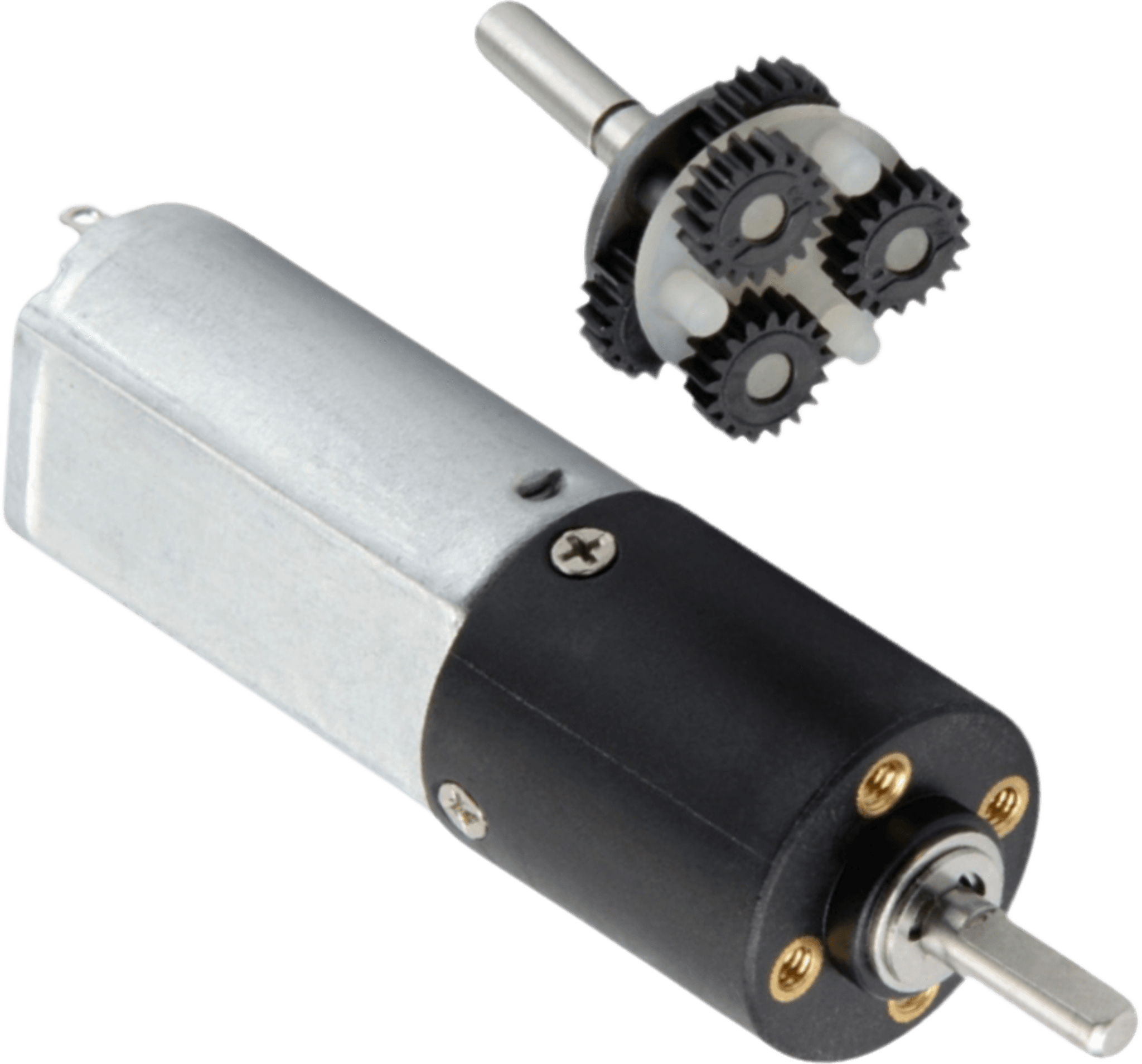

To calculate the RPM of a gearbox, follow these two steps:

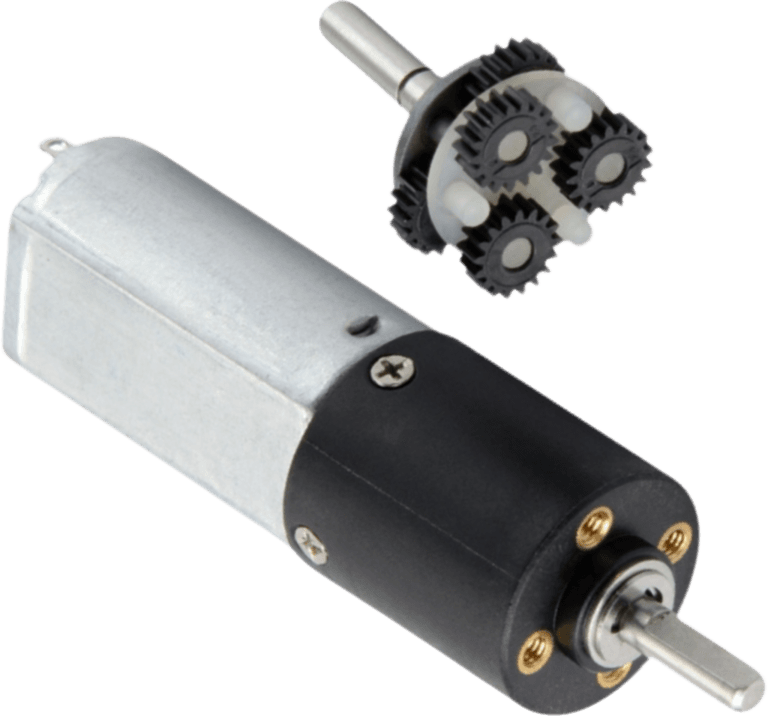

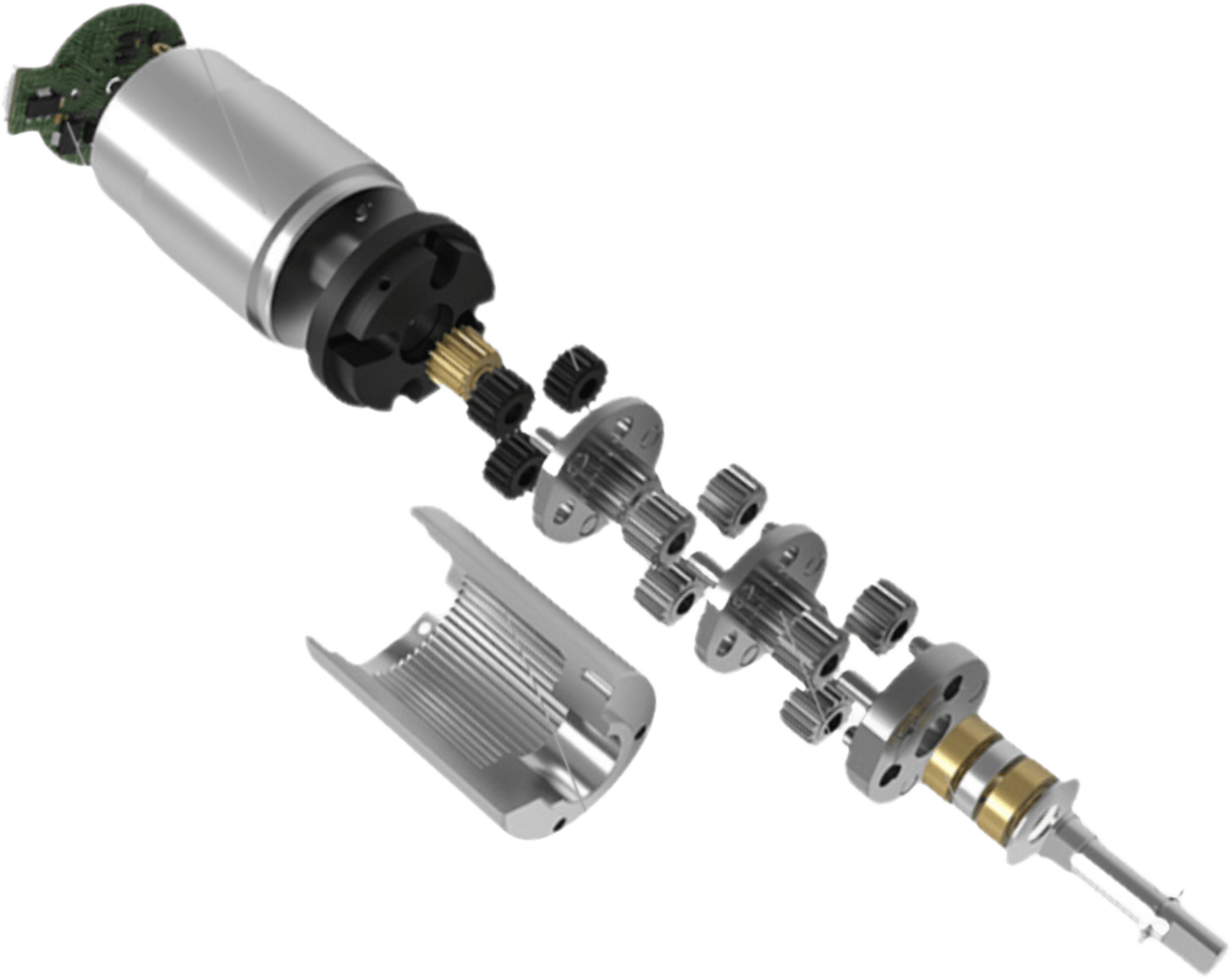

Determine the number of teeth on both the input and output gears. Divide the number of teeth on the output gear by the number of teeth on the input gear to find the gear ratio.

Obtain the input speed, typically measured in revolutions per minute (RPM). Multiply the input speed by the gear ratio to find the output speed in RPM.