In modern mechatronic design, engineers face the constant challenge of achieving higher performance in increasingly compact spaces. How can one meet the demands for high torque, low speed, and safe self-locking within a limited volume?

Among the many drive solutions, the DC Worm Gear Motor stands out as the ideal solution to this specific engineering problem.

However, its true uniqueness lies in its ability to solve three common design contradictions simultaneously:High Torque & High Reduction Ratio,Space & Layout,Power & Safety

To fully utilize these advantages and avoid common selection pitfalls, it is crucial to deeply understand its working principles, core advantages, and key selection parameters.

If selection becomes complex or time-consuming, you can always contact us — TSL MOTOR provides one-stop engineering and motor customization support.

Key Takeaways

- Core Value (90°, Self-Locking, Quiet):DC worm gear motors offer a 90° right-angle output to save space. They use self-locking to hold loads when unpowered. Their sliding gear mesh also makes them extremely quiet.

- How Self-Locking Works (Friction Angle > Lead Angle):Self-locking is achieved through geometry. The design ensures the worm’s “lead angle γ” (its thread slope) is less than the “friction angle φ” When the slope is this gentle, friction is too high for the load to slide backward.

- The Trade-off: Efficiency vs. Self-LockingThis is the key compromise. The same high friction that creates self-locking also causes low efficiency (often <60%). You must choose between strong self-locking and high efficiency.

- Absolute Safety Warning (Self-Locking ≠ Brake):Never rely on self-locking alone for human safety. Locking can fail under vibration or shock. Safety-critical applications (like hoists or medical beds) must use a separate, independent brake.

- Selection Key 1: Define Your Locking NeedsIf your application must self-lock (like a lift desk), prioritize a high-ratio, single-start worm.

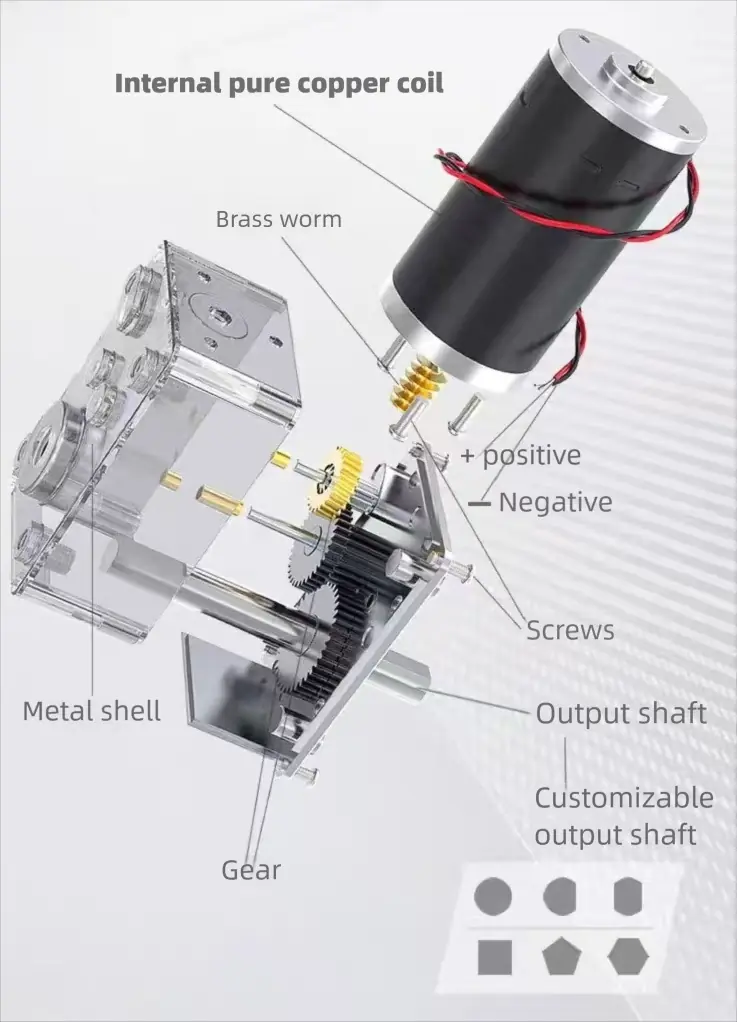

- Selection Key 2: Physical FitPerformance is useless if the motor doesn’t fit. Always confirm the mounting flange (interface) and output shaft type (e.g., D-cut, keyway) match your equipment perfectly.

DC Worm Gear Motors:Constitution, Principle, and Self-Locking

To make a professional selection, you must first understand its internal mechanical principles. The function of a worm gear motor is primarily determined by its unique gearbox structure.

What is a DC worm gear motor?

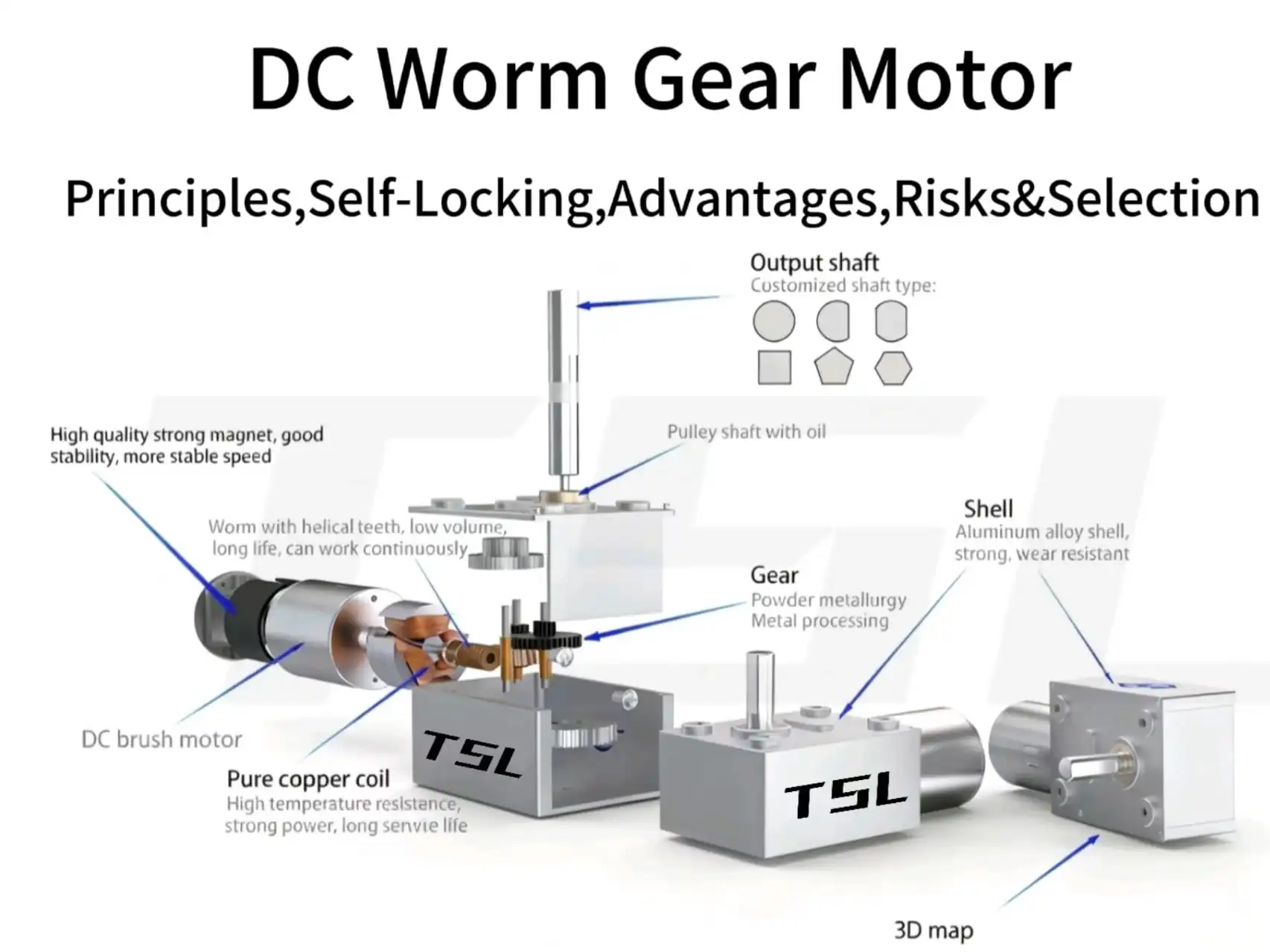

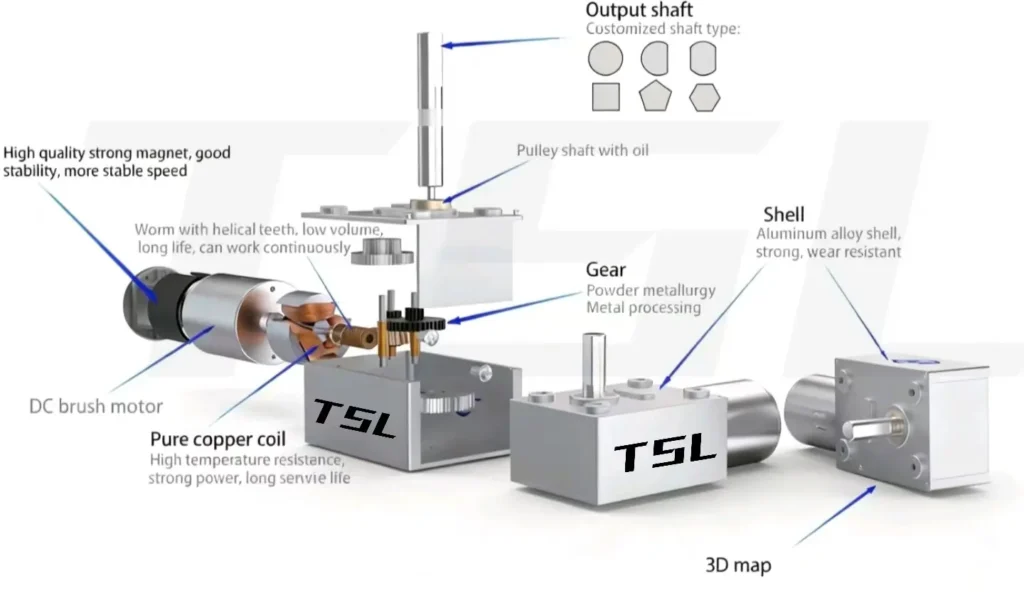

Structurally, a DC worm gear motor (DC gear motor) is an integrated mechatronic system. It consists of two core parts:

- Drive Source: A DC motor (brushed or brushless), providing high-speed, low-torque original rotational power.

- Reducer: A worm gearbox, connected to the motor’s output shaft, used to change motion characteristics.

The gearbox’s function is to convert the high-speed, low-torque input from the DC motor into low-speed, high-torque output to meet the application’s actual load requirements.

How a DC worm gear motor works

The mechanical structure of the worm gear system is the root of all its characteristics. The system consists of two key components:

- Worm: A threaded screw (usually the active part), connected to the motor’s output shaft .

- Worm Wheel: A gear that meshes with the worm (usually the driven part) .

When the DC motor starts, it drives the worm to rotate at high speed. The thread (helix) on the worm pushes the teeth of the worm wheel, forcing the worm wheel to rotate.

The most significant feature of this mechanism is its orthogonal axis (90-degree) power transmission. The worm’s axis and the worm wheel’s axis are perpendicular in space. This means the gearbox’s final output shaft is at a 90-degree angle to the motor’s own axis.

This 90-degree right-angle output is not accidental; it is a core design advantage.

For applications where space is extremely valuable (like conveyors, automatic doors, or medical equipment), this design allows the motor to be “laid flat” or mounted parallel to the equipment.

This significantly reduces the overall footprint of the powertrain, making it more compact than “in-line” planetary or spur gear motors.

How DC worm gear motors achieve self-locking

Self-locking, also known as irreversibility, is one of the most notable features of DC worm gear motors.

It is a static characteristic: When the motor stops and power is cut, the output shaft (worm wheel) cannot be back-driven by an external load to turn the input shaft (worm). This characteristic stems from the unique geometry and friction balance of the worm gear drive system.

The Physical Principle of Self-Locking: Lead Angle vs. Friction Angle

Layman’s Explanation

We can think of self-locking like an object stopped on a very slight incline:

- Forward Drive (Motor Working): When the motor drives the worm, it’s like driving a powerful car up a very gentle slope. Although there is an incline (friction to overcome), moving forward is easy and controllable.

- Reverse Drive (Load Stopped): When the motor stops, and an external load tries to push the worm wheel in reverse (i.e., trying to make the object slide back down the slope), the slope’s angle (lead angle γ) is designed to be extremely gentle, almost horizontal.

- This is like: Trying to push a huge, heavy stone to make it slide down a slope of less than 5 degrees. Because the slope is too small, the downward push from the stone’s own gravity (the back-driving force) is far less than the friction between the slope surface and the stone’s bottom (the friction angle φ).

In summary: The worm gear system utilizes this combination of a “too-small slope angle” and “massive friction.” The reverse thrust generated by the external load cannot overcome the huge static friction on the worm gear transmission surfaces. This causes the system to be firmly locked when powered off or at rest.

Technical Explanation

Self-locking occurs when the sliding friction between the worm thread and the worm wheel teeth is greater than the thrust required for back-driving.

- Lead Angle (γ): The tilt angle of the worm’s helix, determined by the worm’s geometry (diameter, number of starts).

- Friction Angle (φ): The angle corresponding to the coefficient of friction between the tooth surfaces, dependent on materials (e.g., steel on bronze), surface roughness, and lubrication.

The Golden Rule:

The theoretical condition for self-locking is: γ<φ

When the lead angle is smaller than the friction angle, any component of force from the worm wheel trying to back-drive the worm will be completely canceled out by friction. The system is therefore “locked.”

How to design for high self-locking capability?

Self-locking capability is mainly determined by the number of starts (threads) on the worm:

| Worm Type | Lead Angle (γ) | Reduction Ratio | Self-locking Capability |

| Single-start worm | Small (≤ 5–6°) | High (40:1, 60:1, even 100:1) | Strong (Easily achieves self-locking) |

| Multi-start worm | Large (≥ 10°) | Low (10:1, 20:1) | Weak/None (Difficult to achieve self-locking) |

Conclusion: If the application requires absolute self-locking (like lifting platforms, medical beds), priority should be given to high-reduction-ratio, single-start worms. Their lead angle is smaller, making it easier to meet the self-locking condition.

The Key Engineering Trade-off: Self-Locking vs. Efficiency

Self-locking is a double-edged sword. Engineers must understand the accompanying compromise:

High self-locking = Low efficiency. The same massive friction that causes self-locking also exists during forward drive. This friction manifests as energy loss (mainly heat).

- The stronger the self-locking function, the lower the gearbox efficiency.

- Specifically, worms with low lead angles (e.g., <5°) have strong self-locking, but their transmission efficiency may only be 30% to 50%.

- Conversely, high lead angles (e.g., >10°, usually multi-start worms) can have efficiencies from 50% to over 90%, but they lose or significantly reduce self-locking ability.

Manufacturer’s Authoritative Warning (Risk Advisory)

Although self-locking is a key advantage, it is not a 100% reliable safety device:

- Vibration Risk: Self-locking relies on static friction. If external vibration or shock occurs, the friction instantly changes to dynamic friction, which can cause the lock to fail.

- The dynamic friction angle (ϕ_dynamic) is always smaller than the static friction angle (ϕ_static). During a vibration, it’s possible for γ >φ, leading to the load slowly “slipping” or “creeping.”

Critical Advice: In applications involving human safety or high-value loads (like elevators, hoisting equipment), one must never rely on self-locking alone. An independent mechanical brake must be added to ensure absolute safety.

DC Worm Gear Motor:Unique Advantages

Compared to other gear types (like planetary or spur gears), the unique advantages of DC worm gear motors stem almost entirely from their physical properties: sliding friction.

In many mechanical systems, friction is seen as the enemy of efficiency. But in worm drives, this friction is precisely the source of its four core advantages.

Superior Load Capacity and High Torque Output

As mentioned, worm gear reducers can easily achieve high reduction ratios (e.g., 50:1, 100:1, or even higher).

According to physics, when speed is reduced, torque increases proportionally (multiplied by the reduction ratio and efficiency).

This allows DC worm gear motors to provide powerful output torque in a compact size, far exceeding other types of gear motors (like planetary or spur).

- Application Value: Ideal for applications needing heavy-load starting, low-speed smooth operation, or overcoming large inertia, such as heavy gates, lifting devices, or material handling equipment.

Unique Self-Locking Feature: Integrated Safety Protection

This is the decisive advantage that separates DC worm gear motors from planetary and spur gear motors. Self-locking means that when the power is cut, the motor can reliably hold the load’s position, preventing accidental reversal due to gravity or external forces.

| Ratio | No Load | Rated Load | Stall | ||||||

| i:1 | Voltage | Speed | Current | Speed | Current | Torque | Power | Torque | Current |

| V | PRM | A | PRM | A | Kg.cm | W | Kg.cm | A | |

| 6.25 | 12 | 960 | 0.12 | 685 | 0.9 | 0.94 | 15.0 | 4 | 6.5 |

| 10 | 12 | 600 | 0.12 | 428 | 0.9 | 1.50 | 15.0 | 4.8 | 6.5 |

| 18.8 | 12 | 319 | 0.12 | 228 | 0.9 | 2.82 | 15.0 | 6 | 6.5 |

| 30 | 12 | 200 | 0.12 | 142 | 0.9 | 4.50 | 15.0 | 18 | 6.5 |

| 56 | 12 | 107 | 0.13 | 76 | 0.9 | 8.40 | 15.0 | 32 | 6.5 |

| 90 | 12 | 66 | 0.13 | 50 | 0.9 | 13.50 | 15.0 | 52 | 6.5 |

| 131 | 12 | 45 | 0.13 | 32 | 0.9 | 19.65 | 15.0 | 76 | 6.5 |

| 169 | 12 | 35 | 0.13 | 25 | 0.9 | 25.35 | 15.0 | 87.5 | 6.5 |

| 270 | 12 | 22 | 0.13 | 16 | 0.9 | 40.50 | 15.0 | 141 | 6.5 |

| 506 | 12 | 11 | 0.13 | 9 | 0.9 | 60.00 | 15.0 | 180 | 6.5 |

| 810 | 12 | 7 | 0.13 | 8 | 0.9 | 60.00 | 15.0 | 180 | 6.5 |

Application Value:

Simplified Design & Lower Cost: In many applications (like lifting desks, automatic curtains, solar trackers), this feature can completely replace external brakes or electromagnetic brakes. This not only saves the cost of the brake but also reduces system complexity, installation space, and potential failure points.

Enhanced Safety: In applications like medical care beds or patient hoists, self-locking provides critical fail-safe protection, ensuring patient safety during a power outage.

Compact Right-Angle Design: Optimizing Equipment Layout

The mechanical structure of the worm and wheel dictates that their input (motor) and output (wheel) shafts are inherently at a 90-degree right angle.

Application Value: This right-angle configuration is a “layout optimizer.” Unlike planetary or spur reducers, where the output shaft is in-line with the motor, worm gear motors allow engineers to mount the motor parallel to the equipment surface it drives.

For example, in a conveyor system, the motor can be mounted flat against the side frame of the conveyor, rather than sticking out from one end. This greatly saves valuable equipment footprint and aisle space. In automatic doors or smart home devices, this design allows the motor to be hidden in narrow walls or casings.

Low Noise and Smooth Operation

The transmission method of worm gears is fundamentally different from other gears. Spur gears involve “rolling” and “impact” meshing of two gears, which inevitably produces noise and vibration.

However, worm gear transmission is a “sliding action” of the worm thread across the worm wheel teeth. This continuous, smooth sliding contact effectively suppresses noise and vibration.

- Application Value: While this sliding causes efficiency loss (as mentioned), in many applications, quietness is a more important parameter than efficiency. This makes worm gear motors the top choice for medical equipment (like hospital beds), high-end office furniture (like lifting desks), smart homes (like automatic curtains), and professional AV equipment (like projector lifts), where operational noise is unacceptable.

To help engineers weigh the trade-offs, the table below compares three mainstream DC gear motor solutions. It clearly shows that the DC worm gear motor is a solution born for specific working conditions.

Table 1: Comparison of Mainstream DC Gear Motor Technologies

| Feature | Worm Gear Motor | Planetary Gear Motor | Spur Gear Motor |

| Output Shaft | 90-Degree | In-line | In-line |

| Torque Density | Very High | High | Medium |

| Efficiency | Low to Medium (Often <60%) | High (Approx. 90%+) | Very High (Approx. 95%+) |

| Self-Locking | Yes | No | No |

| Noise | Very Low | Medium | High |

| Compactness | Very High | High | Medium |

DC Worm Gear Motor:Applications

The unique combination of advantages of DC worm gear motors makes them indispensable components in the following five major fields.

Precision Smart Locks & Security Modules

Examples:

Electronic smart door locks, safe locks, cabinet locks, vending machine lock actuators.

Pain Point:

Small locks require powerful torque in a very compact space, plus absolute self-locking to avoid forced opening.

Why Micro Worm Gear Motor:

- Extremely compact

- Self-locking prevents mechanical back-driving

- High torque per volume

Solution:

The motor drives the lock mechanism, and when power is removed, the worm reducer itself becomes the lock, preventing prying or forced rotation. No extra solenoid or brake is needed.

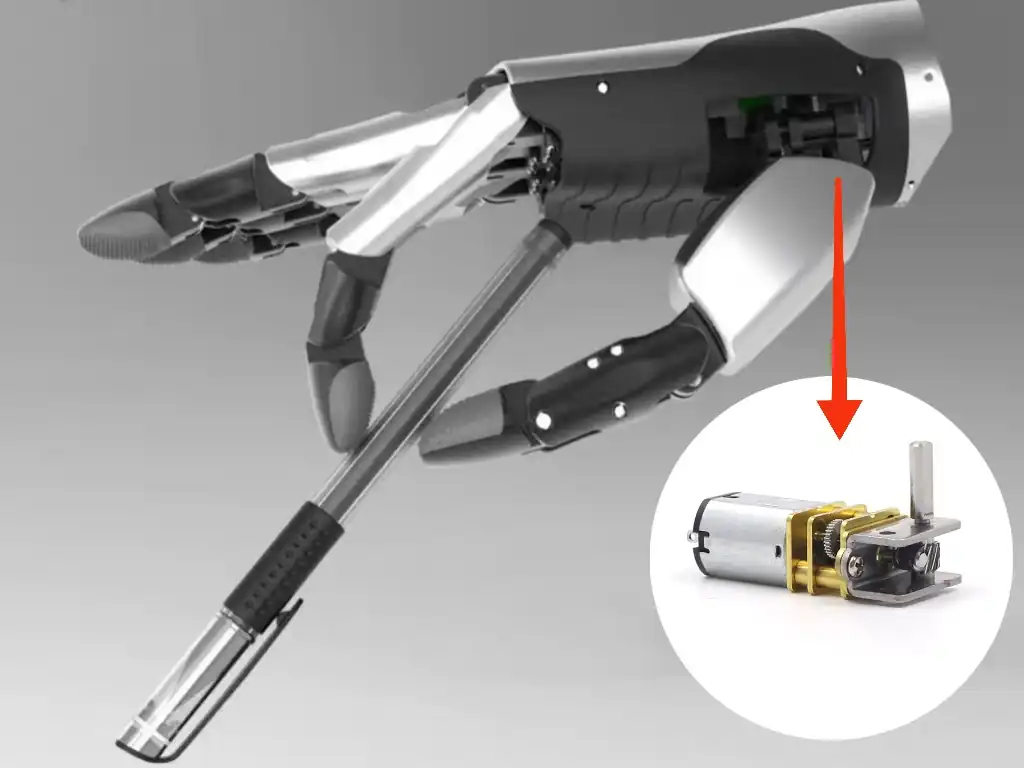

Mini Robotics & Consumer Robots

Examples:

Robotic fingers, micro grippers, humanoid robot joints, desktop cobots.

Pain Point:

Robotic joints need high torque, low speed, stable holding force, and ultra small size.

Why Micro Worm Gear Motor:

- High torque density

- Right-angle structure simplifies joint packaging

- Self-locking allows robots to hold without consuming power

Solution:

A finger or mini arm can hold an object in position with zero power, reducing heat and battery consumption.

Portable Medical & Healthcare Devices

Examples:

Insulin injector drive, portable infusion pumps, handheld surgical devices, compact patient assist equipment.

Pain Point:

Portable medical devices require very low noise, compact size, and absolute position stability (no drifting under load).

Why Micro Worm Gear Motor:

- Extremely quiet sliding transmission

- Precise controlled motion

- Self-locking prevents accidental release or motion during power loss

Solution:

The worm gearbox keeps the mechanism fixed even if battery is removed—critical for safety.

Camera / Optical Mechanisms & Precision Adjustments

Examples:

CCTV PTZ control, micro gimbals, laser alignment modules, telescope focus mechanisms.

Pain Point:

Optical positioning requires slow, ultra-fine movement and zero backlash drifting.

Why Micro Worm Gear Motor:

- Small footprint suits high-density optical housings

- Smooth motion with high reduction ratio

- Worm self-lock maintains angle without continuous current

Solution:

Motor only runs during adjustment; after positioning, the system stays locked without power, improving stability and battery life.

Compact Consumer Mechatronic Devices

Examples:

Smartphone lens actuators, motorized perfume sprayers, micro vending mechanisms, miniature valves, compact folding structures.

Pain Point:

Limited installation space, lightweight design, smooth and silent motion required.

Why Micro Worm Gear Motor:

- Option to fit inside 8–20 mm device thickness

- Quiet transmission

- Built-in torque output sufficient for small actuation tasks

Solution:

Allows motorized transformation, folding, ejecting, lifting in extremely compact designs without adding noise or mechanical brakes.

Manufacturer’s Selection Guide: 5 Key Parameters You Must Consider

As a DC worm gear motor manufacturer, our discussions with customers always focus on the following 5 parameters.

TSL-5840GW-3650BL-1240, 12V DC

| Ratio | No Load | Rated Load | Stall | ||||||

| Voltage | Speed | Current | Speed | Current | Torque | Power | Torque | Current | |

| i:1 | V | RPM | A | RPM | A | Kg.cm | W | Kg.cm | A |

| 17 | 12 | 235 | 0.15 | 180 | 0.4 | 1.3 | 2.45 | 4.3 | 1.2 |

| 31 | 12 | 130 | 0.15 | 100 | 0.4 | 2.4 | 2.51 | 8 | 1.2 |

| 50 | 12 | 80 | 0.15 | 60 | 0.4 | 4 | 2.51 | 12.5 | 1.2 |

| 100 | 12 | 40 | 0.15 | 30 | 0.4 | 8 | 2.51 | 25 | 1.2 |

| 200 | 12 | 20 | 0.15 | 15 | 0.4 | 16 | 2.51 | 51 | 1.2 |

| 290 | 12 | 14 | 0.15 | 10 | 0.4 | 23.2 | 2.43 | 70 | 1.2 |

| 500 | 12 | 8 | 0.15 | 6 | 0.4 | 37.5 | 2.36 | 70 | 1.2 |

| 670 | 12 | 6 | 0.15 | 4 | 0.4 | 50 | 2.09 | 70 | 1.2 |

Parameter 1: Rated Torque and Speed

Torque and Speed are the cornerstones of selection, and they are inversely related. While the gearbox reduces speed, it (ignoring efficiency losses) multiplies torque. Your first task is to precisely define the final output torque and speed required by the application.

Manufacturer’s Insight (Key Pitfall): The most common mistake engineers make during selection is confusing three different types of torque.

- Running Torque: The torque required for the application to run at a constant speed. This is the basis for calculating S1 continuous duty.

- Peak/Acceleration Torque: The extra torque needed to overcome load inertia when starting the system from rest.

- Stall Torque: The maximum torque the motor can output at zero speed, e.g., to “break free” from static friction.

Selection Guide: The motor’s “Rated Torque” must be greater than the application’s “Running Torque.” The motor’s “Stall Torque” (or Peak Torque) must be greater than the “Peak Torque” required for application startup or acceleration. In all calculations, we strongly recommend adding a 20-30% Safety Margin.

Parameter 2: Gear Ratio

The gear ratio defines how many turns the motor (input) makes for the gearbox (output) to turn once.

How to choose the gear ratio?

- The formula is very direct: Gear Ratio = Motor Input Speed (RPM) / Required Load Output Speed (RPM) 18.

Calculation Example: Your DC motor’s efficient speed at rated voltage is 3000 RPM. Your conveyor belt design needs to run at 50 RPM.

- Required Gear Ratio = 3000 RPM / 50 RPM = 60:1.

Parameter 3: Self-Locking Requirement

Do not assume all worm gear motors have strong self-locking.

Clarify the need

Does your application must have self-locking? Is it “nice-to-have” or “mission-critical”?

Technical Implication

The self-locking capability is directly related to the worm’s lead angle (λ\lambda). If you need “absolutely reliable” self-locking, you may need a single-start worm with an extremely small lead angle.

Professional Advice

Please clearly state your self-locking requirements when making an inquiry. This will influence the type of worm our engineers recommend and is directly related to the motor’s final efficiency and cost.

Parameter 4: Duty Cycle (Continuous S1 vs. Intermittent S3)

The biggest enemy of a DC motor is heat. Overheating can burn winding insulation, cause gearbox grease to fail, and even permanently demagnetize the magnets, leading to complete motor failure. The key factor determining heat accumulation is the duty cycle.

Define your duty cycle (IEC International Standards):

S1 – Continuous Duty: The motor runs under a constant load for long enough to reach thermal stability (heating power = cooling power).

Typical Applications: Industrial conveyors, ventilation fans.

S2 – Short-time Duty: The motor runs at a constant load for a specific short time (e.g., S2 30min), followed by a rest period long enough to cool to ambient temperature.

Typical Applications: Emergency winches, backup pumps.

S3 – Intermittent Periodic Duty: The motor performs a series of identical “run-stop” cycles. The key is that the stop time is not sufficient for the motor to cool completely. Often expressed as a percentage, e.g., “S3 25%” (e.g., 15 seconds run, 45 seconds stop).

Typical Applications: Robotic joints, automatic doors, medical actuators.

Manufacturer’s Insight (Huge Cost Savings): This is one of our most important conversations with clients. Many engineers over-specify.

Incorrect Scenario: Customer A says: “I need a motor that provides 10 N·m of torque.”

Traditional Selection: An unprofessional supplier provides a motor rated for S1 (continuous) 10 N·m. This motor must be very large, heavy, and expensive because it’s designed to continuously dissipate the heat generated by a 10 N·m load.

Professional Consultation: We ask: “What is your duty cycle?” Customer A replies: “I only need it to output 10 N·m for 5 seconds to close a gate, once per minute.”

Correct Selection: This is a typical S3 duty cycle (5 sec run, 55 sec stop). We can select a much smaller, less expensive motor. This motor (e.g., with an S1 rating of only 3 N·m) is fully capable of outputting 10 N·m of peak torque for a short time because it has 55 seconds to cool down.

Understanding your duty cycle can significantly save you cost and installation space without sacrificing performance.

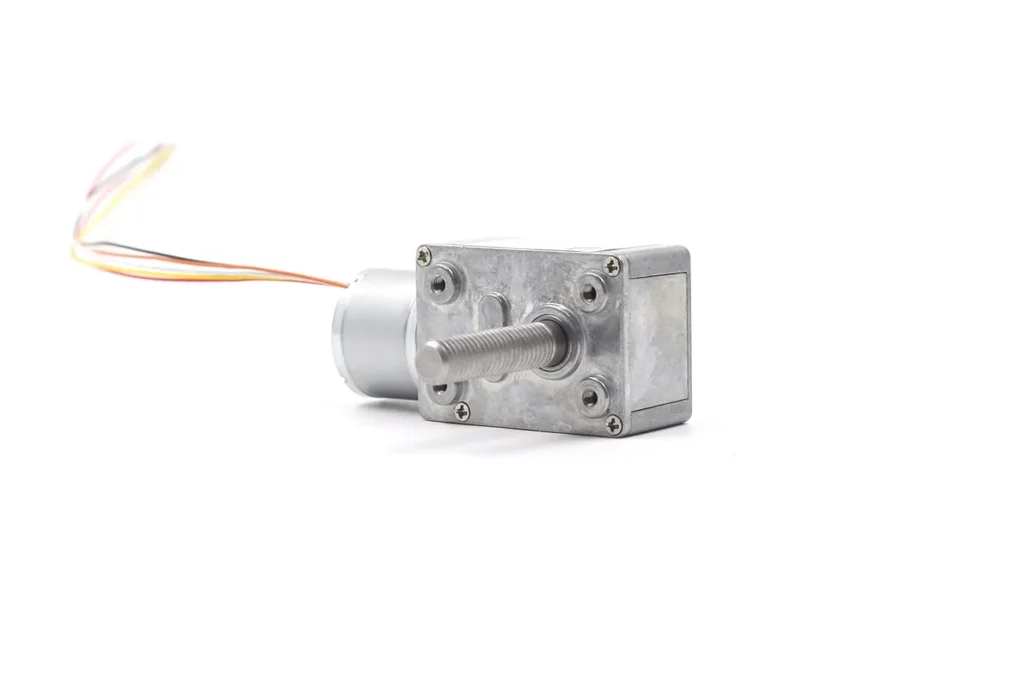

Parameter 5: Dimensions, Mounting & Physical Integration

No matter how perfect the motor’s performance, it’s all useless if it cannot be installed in your equipment.

Key Dimensional Parameters:

- Mounting Interface (Flange/Foot):

- Foot-Mount: The motor has “feet” and is bolted to a mounting base (e.g., IEC B3).

- Flange-Mount: The motor has a machined mounting face on the front, bolting directly to the equipment frame. This is common in NEMA (e.g., C-Face, D-Flange) and IEC (e.g., B5, B14) standards. Flange mounting requires high coaxial alignment.

- Output Shaft: This is the key power transmission interface. You must confirm:

- Shaft diameter and length.

- Shaft type: Does it have a Keyway? A D-cut? Or a threaded shaft?. The wrong shaft type will not connect to your load.

Manufacturer’s Insight (Our Core Advantage): This is the end of the road for standard “off-the-shelf” suppliers, but it’s where we begin as a manufacturing partner.

- Your Dilemma: The bolt holes on your equipment are special, and a standard NEMA 56 C-Face 45 won’t fit. You need an 8mm D-cut shaft, but all standard options are 10mm keyway shafts.

- Our Solution (Customization): As a true manufacturer, we are not bound by “standard products.” We offer comprehensive engineering customization services:

- Custom output shafts (length, diameter, D-cut, keyway, material).

- Custom mounting flanges (to match your special bolt hole pattern).

- Custom electrical characteristics (e.g., non-standard 18V voltage instead of 12V/24V).

- Special grease (for high or low-temperature environments).

This is the greatest value of working with a manufacturer (not a distributor).

Conclusion

Choosing the right DC worm gear motor is not a simple purchase; it is a rigorous engineering analysis.

There is no “best” choice, only the “most suitable” choice. A successful integration depends on your precise analysis of the 5 key parameters: Torque, Gear Ratio, Self-Locking Requirement, Duty Cycle, and Physical Mounting.

Standard product catalogs are just a starting point. As your manufacturing partner, our true value lies in solving challenges that standard solutions cannot meet.

Our engineering team is an extension of your design team, ready to intervene when a standard product is only “almost” right.

From custom output shafts and non-standard mounting flanges 5 to motor windings that match your special power supply, we will ensure you receive a performance-optimized, perfectly matched, customized solution.

Your Next Steps

- Explore: Now that you have the technical knowledge to specify a solution, visit our dc worm gear motor to browse our standard product lines.

- Verify: Need to check specific dimensions, download CAD models, or performance curves? Please dive into our Detailed Spec Page for datasheets and engineering drawings.

- Partner: Does your design face a unique challenge? Standard products don’t meet your needs? Don’t compromise. Contact our application engineers today to discuss your project, and let us build a custom solution for you.

FAQ

Q1: What are its biggest features?

A1: Three things: 1) 90-degree right-angle output (saves space); 2) Self-locking (can hold a load when unpowered); 3) Extremely quiet (uses sliding, not impact, gears).

Q2:Can “self-locking” replace a safety brake?

A2: Absolutely not. Self-locking can fail under vibration or shock. For any application involving human safety, you must add a separate, independent brake.

Q3:What is the “cost” of self-locking?

A3: Low efficiency. The same high friction that creates the lock also wastes energy (as heat) when the motor is running. Its efficiency is much lower than a planetary gearbox.

Q4:What is the biggest “money-saving” tip for selection?

A: Understand your “Duty Cycle.” Don’t buy an expensive “Continuous Duty” (S1) motor for an “Intermittent” (S3) job (e.g., run 5 sec, stop 45 sec). An S3-rated motor can output huge peak torque for short bursts using a much smaller, cheaper frame, as it has time to cool down.

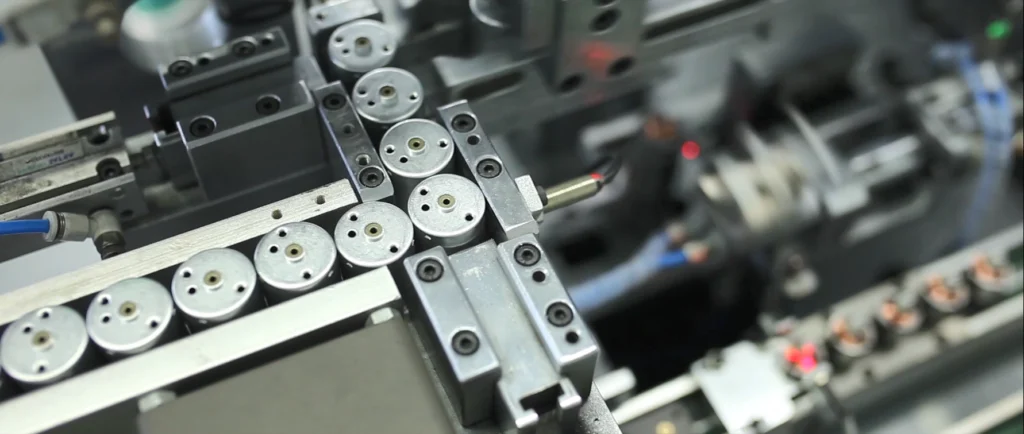

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

Worm Gear Motor

TSL Motors is a leading manufacturer specializing in custom worm gear motors, offering dependable solutions tailored to meet the specific needs of various applications. With our in-depth knowledge of DC worm gear motors and gear technology, we assist OEMs in developing, identifying, and implementing innovative geared motor solutions with greater speed. These compact, quiet, self-locking motors, also capable of static damping, provide exceptional torque density.