV value means high torque and low speed suitable for heavy loads. A high KV value means low torque and high speed suitable for light loads.

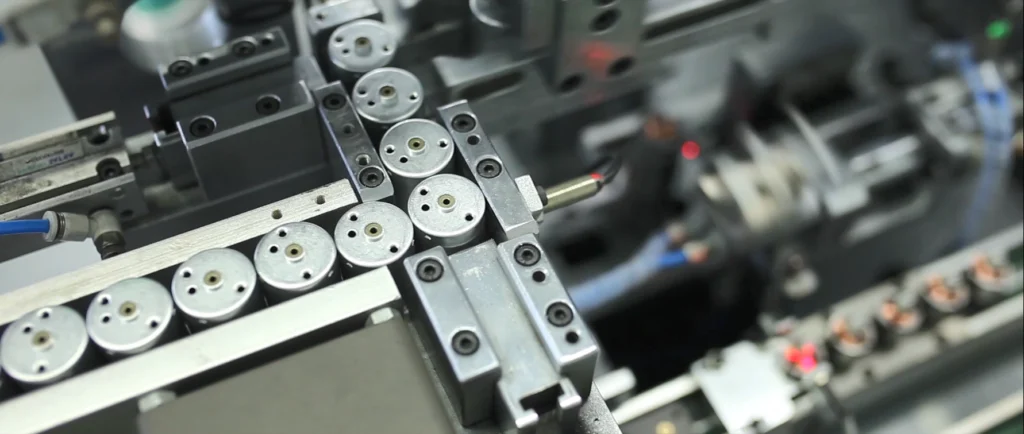

Tsinglin Motor: Custom DC Motor Solutions

Established in 2009, Tsinglin Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Brushless DC Motor

Brushless DC motors provide a solution to meet the demands for higher energy efficiency, longer lifespan, and quieter operation. As a leading manufacturer of BLDC motors,TSL Motors has developed the smallest BLDC motor, measuring just 6mm in diameter and 2mm in thickness, designed as a flat vibration motor.