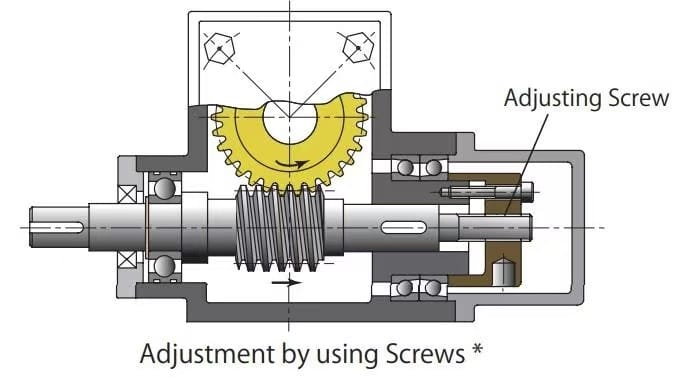

Worm gear motors use gradual tooth engagement, ensuring smoother motion transfer. This method provides precise control over tooth clearance, reducing backlash and resulting in quieter operation compared to other gear systems.

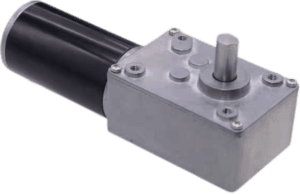

Worm Gear Motor

TSL Motors is a leading manufacturer specializing in custom worm gear motors, offering dependable solutions tailored to meet the specific needs of various applications. With our in-depth knowledge of DC worm gear motors and gear technology, we assist OEMs in developing, identifying, and implementing innovative geared motor solutions with greater speed. These compact, quiet, self-locking motors, also capable of static damping, provide exceptional torque density.

The gear ratio of a single worm gear motor is equivalent to multiple stages of traditional geared motors. Additionally, the motor’s shaft can be positioned at a 90-degree angle, allowing the compact worm gearbox to transmit motion efficiently in confined spaces. This rectangular output shaft is especially advantageous in applications where space is limited. Our 370 12-volt DC worm gear motors offer precise control, with accuracy down to 3 RPM.

Explore Our Worm Gear Motors

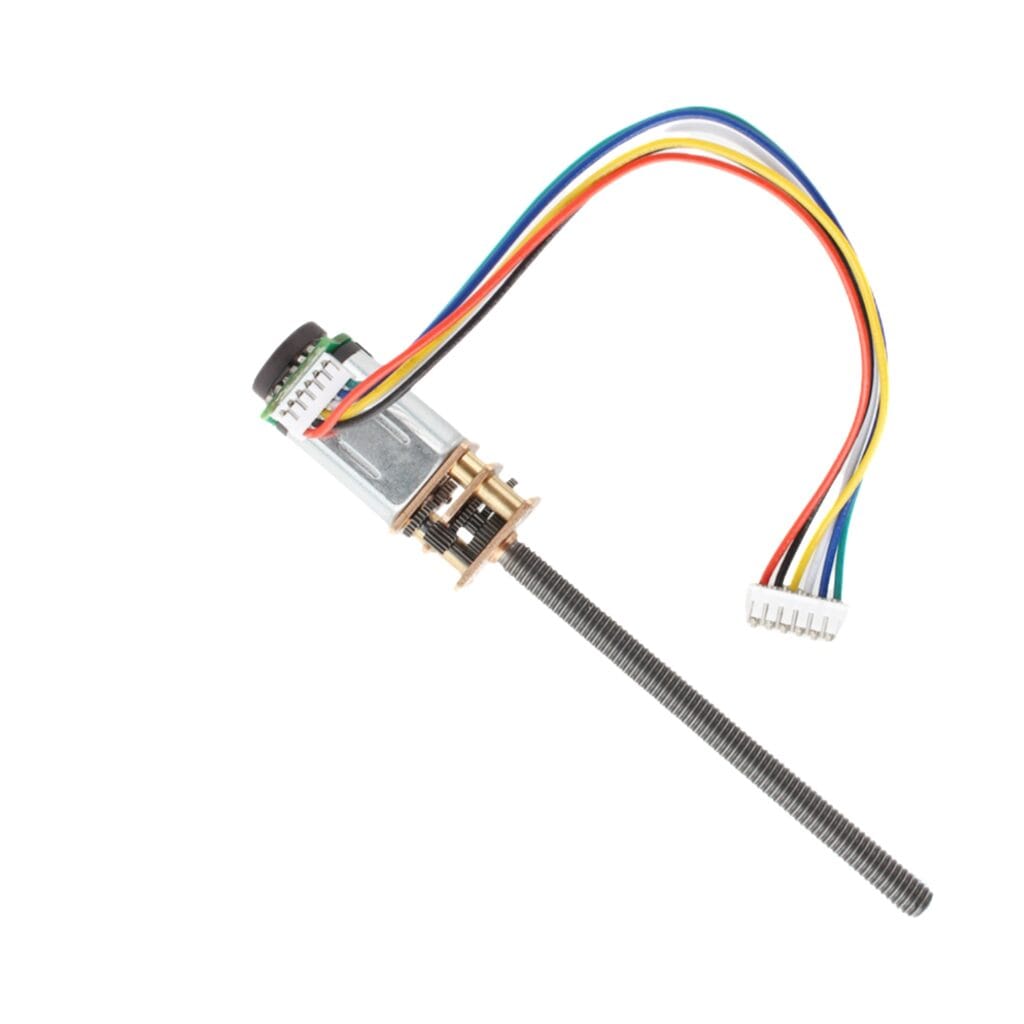

10mm Stepper Motor With Worm Gearbox TSL-GW12T-10BY

12mm Worm Gear Motor Model TSL-1218GW-N20-D

12mm Worm Gear Motor Model TSL-1218GW-N20VA-S

12mm Worm Gear Motor Model TSL-GW12-N20VA

12mm Worm Gear Motor Model TSL-GW1218-050-EN

12mm Worm Gear Motor Model TSL-GW1218T-N20VA

12mm Worm Gear Motor Model TSL-WG1218S-N20-EN

15mm Stepper Motor With Worm Gearbox TSL-GW12T-15SM

16mm Worm Gear Motor Model TSL-1218GM-050-D

16mm Worm Gear Motor Model TSL-1218GM-050-S

20mm Worm Gear Motor Model TSL-GF5560-180

24mm Brushless Worm Gear Motor Model TSL-GW4632-BL2418

The Technology Of Worm Gear Motor

A worm gear motor is a unique and time-tested mechanism that combines a worm gear box and a direct current (DC) motor. The worm gear box consists of a worm and a helical toothed gear, with the worm being the driving component and the wheel acting as the driven part. Typically, the worm is made of steel, and the wheel is made of brass. When the motor is powered on, the electrical current activates the worm, causing it to turn. As the worm rotates, the wheel gear also turns. For every complete rotation of the worm, the wheel completes one full rotation. The wheel gear transmits the force and carries the load. The worm gear’s reduction feature allows the motor to convert high-speed DC motor output into slower rotational speed, achieving the desired speed reduction.

Why Choose A Worm Gear Motor

Worm gear motors are an ideal choice when you need a space-saving solution with self-locking or braking features, along with high gear reduction. Their compact structure makes them perfect for tight spaces, while their natural resistance to back-driving provides built-in braking without the need for additional components. These motors also offer high torque, making them suitable for demanding applications, and are designed to operate smoothly and quietly, reducing noise and vibration in sensitive environments.

High Gear Ratio

A worm gear motor operates by using a worm that is connected to the motor to drive the main gear. This design allows the motor to achieve a high reduction ratio, similar to what multiple stages of standard gears would provide. As a result, even a small rotation of the worm can produce a large rotation of the main gear, enabling it to cover a greater distance.

Limited Reverse Power

When a DC gear motor operates in reverse, it creates a reactive force that turns into reverse power. Traditional gear motors need a backstop or washer damping device to prevent reverse rotation. However, a worm gear motor has a built-in self-locking feature. If power is lost, the output shaft will not rotate backward, preventing damage.

High Load Capacity

Worm gears have a larger contact area and unique material properties, giving them superior load-bearing capacity. They can handle high peak torques, with design ratings allowing for momentary peak loads of up to 300%. In contrast, other gear types typically handle only up to 200% peak loads.

Smooth Operation

Common Gear Motor Designs

Regardless of the chosen gearmotor technology, several standard form factors and design considerations are widely used across different industries. Here are a few examples that can help define your ideal solution.

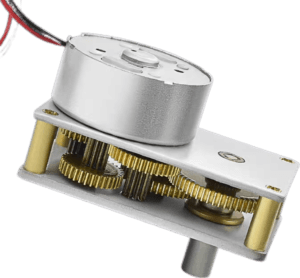

Exposed Frame

Approximately one-third of our designs feature an exposed structure, mainly when the gearbox frame is square or rectangular in shape.

Sealed Frame

Some gearbox designs are round, which allows for easier coverage of the gears. The primary advantage of this design is that it helps keep debris out.

Fold-Back

If space is limited in length, consider using a fold-back gearbox. Alternatively, a non-concentric offset gearbox shaft could be an option.

Shaft Customizations

Certain applications require specialized shafts. Options such as extended or shortened shafts, d-cuts, keyway cuts, location holes, and threaded shafts can all be accommodated.

Clutches and Braking Mechanisms

Clutches allow the gearbox to be separated from the application, while mechanical brakes can secure the gearbox shaft in a stationary “park” position.

Advanced Motion Control Systems

While precise movement is often required, motion controllers can also play a crucial role in prolonging the lifespan of gear motors by optimizing their operation.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro DC motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors,ERM vibration motor, coreless DC motors, Stepper DC Motors,LRA vibration motors, BLDC motors,Brushed DC Motors,Planetary Gear Motors,Spur Gear Motors ,Worm Gear Motor,etc. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

FAQ About Worm Gear Motors

What is a Worm Gear Motor?

A worm gear motor consists of a DC motor connected to a worm gearbox or gear reducer. The motor powers a worm gear, which meshes with a worm wheel to transmit torque and rotation. The worm gear is typically a spiral gear that interacts with either a spur or helical gear. In this setup, the worm gear is the driving component, while the wheel gear is the driven part. This type of motor is ideal for applications that require slow, precise, and powerful motion, offering quiet operation and high load-bearing capacity.

Can a 12V DC Worm Gear Motor Be Used in Automotive Applications?

Yes, 12V DC worm gear motors are frequently used in automotive systems like windshield wipers, power windows, and seat adjustments. Their efficiency and reliability make them suitable for these applications.

What is a Worm Gear Used For?

Worm gears are used in various industrial applications to reduce speed and increase torque. Their self-locking properties also provide a built-in locking mechanism. Common uses include conveyor systems, smart door locks, and robotics, where they enable high-ratio reductions between non-parallel, non-intersecting, perpendicular shafts.

What Voltage Options Are Available for Worm Gear Motors?

Worm gear motors come in various voltage options. The most common are 12V and 24V, designed to meet different power supply needs.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!