Brushed DC Motor

If you’re looking for high-quality 24V or 12V brushed DC motors from a trusted manufacturer, you’ve come to the right place. We cater to both small orders for prototype designs and provide customization options, such as shell material, end cover material, ball bearing or sleeve structures, low noise design, installation terminals, and wiring length. Explore our range of brushed DC motors for more options.

Top recommended models include RS-280, RS-365, RS-380, RS-385, RS-395, RS-540, RS-545, RS-550, and RS-775 series. These motors are used in a wide array of applications, from small toys to large industrial machines, as well as in various vehicles like cars, trucks, and airplanes.

Explore Our Brushed DC Motors

18mm Brushed DC Motor – 30mm Type Model TSL-RS-280A

24mm Micro DC Motor – 20mm Type Model TSL-RS-310

24mm Micro DC Motor – 30mm Type Model TSL-FC-280SA

24mm Micro DC Motor – 30mm Type Model TSL-RS-280

24mm Micro DC Motor – 30mm Type Model TSL-RS-370

27mm Micro DC Motor – 46mm Type Model TSL-RS-390-F

28mm Brushed DC Motor – 46mm Type Model TSL-RS-390A/395A

28mm Brushed DC Motor – 46mm Type Model TSL-RS-390H/395H

33mm Brushed DC Motor – 23mm Type Model TSL-RC-520-TB

35mm Micro DC Motor – 50mm Type Model TSL-RS-545-F

36mm Brushed DC Motor –50mm Type Model TSL-RS-545

36mm Brushed DC Motor –67mm Type Model TSL-RS-595

The Technology Of Brushed DC Motor

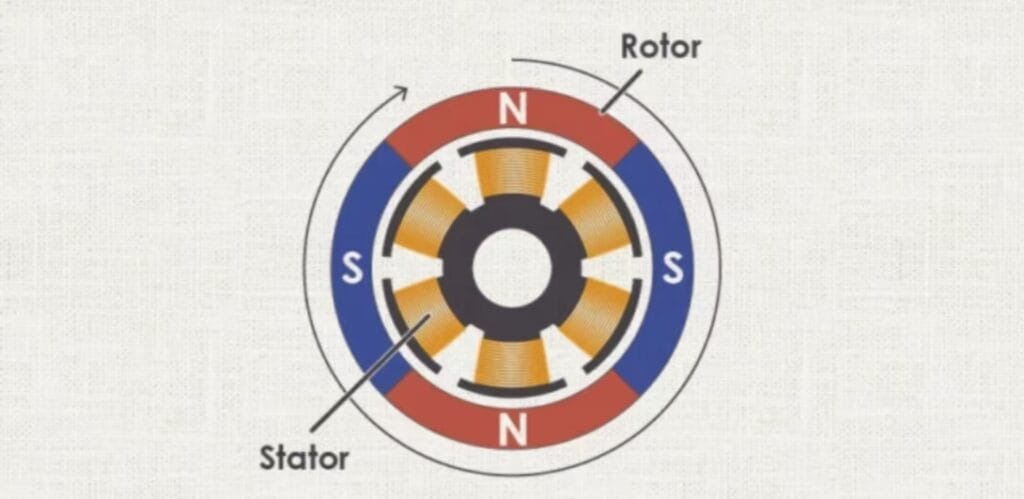

In a brushed DC motor, the coil is placed in the rotor, which spins within a magnetic field. As the rotor turns, the commutator switches the direction of the current flowing through the coil. This current reversal causes the rotor to continue spinning, powering the motor.

Brushed DC motors are categorized into two types: permanent magnet and electromagnet motors, based on the type of magnet used for the magnetic field.

Permanent magnet brushed DC motors are further split into slotted, slotless, and coreless motors, based on the design of the rotor.

The Performance of Brushed DC Motor

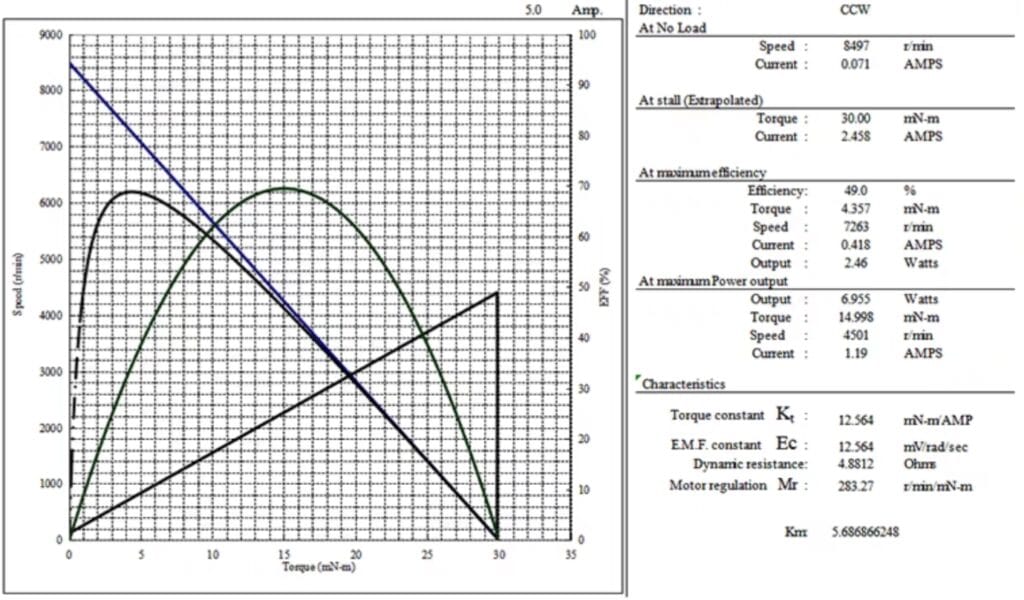

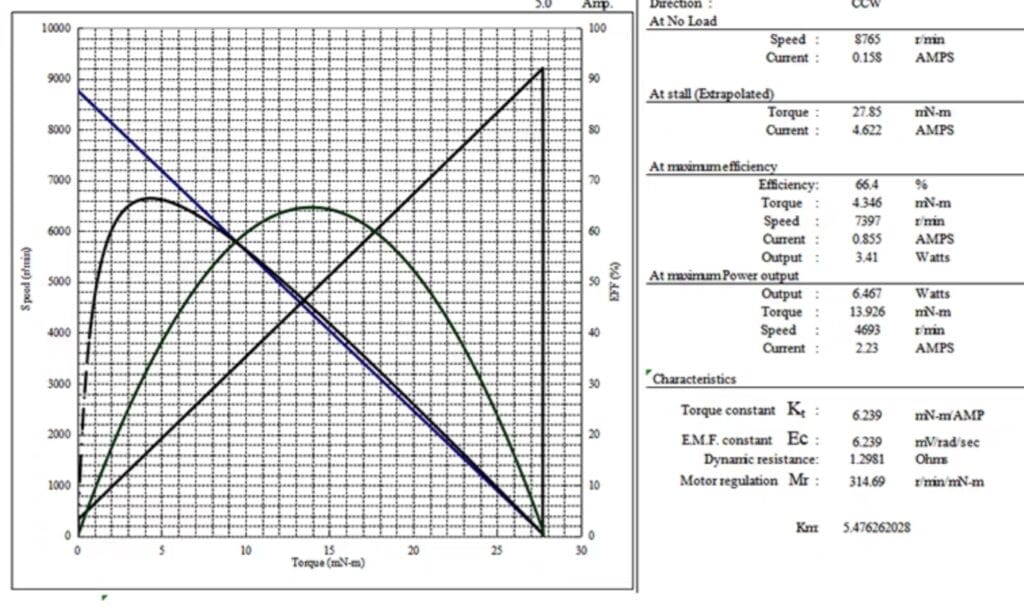

Rotation speed refers to the number of revolutions per minute (rpm) of the rotor. The speed can change depending on variations in the voltage supplied or the load applied to the motor.

Current indicates the amount of electrical charge flowing when voltage is applied between the motor’s terminals. The load applied to the motor is directly linked to the amount of current it draws.

Torque is the twisting force responsible for rotating the rotor. The value of torque is influenced by the load applied to the motor and the current drawn.

Output power is the work done by the motor, calculated as the product of speed and torque. The highest power output occurs at a specific point on the power curve, typically at Ts/2.

Efficiency represents the percentage of work done by the motor in relation to the energy supplied. It is calculated by dividing the mechanical output by the electrical input, multiplied by 100%. Maximum efficiency is typically achieved at a torque range smaller than Ts/2.

Common DC Motor Designs

No matter which DC motor technology is used, certain form factors and design features are common across many industries. These shared elements help guide the selection of the best motor solution. Below are some examples to help describe your ideal choice.

Terminals and connector pins

Connecting the motor to the application is essential. We usually use soldered pins, spring pad connectors, and integrated connectors for this purpose.

Leads and connectors

Wires and leads are commonly used to connect motors in applications. We provide various lengths, gauges, and pre-installed connectors.

Frame modifications

Securing motor frames to your application can be achieved in several ways. Custom fastening points and brackets are often utilized.

EMI filters and backpack PCBs

Operating motors generate EMI electrical noise. This can be reduced by installing filters, which can be either PCB-based or wire-based.

Shaft modifications

The motor must connect mechanically to your product. We can create custom shafts and pre-install gears, bushes, and bosses.

Motion controllers

A small PCB attached to the back of a DC motor can convert it into a precision servo at a fraction of the cost of a similar off-the-shelf unit.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro DC motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors,ERM vibration motor, coreless DC motors, Stepper DC Motors,LRA vibration motors, BLDC motors,Brushed DC Motors,Planetary Gear Motors,Spur Gear Motors ,Worm Gear Motor,etc. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

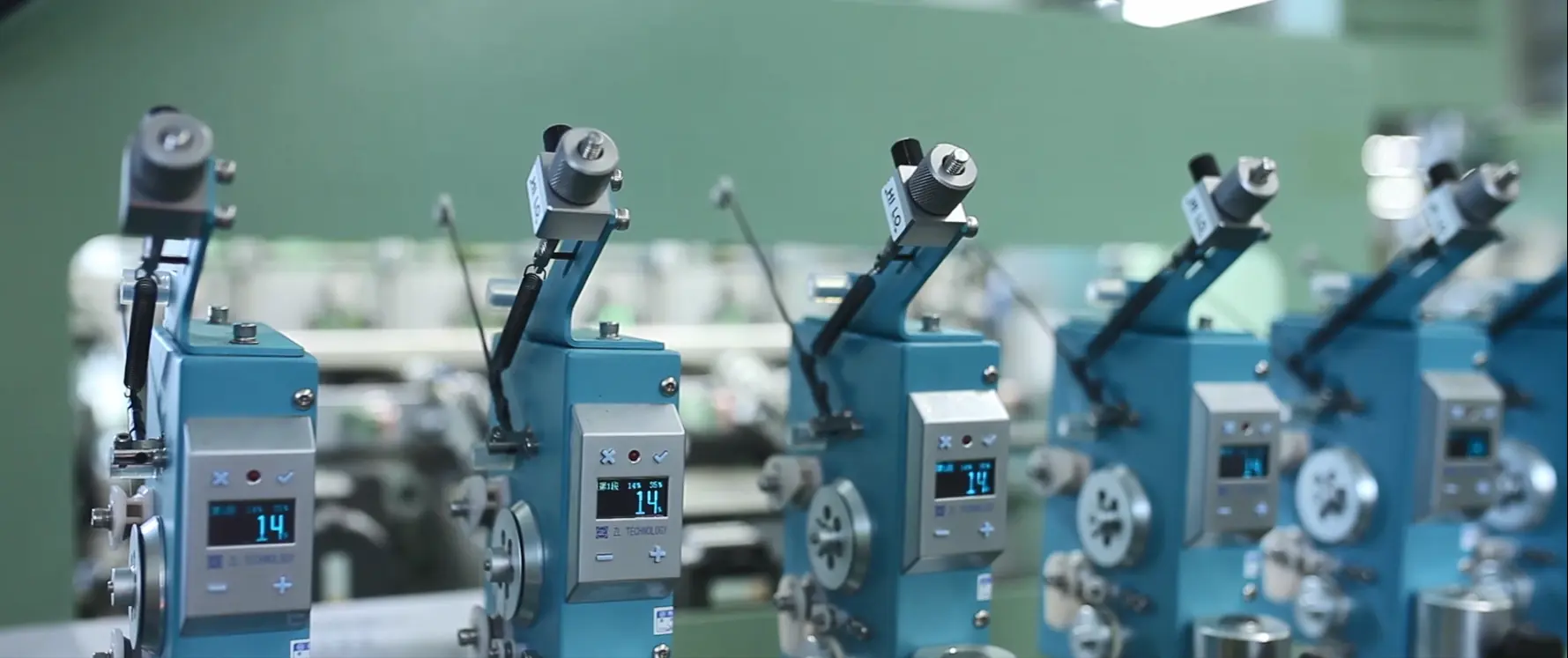

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!