Choosing the right Brushless DC (BLDC) motor topology is critical. It defines your system’s performance, efficiency, and lifespan.

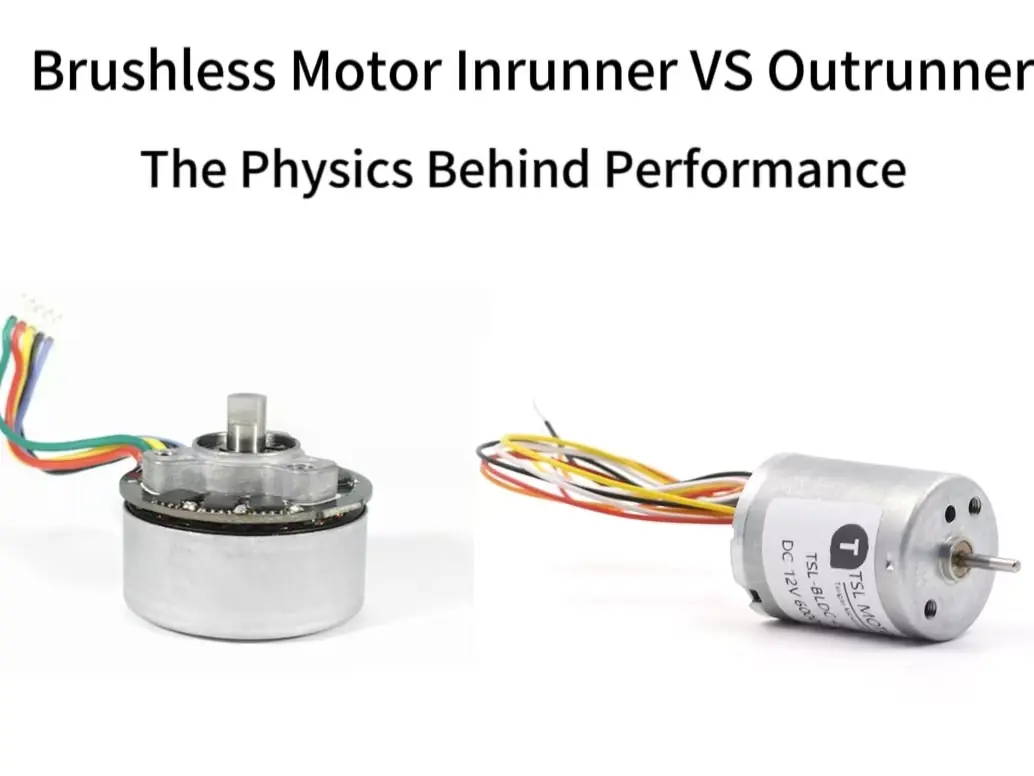

In the BLDC world, there are two main configurations: Inrunners and Outrunners.

On the surface, the difference looks purely structural. But make no mistake: this choice dictates torque, speed, heat management, and dynamic response.

- Inrunner Brushless Motors: Known for high RPM and excellent cooling. They are built for speed.

- Outrunner Brushless Motors: Famous for high torque. They are the go-to for direct-drive applications like drones and electric skateboards.

As a custom BLDC motor manufacturer, we solve this “Inrunner vs. Outrunner” puzzle for clients every day.

In this guide, we break down the physics, performance, and ideal applications for each. Let’s ensure you choose the right motor from day one.

Key Takeaways

- Rotor radius defines torque — Outrunners generate more torque because the electromagnetic force acts at a larger radius.

- KV and Kt are inversely related — High KV motors must have low torque constants, and vice versa.

- Inrunners have low inertia — This gives them fast acceleration, quick braking, and high dynamic response.

- Outrunners have flywheel stability — Higher inertia enables smoother low-speed motion under fluctuating loads.

- Thermal strategy depends on environment — Inrunners excel in sealed systems; outrunners rely on airflow cooling.

- Application decides topology — Drones favor outrunners for direct-drive torque; EDF jets use inrunners for high RPM.

- Gearboxes change the game — When you need high torque + sealed reliability, an inrunner with a planetary gearbox is the strongest solution.

- There is no universal “best motor” — Only the best match between motor physics and application requirements.

The Fundamentals: Anatomy of Inrunners vs. Outrunners

To understand the performance, you must look at the physics. The names come from the position of the Rotor relative to the Stator.

Inrunner Brushless Motor: The High-Speed Standard

This is the “traditional” design. Externally, it looks like a standard brushed motor.

- Construction: The Rotor spins inside the center of the motor.

- Stator Position: The Stator (coils) surrounds the rotor and is fixed to the stationary outer case.

- Key Advantage: The stator windings create heat. Since they touch the outer case, heat transfers easily to the outside. This design allows for easy mounting and retrofitting.

Outrunner Brushless Motor: The Torque Specialist

The Outrunner flips the script.

Construction: The Rotor is on the outside. It forms a spinning “bell” or cup around the center. Permanent magnets are attached to the inside wall of this spinning shell.

Stator Position: The Stator (coils) sits stationary in the very center of the motor.

Key Implication: The entire outer casing spins. You must design your mechanics to allow for this rotating shell.

Why Inrunner vs. Outrunner Topology Determines Performance

The seemingly simple difference of whether the rotor is inside or outside is actually the fundamental reason behind all performance differences between inrunner and outrunner motors. This design choice directly affects two core physical properties:

- Electromagnetic force radius: This directly determines the motor’s torque characteristics and its speed (KV) curve.

- Location of the heat source (stator): This directly defines the motor’s thermal path and cooling efficiency.

In the following sections, we will explore how these two factors evolve into the distinct performance behaviors of the two motor types.

Performance Insights: Torque, RPM & KV in Inrunner vs Outrunner Motors

Why are Outrunners high-torque and Inrunners high-speed? It isn’t magic. It’s physics.

Torque Mechanics: The Lever Arm

Torque (τ) is rotational force. Physics defines it as Force (F) multiplied by Radius (r).

Think of opening a heavy door:

- Push near the hinge (Small r): It is very hard.

- Push near the handle (Large r): It is very easy.

- Inrunner: Electromagnetic force acts on a small internal rotor. This is like pushing near the hinge.

- Outrunner: Force acts on the large outer shell. The radius is much larger. This is like pushing near the handle.

Conclusion: With the same amount of force, the Outrunner generates significantly more torque naturally.

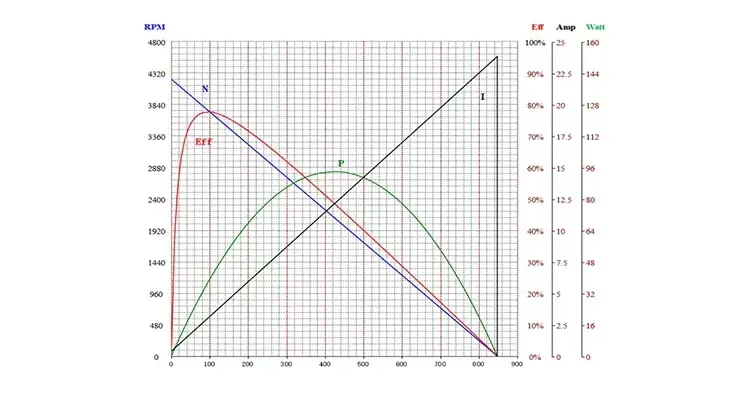

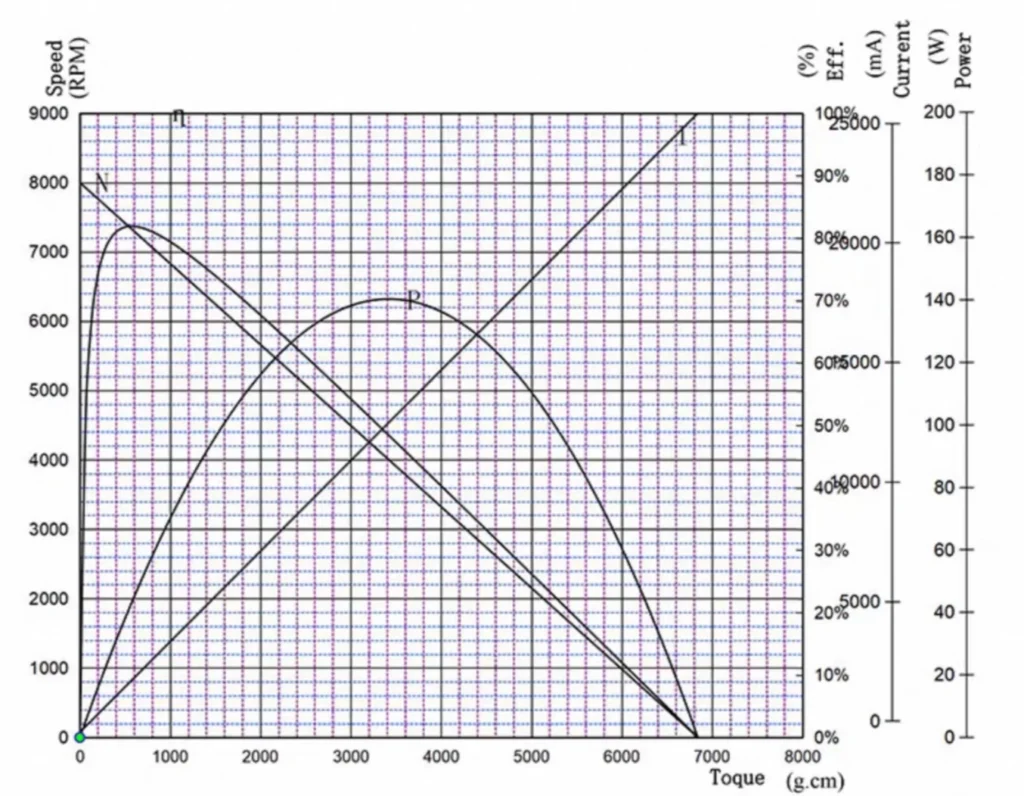

KV & Torque Constant (Kt)

- KV Rating: How fast the motor spins per Volt (RPM/Volt).

- Torque Constant (Kt): How much torque is produced per Amp.

These two constants are physically inversely related.A motor with a high KV value must have a low Kt value, and vice versa.

- Inrunners: Typically High KV (3000–5000+). Great for speed, lower torque per Amp.

- Outrunners: Typically Low KV (100–1500). Lower speed, but massive torque per Amp.

Debunking the “Torque Myth”

Some engineers argue that “Outrunners don’t technically have more torque” if the KV is identical. Theoretically, this is true.

But in the real world, it is about efficiency. Outrunners are physically superior for Low KV / High Torque designs due to their geometry. While you can build a low KV Inrunner, it is often inefficient.

The Data: A 20mm Outrunner can produce 75% more torque than a 20mm Inrunner.

Dynamic Response: Inertia, Acceleration & Stability in Inrunner vs Outrunner Motors

How fast can the motor start and stop? This depends on Moment of Inertia.

Inrunner Motors: Fast Acceleration

Physical Principle:

Rotational inertia (the resistance to changes in rotational motion) depends on mass and its distance from the axis of rotation, and is approximately expressed as:I∼mr

Inrunner Design:

The rotor’s mass is concentrated near the center — with a small radius (r) and low overall mass (m).

Result:

Very low rotational inertia.

Performance Advantage:

This enables fast acceleration response — the motor can start, stop, or reverse direction extremely quickly, making it ideal for high-dynamic applications such as robotic joints or high-speed control systems.

Outrunner Motors: High Inertia for Smooth Operation

Physical Principle:

In an outrunner, the entire outer “bell” rotates — containing all the magnets and the metal housing. This means the mass (mmm) is large, and it is distributed at the maximum radius (rrr).

Result:

Very high rotational inertia.

Performance Drawback:

Slower response and acceleration — it requires more energy to start and stop.

Performance Advantage (Trade-off):

The high inertia creates a flywheel effect, resulting in smoother and more stable rotation at low speeds, especially under load variation.

This is highly beneficial for applications requiring smooth, jitter-free motion, such as camera gimbals or low-speed RC crawlers.

Advanced Topic: How Load Inertia Influences Inrunner vs. Outrunner

A common engineering question is: To what extent does motor inertia affect the entire system?

In some applications—such as driving a large drone propeller—the load’s rotational inertia (the propeller) can be orders of magnitude higher than the rotor inertia of the motor itself.

In this case (high-inertia load), the inertia difference between an inrunner and an outrunner becomes almost negligible in terms of overall system acceleration time.

At that point, the only factor determining acceleration is the motor’s torque (Kt).

Therefore, the difference in internal rotor inertia only becomes truly important in low-inertia load applications, such as small robotic joints or high-speed spindles.

This is a critical nuance that must be considered when designing a motion system.

Thermal Management: Ensuring Longevity in Inrunner vs Outrunner Motors

One of the most misunderstood aspects in motor design is thermal behavior.

There are completely opposite claims about “which cools better, inrunner or outrunner?”

The key to solving this cooling paradox lies in understanding two different heat transfer mechanisms:

- Conduction cooling

- Convection cooling

Heat Source Focus: Why the Stator Matters in Brushless Motors

In both motor topologies, the primary heat source is the stator windings, due to resistive losses ( I² × R).

If this heat cannot be removed efficiently, the motor overheats, and in extreme cases, the magnets in the rotor may permanently demagnetize.

Inrunner Brushless Motor: Conduction cooling& Sealed Design

Cooling Mechanism:

In an inrunner, the heat source (stator) sits at the outer layer, directly touching the static motor housing.

Benefit 1 — Conduction Cooling

This creates a short and efficient thermal path.

Heat can easily conduct through the housing, then dissipate into:

- Ambient air,

- A metal chassis,

- A heatsink,

- Or even a water-cooling jacket.

Benefit 2 — Ruggedness

Because the outer shell does not rotate, the motor can be fully sealed.

Result:

Inrunners can achieve very high IP ratings (e.g., IP68), making them ideal for harsh environments such as:Dust,Mud,Underwater operation,Industrial outdoor robotics

Typical Applications:

Industrial automation, marine equipment, sealed actuators.

Outrunner Brushless Motor: Convection Cooling & Open-Air Design

Cooling Mechanism:

In an outrunner, the stator is isolated at the center, surrounded by the rotating outer shell.

This creates a poor conduction path — heat gets trapped inside.

Engineering Solution:

Outrunners must use open-air convection cooling.

The rotating bell is often shaped like a fan, pulling cool air in and pushing hot air out.

Result:

Outrunners can dissipate heat very effectively — but only if they operate in open airflow, such as:

- Multirotor drones (propeller airflow provides forced cooling)

Limitation:

Not suitable for sealed housings

Highly exposed to:Dust,Water,Debris

This reduces lifetime and ruggedness.

Thermal Takeaways: Choosing Inrunner vs Outrunner for Your Environment

In summary, the choice of cooling is not about “which is better?”, but rather “what is my operating environment?”

- Choose an inrunner: If the environment is sealed, dirty, or wet, or if heat needs to be conducted to a chassis or water-cooling system.

- Choose an outrunner: If the environment is open, and the motor can rely on its rotation or external airflow for convection cooling.

Inrunner vs Outrunner: Quick & Detailed Performance Comparison

Table 1 — Quick Specification Overview

| Feature | Inrunner | Outrunner |

| Form Factor | Slim, small diameter | Large diameter, flat |

| Torque | Lower | Higher |

| RPM | Very high (high KV) | Lower (low KV) |

| Inertia | Low → Fast acceleration | High → Smooth rotation |

| Cooling | Conduction (sealable) | Convection (requires airflow) |

| Environmental Ruggedness | High (IP-rated possible) | Low (open design) |

Table 2 — Engineer-Level Technical Comparison

| Technical Aspect | Internal Rotor (Inrunner) | External Rotor (Outrunner) |

| Rotor Location | Inside | Outside bell |

| Stator Location | Outer case | Center shaft |

| Heat Source Path | Direct conduction | Convection only |

| Typical IP Rating | High (fully sealable) | Low (vented) |

| Inertia Source | Small center rotor | Heavy external rotor |

| Dynamic Response | Very fast | Slower |

| Low-Speed Smoothness | Lower | Excellent |

| System Complexity | Often requires gearbox | Direct-drive compatible |

Motor Selection Guide: When to Choose Inrunner vs Outrunner

Scenario A: Multirotor Drones (from FPV Racing to Agricultural UAVs)

Recommended Topology: Outrunner

Technical Rationale:

Multirotor drones require high torque at relatively low RPM to drive large-diameter propellers directly. The number one priority is avoiding gearboxes, as they add weight, mechanical complexity, failure points, and efficiency losses.

Outrunners are the ideal direct-drive solution because their naturally low KV and high torque output allow the propeller to be mounted directly onto the motor shaft.

Their open-frame structure and reliance on airflow cooling are advantages here, since the propellers themselves generate continuous forced convection.

Scenario B: High-Speed RC Models (EDF – Electric Ducted Fan Jets)

Recommended Topology: Inrunner

Technical Rationale:

EDF systems are fundamentally different from multirotors. They require extremely high rotational speeds (30,000 RPM and above, often 50,000+ RPM) to drive multi-blade fan rotors.

Torque demand is secondary to speed.

This is where inrunners excel: low rotor inertia and high KV make them the optimal architecture.

Outrunners are mechanically unsuitable at such speeds due to severe balance challenges that can lead to catastrophic mechanical failure.

The slender geometry of inrunners also allows perfect integration into the central hub of EDF turbines.

Scenario C: E-Mobility Platforms (Electric Skateboards, E-Bikes, RC Crawlers)

Recommended Topology: Outrunner

Technical Rationale:

Like multirotors, these systems demand high starting torque and precise low-speed control.

The inherent high-torque / low-KV characteristics of outrunners allow them to be used efficiently either in simple belt-drive systems or as direct-drive hub motors.

A comparable inrunner would require a large, heavy, and expensive gearbox.

Additionally, the higher rotor inertia of outrunners produces smoother starts with less cogging.

Although they are more exposed to environmental debris, the torque benefits normally outweigh sealing concerns in these applications.

Scenario D: Industrial Systems (Pumps, Fans, High-Speed Spindles, Robotics)

Recommended Topology: Inrunner

Technical Rationale:

Industrial requirements prioritize reliability, lifespan, and environmental robustness.

Inrunners provide superior conductive heat dissipation, enabling them to operate continuously at high load inside fully sealed housings (high IP rating) — something outrunners cannot achieve due to their open structure.

This sealed capability protects motors from coolant in CNC spindles, dust in material handling robots, and moisture in industrial pump applications.

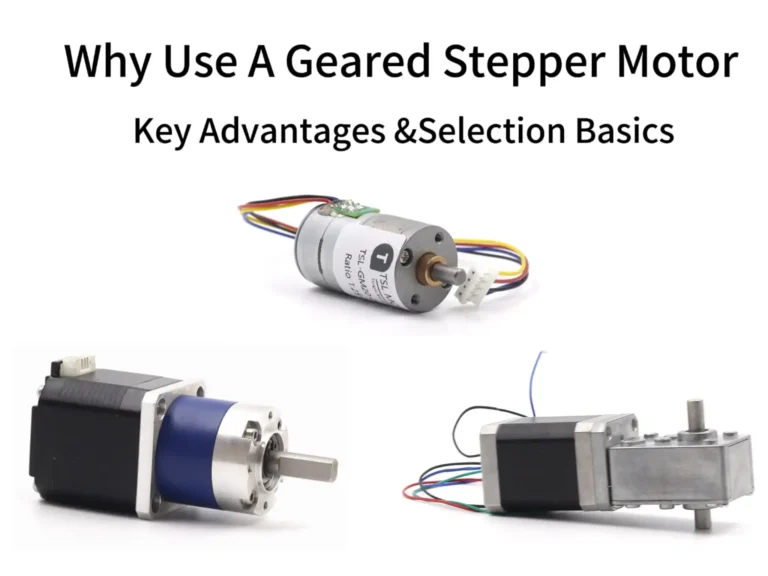

Scenario E: Extreme Torque Applications (Heavy-Lift Drones, Premium E-Bikes)

Recommended Topology: Inrunner + Gearbox

Technical Rationale:

When an application simultaneously requires:

- Extreme output torque, and

- Excellent thermal performance and full sealing,

the most robust engineering solution is an inrunner coupled with a gearbox.

For example, heavy cargo drones and premium e-bikes often use a high-speed inrunner (efficient and easy to cool at high RPM) connected to a compact planetary reduction gearbox.

Although this architecture is heavier than direct-drive outrunners, it enables massive torque multiplication while keeping the motor completely sealed and thermally stable.

Conclusion

Choosing an Outrunner = Choosing Mechanical Simplicity.

When you need direct-drive high torque in a clean, open environment, the outrunner is the optimal choice.

You trade environmental sealing for mechanical simplicity, lower cost, and lower weight.

Choosing an Inrunner = Choosing Environmental Robustness.

When you need high reliability in harsh or enclosed environments and superior thermal management (e.g., liquid cooling or heatsink mounting), the inrunner is the right solution.

You accept the potential need for a gearbox to achieve high torque, in exchange for durability, sealing, and long operating life.

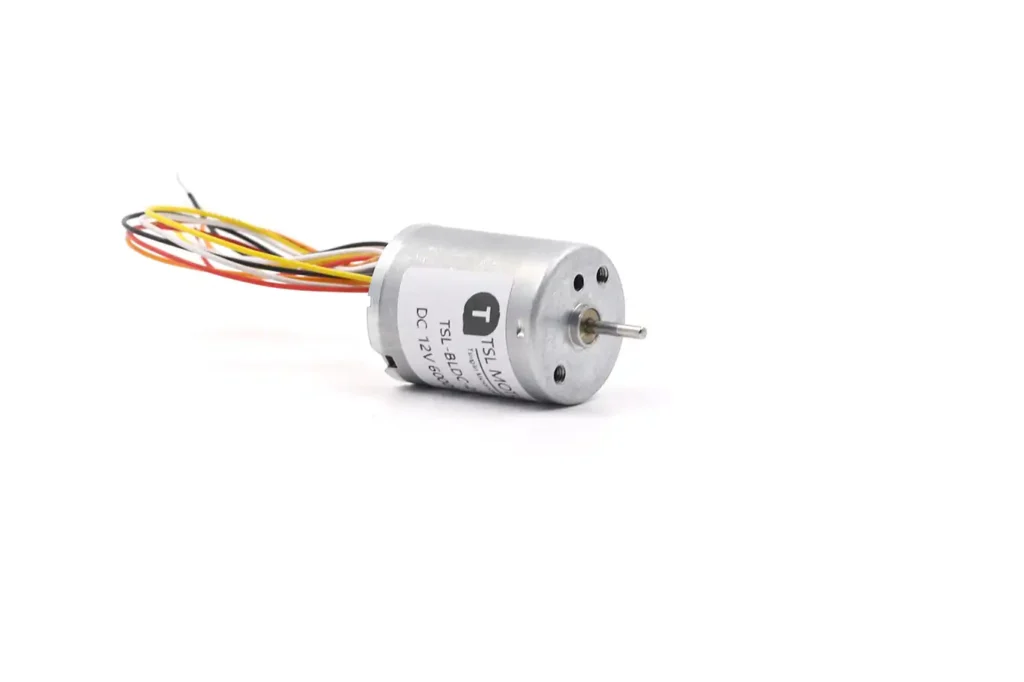

Build the Perfect Motor with TSL MOTOR

Understanding these differences is only the first step — mastering them is what we do best at TSL MOTOR.

Picking a catalog motor is guesswork. Engineering a motor tailored to your exact application is real innovation.

Our application engineering team specializes in thermal modeling, magnetic flux optimization, and inertia matching to deliver the most efficient and reliable solution — whether it’s a high-torque outrunner for your drone fleet or a fully sealed inrunner for your medical device.

Don’t let your next design become a compromise.

Contact the TSL MOTOR engineering team today to discuss your project requirements — and let’s build the perfect motor together.

FAQ

Q1:Why does rotor position (inside vs. outside) change motor performance so much?

Because the rotor radius directly affects torque generation, and stator placement affects heat dissipation. These two physical factors cascade into every major performance difference between inrunners and outrunners.

Q2:Are high KV motors always low torque?

Yes. KV and Kt are physically inversely related. A motor with a high KV value must have a low Kt value, and vice versa.

Q3:Why do drones almost always use outrunners, but RC jets use inrunners?

Because drones need direct-drive high torque, while EDF jets need extremely high RPM. These are opposite requirements.

Q4:If my environment is harsh (dust / coolant / humidity), can I still use an outrunner?

Not safely. Outrunners are structurally open and cannot be fully sealed. In such cases, engineers choose inrunner + gearbox for torque + environmental protection.

Brushless DC Motor

Brushless DC motors provide a solution to meet the demands for higher energy efficiency, longer lifespan, and quieter operation. As a leading manufacturer of BLDC motors,TSL Motors has developed the smallest BLDC motor, measuring just 6mm in diameter and 2mm in thickness, designed as a flat vibration motor.