3D Printing Need To Use Powerful Vibration Motor

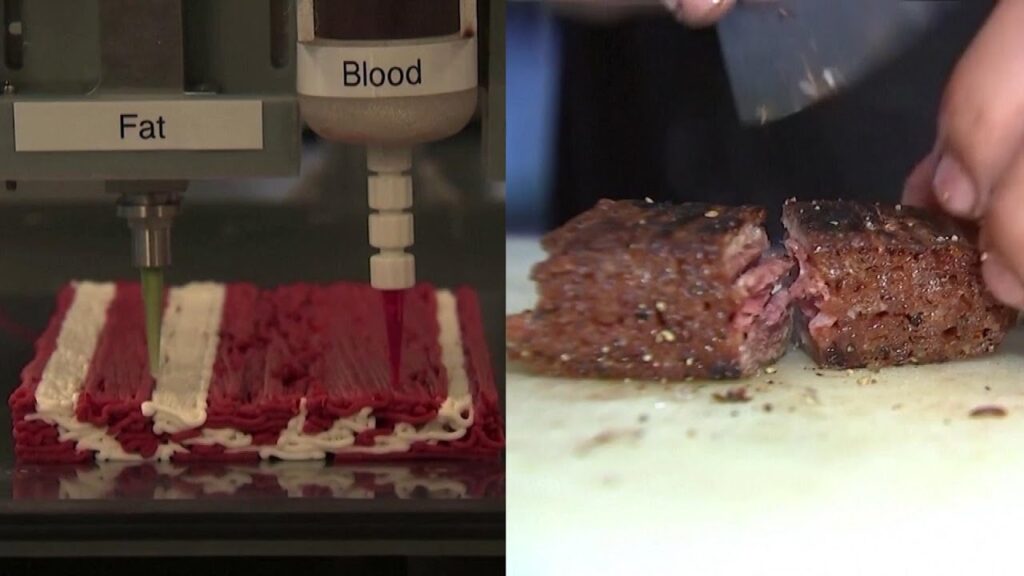

Redefinemeat believes that the world needs an entirely new type of meat, plant-based food that is not just good for the environment but also compassionate to animals. The 3D printer technology can be utilized to achieve this.

3D printing equipment requires motors to control their movements and operate. Particularly, Redefine Meat utilizes high-precision, powerful Motors with DC vibration TSL-DH385-FS which are able to control the motion that is made by the 3D printing machine as well as the location of the printer head, which allows for precision 3D printing. Furthermore, they utilized other electronic components and control system to guarantee stability and dependability that the 3D printing device.

What Are Requirements For Powerful Vibration Motor Used

1.High precision : The micro-vibration motor must have a high-precision control ability to ensure precision and accuracy of the printing.

2.High Speed 2High Speed: The print head or the platform has to be moved swiftly, which is why the dc vibration motor requires a the ability to drive at high speeds.

3. High reliability: It generally has to run continuously for a long time. If the motor for vibration is not reliable and a long-lasting life it’s difficult to assure stability and dependability of the printer.

4.Low noise: A printer requires an environment that is quiet to ensure that noise doesn’t disturb the printer.

5.Low Vibration: Low-vibration properties are necessary to prevent vibrations from causing damage to the printer.

What is the way powerful vibration motor work with a 3D printer step-by-step?

–The control board sends signals to the driver of the powerful vibration motor: It is the control board for the 3D printer transmits an alert to the driver of the motor that is responsible for managing the speed of the motor.

–The motor driver sends a message at the motor. The driver then sends out a signal to the motor telling it to move.

–Motor turns The motor starts to spin, turning electricity into mechanical energy.

–The shaft of the rotates. As the motor turns the shaft that is attached to it also turns.

–The shaft is able to move the pulley, or gear The shaft is attached to a gear or pulley that moves when the shaft turns.

–Belts or gears move the build or print head plate. The pulley, or gear is attached to a conveyor belt or a gear that can move the build or print head plate, based on the kind of 3D printer.

–The print head, or build plate can move as it is programmed. The print head, or build plate is moved according to program in the 3D printer software, forming objects or shapes that are desired.

In general powerful vibration motor plays vital roles for the functioning of the 3D printer as it converts electricity into mechanical energy that allows it to enable the printer’s head to move or the building plate to make an desired 3D object.