Over the past century, automotive door lock systems have advanced from simple mechanical designs to intelligent electronic subsystems.

As a key safeguard for vehicle security, the Central Door Lock System (CDLS) now integrates features such as passive keyless entry, speed-sensing auto-lock, crash auto-unlock, and child safety locks—demanding actuators with high consistency, reliability, and speed.

At the heart of these actuators is the miniature DC motor, which defines performance and durability.

TSL MOTOR, a leading Chinese manufacturer, offers the RS-280A series as a solution optimized for high torque density, wide temperature adaptability, and long-term reliability.

Key Takeaways

- 1. Space Optimization: The RS-280A features a unique flat-side housing design. This allows it to fit perfectly into the extremely confined space within the vehicle door panel.

- 2. Extreme Torque Output: High-performance models deliver a powerful stall torque of 350 g·cm. This force is essential for overcoming high friction or ice in sub-zero conditions.

- 3. Ice-Breaking Capability: The motor’s high speed, exceeding 12,000 RPM, stores kinetic energy. This energy is released as impact force to ensure critical unlocking even when the mechanism is frozen.

- 4. Superior Reliability: TSL uses an F-Class insulation system rated for 155°C. This guarantees performance and longevity even in harsh, high-temperature summer environments.

- 5. Endurance Mechanism: The standard configuration uses a durable carbon brush system. Carbon brushes resist the high-current arcing from frequent start-stop cycles better than metal brushes.

- 6. NVH & Transmission: It pairs ideally with a worm gear mechanism for its high reduction ratio. This combination also offers superior low-noise performance (NVH).

- 7. Fail-Safe Design: Integration with a centrifugal clutch is recommended. This allows the motor to decouple, ensuring effortless manual mechanical unlocking.

Automotive Central Door Lock System (CDLS)

What is the Automotive Central Door Lock System?

Early automotive door locks required the driver to manually operate the lock cylinder of each door with a mechanical key. This was not only cumbersome but also posed a significant security risk due to human error in leaving a door unlocked.

With the introduction of electronic technology, the Central Door Lock System emerged. Its core concept is to drive all door lock actuators synchronously via a single control signal from the driver’s side, enabling “one-touch lock” or “one-touch unlock.”

However, today’s smart lock systems extend far beyond this basic definition. Modern central lock systems integrate features like Passive Keyless Entry (PKE), Speed Sensing Auto-Lock, Crash Impact Auto-Unlock, electronic control of the child safety lock, and logic to prevent keys from being locked inside the car.

The implementation of these complex functions requires the door lock actuator to possess extremely high response consistency and precision.

For example, within milliseconds of a vehicle collision, the Body Control Module (BCM) issues an emergency unlock command.

At this moment, the motor must overcome potential extra mechanical resistance from door deformation and quickly reset the latch to open an escape route. This extreme emphasis on “Fail-Safe” functionality demands a Stall Torque for the driving motor that is far higher than required for normal daily use.

Actuators in the Central Lock System

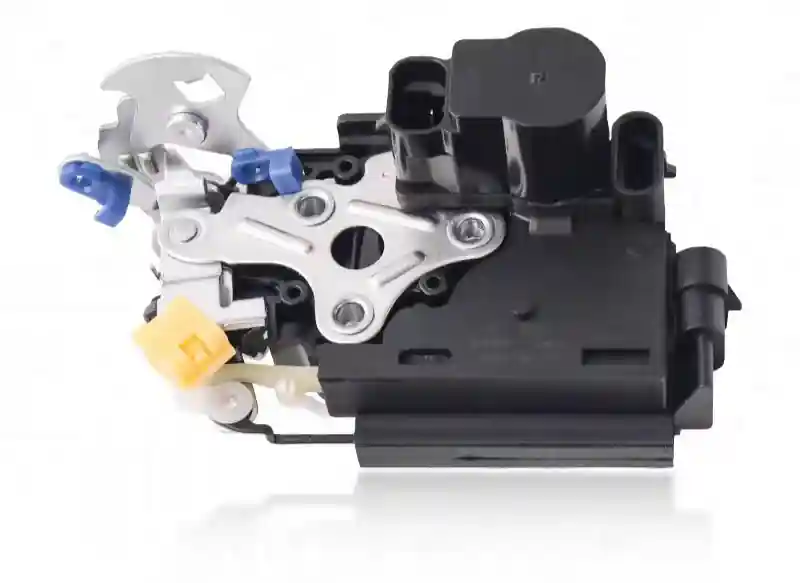

The automotive door lock actuator is a highly integrated electromechanical module, typically consisting of a miniature DC motor, a Gear Reduction Mechanism, a Clutch Assembly, Position Feedback Switches (Microswitches), and an output linkage or cable.

The miniature DC motor acts as the “heart,” responsible for converting electrical energy into rotational mechanical energy.

Due to the extremely confined space inside the door—the “wet zone” door cavity must accommodate the window regulator, speaker, crash beam, and airbag sensor mounting—the size of the door lock actuator is strictly limited.

This directly necessitates an exceptionally high “Power Density” for the drive motor. The motor must generate sufficient force within a limited diameter (usually <25mm) and possess a flat profile to fit the thin-walled installation environment.

The TSL MOTOR RS-280A series motor, based on this extreme consideration for space utilization, features a Flat-Side Housing design with double-sided cutouts.

This design minimizes the installation thickness while maintaining magnetic circuit saturation and torque output, making it one of the standard solutions in this field.

The TSL-RS-280A Solution

To evaluate a motor’s suitability, one must analyze the physical significance behind its specifications. The TSL-RS-280 series demonstrates differentiated configurations tailored for various load characteristics.

Basic Physical Architecture and Size Advantage

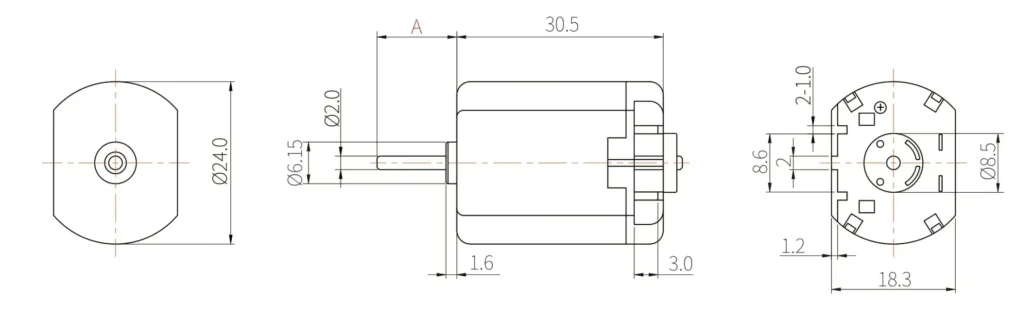

The nominal diameter of the TSL-RS-280A motor housing is 24.0 mm, but the sides are flattened, significantly reducing the thickness dimension to approximately 18.3 mm. This “flattened” feature is a key reason for its dominance in door lock applications.

The door lock body is typically installed on the door sheet metal edge, where thickness is an extremely sensitive parameter. Using a standard circular motor (such as RS-310 or RS-280) would increase the lock body thickness, thereby compressing the window glass operating space or forcing the interior trim panel to bulge, compromising the vehicle interior design.

Furthermore, the Shaft Extension length is about 11.5mm to 14mm (depending on the customized model), with a shaft diameter of 2.0mm. This standard shaft diameter, combined with Knurling process, ensures a secure interference fit with a plastic Worm Gear (made of materials like POM or Nylon), preventing slip failure under high torque shock.

Tips:TSL MOTOR provides one-stop solutions, offering customization of operating voltage and output shaft configurations, including worm gear and worm shaft options.

Electrical Characteristics and Power Output Analysis

We provide four typical reference motor models corresponding to different voltage platforms and performance priorities. We will detail the interpretation of their key parameters:

| Motor Model | Voltage | No Load | At Maximum Efficiency | Stall | |||||

| Current | Speed | Current | Speed | Torque | Output | Current | Torque | ||

| V | A | RPM | A | RPM | g·cm | W | A | g·cm | |

| TSL-RS-280SAV-15250B | 15 | 0.08 | 9000 | 0.38 | 7433 | 46.10 | 3.52 | 1.80 | 264.80 |

| TSL-RS-280PAVT-20150B | 12 | 0.115 | 12300 | 0.65 | 10457 | 52.46 | 5.63 | 3.69 | 350.11 |

| TSL-RS-FT-280SAV-18182LG | 12 | 0.07 | 9565 | 0.44 | 8259 | 40.96 | 3.48 | 2.56 | 299.99 |

| TSL-RS-280PAVT-21120R | 12 | 0.11 | 12850 | 0.68 | 11060 | 48.75 | 5.54 | 4.20 | 349.97 |

The Decisive Significance of Stall Torque

In central lock applications, Stall Torque is the most critical parameter. This is because the door lock mechanism operates near a stall condition at the initial phase of movement (overcoming static friction) and the final phase (reaching the locked position or encountering obstruction).

Data shows that the TSL-RS-280PAVT-20150B and 21120R models provide a stall torque of up to 350 g·cm (approximately 34.3 mN·m). Compared to the 40–50 g·cm of a typical toy motor, this is nearly an order of magnitude increase.

This high torque output is primarily achieved through optimized magnetic circuit design (using high-performance anisotropic ferrite magnets) and low-resistivity coil windings.

Under low-temperature, freezing conditions, the viscosity of the grease inside the lock mechanism increases sharply, and ice layers may form. If the motor’s stall torque is insufficient at this point, the door will fail to unlock. The base torque of 350 g·cm, magnified by the worm gear reduction, generates sufficient thrust to break the ice.

Speed and Response Time

The no-load speed of the two high-performance models is above 12000 RPM. The significance of high speed is not only to quickly complete the locking action (typically required to be less than 200 ms) but also to provide sufficient kinetic energy reserve.

Door lock actuators often have a few millimeters of “free play.” The motor starts and accelerates under no-load, accumulating rotor kinetic energy, which is then used as impact force to engage the locking mechanism.

Kinetic energy is proportional to the square of the speed. A high speed of 12000 RPM means the motor can instantly release a peak force significantly greater than the static stall torque through the impact effect. This is crucial for overcoming mechanism rust or minor jamming.

Current Selection

Comparing the “15250B” (15 V) and “20150B” (12 V) models, we see that the low-voltage, high-torque model (20150B) has a higher stall current (3.69 A vs 1.80 A).

This indicates a smaller internal resistance, allowing a larger current to pass through at the 12 V standard vehicle voltage, thereby generating a stronger Lorentz force.

Although a high current challenges carbon brush life, the door lock operates in an Intermittent Duty cycle, with each power-on duration under 0.5 seconds, limiting heat accumulation. Therefore, this design strategy of “trading current for torque” is highly rational.

Tips:TSL MOTOR provides one-stop solutions, offering customization of operating voltage and output shaft configurations, including worm gear and worm shaft options.

Insulation Class and Thermal Endurance

The automotive application environment is extremely harsh. A critical, albeit not explicitly listed, parameter is the insulation class. The TSL-RS-280A series motors typically adopt an F-Class (Class F) Insulation System.

Temperature Definition: F-Class insulation allows a maximum hot spot operating temperature of 155°C.

Application Scenario: Under summer solar exposure, the internal door environment temperature can easily exceed 80°C. If the motor operates frequently (e.g., children playing with the latch), the coil temperature rise can add an extra 50–60°C. Using common B-Class (130°C) insulation could lead to softening or breakdown of the insulation layer, causing inter-turn short circuits.

Dynamic Matching and Simulation of the Mechanical Transmission System

The motor is merely the power source; achieving the door lock’s linear reciprocating motion requires a precise transmission mechanism. The TSL-RS-280A motor is typically paired with a Worm Gear Mechanism.

Advantages of Worm Gear Drive

Most door lock actuators choose worm gears over spur gears for two reasons:

High Reduction Ratio and Compact Size: A worm gear can achieve a large single-stage reduction ratio (typically 30:1 to 60:1) in an extremely small space. This allows a high-speed, low-torque miniature motor (like the RS-280A) to drive a high load without a complex multi-stage gearbox.

Noise Control (NVH): The meshing of a worm gear drive is continuous sliding contact. Compared to the impact contact of spur gears, its running noise is lower, meeting the automotive NVH (Noise, Vibration, and Harshness) requirements.

Dynamic Calculation: From Torque to Thrust

To verify if the TSL-RS-280A can meet door lock requirements, we establish the following model:

- Motor Stall Torque = 350 g·cm = 0.0343 N·m (Model 20150B)

- Reduction Ratio = 45:1 (Typical Value)

- Transmission Efficiency = 40% (worm gear efficiency typically 30%–60%)

- Output Lever Radius = 20 mm = 0.02 m

The gearbox output shaft torque is: T_out = 0.0343 N·m × 45 × 0.40 = 0.6174 N·m

Converted to linear thrust at the end point: F = 0.6174 N·m ÷ 0.02 m ≈ 30.87 N

Analysis: The force required to move a door lock latch at room temperature is typically 15–25 N. The calculated 30.87 N shows that the TSL-RS-280 motor easily satisfies normal operation.

Extreme Condition Challenge:

In winter, a frozen door lock may require 60–100 N of opening force. The static calculation of 30.87 N is insufficient, which explains why the motor must have “Impact Ice-Breaking” capability.

In practice, the motor first runs at no-load, quickly accelerating above 8000 RPM. When the gear clearance is eliminated, the rotor’s stored angular momentum is released in a very short time, producing impact torque several times greater than static torque.

The high-speed characteristic of the TSL-RS-280A (12300 RPM) is tailored for this mechanism, ensuring it can instantly deliver “ice-breaking force” under freezing conditions.

The Necessity of a Centrifugal Clutch

In door lock actuator design, the system must also allow manual unlocking with a mechanical key or interior handle.

If the motor is always rigidly connected to the output shaft, manual unlocking would require back-driving the reduction gear set and spinning the motor rotor at high speed. Because worm gears tend to self-lock or have high reverse friction, this would make manual unlocking very difficult or even impossible.

TSL Solution: A centrifugal clutch is integrated into the drivetrain.

- Principle: Mounted inside the worm wheel, when the motor rotates, centrifugal force moves the flyweights outward, engaging the output shaft and transmitting power.

- Manual Mode: When the motor is unpowered, the flyweights retract under spring force, decoupling the motor from the output shaft. The user then only needs to overcome the lock body’s spring force.

- Adaptability: The high-speed characteristic of the TSL-RS-280A (>9000 RPM) ensures rapid clutch engagement. Higher speed generates greater centrifugal force, reducing clutch slip and ensuring reliable transmission.

TSL Solution’s Core Competitiveness

Automotive component testing standards are far more stringent than those for consumer electronics. The TSL-RS-280A motor was designed from the outset with the harsh automotive environment in mind.

Advantages of the Carbon Brush Commutation System

Low-cost toy motors often use metal finger brushes. However, in automotive door lock applications, a Carbon Brush is the absolute industry standard and the core configuration of the TSL-RS-280.

- Resistance to Arc Erosion: Door lock motors have a high starting current (greater than 3 A) and frequent start-stop cycles, with back EMF generating intense commutation sparks. Metal brushes are highly susceptible to fusion welding or rapid wear. Carbon brush material has a high melting point, and its graphite component is self-lubricating, allowing it to withstand tens of thousands of high-energy spark impacts.

- Anti-Oxidation: The door interior has high humidity, making metal contacts prone to oxidation and forming an insulating film. Carbon brushes are chemically stable and maintain low contact resistance even after long periods of inactivity, ensuring the motor can start at full power at any time.

Wide Operating Temperature Lubrication Solution

Temperature is the biggest challenge to door lock reliability.

- Low Temperature (-40°C): Ordinary lubricants congeal into a wax-like substance, leading to a sharp increase in motor resistance. The TSL solution recommends using fully synthetic wide-temperature range grease for bearings and gearboxes. Its pour point is below -50°C, ensuring the motor can start easily in extreme cold.

- High Temperature (+85°C): At high temperatures, grease can thin and flow away. The TSL-RS-280A uses Oil-impregnated Sintered Bronze Bearings. Lubricating oil is locked in the micro-pores of the bearing through capillary action, and the bearing end cap is designed with an oil-retaining ring to prevent grease splatter from contaminating the commutator.

TSL MOTOR Comprehensive Door Lock Application Solution Recommendations

Based on the above analysis, we offer the following application extension suggestions for the TSL-RS-280 motor to maximize its technical value.

Product Selection Matrix

Standard passenger cars (economy models):

Recommended model TSL-RS-FT-280SAV-18182LG. This motor delivers a moderate speed of 9500 RPM at 12V, with low noise and sufficient torque. It strikes a balance between cost and performance, making it suitable for standard central locking modules.

SUVs / Off-road vehicles / Luxury cars:

Recommended model TSL-RS-280PAVT-20150B. Door lock mechanisms in these vehicles are typically heavier and may face harsher outdoor freezing conditions. This motor provides high stall torque (350 g·cm) and greater power reserves, ensuring stronger safety redundancy.

Trunk / Tailgate locks:

Since tailgate latches bear heavier loads, it is likewise recommended to use the high-torque version, with an appropriately increased gear reduction ratio.

Noise (NVH) Optimization Strategy

With the popularity of Electric Vehicles (EVs), engine noise has disappeared, making the sound of the door lock operation stand out. To enhance the vehicle’s “sense of quality,” the TSL solution recommends:

- Skewed Slot Rotor: Design the rotor slots with a slight angle during manufacturing. This effectively smooths the reluctance variation, significantly reducing electromagnetic vibration and the low-speed “humming” sound caused by cogging torque.

- Axial Damping: Add Teflon washers at the motor bearing steps to limit the rotor’s axial movement (end play), eliminating the “clack” sound when the rotor strikes the end cap at the moment of motor startup.

Smart Drive and Protection Logic

We recommend that OEMs incorporate the motor characteristics into the BCM control strategy:

- Soft Start: Use PWM modulation to linearly increase the voltage over 10–20 milliseconds, reducing the mechanical shock sound upon motor startup.

- Stall Protection: Monitor the motor current. If the current exceeds a threshold (for example, 5 amperes) for 200 milliseconds, it is deemed a mechanical jam, and the power is immediately cut off to prevent motor overheating or draining the battery.

Conclusion

The TSL-RS-280A series motor is not merely a standard miniature brushed DC motor; it is a dedicated power solution deeply optimized for the pain points of automotive central lock applications.

Its flattened package solves the door space layout challenge; the high torque and high speed power combination perfectly balances the agility of normal temperature operation with the powerful ice-breaking demand of low-temperature freezing conditions; and the application of a carbon brush and F-Class insulation system builds a solid moat of reliability.

Through proper model selection (such as the 20150B high-torque version) and cooperation with a centrifugal clutch and scientific lubrication design, the TSL-RS-280A can provide a safe, durable, and acoustically refined central lock drive solution for modern automobiles, fully meeting the diverse technical requirements from entry-level sedans to high-end luxury models.

FAQ

Q1:What is the core advantage of the TSL-RS-280A motor?

A1:Its flat-side housing design (thickness approx 18.3 mm) is its core feature, allowing it to fit perfectly into the narrow automotive door cavity space.

Q2:Why is a worm gear mechanism typically chosen for the actuator?

A2:The worm gear provides a large reduction ratio in a compact size, while its continuous sliding contact helps achieve low noise (NVH optimization).

Q3:What does Class F insulation mean for reliability?

A3:It means the motor windings can withstand a maximum hot spot temperature of 155°C, ensuring reliable performance even under extreme high temperatures caused by summer solar exposure.

Q4:What is the role of the Centrifugal Clutch in the system?

A4:When the motor is unpowered, it decouples the motor from the output shaft, allowing the user to easily perform manual mechanical unlocking without having to back-drive the motor and gearbox.

TSL-Motor: Custom Motor Solutions

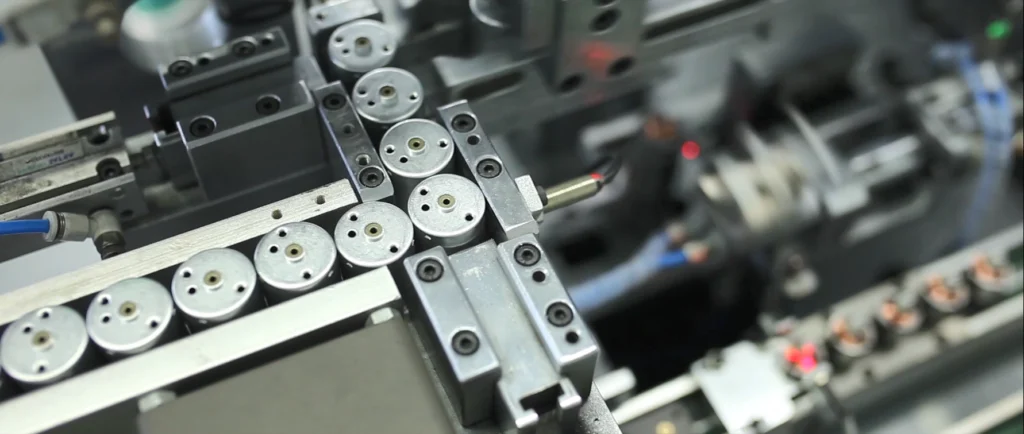

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.