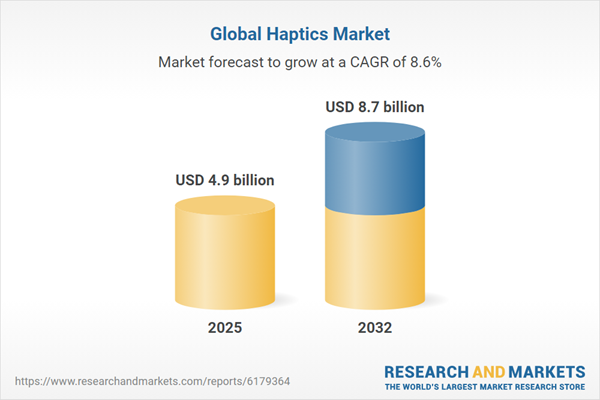

The global haptic feedback market is rapidly growing. It is projected to expand from approximately $4.9 billion in 2025 to nearly $8.7 billion by 2032. This represents a Compound Annual Growth Rate (CAGR) of about 8.6%.

Among various haptic actuators, the LRA (Linear Resonant Actuator) is dominant. It holds about a 45% market share. LRAs are widely used in smartphones, wearables, and high-end electronics. They are a mainstream choice due to their high efficiency and fast response.

We are TSL MOTOR, a dedicated LRA motor manufacturer. We provide high-performance, reliable haptic solutions globally.

This article explores four key areas. It covers the working principle, core advantages, typical applications, and selection essentials. This helps engineers and product managers better understand and utilize this critical component.

Key Takeaways

- Resonance Principle: Relies on resonant frequency for high efficiency and maximum amplitude.

- Speed Advantage: Fast response; start/stop requires only 10–50 ms.

- Feedback Quality: Delivers crisp, fine HD haptic feedback.

- Technical Requirement: Must use a dedicated driver IC with automatic frequency tracking.

- Market Position: The top choice for high-end products like smartphones and wearables

LRA Motor: Fundamental Principles & Structure

What is an LRA Motor?

An LRA motor is a linear vibrator. Its vibration does not come from rotation. It uses an internal mass block. This mass moves back and forth linearly within an elastic structure.

It differs from the common ERM (Eccentric Rotating Mass) motor. An LRA motor operates near a fixed mechanical resonant frequency. This achieves higher vibration efficiency. It also provides clearer haptic feedback. This is done with lower power consumption.

LRA motors typically have a single vibration direction. They feature fast response and high control precision. They are ideal for applications demanding a high-quality haptic experience.

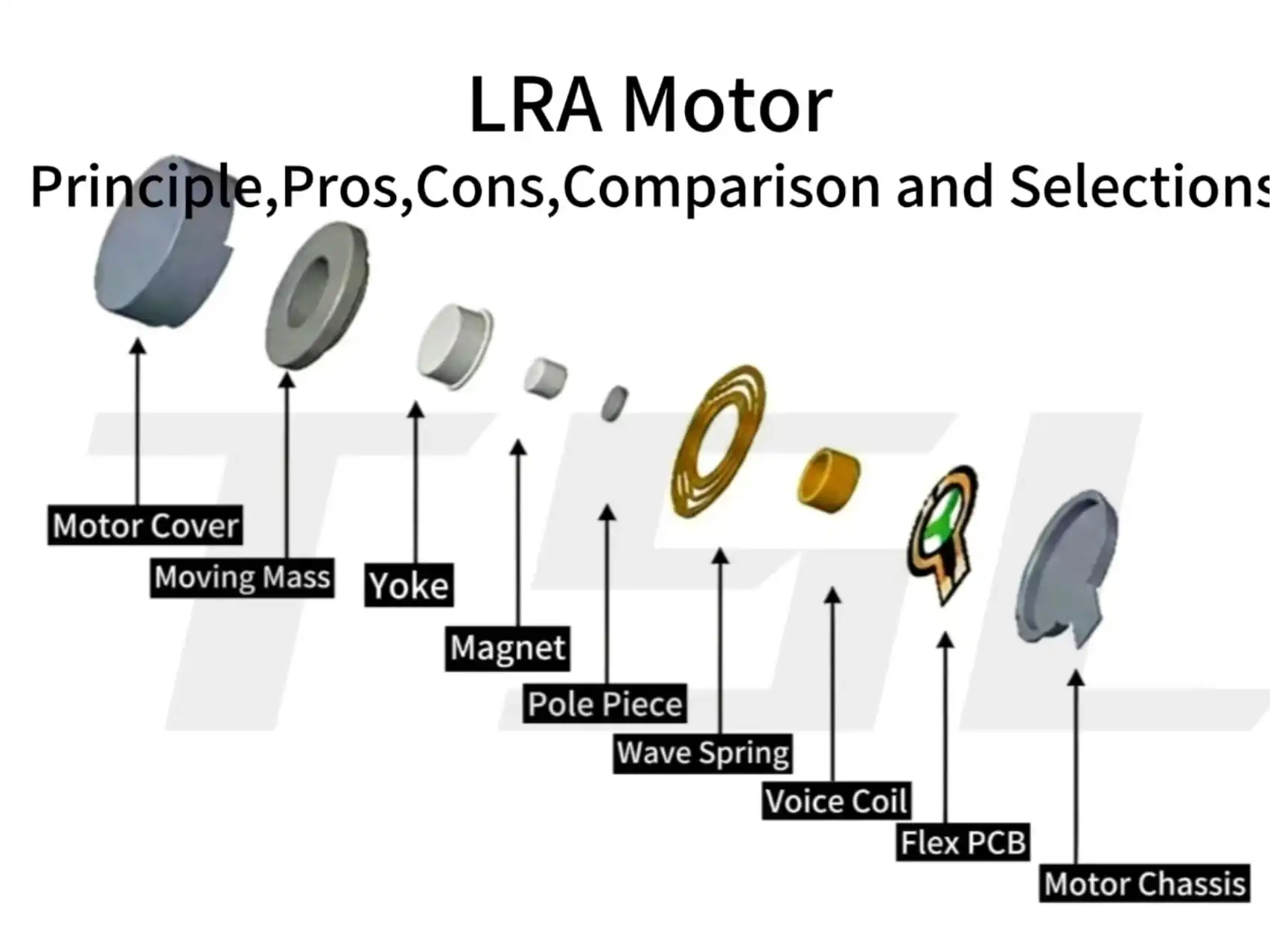

LRA Motor Structure

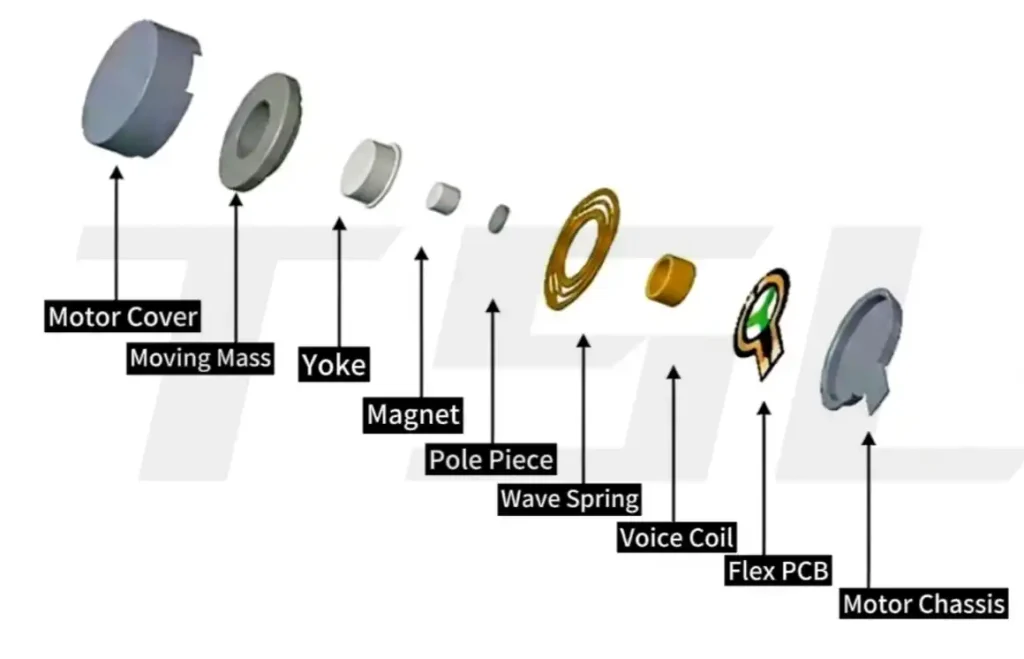

A typical LRA motor is encased in a compact metal shell. It consists of the following core components:

- Voice Coil: A copper wire coil fixed to the base or casing. When AC current passes through, it generates an alternating magnetic field and serves as the core input for electrical energy.

- Moving Mass: Usually made of NdFeB (Neodymium Iron Boron) high-energy magnets. Sometimes, a tungsten alloy block is added to increase mass. The inertia of the mass determines the maximum impact force (G-force).

- Spring Suspension: Suspends the moving mass centrally in the casing, allowing free vibration along a specific axis (Z-axis or X-axis). The stiffness of the spring and the mass together determine the resonant frequency. Common spring types include wave, leaf, or helical springs.

- Magnetic Circuit: Includes the permanent magnet and the yoke (magnetic conductor). Its role is to concentrate magnetic lines and improve the efficiency of electromagnetic energy conversion.

This architecture enables the LRA to work efficiently at a fixed resonant frequency. It balances low power consumption, fast response, and high-precision haptic feedback, making it widely used in smartphones, wearables, and VR/AR systems.

How Does an LRA Motor Work?

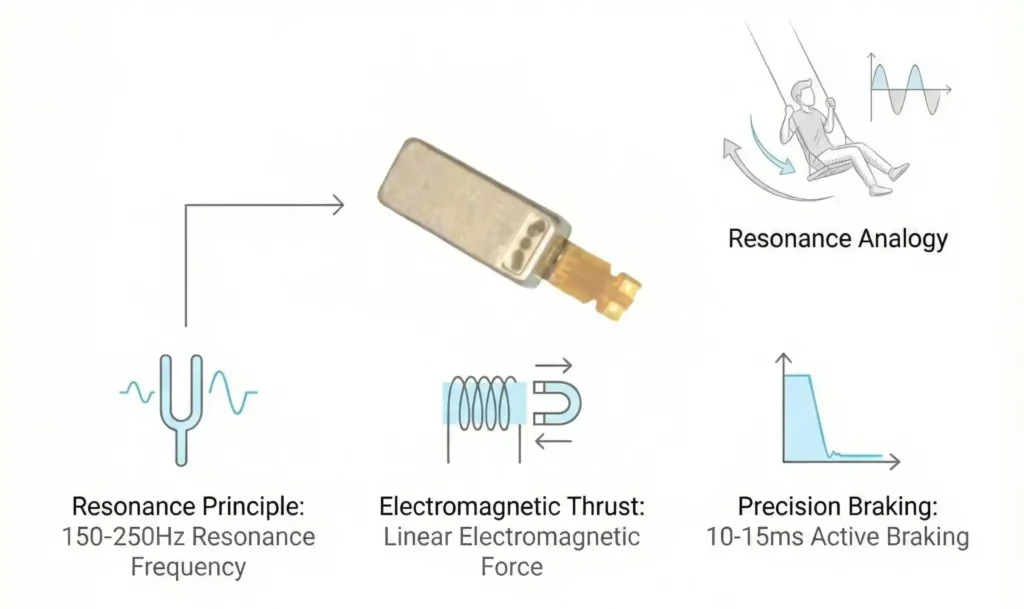

The LRA’s core principle is forced vibration at the resonant frequency. It is based on a spring-mass system. Simply put, it’s like pushing a swing. A small force applied at the correct time creates a large oscillation.

Step 1: Drive Signal Input

The controller sends a pulse signal to the LRA driver chip. This happens when haptic feedback is needed.

The signal frequency is usually 150–250 Hz. This matches the motor’s mechanical resonance point.

TSL MOTOR precisely tunes the frequency. Deviation is controlled within ±10Hz. This ensures consistent feedback across different devices.

Step 2: Electromagnetic Force Generation

The driver chip converts the signal into AC current. This current flows through the coil.

The coil creates an alternating magnetic field. This interacts with the permanent magnet. It generates a thrust force.

The thrust direction is always linear. It follows the basic laws of electromagnetism.

TSL MOTOR optimizes the magnetic circuit design for efficiency. This yields greater driving force with smaller current.

Step 3: Resonance Amplification

The mass and spring system enters resonance. This happens when the drive frequency matches the system’s natural frequency.

Each thrust is applied at the opportune moment. Energy converts efficiently between the spring and the mass.

The result is a noticeable vibration. This is achieved with a very small driving force. It is like pushing a swing. A gentle push at the right time makes it swing higher and higher.

Step 4: Precise Braking

The driver chip sends a reverse pulse or a short-circuit signal. This happens when vibration needs to stop.

This quickly cancels the remaining kinetic energy.

Vibration stops completely within 10–15 milliseconds. Traditional ERM motors usually take 50–150 ms.

This active braking mechanism makes the feedback crisp. There is no lingering feeling.

Advantages of LRA Motors

The LRA Motor’s structure and principle offer unique advantages. These are key to haptic feedback. The benefits mainly lie in response speed, frequency control, haptic performance, and energy efficiency.

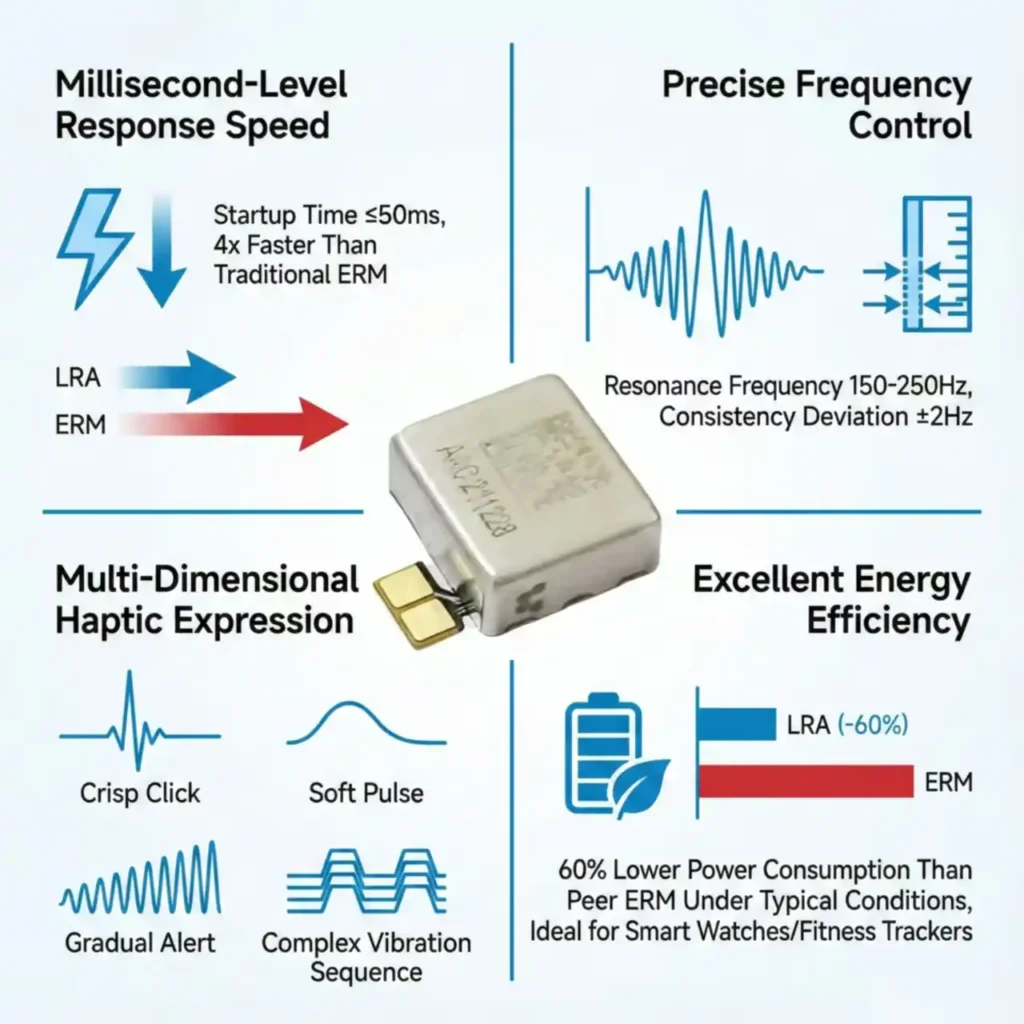

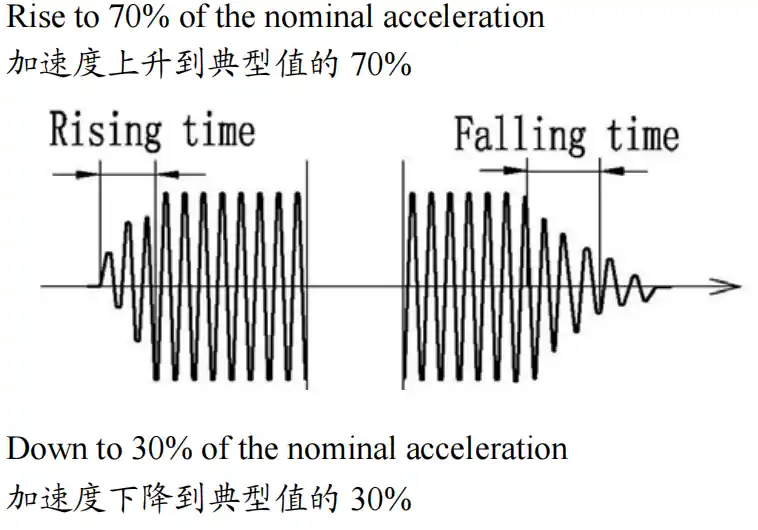

Millisecond-Level Response Speed

LRA motors respond very fast. For example, the TSL208-17S starts up in ≤ 50 milliseconds. This is about four times faster than traditional ERM. This instant response makes gaming, keyboard feedback, and alerts feel more natural. Users perceive almost no delay.

Precise Frequency Control

The LRA operates at a fixed resonant frequency (typically 150–250 Hz). This maximizes vibration output with minimum energy input. Through precise tuning, frequency consistency is controlled within ±2 Hz. This ensures a uniform haptic experience across different devices.

Multi-Dimensional Haptic Expression

The LRA offers more than simple vibration. It supports multi-mode waveform programming. Designers can achieve various effects: crisp clicks, gentle pulsations, gradual reminders, or complex sequences. This provides a richer “haptic language” for interaction design.

Excellent Energy Efficiency

In typical operation, the LRA consumes about 60% less power than comparable ERMs. This efficiency is vital for devices needing long battery life. Examples include smartwatches and fitness trackers.

Comparison of LRA with Other Haptic Motors

The LRA’s greatest strength is its balance. It sits perfectly between the ERM’s low cost and the Piezo’s high performance. It delivers a cleaner, more efficient vibration than the ERM. It also avoids the high-voltage drive and complexity of the Piezo.

Table 1:Simple Comparison of LRA Motor and Other Haptic Motors

| Feature | LRA (Linear Resonant Actuator) | ERM (Eccentric Rotating Mass) | VCM (Voice Coil Motor) | Piezo Actuator |

| Principle | Mass block resonates on a single axis | Eccentric mass rotation | Non-resonant linear drive | Piezoelectric effect deformation |

| Response Speed | Faster (20–50 ms) | Slowest (100–200 ms) | Faster (non-resonant operation) | Fastest (<1 ms) |

| Energy Efficiency | High | Low | Medium | High / Very low (short bursts) |

| Vibration Quality | Crisp, precise, linear | Vague, "buzzing" | Very strong, more realistic | Extremely high, wideband, HD |

| Operating Frequency | Narrow band (best at resonance) | Wideband (but single effect) | Wideband (high controllability) | Widest band (0–500 Hz) |

| Size/Thickness | Thinner / Compact | Larger (usually cylindrical) | Larger / Thicker | Extremely thin |

| Cost | Higher | Lowest | High | Highest |

| Drive Requirement | Dedicated IC | DC voltage | drive and control | tens to hundreds of volts |

Versus ERM (Eccentric Rotating Mass)

ERM relies on a motor rotating an eccentric mass. This generates vibration.

- LRA Advantages: Faster response, higher efficiency, finer vibration, longer lifespan.

- ERM Advantages: Simple structure, lowest cost, strong vibration. It is still used in low-end applications.

Versus VCM (Voice Coil Motor)

VCM is similar to LRA. It is also a linear drive. But it is usually designed for non-resonant or wideband operation.

- LRA Advantage: Higher efficiency at its resonant frequency.

- VCM Advantage: VCM works better over a wider frequency range. It offers richer, more realistic haptic experiences. But it generally requires a larger size and higher power consumption. In high-end phones, LRA performance is approaching VCM. Some LRAs can even achieve wideband or dual-frequency operation.

Versus Piezo Actuator

Piezo actuators generate vibration through piezoelectric material deformation.

- LRA Advantages: Low drive voltage (LRA needs only a few volts; Piezo needs tens to hundreds of volts). Lower cost. Easier drive circuit design.

- Piezo Advantages: Extremely fast response (millisecond level, tens of times faster than LRA). Wide operating frequency band. It achieves the finest, highest-fidelity haptic effects (true HD Haptics). It can be made very thin.

- Main Piezo Drawbacks: High-voltage drive requirement and higher cost.

Limitations of LRA Motors

Despite their many advantages, LRA motors have limitations. These mainly focus on the frequency bandwidth restriction. This leads to insufficient haptic diversity. Drive circuit complexity is also a factor.

These limitations make LRA inferior to wideband, ultra-fast Piezo actuators. This is true in scenarios needing the highest fidelity haptics (e.g., advanced VR, medical haptics).

Narrow-Band Operation (Resonance-Limited Bandwidth)

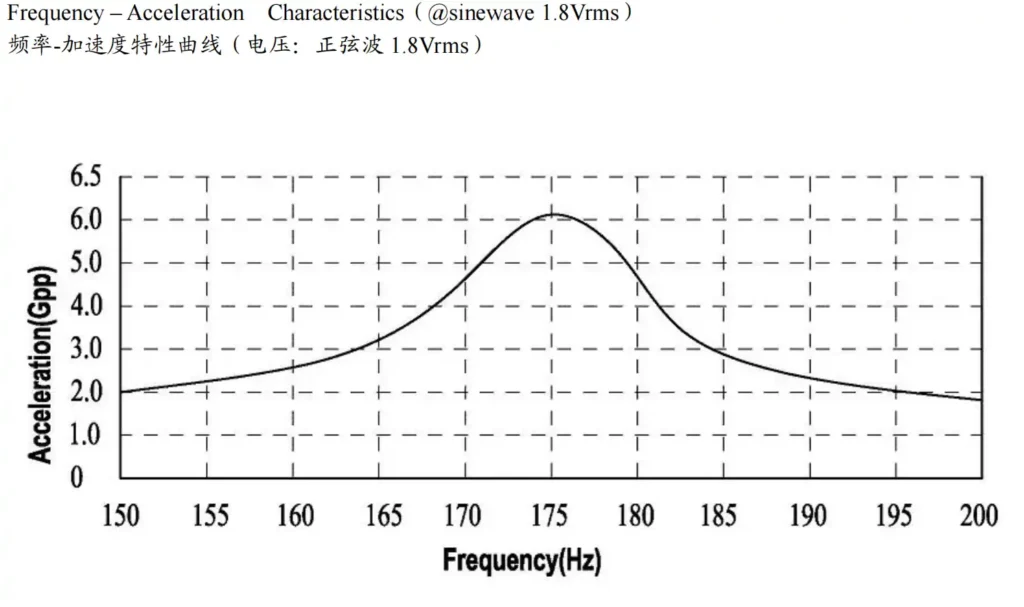

Narrow operating frequency range: The LRA is most efficient near its natural resonant frequency, typically 150–200 Hz.

High-performance loss: Vibration intensity drops sharply when the drive frequency deviates. A 10% deviation can cause a 30% or greater loss.

Limited haptic effect: It is hard to maintain a consistent haptic experience over a wide frequency range. This limits the diversity of HD Haptics and complex waveforms.

Resonant Frequency Drift

Environmental impact: Temperature, mounting, and casing damping can cause the optimal resonant frequency to drift.

Drive complexity: Dedicated drive chips (Haptic Driver IC) are required. They monitor back-EMF (BEMF) and automatically track the frequency in real-time.

Increased cost: The LRA drive circuit is more complex. This compares to ERM (only needs DC power) or Piezo (simple drive but needs high voltage).

Requires Moving Mass

Response speed limited: Startup time is about 20–50 ms. It is faster than ERM, but slower than Piezo actuators (<1 ms).

Larger size: It requires a mass block, spring, and magnetic structure. The thickness is usually greater than very thin Piezo actuators.

Relatively Higher Cost

Higher than ERM: Design and manufacturing require greater precision, and a dedicated drive chip is also necessary.

Increases system BOM: While a single LRA might be cheaper than a Piezo, the drive chip and mounting requirements increase the overall system cost.

LRA Motor Applications

The LRA is quickly replacing traditional ERM motors. This is due to its fast response, fine haptic feedback, and high efficiency.

LRA is now the mainstream choice in consumer electronics. This includes smartphones and wearables. These devices demand a higher-quality haptic experience.

Consumer Electronics

This is the primary application area for LRA motors. They provide Haptic Feedback. This enhances the user interaction experience:

- Smartphones and Tablets: Vibration alerts for calls, texts, or notifications. Realistic “click feel” for virtual buttons, keyboard input, and scrolling. (Apple’s Taptic Engine is a typical LRA application.)

- Game Controllers: Simulation of immersive haptic effects. This includes explosions, impacts, shooting, and friction. It enhances immersion.

- Wearable Devices: Notification alerts and alarms for smartwatches and fitness trackers.

- Laptop Touchpads / Capacitive Pens: Simulation of physical button clicks. Provides precise pressure feedback.

Virtual / Augmented Reality (VR/AR)

In VR/AR systems, LRA creates a more realistic immersive experience. For VR headsets and controllers, LRA Motors simulate different sensations. Examples include grabbing objects, touching surfaces, or being injured.

Automotive Systems

LRA is entering the automotive electronics field. It is used to improve the driving and operation experience:

Dashboards and Center Consoles: Provides haptic feedback on touchscreens or touch buttons. This confirms operations and improves safety.

Medical and Precision Instruments

LRA is also used in high-precision equipment. This is thanks to its good dynamic response and precise control. For example, in precision instruments, the LRA motor is chosen for high-accuracy control.

How to Select the Right LRA Motor

When selecting an LRA, several factors must be considered. These include resonant frequency, rated voltage and current, vibration intensity (G-value), size/form factor, and mounting method. The availability of a suitable driver IC must also be confirmed. These factors directly affect the haptic experience and development efficiency.

Resonant Frequency

Definition: The LRA must operate near its natural resonant frequency to maximize amplitude and efficiency.

Selection Range:

- High Frequency (170–200 Hz): Vibration feels clearer and sharper. Suitable for fine interactions on phones and tablets (e.g., key clicks, virtual keyboard input).

- Low Frequency (100–150 Hz): Vibration feels deeper and stronger. Suitable for game controllers or strong alert scenarios.

Drive Requirement: Resonant frequency may drift with temperature and mounting. An automatic resonant frequency tracking driver IC must be used to ensure operation at the optimal efficiency point.

Vibration Intensity (G-Value / Acceleration)

Definition: G-value represents the vibration amplitude’s acceleration, measured in G (≈ 9.8 m/s²).

Selection Range:

- High G-value (≥ 2 G): Suitable for immersive experiences or strong warnings (e.g., game controllers, industrial control).

- Medium-Low G-value (1.0–1.5 G): Suitable for most consumer electronics (e.g., phones, watches). Provides clear and comfortable feedback.

Power Relationship: G-value is proportional to drive voltage. A driver IC is usually required to boost system voltage (e.g., from 3.3 V to 5–8 V) to achieve higher G-values.

Drive Solution and Power Matching: The System Core

AC Drive: The LRA is an AC-driven device and requires a dedicated driver IC.

Driver IC Functions:

- Provide a sine or square wave matching the resonant frequency.

- Boost voltage to meet high G-value demands.

- Track frequency to ensure efficiency.

- Offer built-in waveform libraries to simplify software development.

Matching Principle: Ensure the LRA’s rated voltage and maximum drive current fully match the driver IC’s output capability and the system’s power budget.

Size, Form Factor, and Mounting Method

Form Factor Options:

- Coin Type: Suitable for products requiring extreme thinness (e.g., smartwatches).

- Bar Type: Suitable for devices needing higher G-values and allowing more space (e.g., smartphones).

- Cylindrical Type: Suitable for wider frequency ranges and devices with ample space.

Mounting Requirement: The LRA must be firmly fixed to the device casing or a rigid frame to efficiently transfer vibration energy. Any looseness or mounting on a soft bracket significantly reduces the perceived G-value.

Solution: TSL MOTOR provides optimized mounting solutions to prevent performance loss due to structural design issues.

TSL MOTOR Support as an LRA Motor Manufacturer

We specialize in LRA motor R&D and manufacturing. We offer a variety of standard models. These cover different sizes, resonant frequencies, and vibration intensities.

We also offer custom development. This includes structural size optimization, frequency parameter tuning, and performance enhancement.

Our support is mainly in these areas:

- Rich Product Line: We offer products from coin to bar type. From low to high frequency. From medium-low to high G-value. This meets the needs of smartphones, wearables, game controllers, automotive electronics, and medical instruments.

- Custom Development Capability: We adjust motor size, resonant frequency, and drive characteristics. This is based on the customer’s product structure and interaction needs. We ensure the best haptic experience.

- Drive and System Support: We recommend matched drive ICs and provide reference designs. This helps customers shorten development cycles. It also lowers system integration risk.

- Consistency and Reliability Testing: Strict batch consistency control and long-term reliability validation. This ensures stability and consistency during mass production.

- Full-Process Technical Support: We offer professional engineering support. This covers product validation and mass production phases. It includes selection consultation, mounting solution optimization, drive debugging, and performance evaluation.

We are more than an LRA motor manufacturer. We are a haptic solution partner. We combine standardized products with customized services.

We help customers achieve the best haptic feedback. This is for various application scenarios. We ensure development efficiency and system reliability.

Conclusion

The LRA Motor (Linear Resonant Actuator) is dominant. This is thanks to its unique resonant working principle. It leads the rapidly growing global haptic feedback market.

Its core value is in finding the best balance. This balance is between high response speed, high efficiency, and fine haptic experience. It is far superior to traditional ERM motors. It avoids the high-voltage drive and complexity of Piezo actuators.

The LRA faces challenges: narrow-band operation and resonant frequency drift. However, these limitations can be overcome. This is done with dedicated driver ICs that feature automatic frequency tracking. Professional structural design optimization also helps.

Selecting the LRA motor and the right drive solution is crucial. This is for smart hardware manufacturers aiming for premium interaction experiences.

TSL MOTOR is committed to helping global customers. We provide a diverse product line and strong customized technical support.

We help overcome design challenges. We ensure the integration of high-performance, highly reliable haptic feedback. This is for their next-generation products. The LRA is more than a component. It is key to enhancing user immersion and device premium feel.

FAQ

Q1: What is the biggest difference between LRA and ERM?

LRA operates based on the principle of resonance, offering fast response times (20–50 ms) and high energy efficiency. In contrast, ERM uses rotation, resulting in a slower response (100–200 ms) and higher power consumption.

Q2: How does the LRA motor work?

The LRA generates an alternating electromagnetic force through its voice coil and permanent magnet. This force drives the mass block to oscillate linearly at its natural resonant frequency, amplifying the vibration.

Q3: Why does an LRA require a dedicated driver IC?

LRAs operate within a narrow frequency band. The dedicated IC is necessary to output the precise AC signal, enable automatic frequency tracking, and perform voltage boosting to ensure optimal efficiency and maximum performance.

Q4: What are the main limitations of LRA motors?

Their operating frequency range is relatively narrow (near $F_0$). The resonant frequency is also prone to drift due to changes in temperature and mounting conditions.

Q5: What are the primary applications of LRAs?

Key applications include smartphones (for crisp click sensations), wearable devices, and game controllers, where they are used to deliver high-quality haptic feedback.

Linear Resonant Actuator

TSL offers high-performance Linear Resonant Actuators (LRAs), designed to provide precise and efficient haptic feedback for a wide range of applications. LRAs are typically used in mobile devices, wearables, and automotive systems, offering excellent performance in terms of vibration intensity and energy efficiency. Our LRAs come in the following types:Standard LRAs,Miniature LRAs and Custom LRAs.TSL supports custom designs to fit your exact requirements, ensuring optimal user experience and seamless integration into your products.