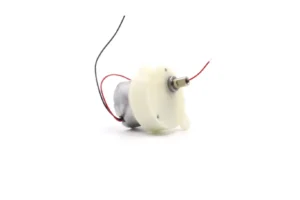

Plastic Gearbox Motor

A plastic gear motor uses plastic gears instead of metal ones. Plastic planetary gear motors are typically smaller and lighter than metal gear motors, making them suitable for various applications. One benefit is that plastic gear motors are often more affordable than their metal counterparts. They can also be designed for better durability and wear resistance. Additionally, plastic gearbox motors tend to operate more quietly than metal gear motors.

Plastic gear motors provide a budget-friendly, lightweight alternative to metal gear motors. They operate quietly with minimal vibration, making them perfect for noise-sensitive applications. These motors are commonly used in toys, home appliances, automotive systems, and medical devices. With their low cost, durability, and lightweight design, plastic gear motors are ideal for applications requiring precise motor control and an economical solution for power transmission and speed reduction.

Explore All of Our Plastic Gear Motor

10mm DC Gear Motor Model TSL-10GP-M30

10mm Planetary Gear Motor Model TSL-10GP-M10

12mm DC Planetary Gear Motor Model TSL-12GP-N20VA-EN

12mm Planetary Gear Motor Model TSL-12GP-N20VA

12mm Planetary Gear Motor Model TSL-12GP-N20VA-ME

16mm Planetary DC Gearmotor 5V DC, 130g.cm – 8,554g.cm TSL-PGM16

32mm Spur Gear Motor Model TSL-JS30

38mm Small DC Motor With Gearbox − 39mm Type Model TSL-JS6839-520

Common Gear Motor Designs

Regardless of the chosen gearmotor technology, several standard form factors and design considerations are widely used across different industries. Here are a few examples that can help define your ideal solution.

Exposed Frame

Approximately one-third of our designs feature an exposed structure, mainly when the gearbox frame is square or rectangular in shape.

Sealed Frame

Some gearbox designs are round, which allows for easier coverage of the gears. The primary advantage of this design is that it helps keep debris out.

Fold-Back

If space is limited in length, consider using a fold-back gearbox. Alternatively, a non-concentric offset gearbox shaft could be an option.

Shaft Customizations

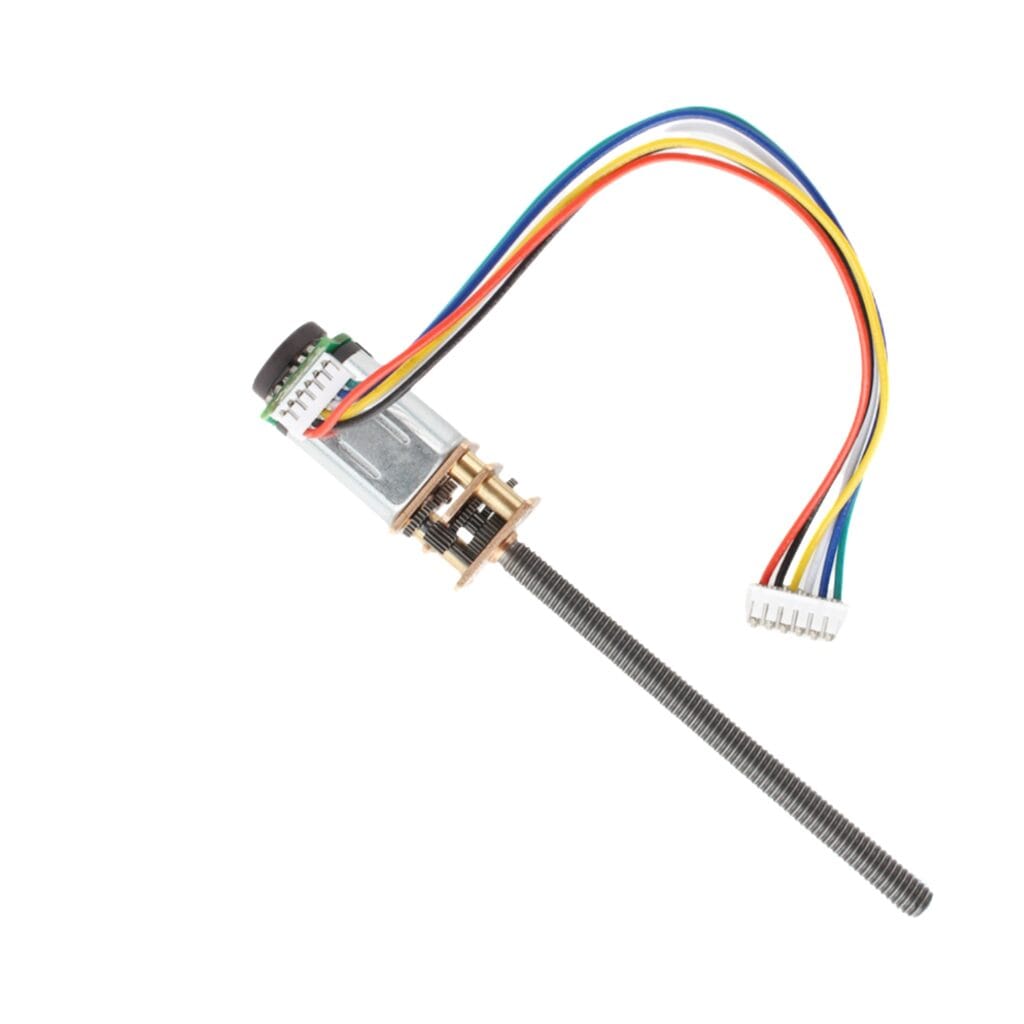

Certain applications require specialized shafts. Options such as extended or shortened shafts, d-cuts, keyway cuts, location holes, and threaded shafts can all be accommodated.

Clutches and Braking Mechanisms

Clutches allow the gearbox to be separated from the application, while mechanical brakes can secure the gearbox shaft in a stationary “park” position.

Advanced Motion Control Systems

While precise movement is often required, motion controllers can also play a crucial role in prolonging the lifespan of gear motors by optimizing their operation.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro DC motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors,ERM vibration motor, coreless DC motors, Stepper DC Motors,LRA vibration motors, BLDC motors,Brushed DC Motors,Planetary Gear Motors,Spur Gear Motors ,Worm Gear Motor,etc. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

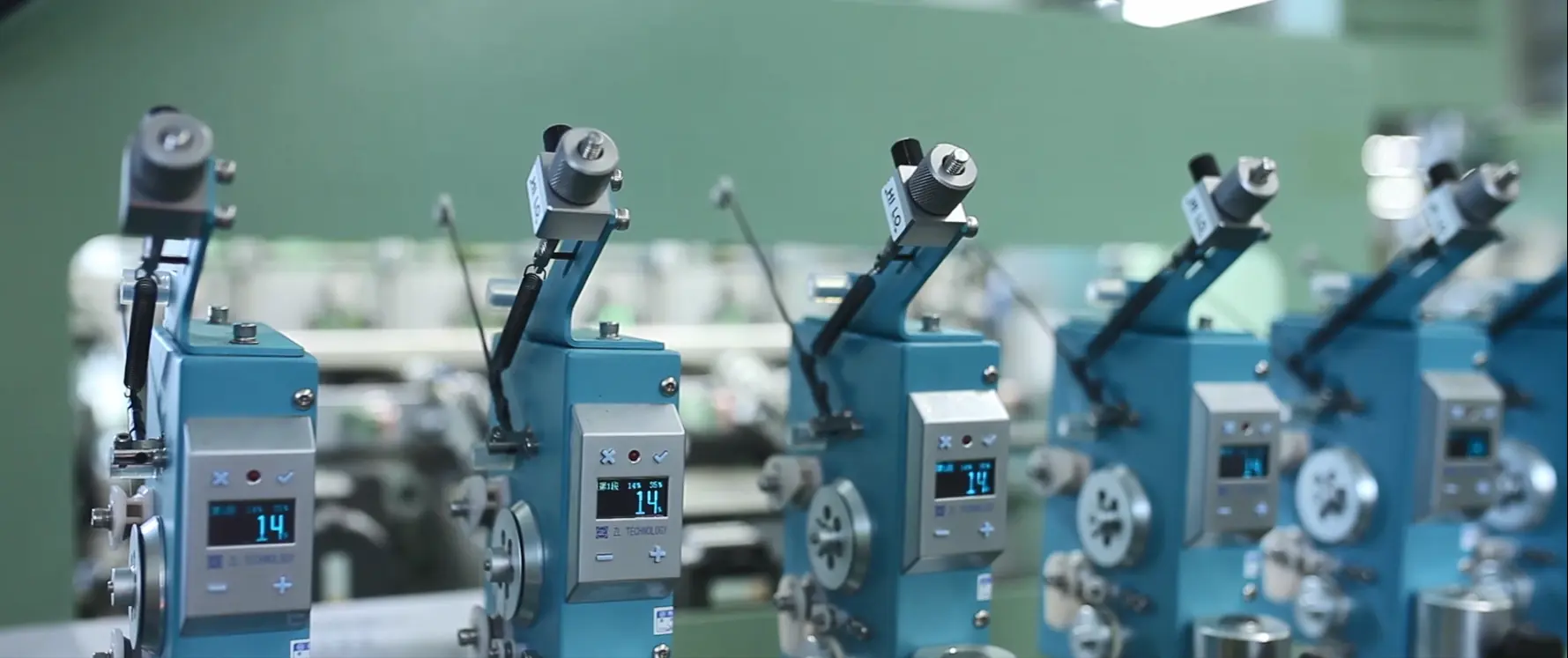

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

Applications Of Plastic Gear Motors

Plastic gear motors are used in various applications where a lightweight, cost-effective solution is needed for power transmission and speed reduction. Common applications include:

Toys and Hobbies

Plastic gear motors are widely used in toys and hobby projects, such as model airplanes, cars, and boats. They provide motor control while minimizing noise and vibration.

Home Appliances

Plastic gear motors are found in various home appliances, such as kitchen gadgets, power tools, and vacuum cleaners. They help with motor control and minimize noise and vibration.

Automotive Applications

Plastic gear motors are utilized in automotive systems like power windows, door locks, and seat adjusters. They provide motor control while reducing weight and noise.

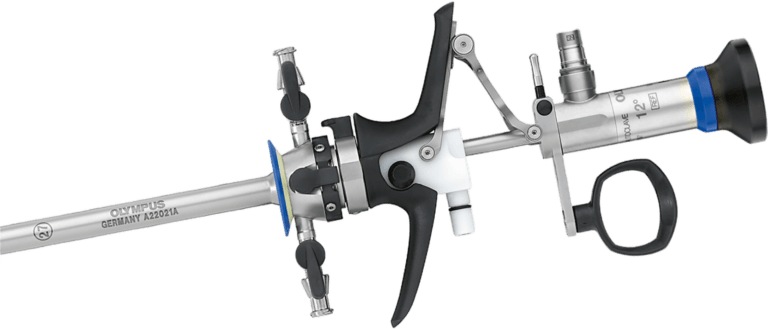

Medical Equipment

Plastic gear motors are used in medical devices to provide precise motor control and low noise output. They are commonly found in prosthetics, surgical instruments, and diagnostic equipment.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!