Customized Solutions

Our team of experienced sales engineers is prepared to deliver the optimal solution for your application.

Motor Customized Solutions

At TSL, we transform your unique requirements into high-performance, reliable motor solutions. From concept to mass production, our engineering expertise ensures your devices stand out with durability and efficiency.

To Accelerate Your Project, Prepare These Details:

- Electrical Requirements: Operating voltage , Current consumption limits, Drive signal type , etc.

- Mechanical Constraints:Max dimensions,Mounting method,Shaft direction,etc.

- Performance Targets:Vibration force (G-level) at specific frequencies ,Start/stop response time ,Durability,etc.

- The timeline for this project and the annual consumption of motor products.

Common Gear Motor Designs

Regardless of the chosen gearmotor technology, several standard form factors and design considerations are widely used across different industries. Here are a few examples that can help define your ideal solution.

Exposed Frame

Approximately one-third of our designs feature an exposed structure, mainly when the gearbox frame is square or rectangular in shape.

Sealed Frame

Some gearbox designs are round, which allows for easier coverage of the gears. The primary advantage of this design is that it helps keep debris out.

Fold-Back

If space is limited in length, consider using a fold-back gearbox. Alternatively, a non-concentric offset gearbox shaft could be an option.

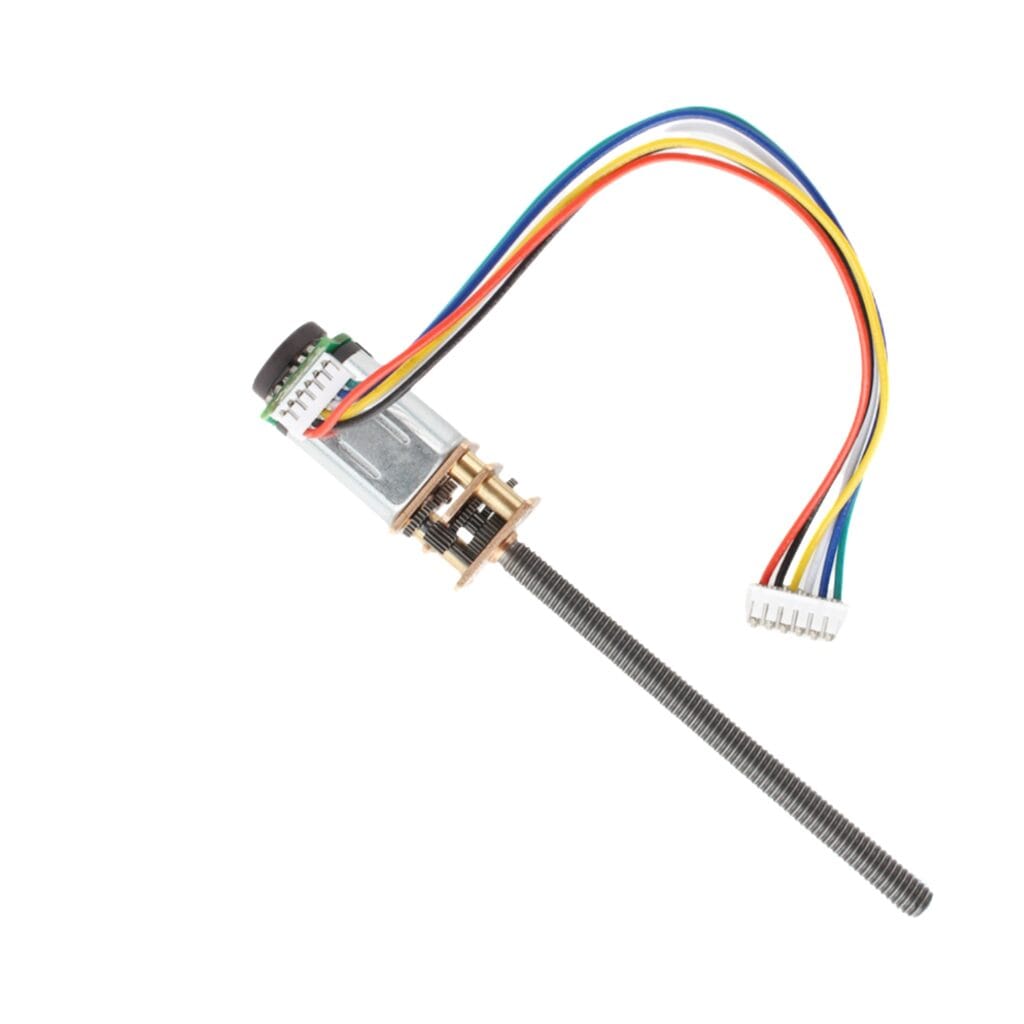

Shaft Customizations

Certain applications require specialized shafts. Options such as extended or shortened shafts, d-cuts, keyway cuts, location holes, and threaded shafts can all be accommodated.

Clutches and Braking Mechanisms

Clutches allow the gearbox to be separated from the application, while mechanical brakes can secure the gearbox shaft in a stationary “park” position.

Advanced Motion Control Systems

While precise movement is often required, motion controllers can also play a crucial role in prolonging the lifespan of gear motors by optimizing their operation.

Common DC Motor Designs

No matter which DC motor technology is used, certain form factors and design features are common across many industries. These shared elements help guide the selection of the best motor solution. Below are some examples to help describe your ideal choice.

Terminals and connector pins

Connecting the motor to the application is essential. We usually use soldered pins, spring pad connectors, and integrated connectors for this purpose.

Leads and connectors

Wires and leads are commonly used to connect motors in applications. We provide various lengths, gauges, and pre-installed connectors.

Frame modifications

Securing motor frames to your application can be achieved in several ways. Custom fastening points and brackets are often utilized.

EMI filters and backpack PCBs

Operating motors generate EMI electrical noise. This can be reduced by installing filters, which can be either PCB-based or wire-based.

Shaft modifications

The motor must connect mechanically to your product. We can create custom shafts and pre-install gears, bushes, and bosses.

Motion controllers

A small PCB attached to the back of a DC motor can convert it into a precision servo at a fraction of the cost of a similar off-the-shelf unit.

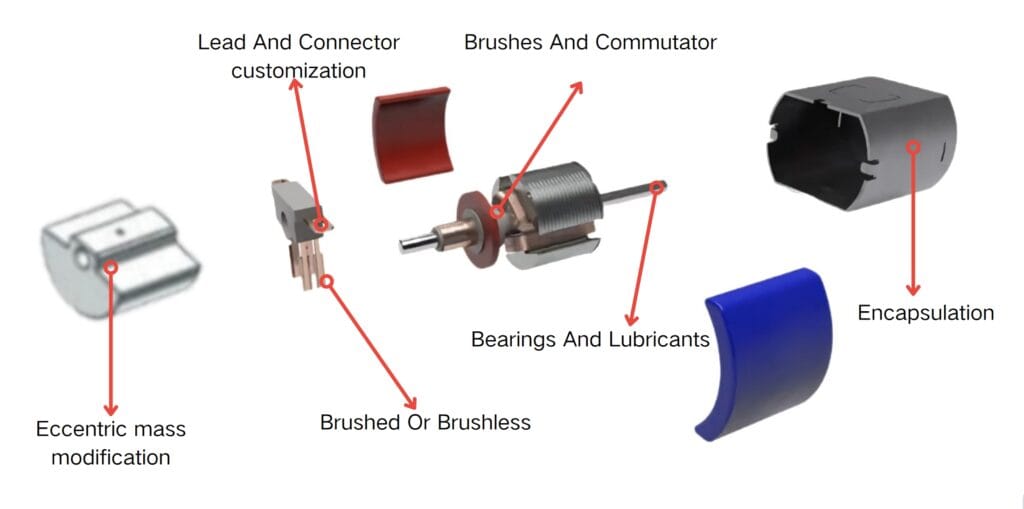

Vibration Motor Customization

We specialize in redesigning and tailoring vibration motors to meet the unique needs of our customers. The interactive graphic below highlights some common customizations we offer for brushed DC vibration motors. We also apply similar modifications to other technologies, including brushless, LRA, solenoid, and piezo motors.

Eccentric Mass

Modification

Modify the size, material, shape, and quantity of the eccentric mass(es) to optimize the vibration frequency and amplitude for the desired performance range.

Brushed Or

Brushless

While long-life brushes come at a higher cost, they remain more affordable compared to adopting brushless technology.a

Lead And Connector

Customization

We offer customized wire sets with a variety of connectors from brands like JST, Hirose, AMP, Molex, AVX, and Kyocera, which can be integrated into any motor we manufacture. Additionally, we can attach PCB “backpacks” to certain motors to reduce local EMI or provide extra circuit functionalities.

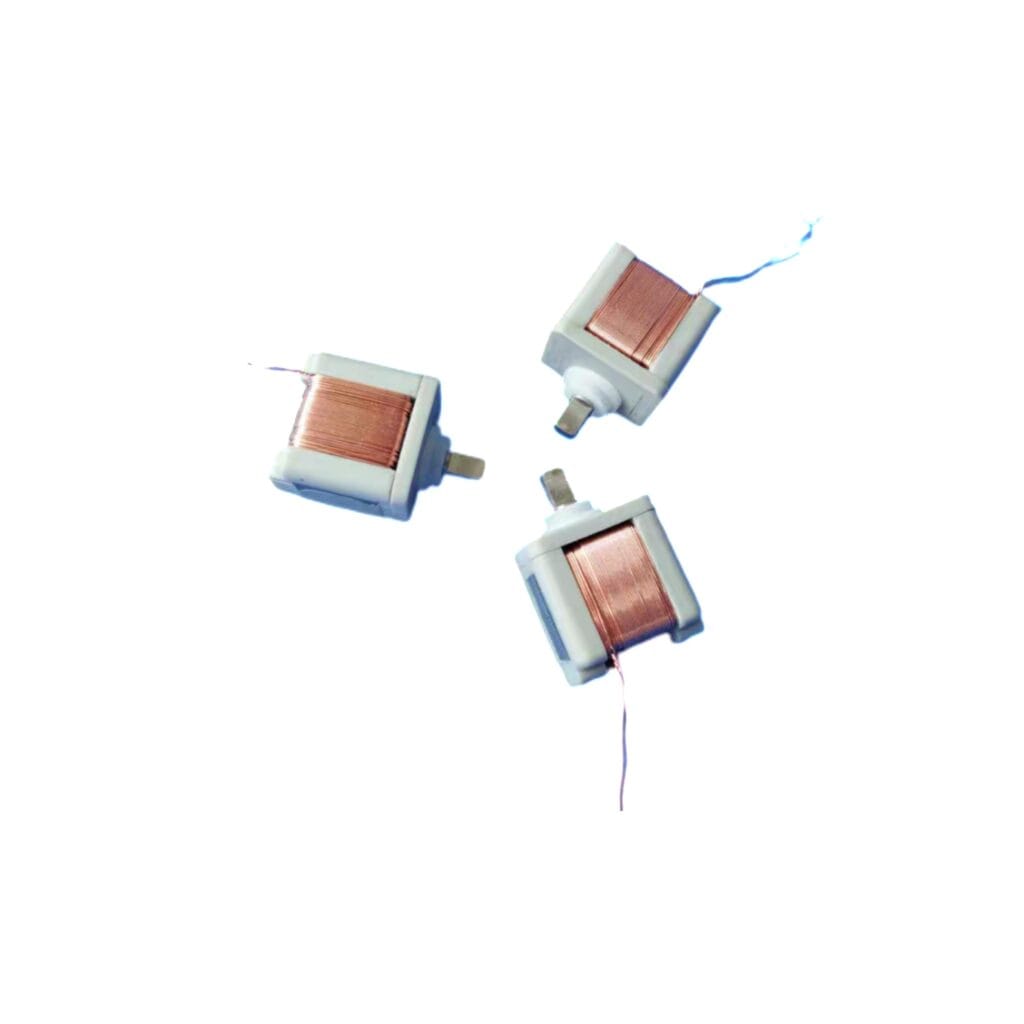

Brushes And

Commutator

The brushes and commutator play a crucial role in the performance of any DC motor. The choice of plating type and the method used for the components significantly impact the motor’s lifespan, just as the type of commutator polishing and lubricant applied can also influence its durability.

Bearings And

Lubricants

Our motor designs incorporate a variety of bearings and lubricants, chosen based on the specific application environment. In larger vibration motors, the bearing typically experiences the most wear, primarily due to the centrifugal force generated by the rotation of the eccentric mass. We will provide recommendations to help avoid any issues with the application specifications.

Encapsulation

In certain applications, covering the rotating mass can be beneficial. Additionally, the motor can undergo an extra sealing process to offer enhanced protection against the penetration of fluids.

Customer Process

Meticulous Manufacturing

1.Spec-based Quotation

Communicate and quote byspecs & quantity

2.Customize as Needed

Custom - produce according to drawings

3.Sample Confirmation

Quick sample outconfirm sample & plan

4.Contract Signing

After sample ok pay depositstart production

5.Logistics Delivery

Start shippingafter production done.

6.After -sales Service

Check on receipt transfer to after-salesif all clear

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!