Haptic feedback is crucial for enhancing interaction in devices like smartphones, wearables, game controllers, VR/AR systems, and in medical/bionic fields. The core component enabling this is the Haptic Motor (or tactile actuator).

This guide breaks down common haptic motors (ERM, LRA, VCM, Piezo). We will cover their working principles, pros, cons, and selection logic for different applications. This aims to help engineers and product managers make fast, informed technical decisions.

Here is a quick comparison table for overall understanding:

| Type | Vibration Method | Response Speed | Tactile Precision | Cost |

| ERM | Eccentric Rotation | Slow | Low | Low |

| LRA | Linear Resonance | Fast | Medium-High | Medium |

| VCM | Linear Drive | Very Fast | High | High |

| Piezo | Piezoelectric Deformation | Extremely Fast | Extremely High | High |

Key Takeaways

- Experience Determines Tech: Simple alerts choose ERM (lowest cost); clear “clicks” choose LRA (mainstream balance); realistic “force mechanics” choose VCM/Piezo (premium feel).

- LRA is the Balanced Standard: LRA balances response speed (faster than ERM), power efficiency, and tactile quality, making it the primary choice for smartphones and wearables.

- VCM is for High-End Force: VCM uses precise displacement and force control for the most realistic pressing, damping, and multi-dimensional feel, but it is high cost and large.

- Piezo for Thinness & Detail: Piezo offers extremely fast response (microsecond) and minimal thickness (sub-millimeter), best for ultra-thin devices or simulating fine textures.

- Complexity Ties to Cost: ERM uses simple DC drive; LRA/VCM/Piezo require dedicated driver ICs and complex algorithms, increasing total cost and development effort.

- Space Constraints Favor Piezo/LRA: If device space (especially thickness) is severely limited, prioritize the ultra-thin Piezo or compact LRA.

- ERM is Low-End Alerts Only: Due to slow start/stop and coarse feel, ERM is now mainly used in feature phones or for simple vibration cues with minimal tactile requirements.

Main Types of Haptic Motors

Haptic Motors are actuators. They convert electrical signals into mechanical vibration or force feedback. This simulates human “touch” during interaction.

The four common types are: ERM (Eccentric Rotating Mass), LRA (Linear Resonant Actuator), VCM (Voice Coil Motor), and Piezo (Piezoelectric Haptic Actuator).

ERM and LRA are the most common. They are almost standard in smartphones and wearables. VCM and Piezo appear in high-end or specialized applications. Examples include VR/AR or medical devices.

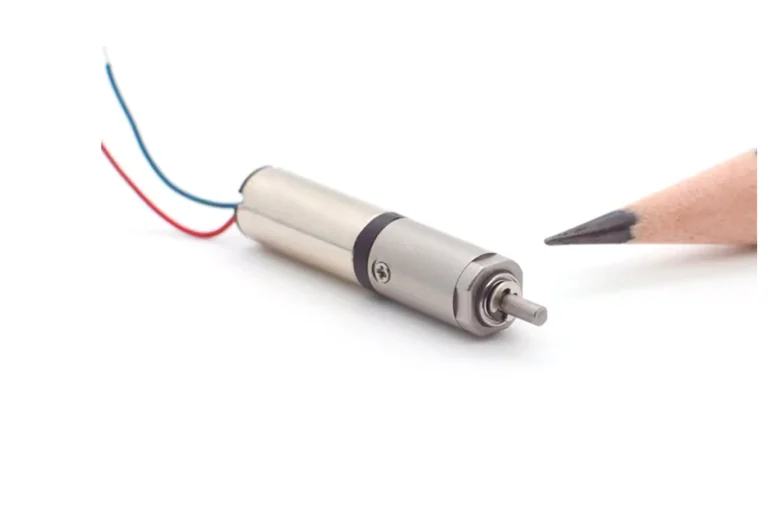

ERM (Eccentric Rotating Mass) Motor

ERM is the most classic and cost-effective solution for “vibration.” But it has the most limited tactile expressiveness.

Working Principle

A dc motor drives a rotor with an eccentric (off-center) weight. The rotation generates periodic centrifugal force, causing vibration. Its structure is simple: a small motor plus an eccentric block. It was the first widely adopted haptic motor.

Pros:

- Simple Structure: No complex resonance or precision drive needed. Mature manufacturing process.

- Low Cost: Few parts. Suitable for mass production and high cost-effectiveness in consumer electronics.

- Simple Drive Circuit: Driven by DC power. No complex waveform control required.

- Easy Integration: Universal size and interface. Design mainly focuses on power and space.

Cons:

- Slow Start/Stop: High inertia from rotor spinning. Startup and stop take tens of milliseconds or more. Difficult to achieve fast haptics.

- Inaccurate Frequency Control: Vibration frequency depends on rotation speed. Speed is affected by voltage, current, and load, limiting precision.

- Coarse Tactile Feedback: Vibration is like “mechanical shaking.” Hard to simulate fine textures or complex tactile effects.

Typical Applications:

- Feature Phones: Almost all early phone ring alerts used ERM: simple, cheap, and sufficient.

- Simple Alert Devices: Like bands, alarms, industrial indicators. Used for “on/off” vibration alerts, not fine haptics.

- Industrial Vibration Alerts: Reliable supplement where sound/light alerts might fail due to noise or poor visibility. ERM excels here for durability and low cost.

LRA (Linear Resonant Actuator)

Modern smartphone haptic motors are mostly LRA. LRA was a major leap after ERM. It moved haptic feedback from simple “notification vibration” to programmable “tactile simulation.”

Working Principle

Based on a typical spring-mass-electromagnetic drive system. An internal permanent magnet mass is connected to a spring (or flexible cantilever). It is surrounded by a coil. AC current through the coil creates an alternating magnetic field. This drives the mass to move back and forth linearly.

Pros:

- Fast Response: Typically starts or stops in 10-20ms. Significantly better than ERM.

- Strong Controllability: Precise frequency and amplitude control. Suitable for diverse haptic effects.

- Finer Tactile Feedback: Waveform is closer to sinusoidal. User feedback feels more natural.

- Higher Efficiency: Works at the resonant point, resulting in relatively low power consumption.

- Moderate Size: Common in space-limited devices like smartphones and smartwatches.

Cons:

- Complex Drive Circuit: Requires AC drive or a specialized IC to maintain resonance. Cannot use direct DC like ERM.

- Fixed Frequency: Resonant frequency is set during design. Hard to cover a wide range of haptic effects.

- Higher Cost: Manufacturing and control circuits are more complex than ERM.

Typical Applications:

- Smartphones: Virtual key feedback, scrolling resistance, improving interaction experience.

- Wearable Devices: Bands, smartwatches for alerts and light interaction.

- Game Controllers: Provides more realistic tactile feedback, simulating various actions or environments.

- VR/AR Devices: Delivers fine haptics in immersive interaction, enhancing realism.

VCM (Voice Coil Motor) (High-End Haptics)

VCM technology represents a qualitative change in haptic feedback. It moves from “vibration simulation” to “force simulation.” It aims to precisely simulate force, displacement, and stiffness. It makes users feel like they are interacting with real physical objects.

Working Principle

VCM is very similar to a loudspeaker. Current through a voice coil placed in a magnetic field generates linear displacement. Precise control of the current waveform drives the mass linearly. This achieves programmable force feedback.

Unlike ERM and LRA, VCM does not rely on a fixed resonant frequency. It works across a wider frequency range, supporting complex haptic effects.

Features:

- Precise Displacement and Force Control: Output displacement and force are highly controllable via current magnitude and waveform.

- Supports Complex Waveforms: Can simulate varying forces, textures, and dynamically changing tactile effects, not just single vibrations.

- High Flexibility: Strong programmability, suitable for multi-dimensional haptic design.

Pros:

- Most Realistic Tactile Feedback: Simulates “pressing feeling” and damping effects closer to the physical world, compared to ERM and LRA.

- Supports Multi-Dimensional Feedback: Achieves depth, force variation, and other complex interactions, not just single-direction vibration.

- Can Simulate “Press Depth”: For example, in virtual buttons, users feel multi-layered feedback, close to a real mechanical button.

Cons & Engineering Challenges:

- High Cost: Complex manufacturing process, requiring high component precision.

- Larger Size: Harder to integrate into ultra-thin devices compared to LRA and Piezo.

- Complex Control Algorithm: Requires dedicated drivers and precise algorithms for stable multi-dimensional feedback.

Typical Applications:

- High-End Smartphones: Such as Apple’s Taptic Engine, providing delicate tactile feedback via VCM.

- VR/AR Controllers: Simulates realistic pressing, damping, and environmental haptics in immersive interaction.

- High-End Gaming Devices: Offers more realistic operational feedback, enhancing immersion.

Piezoelectric Haptic Actuator (Piezo)

Piezoelectric technology uses a completely different physical path than electromagnetic methods (ERM/LRA/VCM). It uses the intrinsic properties of materials to achieve haptic feedback.

Working Principle

Piezo actuators are based on the piezoelectric effect. Piezo materials undergo tiny deformation when subjected to an electric field. This deformation can be amplified into high-frequency vibration or directly converted into force feedback. The extremely fast response (microsecond level) allows it to produce fine haptic effects in a very short time.

Pros:

- Extremely Fast Response: Microsecond response, much faster than ERM and LRA.

- Extremely Thin: Can achieve sub-millimeter thickness, ideal for ultra-thin devices.

- Extremely High Precision: Can simulate complex haptic effects, like texture and friction.

- High-Frequency Vibration Capability: Suitable for simulating fine surface textures.

Cons:

- High Drive Voltage: Requires a specialized high-voltage drive circuit, increasing design complexity.

- Small Travel Distance: Limited displacement. Not suitable for large-amplitude vibration feedback.

- Higher Cost: Materials and drive circuits are expensive, limiting large-scale adoption.

Typical Applications:

- Ultra-Thin Phones: Provides haptic feedback within limited space.

- Touchpads: Simulates clicking or sliding resistance.

- Precision Medical Equipment: Used for micro-operations or tactile cues.

- High-End Laptops/Tablets: Offers realistic feedback in virtual buttons or touch interfaces.

Key Factors for Haptic Motors Selection

Selecting a haptic motor involves a trade-off. Designers must balance experience, space, power consumption, control complexity, and cost.

Tactile Experience Requirements

If the product only needs “any vibration,” like a call alert or simple cue, ERM is the most economical. Limited expressiveness is an advantage here: simple, reliable, low cost.

If a clear “click feeling” is needed, like virtual button feedback, LRA is better. It responds in 10-20ms. The sinusoidal waveform feels more natural.

To simulate realistic “press depth” or damping, VCM or Piezo are needed. They offer complex force feedback, even simulating different material textures.

Device Space Constraints

In ultra-thin devices (phones, laptop touchpads), space is the biggest constraint. Piezo or LRA are more suitable. Piezo can be sub-millimeter thin. LRA provides good haptics in limited space.

If space is ample (VR controllers, industrial devices), ERM or VCM can be chosen. Their larger size provides stronger vibration or force feedback.

Power Consumption and Battery Life

Battery-powered devices (phones, bands, wearables) are sensitive to power. LRA and Piezo are preferred. They have lower energy consumption at resonance or with efficient driving.

Plugged-in devices (game controllers, industrial equipment) can accept higher power. ERM and VCM are better here. They provide stronger feedback without battery life concerns.

Control and Drive Complexity

ERM‘s biggest advantage is simplicity. An MCU can drive it directly. No extra driver IC is needed.

LRA, Piezo, VCM require specialized drive circuits. They may need complex closed-loop control algorithms. Engineers must consider:

If the MCU performance is limited or the development cycle is tight, ERM might be better.

If the cost of adding a driver IC and algorithm development is acceptable, LRA/VCM/Piezo can be utilized.

Cost and Production Scale

ERM and LRA are the main choices for consumer electronics. Low cost and mature technology suit mass production. Feature phones, smart bands, and mainstream smartphones use these two.

VCM and Piezo target high-end, differentiated products. Examples are flagship phones, VR/AR controllers, and medical devices. Their high cost and complexity provide a unique tactile experience, which is key for product competitiveness.

The Core Selection Logic is: Experience vs. Cost vs. Constraints:

- ERM: Most economical. Suitable for “just needs vibration” scenarios.

- LRA: Mainstream choice. Balances space, power, and tactile quality.

- VCM: High-end solution. Pursues realistic force feedback. High cost and algorithm complexity.

- Piezo: Preferred for ultra-thin devices and fine haptics. Drive voltage and cost are challenges.

Conclusion

Haptic Motors are key to enhancing interaction in smart devices and systems.

From the classic ERM to the mainstream LRA, and the high-end VCM and Piezo, each technology has its pros and cons. This determines the best fit for different applications. Engineers must balance experience requirements, space constraints, power consumption, control complexity, and cost to find the most suitable solution.

In the future, haptic feedback will go beyond “vibration alerts.” It will evolve into force simulation and multi-dimensional haptics, closer to the real physical world. This will bring users a more natural and immersive interaction experience.

As an industry expert, TSL Motor specializes in producing ERM and LRA haptic motors. We provide reliable solutions for consumer electronics and smart devices. We aim to help engineers and product managers streamline the design process.

We empower the next generation of smart interaction with high-quality haptic technology.

FAQs

Q1:What is the main difference between ERM, LRA, VCM, and Piezo motors?

ERM is lowest cost/slowest response (coarse vibration); LRA is mainstream, fast response (fine vibration); VCM provides force feedback, most realistic feel; Piezo is extremely fast, allows ultra-thin designs.

Q2:Which motor type is currently dominant in smartphones?

Most smartphones use LRA (Linear Resonant Actuator), which balances space, power, and tactile quality. High-end flagship phones may use VCM for a more realistic pressing feel.

Q3:If a device requires an ultra-thin design and extremely high tactile precision, which should be chosen?

You should choose the Piezo (Piezoelectric) actuator. It can be sub-millimeter thin, responds extremely fast, and is suitable for simulating fine textures and high-frequency vibrations.

Q4:What are the pros and cons of the ERM motor?

Pros: Simple structure, lowest cost, simple drive circuit.

Cons: Slow response (slow start/stop), coarse tactile feel, difficult to control frequency precisely.

Q5:Which motor can simulate the most realistic “press depth” or “damping effect”?

VCM (Voice Coil Motor) or Piezo. They can precisely control force and displacement, achieving complex, physics-like mechanical simulation.

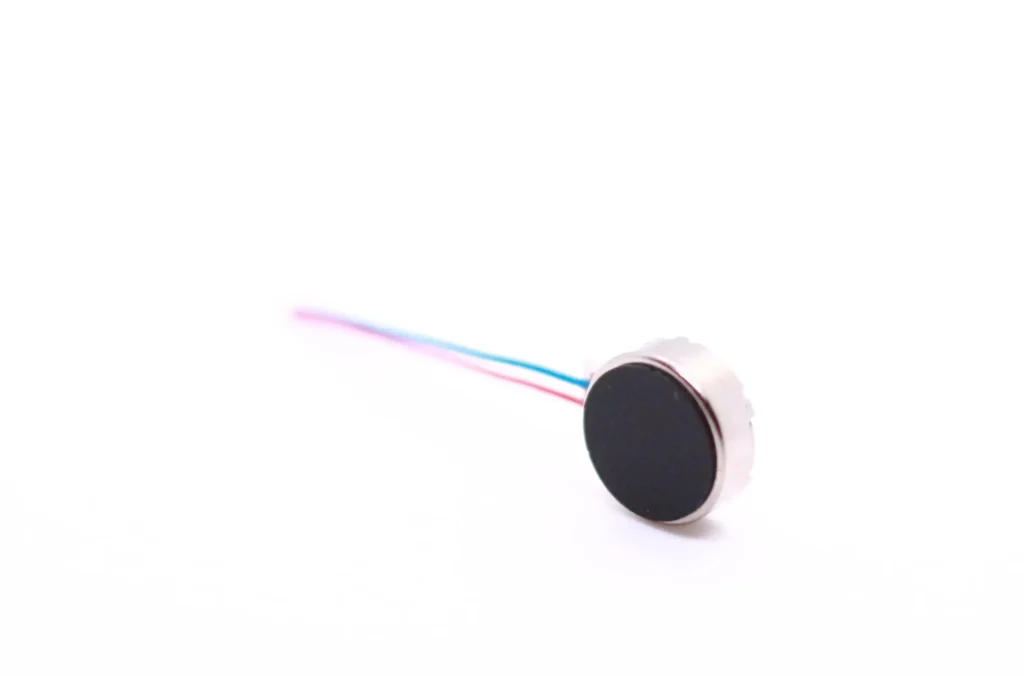

Vibration Motors

TSL MOTORS designs and manufactures a wide range of high-quality, and cost-effective vibration motors. If you request high-quality micro vibration motors, this is the right place, the quality is guaranteed, and we can provide specifications, datasheets, test reports, performance, and related certifications. Various connection interfaces to choose from. All types of vibration motors can be highly customized for applications. Please contact us freely for samples and detailed quotations.