DC Gear Motor

A small gear motor is a compact DC motor paired with a miniature gearbox, designed to lower the output speed while boosting torque.

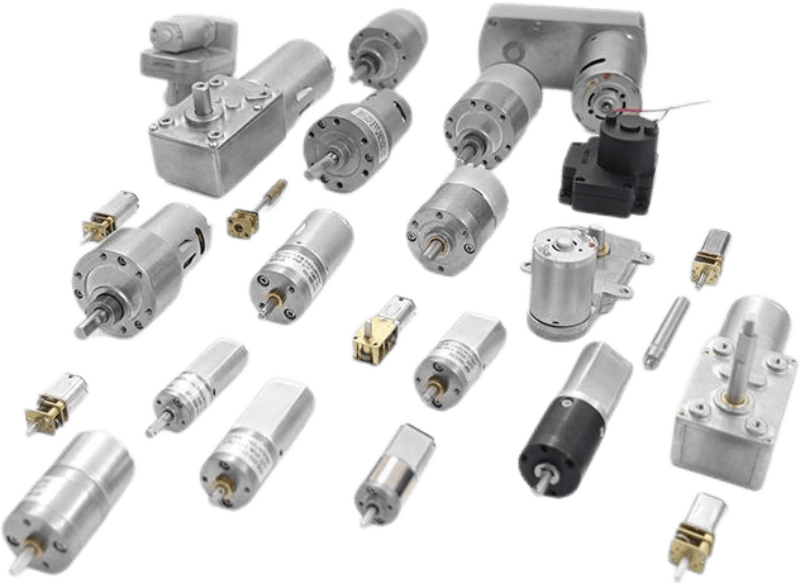

TSL-Motor provides a comprehensive selection of high-precision gear motors, featuring spur, planetary, and epicyclic gear systems. We offer customizable options including different diameters, voltages, and gear ratios. Our range includes micro gear motors from the GM12-N10VAV, N20VAV, and N30VAV series, as well as stepper gear motors, all designed to meet a variety of specialized requirements.

Considering the specific needs of your application, many of these standard motors may not be directly compatible with your product. As a leading manufacturer of gear motors, we are committed to surpassing your device’s performance requirements. Our expert team is ready to develop a tailored gear motor solution that perfectly fits your needs. Let’s begin crafting your custom small DC gear motor today, offering a unique and personalized experience from start to finish.

Explore Our 9 Kinds of DC Gear Motors

The 609 series planetary DC gear motor is a compact, high-torque motor with four ratio options, offering low noise performance.

A small, efficient motor delivering high torque and precision. Perfect for applications needing dependable and accurate motion control.

High-efficiency coreless DC motor with metal gearbox, low speed, high torque, fast response, and low consumption.

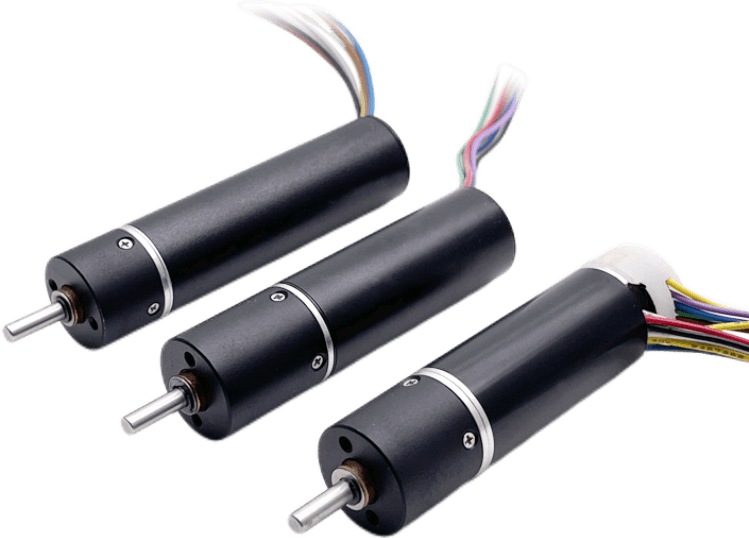

Gear BLDC motor provides better efficiency and longer life, ideal for high-performance, durable applications.

Micro DC gearmotor with high torque, low speed, and robust gearboxes for handling heavier loads.

Offers precise control and positioning through step-by-step motion, ideal for tasks needing accurate, repeatable movements.

Premium small spur gear motors, offering top performance with N20 Micro Metal Gearmotors.

Micro DC gearmotor with high torque and low speed, featuring heavy-duty gearboxes for increased load capacity.

Plastic gear motor with lightweight plastic gears, ideal for robots, offering high torque with worm gears.

How Do Gear Motors Function?

Composition

A gear motor combines an electric motor and gears to create rotational motion. The motor generates torque, which is transferred to the gears. These gears adjust the speed and torque by using a gear reduction ratio, which compares the teeth of the driving gear to the driven gear.

Gear Adjustment

The gear reduction ratio allows for various speed and torque adjustments. Different gears, such as spur gears for efficiency or helical gears for quieter operation, can be used depending on the application. The arrangement of these gears influences how power is transmitted and can include multiple stages to fine-tune speed and torque output.

Summary

In short, gear motors work by converting electrical power into mechanical motion, adjusting speed and torque through specific gear combinations and reduction ratios.

The Main Gear Motor Technologies

We create and produce gear motors, both as standalone parts and as integral elements of more extensive systems. During this process, we utilize four distinct technology categories based on the specific requirements of the final application.

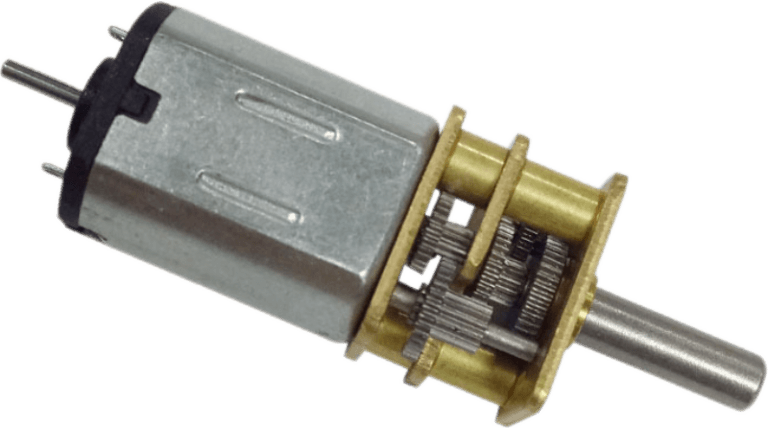

Spur Gear Motor

Gear motors are often paired with gearboxes to decrease rotational speed while increasing torque. Our spur gearboxes are made from high-quality steel gears to ensure maximum strength and extended lifespan. They can be attached to various types of motors, including iron core, coreless, and brushless options.

While similar designs are common in the market, the true durability and performance depend on precise details. The steel’s metallurgy plays a crucial role in the gearbox’s longevity, as does the choice of lubricant used. We’ve observed that lower-grade steel often leads to chipped gear teeth, which can quickly cause gearbox failure.

The quality of brass alloy used for the gearbox housing also significantly affects the durability of the internal bearings. This, in turn, influences gear alignment and meshing, which can lead to excessive wear and increase the likelihood of gear damage, including broken or chipped teeth.

When properly paired with the right motor type, windings, gear ratios, and materials, our open-frame spur geared DC motors provide exceptional performance that can outperform motors costing 6 to 10 times more in many use cases, offering outstanding value for the price.

We also offer spur gearboxes in various configurations, designed to meet specific application needs, and, for high-load situations, we can implement helical cut gears. For applications where noise reduction is critical, we can introduce additional gear stages made from engineered plastics to help minimize sound.

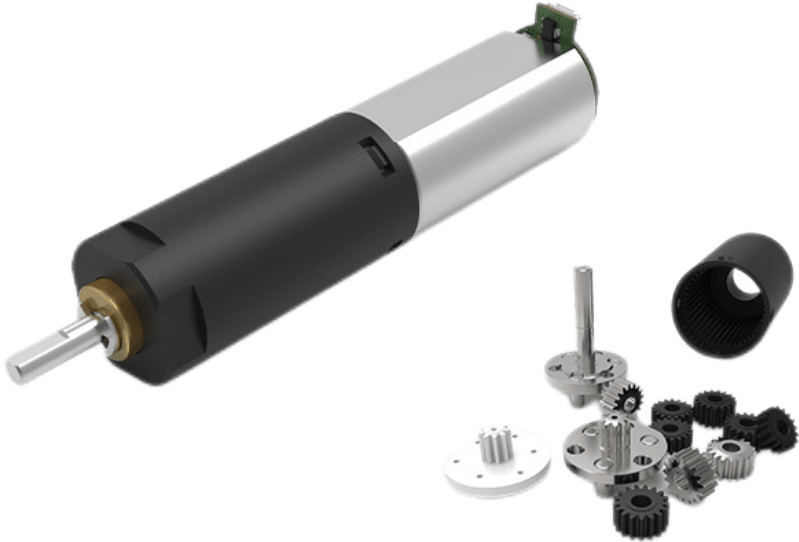

Planetary Gear Motor

Our typical strategy is to opt for spur gearboxes whenever possible to keep costs down. However, there are situations where we must focus on performance or compactness, in which case, a planetary gearbox becomes the better choice.

For geared motors with diameters under 10mm, metal gears become prohibitively expensive. As a result, we often use gears made from injection-molded engineering plastics like POM or LCP. In these cases, a planetary gearbox arrangement is preferred since it offers more mesh points per gear, which helps reduce the load on each gear tooth.

The same principle applies to larger gearboxes that handle higher loads. Although these larger systems utilize steel gears, the planetary gearbox design helps to distribute the load more evenly across the gears, allowing the system to bear heavier loads while increasing its overall durability.

While planetary designs are more intricate and costlier than spur gearboxes, their specifications still make them a cost-effective solution for many applications.

Iron-cored, Without Core, And Brushless Designs

We can pair any of our gearbox configurations with various motor technologies. There are three common motor types we typically use.

Iron-cored brushed motors are the most cost-effective option and can be easily powered with a simple DC voltage. When equipped with the right components, they can be engineered to meet high durability standards, though their design and construction limit their performance. These motors are suitable for applications with frame diameters larger than 8mm.

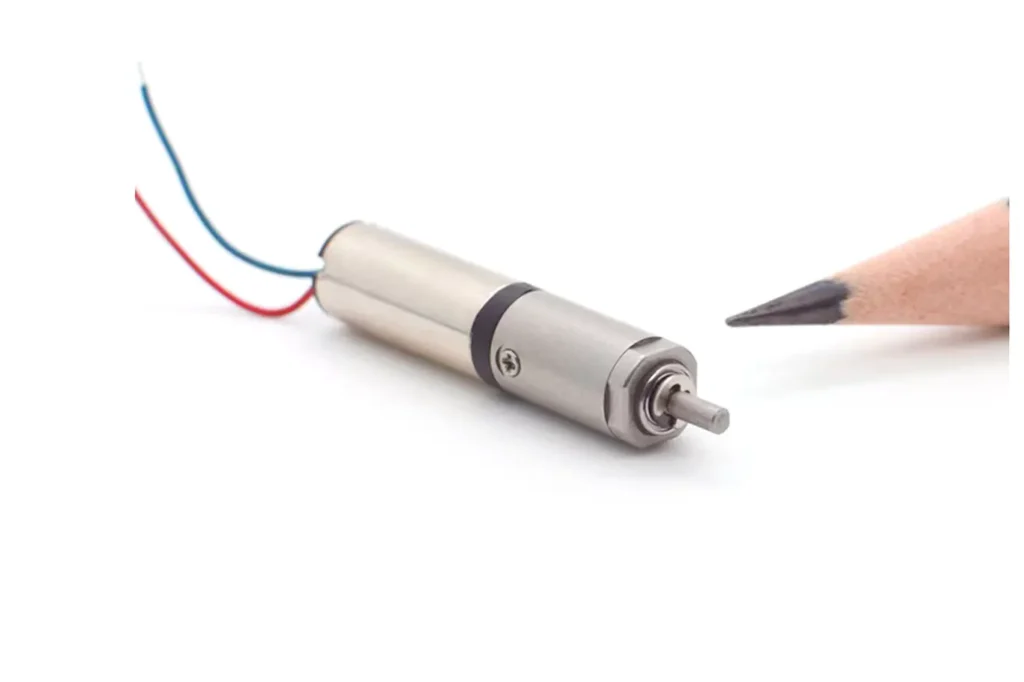

Coreless brushed motors, also powered by a DC voltage, offer improved performance in larger sizes and are the only type available for motors with frame diameters smaller than 8mm. While the manufacturing process for these motors is more expensive than iron-core alternatives, they are the most viable option at smaller scales.

Brushless motors are more complex to operate, requiring a controller and driver circuit to generate the three-phase drive signals. However, due to the absence of brushes—one of the most wear-prone components—they are highly durable. These motors are typically available in frame sizes larger than 12mm and can be optimized for either speed or torque, depending on the specific needs of the application.

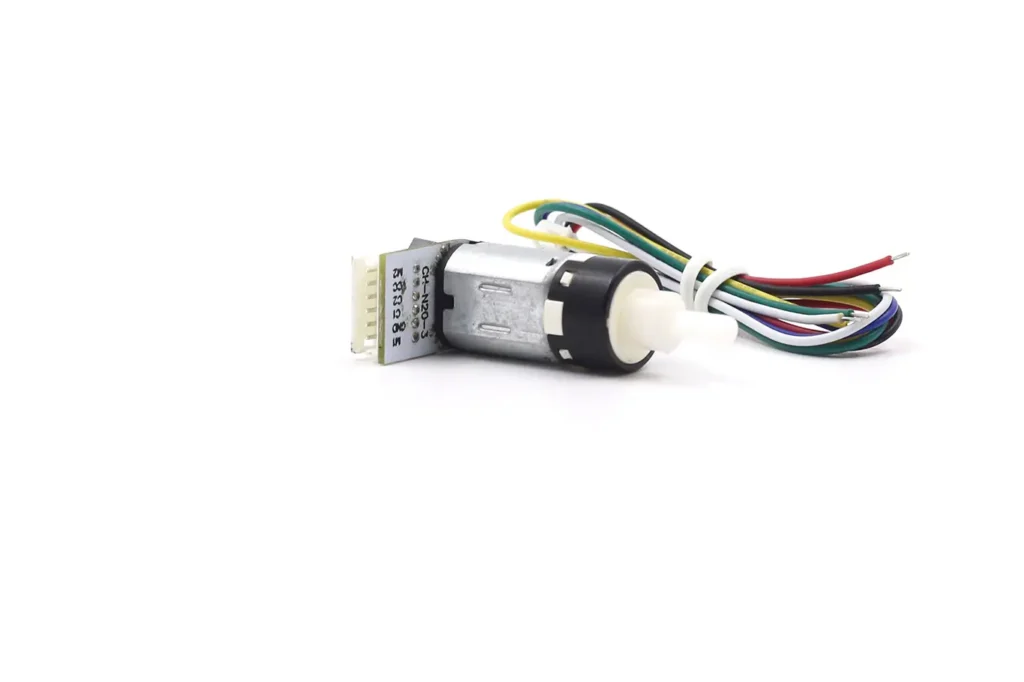

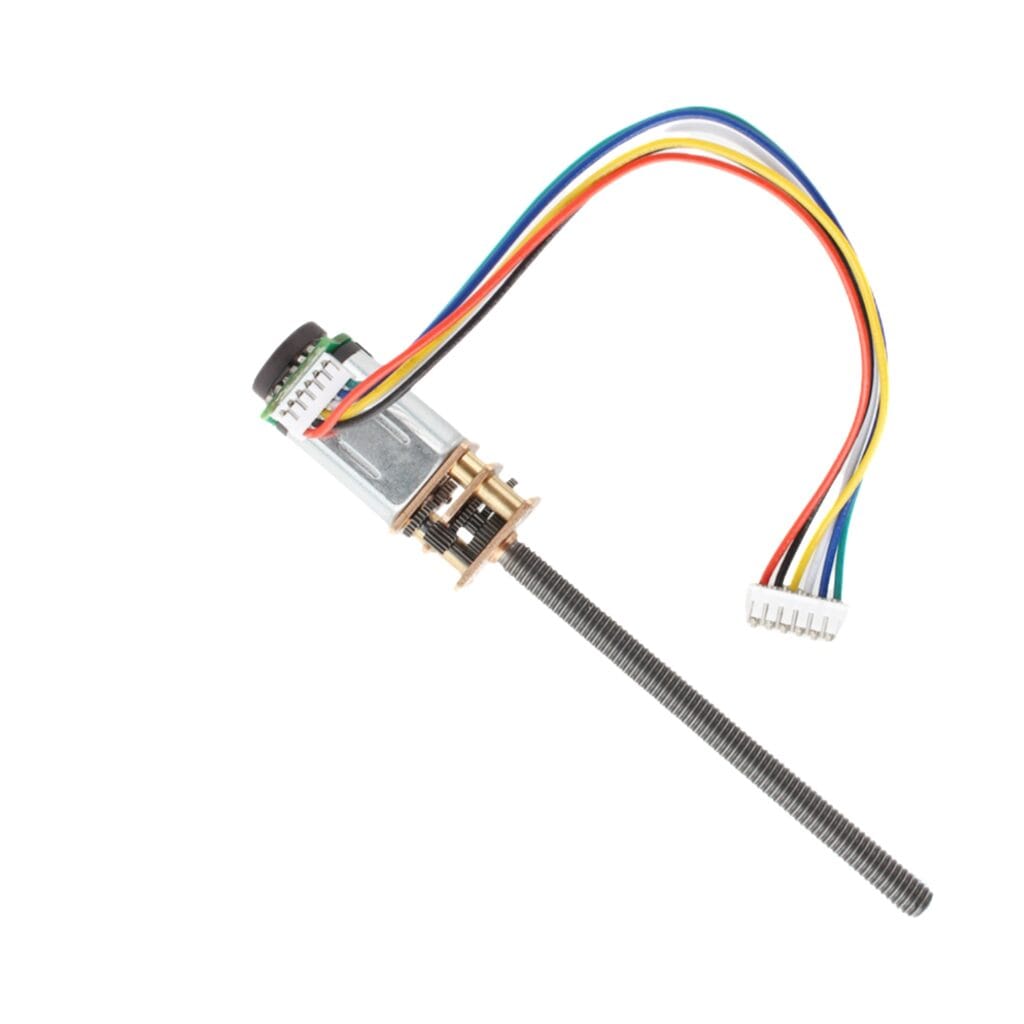

Encoders And Integrated Motion Controllers

Gear motors are incorporated into products and systems to generate motion. In some cases, simple rotation is sufficient for the design’s needs. However, in other situations, the motion may need to be more intricate, and various mechanisms can be added to the gearbox’s output shaft to transform it.

Typically, higher voltage results in faster motor rotation. As the torque load on the motor increases, so does the current it draws. For some applications, a basic on/off motion is all that’s required, such as a gear motor gradually and securely turning the blades of an ice crusher.

However, many applications demand far more precise control. This could involve maintaining a specific speed, such as when a gear motor powers an electric screwdriver. A more common scenario involves controlling the number of rotations, such as when a motor mechanism is used to produce linear motion. The number of rotations can then be used to determine how far a linear slide has moved.

For these types of applications, we add an encoder (a sophisticated counter) to the motor and, when needed, an integrated motion controller. This setup can accept commands from the main system, such as moving a syringe plunger back and forth by a set distance, like 10mm.

Common Gear Motor Designs

Regardless of the chosen gearmotor technology, several standard form factors and design considerations are widely used across different industries. Here are a few examples that can help define your ideal solution.

Exposed Frame

Approximately one-third of our designs feature an exposed structure, mainly when the gearbox frame is square or rectangular in shape.

Sealed Frame

Some gearbox designs are round, which allows for easier coverage of the gears. The primary advantage of this design is that it helps keep debris out.

Fold-Back

If space is limited in length, consider using a fold-back gearbox. Alternatively, a non-concentric offset gearbox shaft could be an option.

Shaft Customizations

Certain applications require specialized shafts. Options such as extended or shortened shafts, d-cuts, keyway cuts, location holes, and threaded shafts can all be accommodated.

Clutches and Braking Mechanisms

Clutches allow the gearbox to be separated from the application, while mechanical brakes can secure the gearbox shaft in a stationary “park” position.

Advanced Motion Control Systems

While precise movement is often required, motion controllers can also play a crucial role in prolonging the lifespan of gear motors by optimizing their operation.

Applications Of DC Gear Motors

Our DC gearmotors are widely applied across various industries and applications. Discover more about the common uses and examples we’ve worked on.

Motors used in instruments, measuring, and testing equipment must be reliable, precise, and consistent, demanding both accuracy and power.

Precision DC gearmotors are ideal for applications like small fluid pumps, rotating trays in sterilizers, and various automated laboratory tasks.

Our products offer variable speed and torque control necessary for healthcare environments, along with top-tier features such as reliability, durability, and compactness.

Motors that control movement are integral to many consumer products, enhancing convenience and comfort in daily life.

As smarter designs become the standard for consumer devices, selecting a trusted design and manufacturing partner is essential.

Gear motors play a crucial role in robotics, where they are commonly used to power servo systems, joints, and arm movements. Given the need for flexibility and precision in robots, a reduction motor is employed to enable precise motion control and positional adjustments, ensuring more accurate, stable, and dependable operation.

Gear motors are extensively utilized in logistics and transportation systems across various equipment. For instance, in automated warehouses and sorting systems, reduction motors are essential for powering conveyor belts, lifts, and other machinery. Additionally, in logistics equipment like electric forklifts and trucks, deceleration motors provide the necessary torque and precise speed control.

Key Performance Metrics Of A Gear Motor

Gear Ratio

The gear ratio, or reduction ratio, represents the relationship between the input and output gear speeds in a gearbox. A ratio greater than one indicates speed reduction, while a ratio less than one signifies speed increase. This ratio depends on the number of teeth on each gear. For example, if the output gear has 20 teeth and the input gear has 10 teeth, the ratio is 2:1. In compound systems, the total ratio is the product of each individual gear ratio.

Torque

Torque refers to the rotational force the motor generates to move a load, measured in units like foot-pounds (ft-lb) or newton meters (N-m). Starting torque is the force generated at motor startup, while continuous torque is the force at steady operating conditions. The output torque in a gearmotor is influenced by the gear ratio. A higher gear ratio provides more torque but lowers the shaft speed.

Speed (RPM)

Speed (RPM) is the rotational speed of the motor’s shaft, expressed in revolutions per minute (rpm). In gearmotors, shaft speed is inversely proportional to the gear ratio. A higher gear ratio reduces speed, while a lower ratio increases it.

Gearbox Efficiency

Gearbox efficiency refers to the percentage of power or torque transmitted through the gearbox. This metric is typically included in gearmotor specifications and reflects the gearbox’s overall performance, accounting for losses due to friction and slippage.

Backlash

Backlash is the free rotation of the output shaft without movement from the input shaft, or the gap between adjacent gear teeth. In applications without load reversals, backlash is less important. However, in precision applications like robotics or CNC machines, minimizing backlash is critical for accuracy and positioning.

Four Steps To Selecting A Gear Motor

Step 1:Understand Your Application Requirements

The first step is to ensure you fully understand your application needs. Consider the following factors:

Environment: Temperature range, necessary IP ratings, and any specific environmental needs.

General Needs: Mounting type, size, orientation, lubrication type, and envelope size.

Input Power: Voltage, frequency, maximum current, and control type.

Gearmotor Specs: Weight, size, noise level, and maintenance requirements.

Performance Needs: Required torque, speed, horsepower, and starting/running torque.

Overhung Load: The force exerted at right angles to the shaft beyond the outer bearing. Excessive overhung load can overload shafts and bearings, causing wear. To minimize the effect on gearmotor lifespan, place the drive component close to the reducer.

Step 2: Select the Right Gearmotor

Once you’ve reviewed your application’s requirements, compare gearmotor specifications to find the best match for your needs.

Step 3: Match Speed and Torque Requirements

Align the output speed and torque with your application’s needs. Use the manufacturer’s performance curve to find a suitable motor. A key advantage of gearmotors is that both the motor and gears are already optimized for compatibility and performance.

Step 4: Test the Gearmotor

Manufacturer specifications are based on controlled tests, but real-world conditions may vary. Test the gearmotor under actual operating conditions to ensure it functions properly. Watch for high temperatures, unusual noises, or signs of stress. If issues arise, contact the manufacturer and consult with an applications engineer.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

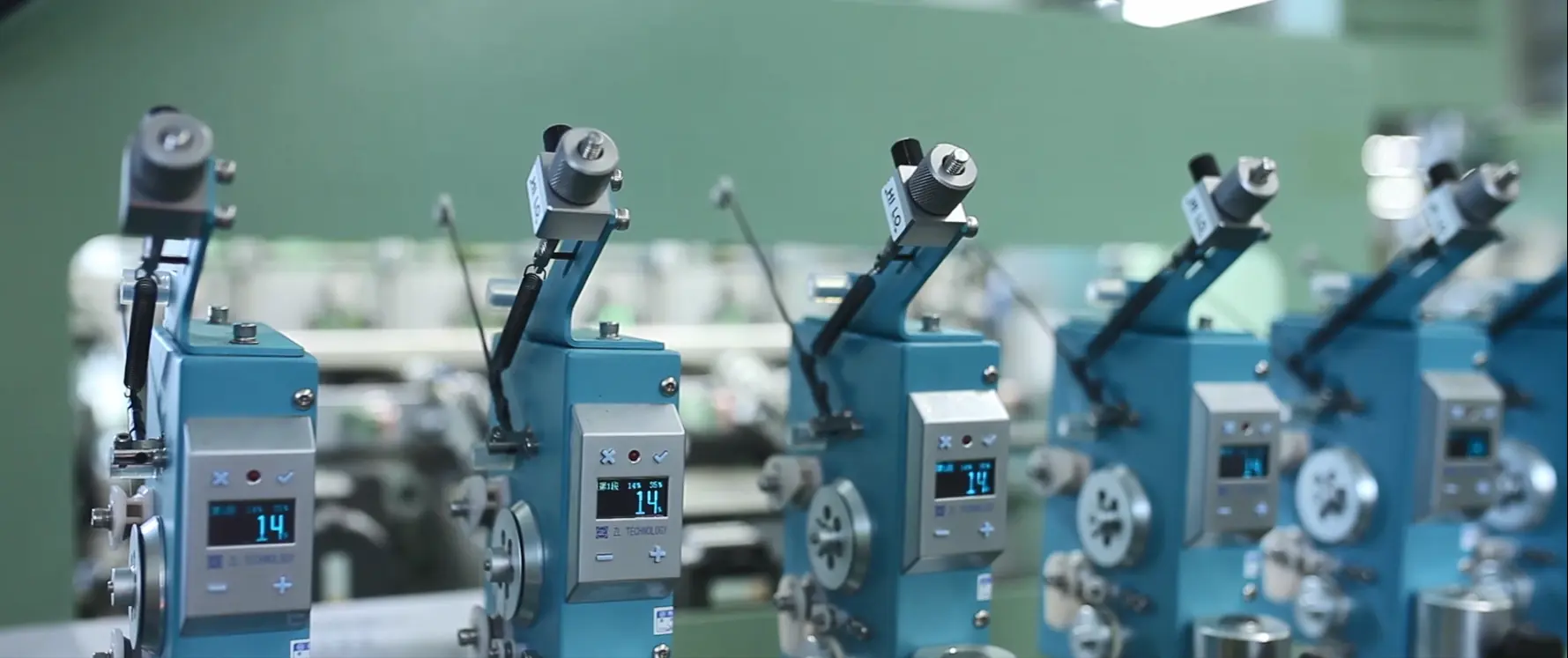

Founded in 2009, TSL Motors has been at the forefront of micro DC motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors,ERM vibration motor, coreless DC motors, Stepper DC Motors,LRA vibration motors, BLDC motors,Brushed DC Motors,Planetary Gear Motors,Spur Gear Motors ,Worm Gear Motor,etc. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

Why Are Gear Motors Beneficial?

Space Efficiency

Their compact design allows for easy integration into systems with limited space, making them an excellent choice for applications where space is a constraint.

High Torque Output

Small gear DC motors are designed to deliver high torque, making them ideal for applications requiring more power and efficiency.

Precision Control

With a geared mechanism, these motors offer fine control over speed and direction, ensuring accurate positioning and smooth operation in tasks that demand precision.

Overload Protection

The gear system naturally provides overload protection, reducing the risk of motor and component damage during high-load conditions, ensuring the longevity and reliability of the motor.

FAQ About Gear Motors

How to Select a DC Gear Motor?

1. Identify the Application

The first step in choosing a DC gear motor is to clearly define the specific application and its requirements.

2. Determine Output Speed and Torque

Next, specify the desired output speed and torque, as well as the necessary rated voltage for the motor to function effectively.

3. Consider Motor Size and Shaft Type

You’ll also need to measure the motor’s diameter and length, and choose the appropriate output shaft type (e.g., D-type, round, double flat, knurled, etc.) depending on the application.

4. Select the Best Fit

Once the essential details are outlined, you can select the most suitable motor type for your needs or reach out for assistance in finding the right solution. The key is to choose a gear motor that meets your power requirements and operates efficiently under the expected load conditions.

What types of DC gear motors do you offer?

TSL-Motor provides a comprehensive selection of precision gear motors, including models with spur, planetary, and epicyclic gearboxes. We offer customizable options for diameters, voltages, and gear ratios. Our range includes micro gear motors like the GM12-N10VA, N20VA, and N30VA series, as well as stepper gear motors to meet various application needs.

How can I order a custom miniature DC gear motor?

Customizing a miniature DC gear motor is straightforward. Simply complete the provided form with your specifications, such as voltage, speed, and torque, or send us an email detailing your requirements. Our sales engineers will get back to you within 8 hours. After confirming the performance parameters, you can expect to receive your custom gear motor samples within 7-10 days.

How does a mini DC gear motor operate?

A mini DC gear motor is a compact electric motor equipped with a gear system designed to produce high torque at lower speeds. It is powered by a direct current (DC) source, and its speed and torque are influenced by the voltage, frequency, and current provided by the power supply. The motor’s internal gear system typically includes either a planetary or spur gear arrangement, which converts the motor’s high speed into the desired output speed for the connected equipment. This gear setup also helps reduce the motor’s speed while increasing its torque, making it ideal for driving applications that require both power and control.

Are gear motors AC or DC?

Gear motors are available in both AC and DC versions, depending on the type of motor they are paired with. While some gear motors operate on alternating current (AC), all of our gear motors are designed to work with direct current (DC) power.

What are the different types of gear motors?

There are primarily two types of gear motors: right-angle motors and inline motors.

Right-angle motors utilize gears like worm, bevel, or hypoid gears to achieve a 90-degree output shaft.

Inline motors, on the other hand, typically incorporate spur gears or planetary gear systems to provide direct output.

Worm, spur, and planetary gears are frequently used in the design of these gear motors, offering different benefits depending on the application.

Are you a gear motor manufacturer or a distributor?

TSL Motors is a specialized motor manufacturer with over a decade of experience in the industry. We serve a diverse customer base from Europe, North America, and Southeast Asia. Our commitment to quality includes 100% product inspection, and we pride ourselves on achieving a 98% customer satisfaction rate.

What is your minimum order quantity (MOQ)?

There are no minimum order quantity (MOQ) requirements from our side. However, please note that customized components must comply with our material supplier’s established MOQ specifications. For detailed requirements and pricing specifics, kindly refer to the attached quotation document.

What is the lead time for samples and orders?

For sample orders, the lead time is typically 7-10 days. For larger bulk orders, the lead time varies based on the order quantity. For example, orders of 10,000 pieces generally take 20-25 days to process.

How do we handle shipments?

For samples or small orders, we typically use door-to-door services like DHL, FedEx, or UPS, or you can provide your own international shipping account to handle the collection. For larger bulk orders, we can arrange sea or air freight depending on your preference. As for who covers the freight costs, it depends on the Incoterms agreed upon between us.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!