Introduction

In today’s consumer electronics, user experience is about more than just sight and sound. Touch, as a powerful sensory channel, is redefining how we interact with our devices. From the crisp clicks of a smartphone to the immersive feedback of a game controller, high-quality haptic experiences have become a hallmark of premium products. However, in the realm of PC peripherals, especially mice, the application of haptic technology still holds immense untapped potential.

Traditional ERM vibration motors (ERMs) can only provide a vague “buzz,” whereas the new generation of Linear Resonant Actuators (LRAs) delivers precise, nuanced, and responsive “HD” tactile sensations. For mouse manufacturers looking to stand out from the competition, mastering LRA integration technology is the key to the future.

Tsinglin Motors will delve into the core principles of LRAs and provide product designers and engineers with a detailed hardware integration roadmap to help you seamlessly incorporate superior haptic feedback into your next-generation mouse products.

Key Takeaways

- LRA (Linear Resonant Actuator) is key to next-gen, high-fidelity mouse haptics.

- It delivers instant response, nuanced textures, and diverse effects, far beyond traditional vibration.

- Dedicated driver ICs simplify integration, enabling auto-calibration and advanced features.

- Optimized mechanical design effectively reduces noise, ensuring a pure haptic experience.

- LRA is more energy-efficient, a win-win for wireless mouse battery life and feel.

- This enhances immersion and is crucial for differentiating premium brands.

Why LRA is the Future of Haptic Feedback

To understand why LRA represents a technological leap, we first need to explore its working principles and how it fundamentally differs from traditional technologies.

What is LRA

A Linear Resonant Actuator (LRA) is a sophisticated electromagnetic actuator. Its internal structure can be simplified as a magnetic mass suspended by a spring, surrounded by a voice coil.

Its operation is entirely different from the old-fashioned Eccentric Rotating Mass (ERM) motor. An ERM is essentially a DC motor with an unbalanced counterweight that generates centrifugal force through rotation, causing non-directional vibration.

In contrast, an LRA operates by applying an alternating current (AC) signal to its voice coil.4The changing current creates an alternating magnetic field in the coil, which interacts with a permanent magnet to push the mass back and forth in a linear motion along a single axis. This mass and spring form a resonant system with an inherent “natural resonant frequency” determined by its physical properties (mass and spring stiffness).

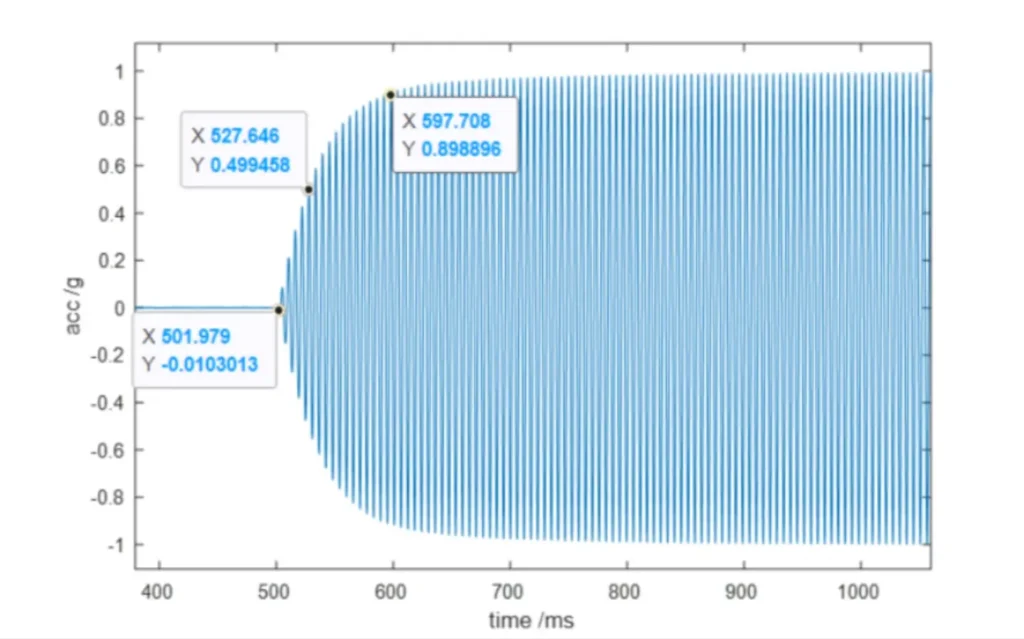

When the frequency of the driving signal precisely matches this resonant frequency, the LRA achieves maximum vibration amplitude with minimal energy input, resulting in the most efficient energy conversion. It is this resonance-based linear motion that gives the LRA the ability to provide precise, fast, and efficient haptic feedback.

Performance Showdown: LRA vs. ERM

The advantages of LRA over ERM are comprehensive and directly translate into a generational difference in user experience.

Response Time (The Source of “Crispness”)

An LRA’s start-up time is extremely fast, typically between 5-15 milliseconds, whereas an ERM needs 20-50 milliseconds to “warm up” and reach an effective rotational speed.This means LRA can achieve perfect synchronization with on-screen events, providing instantaneous, crisp feedback, while ERM always has a sense of lag.

Control Fidelity (The Key to Nuance)

This is LRA’s core advantage. Driven by an AC signal, an LRA’s vibration amplitude and frequency can be controlled independently, opening the door to creating complex and subtle “HD haptic” effects. In contrast, an ERM’s frequency and amplitude are coupled (the faster it spins, the stronger it vibrates), limiting it to a single “buzzy” sensation.

Power Consumption (A Boon for Wireless Devices)

When operating at its resonant frequency, an LRA is far more energy-efficient than an ERM, making it the ideal choice for wireless mice with strict battery life requirements.

Active Braking (A Clean Finish)

An LRA can achieve “active braking” in about 10 milliseconds by applying a reverse-phase signal, bringing the vibration to an abrupt halt and preventing effects from blurring together.An ERM can only stop slowly and uncontrollably by cutting power.

Table 1: Haptic Actuator Technology Comparison

| Feature | Eccentric Rotating Mass (ERM) | Linear Resonant Actuator (LRA) | Piezoelectric Actuator (Piezo) |

| Working Principle | DC motor spins an eccentric mass | AC signal drives a magnetic mass on a spring | Voltage applied to piezoelectric material causes deformation |

| Response Time (Start) | Slow (20-50 ms) | Fast (5-15 ms) | Extremely Fast (~1 ms) |

| Response Time (Stop) | Slow, uncontrolled spin-down | Slow natural decay (300ms), but extremely fast with active braking (~10ms) | Extremely Fast (~1 ms) |

| Haptic Fidelity | Low ("Buzzy"); Amplitude & frequency are coupled | High ("Crisp"); Amplitude & frequency independently controlled | Very High (HD); Can reproduce complex waveforms |

| Power Consumption | High | Low (at resonant frequency) | Lower |

| Drive Complexity | Simple (DC Voltage) | Medium (Requires AC signal at resonant frequency, driver IC needed) | High (Requires high-voltage boost driver IC) |

| Durability/Lifespan | Lower (Brush wear) | High (Brushless design) | Very High (Solid-state) |

| Component Cost | Low ($) | Medium ($$) | High ($$$) |

How to Choose the Right LRA for Your Design

When selecting an LRA component, you need to focus on the following Key Performance Indicators (KPIs) to ensure it meets your product design requirements.

Dimensions: The physical size of the component must integrate seamlessly into the mouse’s internal structure without affecting ergonomics and weight balance. Miniature “coin-style” LRAs are ideal for compact designs.

Resonant Frequency: Typically in the 175-235 Hz range, this frequency band is most sensitive to human tactile perception.

Vibration Force (Grms): Quantifies vibration intensity in terms of gravitational acceleration (G). An optimal balance must be found between feedback strength, power consumption, and noise.

Driving Voltage: Ensure the LRA’s rated operating voltage matches the mouse’s power system and the output capability of the selected driver IC.

Hardware Architecture Blueprint: Integrating LRA into a Mouse

With the right components in hand, the next step is to unleash their full potential through sophisticated hardware design.

LRA Selection and Strategic Placement

The placement of the LRA inside the mouse directly determines what the user ultimately “feels.”

Component Form Factor: Miniature “coin-style” (providing Z-axis/vertical vibration) or rectangular LRAs (providing X/Y-axis/horizontal vibration) are the mainstream choices.The choice of vibration axis should be determined through ergonomic testing to achieve the most natural and effective feedback.

Layout Options

- Palm Area: The most straightforward solution, placing a single LRA under the palm rest, can produce a general, full-hand vibration.

- Under Main Buttons: Placing a micro LRA under each of the left and right buttons can provide highly localized and precise feedback for actions like clicks and weapon fire.

- Scroll Wheel: Equipping the scroll wheel with a dedicated LRA can simulate the “detent” feel of scrolling or the “click” of switching weapons.

Drive Electronics: The “Brain” of the Haptic System

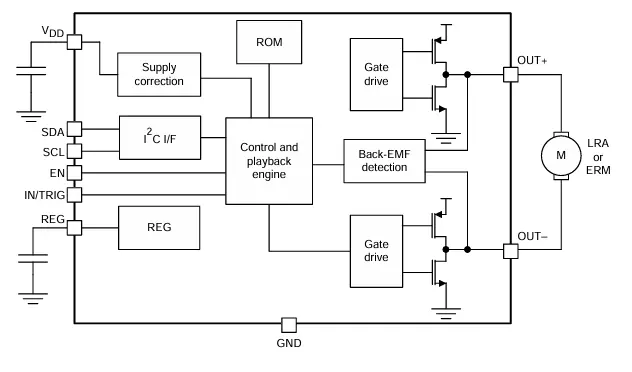

Precise control of an LRA depends on a dedicated driver IC—this is the cornerstone of the entire hardware architecture. Attempting to drive an LRA directly with a general-purpose microcontroller’s (MCU) PWM output is not feasible.

Why is a Dedicated Driver IC Essential?

A high-performance haptic driver IC, such as Texas Instruments’ (TI) DRV2605L, is more than just a signal generator; it integrates multiple smart features that are crucial for project success.

The Core Value of a Driver IC

Auto-Resonance Tracking

An LRA’s resonant frequency can shift slightly due to temperature, aging, or even the user’s grip.A smart driver IC can detect and dynamically adjust the drive signal in real-time to always stay at the most efficient resonance point, ensuring consistent and strong vibration effects. This is something no open-loop solution can match.

Simplified Control Logic

The driver IC handles all complex low-level waveform generation. The main MCU only needs to send simple I2C commands to trigger sophisticated haptic effects, freeing it up to focus on higher-level tasks.

Integrated Advanced Features

Technologies like “overdrive” (to shorten start-up time) and “active braking” (for quick stops) are built into the driver IC, greatly accelerating the development process and improving the final effect.

Investing in a driver IC is a strategic “force multiplier.” It encapsulates complex low-level engineering problems within the chip, significantly reducing technical risk and allowing the development team to focus on creating a superior user experience.

Mechanical and Acoustic Design: Tuning a Pure “Feel”

An excellent haptic experience should be “pure,” not “noisy.” This requires careful management of Noise, Vibration, and Harshness (NVH).

Secure Mounting

The LRA must be firmly secured to the mouse’s internal frame to ensure efficient energy transfer to the casing. Any looseness will result in energy loss and unpleasant “rattling” sounds.

NVH Suppression

Use Damping Materials: Strategically applying vibration-damping foam or rubber gaskets at the LRA mounting points and internal component contact surfaces can effectively absorb and isolate excess vibrations, reducing noise.

Ensure Structural Rigidity: A sufficiently rigid casing and internal support structure can prevent noise amplification due to resonance.

Proper Cable Management: Secure all internal cables to prevent them from rattling against the casing during vibration.

Choosing Tsinglin Motor means you no longer have to worry about complex NVH tuning. We have integrated a sophisticated NVH suppression structure within the motor itself, simplifying your design and delivering pure, crisp haptic feedback in a single step.

Power Consumption for Wireless Mice

For wireless devices, adding an LRA presents a challenge to battery life.

LRA’s Energy Efficiency

Compared to ERM, LRA is more energy-efficient when producing a single haptic event. For example, TI data shows that creating a “click” effect with an LRA consumes only about one-third of the energy of an ERM.

Power Management

The power consumption of an LRA is event-driven, and its impact depends on the haptic feedback’s duty cycle (the duration and intensity of motor activity). Therefore, it is essential to provide users with fine-grained control options at the software level, such as global intensity adjustment, toggles for specific event types, and different power profiles (e.g., “Performance Mode” vs. “Battery Saver Mode”), to strike a balance between immersive experience and acceptable battery life.

Summary

This project presents a complete high-fidelity haptic feedback solution for next-generation premium computer mice, based on Linear Resonant Actuators (LRAs). We are not just supplying a component; we are delivering an integrated system of “advanced hardware, integration expertise, and a content ecosystem” designed to help mouse brands seize the initiative in the next wave of peripheral technology upgrades.

Core Technology & Advantages:

- Technology Core: Utilizes high-performance, compact Linear Resonant Actuators (LRAs), which comprehensively outperform traditional ERM motors in response time, feedback fidelity, control precision, and power efficiency. They are the definitive choice for creating advanced tactile experiences.

- Hardware Solution: Provides a proven “LRA + dedicated Driver IC” hardware combination, supported by expert guidance on mechanical integration, including NVH (Noise, Vibration, and Harshness) control, to ensure an optimal physical product experience.

- Ecosystem Strategy: The innovative “Three-Layer Software Ecosystem” model (SDK deep integration, universal API compatibility, and audio-to-vibe global coverage) is the key to this solution’s success. It fundamentally solves the industry pain point of advanced features lacking application, ensuring broad usability and long-term viability.

Market Value & Vision:

For end-users, this solution offers unprecedented gaming immersion and richer, more precise daily human-computer interaction. For mouse brands, it is not only a technical engine to boost product performance and price points but also a strategic opportunity to stand out in a commoditized market and build a premium brand image.

Our vision is to elevate computer peripherals from simple “functional interaction” to profound “emotional and physical experience interaction.” By integrating this LRA solution, you will be defining not just a new product, but the new standard of experience for the next generation of premium peripherals.

FAQ

1. Q: Why do mice need LRA haptic feedback? How is it better than traditional vibration?

A: LRAs provide high-fidelity, precise haptics. Unlike the vague “buzz” of traditional ERM motors, LRAs offer instant response, nuanced textures, and diverse effects. This significantly enhances gaming immersion and provides a “crisp” feel for daily interactions, representing a true experience upgrade, not a gimmick.

2. Q: What are the technical challenges of integrating LRAs, and how are they addressed?

A: The main challenges are precise LRA driving and structural noise control. We recommend using dedicated haptic driver ICs to simplify driving and waveform management. Additionally, mechanically isolating the LRA and optimizing structural design effectively suppresses unwanted noise, ensuring a pure haptic experience.

3. Q: Will LRAs impact the battery life of a wireless mouse?

A: No. In the high-frequency, short-burst feedback scenarios required for a mouse, LRAs are more energy-efficient than traditional ERM motors. Their high efficiency makes them ideal for wireless mice, allowing for an excellent experience while maintaining good battery life.

4. Q: Is there real market demand for such haptic mice?

A: Market demand is growing. The success of Sony’s PS5 DualSense controller has proven users are willing to pay for high-quality haptics. Our target market is high-end gamers seeking ultimate experiences, with further expansion into creative and productivity applications to broaden market appeal.

Tsinglin Motor: Custom Motor Solutions

Established in 2009, Tsinglin Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

- Custom Micro Motors8 products

- DC Gear Motor137 products

- 6mm Planetary Gear Motor4 products

- 6mm Planetary Metal Gear Motor3 products

- Brushless Gear Motor17 products

- Micro Gear Motor62 products

- Coreless Gear Motor11 products

- N20 Gear Motor26 products

- Plastic Gearbox Motor8 products

- Standard Gear Motor15 products

- Stepper Gear Motor13 products

- Planetary Gear Motor29 products

- Spur Gear Motor63 products

- Worm Gear Motor28 products

- DC Motor68 products

- Brushed DC Motor16 products

- Brushless DC Motor24 products

- Inrunner Rotor BLDC Motor6 products

- Outrunner Rotor BLDC Motor16 products

- Coreless DC Motor13 products

- Micro DC Motor15 products

- Stepper Motor18 products

- Micro Stepper Motor13 products

- NEMA Stepper Motor2 products

- Stepper Motor Linear Actuator4 products

- Vibration Motors71 products

- Brushless Vibration Motor8 products

- Coin Vibration Motor22 products

- Coreless Vibration Motor3 products

- Encapsulated Vibration Motor6 products

- Linear Resonant Actuator12 products

- Powerful Vibrating Motor17 products

- SMD Vibration Motor4 products

- Sonic Vibration Motor2 products