From a car window’s smooth move, to a surgical robot’s precise action, DC gear motors quietly matter. They are at the heart of modern electromechanical systems. They provide steady power and sharp control.

A DC gear motor is not a simple combo. It tightly couples a DC motor with a gearbox. It turns high speed and low torque into low speed and high torque. This makes it better for real-world use.

Next, TSL MOTOR introduces its working principle, categories, key specs, and applications. You will gain a full view—from theory to practice. This will help you pick the right motor for your project.

Key Takeaways

- DC gear motors combine a DC motor and gearbox to convert high-speed, low-torque rotation into low-speed, high-torque output—ideal for real-world power and control needs.

- Gear reduction ratio is the core design parameter, directly balancing output speed and torque to match specific load and performance requirements.

- Motor type matters: brushed for low cost, brushless and hollow-cup for high efficiency, and stepper for precise position control.

- Gearbox structure defines performance: spur for simplicity, planetary for high torque density and precision, and worm for quiet, self-locking applications.

- Datasheet parameters are interconnected—voltage, speed, torque, current, and efficiency must be evaluated together to ensure safe, efficient operation.

- Application drives selection: robotics, automotive, medical, and smart-home systems each require tailored torque, speed, noise, and reliability levels.

- The future is smart and integrated: brushless, stepper, and sensor-equipped IoT-connected gear motors will evolve into intelligent actuators that enable next-generation automation.

Core Principle: Trade Speed for Torque

The goal of the DC gear motor is to resolve the clash between “high speed, low torque” and “low speed, high torque.” Through clever gear structure, it turns highspeed rotation into strong, controllable output. It plays a key role in modern systems.

Why is reduction needed?

Standard DC motors spin at thousands RPM. But they produce low torque. That limits heavy loads and precision control.

A gear motor uses a gearbox to slow the speed and boost the torque. That lets a small motor handle big tasks.

What the gearbox does?

The gearbox (or reducer) is the core part of a gear motor. It works like a “mechanical transmission.” Gear meshing turns high speed into low speed, high force output.

The law of energy conservation applies: speed goes down, torque goes up, power stays almost the same. It’s like a lever: small effort moves big loads.

Gear reduction ratio

Definition: Reduction ratio = Motor revolutions ÷ Output shaft revolutions.

For example, 10:1 means the motor turns ten times, the output shaft turns once.

Impact:

- Higher ratio → output speed falls, output torque rises.

- Lower ratio → output speed rises, output torque falls.

Formula:

- Output speed = Motor speed ÷ Reduction ratio

- Output torque ≈ Motor torque × Reduction ratio × Gear efficiency

Real-world efficiency

Gear transmission isn’t lossless. Friction, lubrication, bearings all waste energy. Gearbox efficiency is often 70%–98%. So actual output torque is a bit lower than theory.

Choosing the reduction ratio

The chosen ratio directly affects whether the motor meets the load. Choose too low → risk stall or overheating. Choose too high → speed might be too low, efficiency drops.

A good ratio forms the “bridge” between motor specs and real demands. It’s the engineering art of translating theory into practice.

Types of DC Gear Motor

DC gear motors are a large family, not just one product. Based on dc motor and gearbox type, we can classify them. Knowing these helps you make smarter choices.

By DC Motor Type

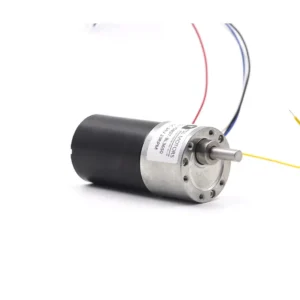

Brushed DC Gear Motor

Description: Classic type. Uses carbon brushes and a mechanical commutator to reverse current in the rotor windings.

Pros: Simple design. Low initial cost. Direct speed control (via voltage). High starting torque.

Cons: Mechanical contact drives wear. Brushes and commutator wear out. Shorter life. Requires maintenance. Friction causes EMI and sparks. Not safe in explosive or flammable settings. Efficiency is lower.

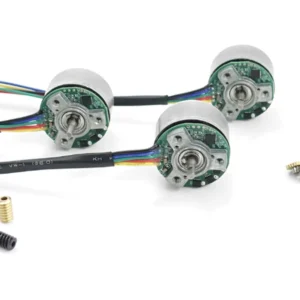

Brushless DC (BLDC) Gear Motor

Description: Replaces brushes with an electronic controller and position sensors (like Hall sensors). Commutation is done electronically. Rotor uses permanent magnets; stator has windings.

Pros: No brushes = much longer life (10,000–20,000 hours+). Low maintenance. Higher efficiency (85-90%+). Quieter. Less EMI. Higher power-density. Less heat—better for high speed or continuous use.

Cons: Higher cost. Requires complex controller. System design is more complex. Higher initial investment.

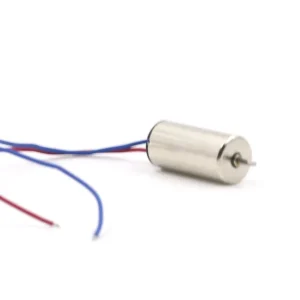

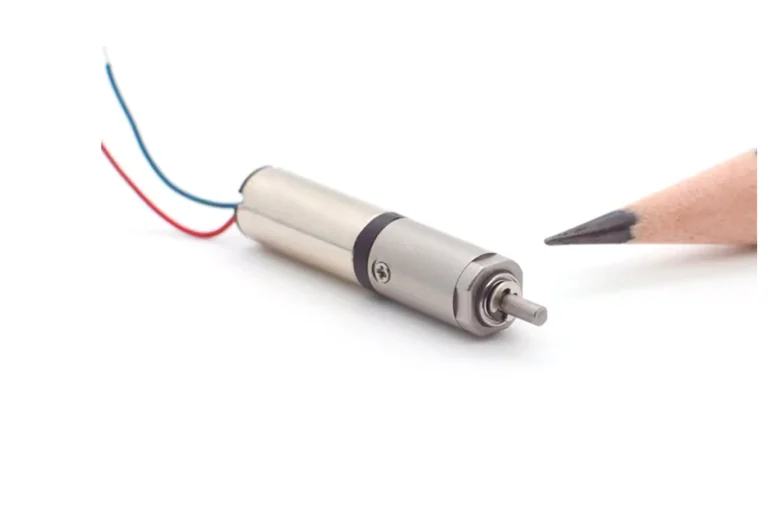

Coreless DC Gear Motor

Description: Special design. The rotor has no traditional iron core. Windings form a self-supporting hollow cylinder.

Pros: Very light rotor, very low inertia. Excellent dynamic response (fast accel/decel). Smooth operation, no cogging. High efficiency. Compact. Very low no-load current—ideal for battery-powered devices.

Ideal uses: High performance tasks needing very fast response, like advanced prosthetics, micro-pumps, high-precision robots.

Stepper Gear Motor

Description: Converts electrical pulse signals into precise angular displacement or linear motion. Integrates a stepper motor with a gearbox. Moves in fixed “steps” without feedback (open-loop control) by default.

Pros: Exceptional positional accuracy and repeatability. No cumulative error in open-loop systems. Simple speed and position control via pulse signals. High holding torque (maintains position without power in some cases). Compatible with most gearbox types (planetary, spur).

Cons: Lower efficiency at high speeds. Prone to resonance at specific speeds (may require damping or micro-stepping). Higher power consumption under no-load or light-load conditions. Less suitable for high-speed continuous operation.

When choosing brushed vs brushless motors, think long-term. Brushed motors cost less upfront, but their limited lifespan and maintenance needs can become a burden in continuous or mission-critical tasks.

Choosing a brushless motor costs more at start but offers high reliability and lower total cost of ownership.

By Gearbox Structure

Spur gear gearbox (parallel-shaft)

Design: Simple and common. Straight-cut cylindrical gears on parallel shafts. Multi-stage gear meshing gives higher reduction.

Features: Low cost. Reliable for standard use. But at high speed it may be noisy. Load is carried by a single contact point — so torque capacity is limited relative to other types.

Planetary gearbox (coaxial)

Design: More complex. A central “sun” gear, multiple planets around it, an outer ring gear. Input and output shafts share the same axis (coaxial).

Features: High power density—large torque in compact size. Load spreads across multiple planets => higher capacity, high efficiency, low backlash, smoother operation. Ideal for high-torque, high-precision tasks. But cost is higher.

Worm gear gearbox (right-angle output)

Design: A “worm” screw meshes with a worm wheel. Output shaft is at 90° to input.

Features: Main benefit: very high reduction ratio in one stage. Sliding contact gear faces => very quiet. Self-locking ability at high reduction ratio: output cannot drive input. Useful for applications needing hold when power is off (like lifts). But sliding friction means lower efficiency (typically 30%–60%).

The gearbox geometry heavily impacts mechanical design. For example, the right-angle output of a worm gear is good when motor and drive must sit side-by-side in tight space.

Planetary gearbox’s coaxial layout supports compact and neat line layouts. So, the gearbox type should be chosen early in design—it’s about the architecture, not just a component.

To help comparison, here is a table of the main traits of the three common gearbox types:

| Feature | Spur Gearbox | Planetary Gearbox | Worm Gearbox |

| Torque capacity | Low to medium | High | Very high |

| Efficiency | High (95-98%) | High (90-95%) | Low (30-90%) |

| Reduction ratio | Low to medium | Medium to high | Very high |

| Size/compactness | Larger at high ratio | Very compact (high power density) | Compact structure, right-angle output |

| Cost | Low | High | Medium |

| Noise level | Possibly noisy | Quiet | Very quiet |

| Backlash | Medium | Low | High |

| Key traits | Simple structure, low cost | High torque density, high efficiency | Self-locking, large reduction ratio |

Key Parameters & Specifications

To pick the right DC gear motor for your project, you must read its datasheet carefully. The datasheet is the motor’s “ID.” It lists all performance specs.

Key performance parameters explained

| Operating | Motor | No Load | Rated Load | Stall | ||||

| Voltage | Model | Speed | Current | Torque | Speed | Current | Torque | Current |

| 3V | A26 | 53rpm | ≤0.035A | 0.6kg.cm | 30rpm | ≤0.18A | 1.2kg.cm | ≤0.35A |

| 3V | A45 | 80rpm | ≤0.045A | 0.6kg.cm | 52rpm | ≤0.27A | 1.5kg.cm | ≤0.65A |

| 3V | A15 | 100rpm | ≤0.05A | 0.6kg.cm | 60rpm | ≤0.33A | 1.5kg.cm | ≤0.75A |

| 6V | A05 | 51rpm | ≤0.03A | 0.3kg.cm | 20rpm | ≤0.08A | 0.6kg.cm | ≤0.2A |

| 6V | A35 | 72rpm | ≤0.04A | 0.6kg.cm | 35rpm | ≤0.15A | 1.1kg.cm | ≤0.3A |

| 6V | A26 | 110rpm | ≤0.05A | 0.7kg.cm | 63rpm | ≤0.25A | 1.5kg.cm | ≤0.6A |

| 12V | A05 | 100rpm | ≤0.04A | 0.6kg.cm | 55rpm | ≤0.1A | 1.2kg.cm | ≤0.3A |

| 12V | A35 | 142rpm | ≤0.05A | 0.7kg.cm | 90rpm | ≤0.2A | 1.5kg.cm | ≤0.6A |

Rated Voltage (V)

The DC operating voltage at which the motor is designed for best performance and highest efficiency. Running under it reduces power. Exceeding it may overheat or damage the motor.

Speed (RPM):

No-Load Speed: The maximum speed the motor output shaft can reach at rated voltage with no load. It’s a theoretical maximum.

Rated Speed: The output shaft speed when the motor delivers rated torque. This is the safe continuous working point.

Torque (Nm, kg-cm, oz-in):

Rated Torque (Continuous Torque): The maximum torque the motor can sustain without overheating. It is the core indicator of continuous operation capability.

Stall Torque: The maximum torque the motor can exert when the output shaft is locked (zero speed). Running in stall for more than a few seconds can burn the motor due to excessive current. It marks the motor’s extreme strength.

Current (A):

No-Load Current: The current drawn at rated voltage with no load.

Rated Current: The current drawn when the motor runs at rated torque and rated speed.

Stall Current: The maximum current drawn when the motor is stalled. The power supply and driver must handle this peak current or risk damage.

Output Power (W)

The mechanical power produced by the motor—torque × speed. When torque is zero (no load) or speed is zero (stall), output power is zero. Peak power usually occurs around 50% of stall torque.

Efficiency (%)

The ratio of mechanical output power to electrical input power (P_out / P_in). It shows how well the motor converts electricity to motion. Peak efficiency usually occurs at fairly low torque and fairly high speed. Running near that point gives longest life and lowest heat.

Understanding performance curves

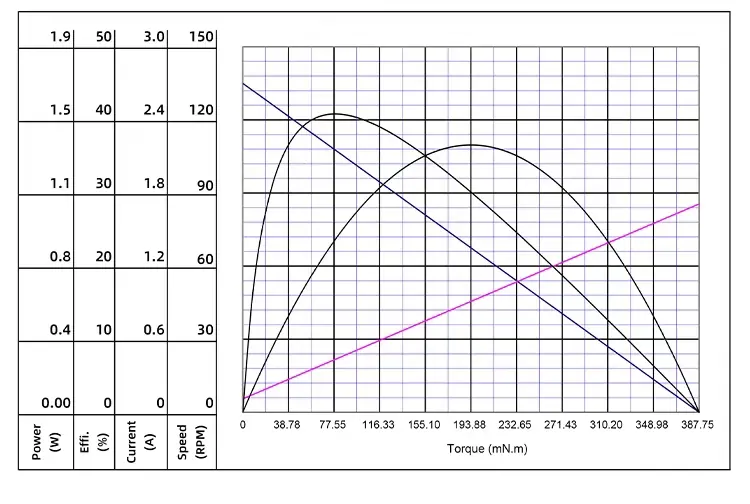

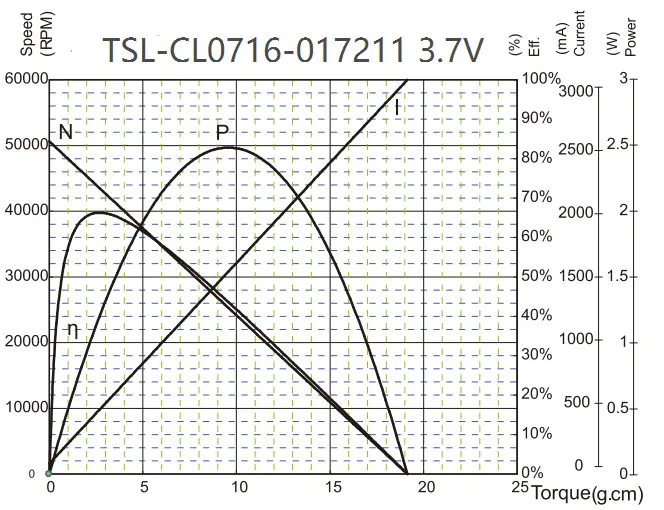

Datasheets often provide performance curves showing how speed, current, power, and efficiency vary with torque.

In the figure, the letters N, I, P, and η correspond to the speed-torque curve, current-torque curve, power curve, and efficiency curve respectively.

Speed-Torque curve(N): A line sloping downward. It shows speed falls as torque rises.

Current-Torque curve(I): A line sloping upward. It shows current consumption rises as torque load increases.

Power curve(P): A parabola. Peak around ~50% of stall torque. Represents maximum mechanical power.

Efficiency curve(η): Also a parabola. Its peak often lies at ~10-30% of stall torque. That highest point is the motor’s optimum operating point and sets its rated performance.

These curves reveal an important fact: the motor’s maximum power point is not the best or safest for continuous duty.

At ~50% of stall torque (peak power point) current is high. Heating drives as P_heat = I²R. So at that point, the heating is far higher than at the high-efficiency point (~10-30% stall torque). Excess heat causes insulation aging, magnet demagnetisation, and early failure.

Therefore, performance curves define safe working zones:

- Continuous duty region: Around the highest efficiency point, typically 0–30% of stall torque. The motor can run continuously here without overheating.

- Intermittent duty region: Between highest efficiency and maximum power point, typically 30–60% of stall torque. Motor can run here for short periods but needs cooling time — not for continuous duty.

- Danger zone: Above ~60% of stall torque. Operation here should be strongly avoided as motor may burn out quickly.

Also, datasheet parameters aren’t independent. They are tightly linked by internal physical laws. For example, voltage ∝ no-load speed; current ∝ torque. Knowing these links means motor selection is a system-level task. You can’t pick based on one parameter only.

You must consider load characteristics, power supply capability, driver specs, mechanical design to reach the optimal choice.

How to Choose the Right DC Gear Motor

Turning theory into practice requires a systematic selection method. Motor selection is matching application demands with motor specs, while balancing cost, size and other constraints.

Step One: Determine mechanical requirements (torque & speed)

This is the most important step—it directly decides if the motor can “do the job.”

Calculate required torque: Estimate the torque needed to drive the load. Consider load mass, friction, motion radius, incline etc. For example, for a pulley lifting weight: Torque = Force × Radius.

Determine required speed: Calculate the output speed (RPM) your application needs. For example, if a robot must reach a certain travel speed you compute tube/wheel speed from diameter.

Add safety margin: Add ~20–30% margin on top of the calculated torque. That compensates for friction, efficiency losses and load changes. It ensures the motor has enough head-room for real conditions.

A common mistake is picking the motor based on starting or acceleration peak torque only. That often leads to oversizing—higher cost and lower efficiency in normal use.

The right choice is based on continuous operating torque or RMS torque so the motor won’t overheat during long operation, while ensuring the peak or stall torque can cover startup surges.

Step Two: Determine electrical & control requirements

- Voltage: Choose a motor whose rated voltage matches your power supply. Common: 12 V for battery mobile devices; 24 V for industrial systems.

- Control complexity: Clarify your control needs. If you only need simple start/stop or rough speed control, a brushed motor with simple voltage control may suffice. If you need precise position or speed closed-loop control, consider brushless or encoder-equipped motors.

Step Three: Evaluate physical & environmental constraints

- Size & weight: Measure the space you allocated for the motor. Larger power often means bigger size, but selecting a high power-density solution (like planetary gearbox) gives greater torque in limited space.

- Operating environment: Check temperature, humidity, dust or liquid exposure. For harsh environments you may need motors with certain protection ratings (IP rating) for durability.

- Noise level: For home, office or medical use where noise matters, prioritise low-noise solutions—like brushless motors, planetary or worm gearboxes.

Step Four: Consider duty cycle & lifespan

- Duty cycle (duty ratio): Determine if the motor runs continuously or intermittently. A motor rated for intermittent use might overheat if forced to run continuously.

- Expected lifespan: Match the motor’s expected operational lifespan (which differs greatly between brushed vs brushless motors) with your product’s design life. Avoid the motor becoming the weak link in the system.

Too complicated? No worries! Just tell us your requirements, and we’ll handle the rest. We offer one-stop service to make selection easy and worry-free.

DC Gear Motor Applications

DC gear motors are highly versatile and essential across industries. Using real application cases helps us understand how theory meets practice.

Robotics & Industrial Automation

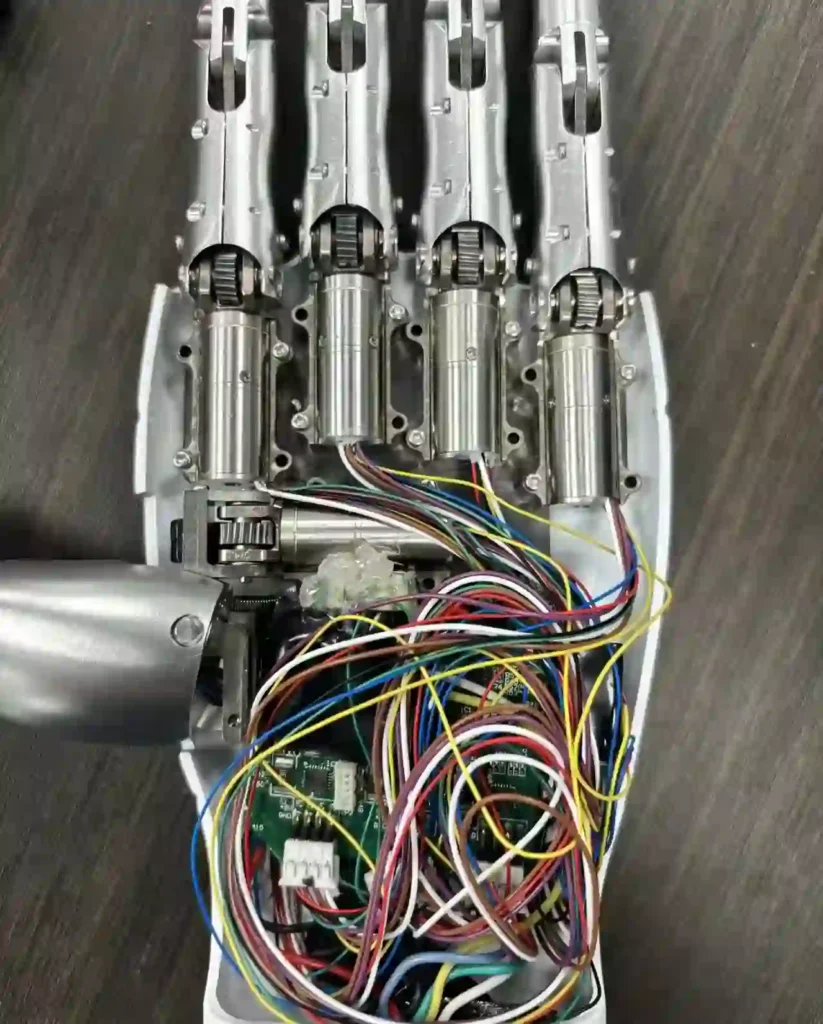

Robot arms: Their joint motions need very high torque and precise position control to pick heavy items or perform delicate tasks. Planetary-gear DC gear motors are ideal here due to high torque density and low backlash.

Mobile robots (AGVs): In automated warehouses/factories, autonomous vehicles need strong drive power to move heavy loads smoothly. High-torque DC gear motors provide that power.

Conveyor belts & packaging machines: On assembly lines, DC gear motors drive conveyors at steady, controllable speed and power machinery like labelers, fillers, packers—ensuring process sync and stability.

Automotive systems

Power windows, seats, sunroofs: Compact DC gear motors (often worm-gear type) provide smooth, strong actuation for windows, seat adjustments, roof openings; and their self-locking ability helps hold position when power is off.

Wipers: Wiper motors must deliver continuous stable torque to overcome blade-glass friction and ensure clear windscreen cleaning in varied conditions.

Electronic Power Steering (EPS): Brushless DC gear motors (BLDC) are increasingly adopted because of high efficiency and reliability. They assist steering and improve driving feel and fuel economy.

Medical & Laboratory Equipment

Infusion pumps & injection pumps: These need extremely precise, slow, stable fluid delivery. DC gear motors give the low-speed, constant-speed control necessary for accurate dosing and safety.

Surgical tools: Micro, high-torque DC gear motors (often hollow-cup type) power drills, saws. Their compact size and ergonomic design give surgeons precise control.

Patient care & mobility devices: Electric wheelchairs, adjustable beds, patient lifts rely on high-torque, low-noise DC gear motors to ensure patient safety and comfort.

Smart Home & Consumer Electronics

Motorised curtains & blinds: Quiet, smooth DC gear motors are key to automatic opening/closing of curtains/blinds. They’re often integrated with smart home systems for remote or voice control.

Smart locks: Small DC gear motors provide enough torque to drive bolts for automatic locking/unlocking of doors.

Robot vacuums: DC gear motors drive the wheels for navigation and movement, and the brush heads for cleaning. They demand high torque, high efficiency (for battery life) and low noise.

High-end appliances: In coffee grinders, vending machines and such, DC gear motors achieve precise, reliable mechanical motion.

Different industries’ needs deeply affect the motor technology and type selected. Medical equipment puts reliability, low noise, precision first ⇒ tends to adopt higher-cost brushless or hollow-cup motors with planetary gearboxes.

The automotive industry needs high reliability and durability but is extremely cost‐sensitive ⇒ mature, cost‐effective brushed motors and worm gear reducers are widely used.

Consumer electronics and smart home fields balance cost, performance, noise ⇒ depending on market positioning they may use low-cost brushed solutions for budget models, or high-end brushless solutions for flagship products.

This shows that the “best” motor solution fully depends on the specific application scenario and its commercial background.

Conclusion: The Future of Motion Control

DC gear motors, as the core component converting electrical energy into precise, powerful mechanical motion, have proven their value across industries.

With compact size, efficient energy conversion and flexible control, they are the indispensable foundation of modern automation.

Looking ahead, many trends point the way: smarter, more integrated, higher-efficiency gear motors.

In short, DC gear motors are not only the backbone of today’s precision motion control—they are the enabling technology for the future of automation, intelligent mobility and the IoT era. With ongoing innovation, they will continue playing a crucial role in driving societal progress.

FAQ

Q1. What is a DC gear motor?

A DC gear motor combines a DC motor with a gearbox to convert high-speed, low-torque rotation into low-speed, high-torque output—ideal for controlled, powerful motion.

Q2. Why use a gear motor instead of a DC motor?

Because the gearbox increases torque and reduces speed, allowing small motors to handle heavier loads and operate with greater precision and stability.

Q3. What are the main types of DC gear motors?

The main types include brushed, brushless, hollow-cup, and stepper gear motors. Each type balances cost, efficiency, precision, and lifespan differently.

Q4. How do I choose the right gear reduction ratio?

Match it to your required speed and torque. A higher ratio gives more torque but slower speed. The right ratio ensures the motor meets your load without overheating or inefficiency.

Q5. What are the key parameters to check on a motor datasheet?

Focus on rated voltage, speed, torque, current, power, and efficiency. These define the motor’s safe operating range and performance.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Tsinglin Motor’s Relevant DC Motor Series

-

Custom Micro Motors5 products

Custom Micro Motors5 products -

DC Gear Motor139 products

DC Gear Motor139 products-

6mm Planetary Gear Motor4 products

6mm Planetary Gear Motor4 products -

6mm Planetary Metal Gear Motor3 products

6mm Planetary Metal Gear Motor3 products -

Brushless Gear Motor17 products

Brushless Gear Motor17 products -

Micro Gear Motor64 products

Micro Gear Motor64 products-

Coreless Gear Motor11 products

Coreless Gear Motor11 products -

N20 Gear Motor26 products

N20 Gear Motor26 products -

Plastic Gearbox Motor8 products

Plastic Gearbox Motor8 products -

Standard Gear Motor15 products

Standard Gear Motor15 products -

Stepper Gear Motor15 products

Stepper Gear Motor15 products

-

-

Planetary Gear Motor29 products

Planetary Gear Motor29 products -

Spur Gear Motor63 products

Spur Gear Motor63 products -

Worm Gear Motor28 products

Worm Gear Motor28 products

-

-

DC Motor78 products

DC Motor78 products-

Brushed DC Motor16 products

Brushed DC Motor16 products -

Brushless DC Motor21 products

Brushless DC Motor21 products-

Inrunner Rotor BLDC Motor6 products

Inrunner Rotor BLDC Motor6 products -

Outrunner Rotor BLDC Motor13 products

Outrunner Rotor BLDC Motor13 products

-

-

Coreless DC Motor13 products

Coreless DC Motor13 products -

Micro DC Motor15 products

Micro DC Motor15 products -

Stepper Motor13 products

Stepper Motor13 products

-

-

Vibration Motors71 products

Vibration Motors71 products-

Brushless Vibration Motor8 products

Brushless Vibration Motor8 products -

Coin Vibration Motor22 products

Coin Vibration Motor22 products -

Coreless Vibration Motor3 products

Coreless Vibration Motor3 products -

Encapsulated Vibration Motor6 products

Encapsulated Vibration Motor6 products -

Linear Resonant Actuator12 products

Linear Resonant Actuator12 products -

Powerful Vibrating Motor17 products

Powerful Vibrating Motor17 products -

SMD Vibration Motor4 products

SMD Vibration Motor4 products -

Sonic Vibration Motor2 products

Sonic Vibration Motor2 products

-