Brushless DC Motor

BLDC stands for Brushless Direct Current. The demand for BLDC motors is growing rapidly across various industries. These motors are commonly used in household appliances, consumer goods, medical devices, industrial automation, and instruments.

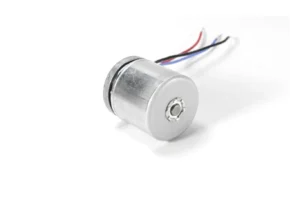

Brushless DC motors provide a solution to meet the demands for higher energy efficiency, longer lifespan, and quieter operation. As a leading manufacturer of BLDC motors,TSL Motors has developed the smallest BLDC motor, measuring just 6mm in diameter and 2mm in thickness, designed as a flat vibration motor.

We offer a range of cylindrical brushless DC motors with the latest BLDC technology, from 12V and 24V models to custom solutions. For flat vibrating brushless DC motors, visit our coin vibration motor page to find the ideal small brushless motor for your needs.

Explore Our Brushless DC Motors

14mm Outrunner Rotor BLDC Motor TSL-BLDC-1413

18mm Outrunner Rotor BLDC Motor TSL-BLDC-1811

24mm Brushless DC Motor – 18mm Type Model TSL-BLDC-2418

24mm Brushless DC Motor – 30mm Type Model TSL-BLDC-2430

28mm Brushless DC Motor – 38mm Type Model TSL-BLDC-2838

28mm Outrunner Rotor BLDC Motor TSL-BLDC-2826

29mm Outrunner Rotor BLDC Motor TSL-BLDC-2931

30mm Outrunner Rotor BLDC Motor TSL-BLDC-3025

33mm Outrunner Rotor BLDC Motor TSL-BLDC-3315-900KV

33mm Outrunner Rotor BLDC Motor TSL-BLDC-3320

35mm Outrunner Rotor BLDC Motor TSL-BLDC-3523

36mm Brushless DC Motor – 25mm Type Model TSL-BLDC-3625

The Technology Of Brushless DC Motor

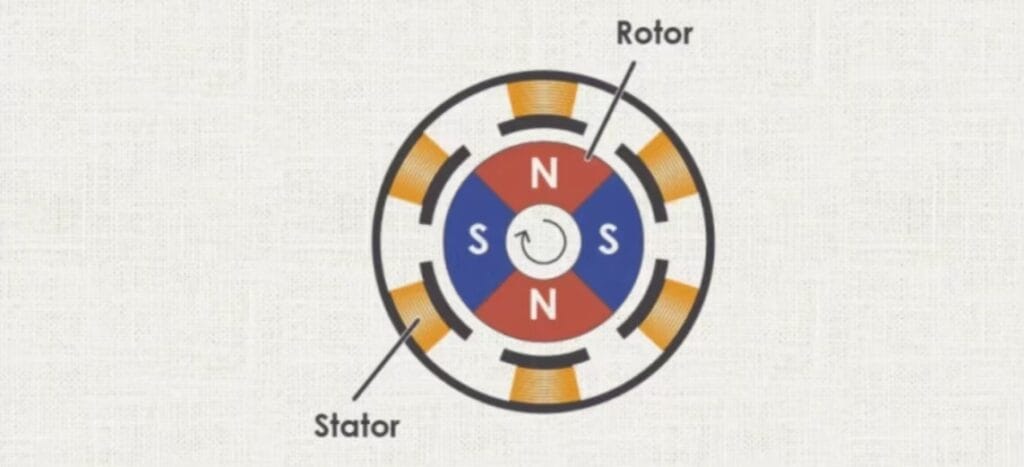

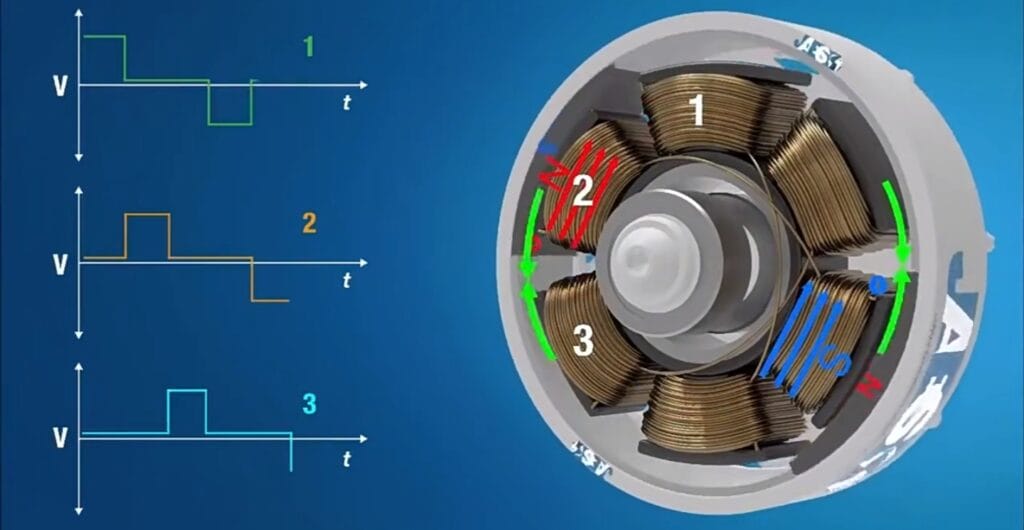

A brushless DC motor eliminates the need for a commutator and brushes by placing permanent magnets on the rotor. The rotor’s rotation is controlled by detecting its magnetic poles and adjusting the current flow through the coils accordingly.

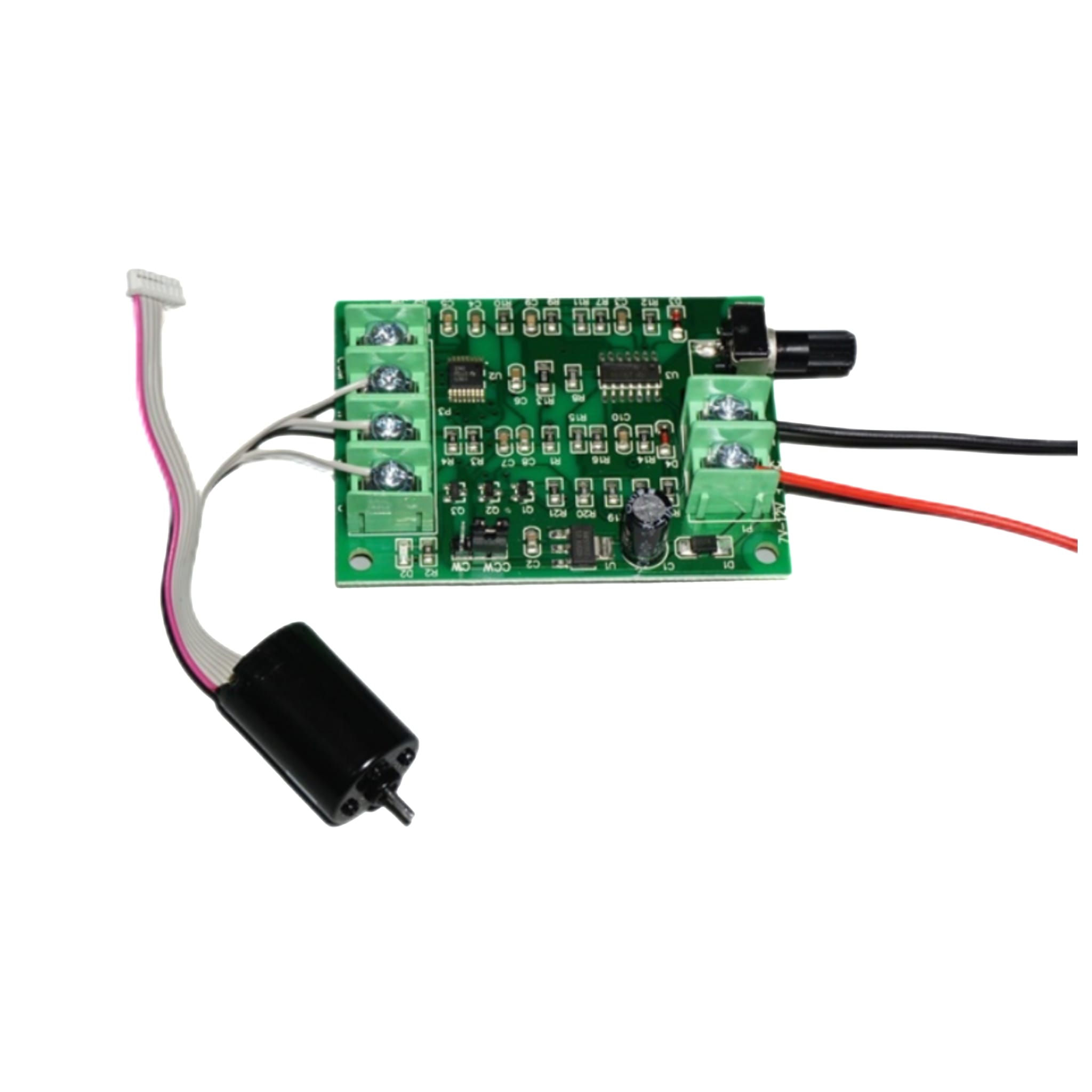

This process requires a drive circuit, as the rotor won’t rotate simply by connecting the motor to power.

Brushless DC motors come in two types: surface permanent magnet (SPM) motors, where magnets are on the rotor’s outer edge, and interior permanent magnet (IPM) motors, where magnets are embedded inside the rotor.

Without brushes or a commutator, brushless DC motors offer benefits such as reduced maintenance, longer lifespan, and quieter operation compared to brushed DC motors.

Key Points of Brushless DC Motors

Commutation Sequence: The coil winding current sequence controls the rotating magnetic field’s direction, which determines the rotor’s rotation direction.

Rotor Position Detection: Hall sensors or controllers estimate the rotor’s position, signaling when commutation should occur.

Speed Control: PWM waveforms, generated by a microcontroller, manage the motor windings’ energizing duration, adjusting the rotor speed.

Brushed Vs Brushless DC Motors:Advantages of Brushless DC Motors

Brushless DC motors offer several key benefits compared to brushed motors.

Firstly, their internal components experience little mechanical wear, making them nearly maintenance-free. In contrast, brushed motors suffer from brush wear, which leads to eventual failure. This results in a longer lifespan for brushless DC motors.

Additionally, by eliminating brushes, brushless motors produce no dust, debris, or sparks. This reduces electromagnetic interference, minimizes heat, and lowers noise levels. Brushless DC motors operate with ultra-low electrical noise, smooth operation, and low friction. On the other hand, brushed motors generate high motor noise due to intense sparking during commutation.

For applications that require minimal electrical noise, brushless DC motors are the preferred choice.

Common DC Motor Designs

No matter which DC motor technology is used, certain form factors and design features are common across many industries. These shared elements help guide the selection of the best motor solution. Below are some examples to help describe your ideal choice.

Terminals and connector pins

Connecting the motor to the application is essential. We usually use soldered pins, spring pad connectors, and integrated connectors for this purpose.

Leads and connectors

Wires and leads are commonly used to connect motors in applications. We provide various lengths, gauges, and pre-installed connectors.

Frame modifications

Securing motor frames to your application can be achieved in several ways. Custom fastening points and brackets are often utilized.

EMI filters and backpack PCBs

Operating motors generate EMI electrical noise. This can be reduced by installing filters, which can be either PCB-based or wire-based.

Shaft modifications

The motor must connect mechanically to your product. We can create custom shafts and pre-install gears, bushes, and bosses.

Motion controllers

A small PCB attached to the back of a DC motor can convert it into a precision servo at a fraction of the cost of a similar off-the-shelf unit.

Why Choose TSL?

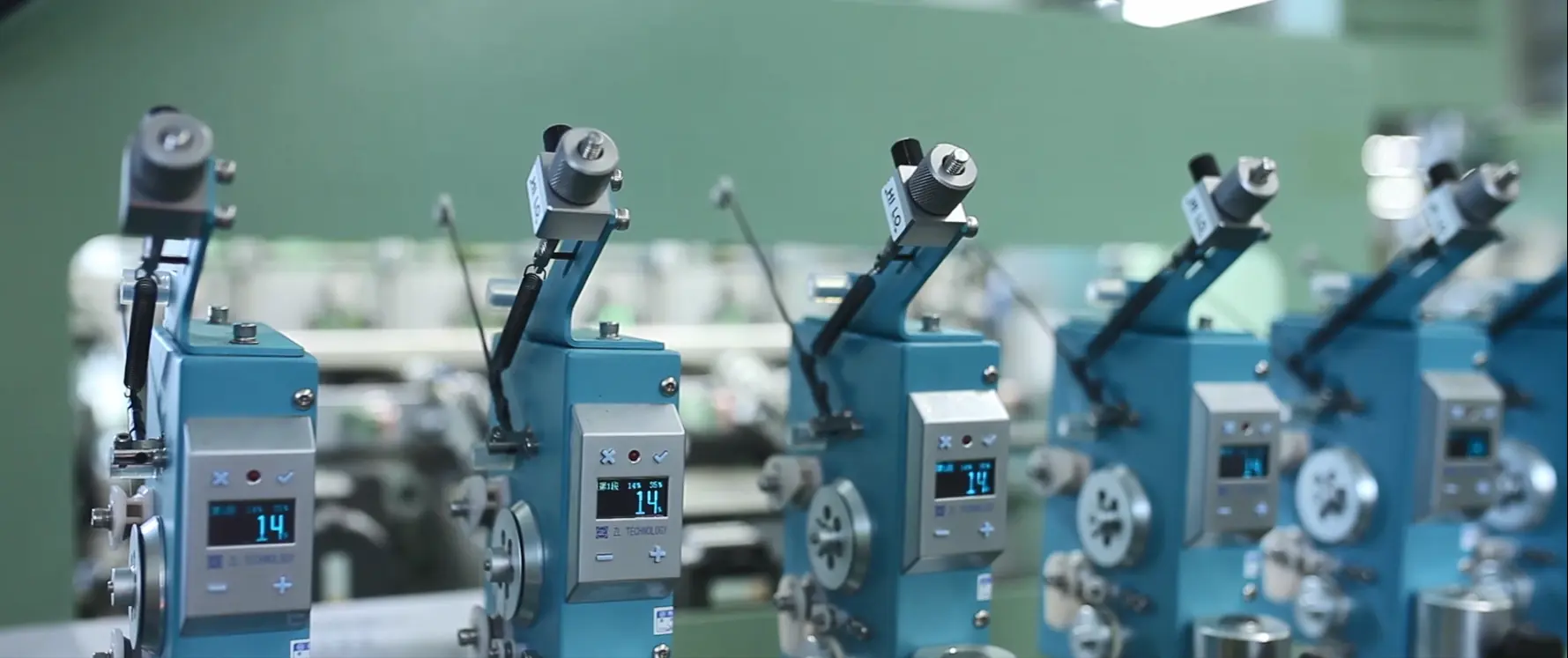

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro DC motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors,ERM vibration motor, coreless DC motors, Stepper DC Motors,LRA vibration motors, BLDC motors,Brushed DC Motors,Planetary Gear Motors,Spur Gear Motors ,Worm Gear Motor,etc. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!