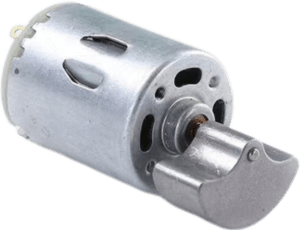

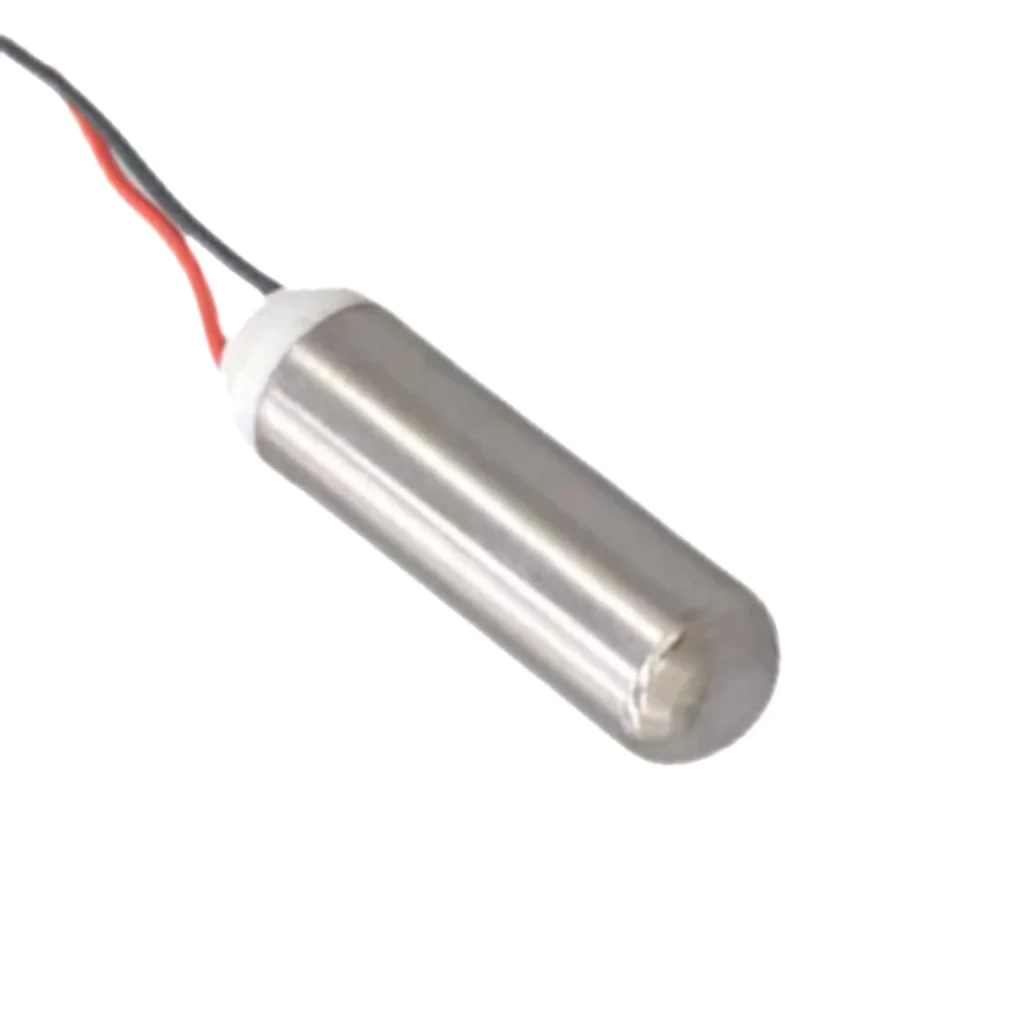

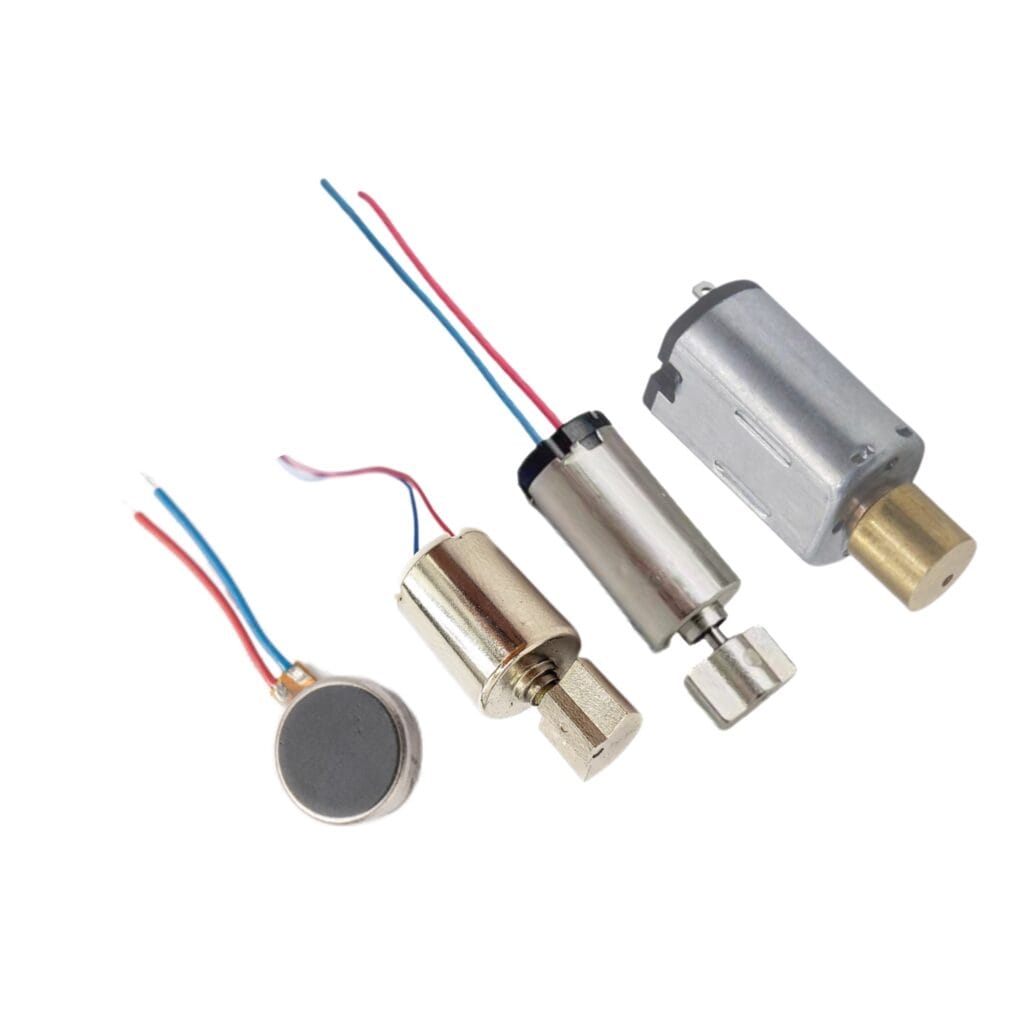

Eccentric Rotating Mass (ERM) motors are the original technology for generating vibrations. They are easy to use and come in various sizes, offering different vibration amplitudes and frequencies to suit various applications. These motors are found in products ranging from smartwatches to truck steering wheels.

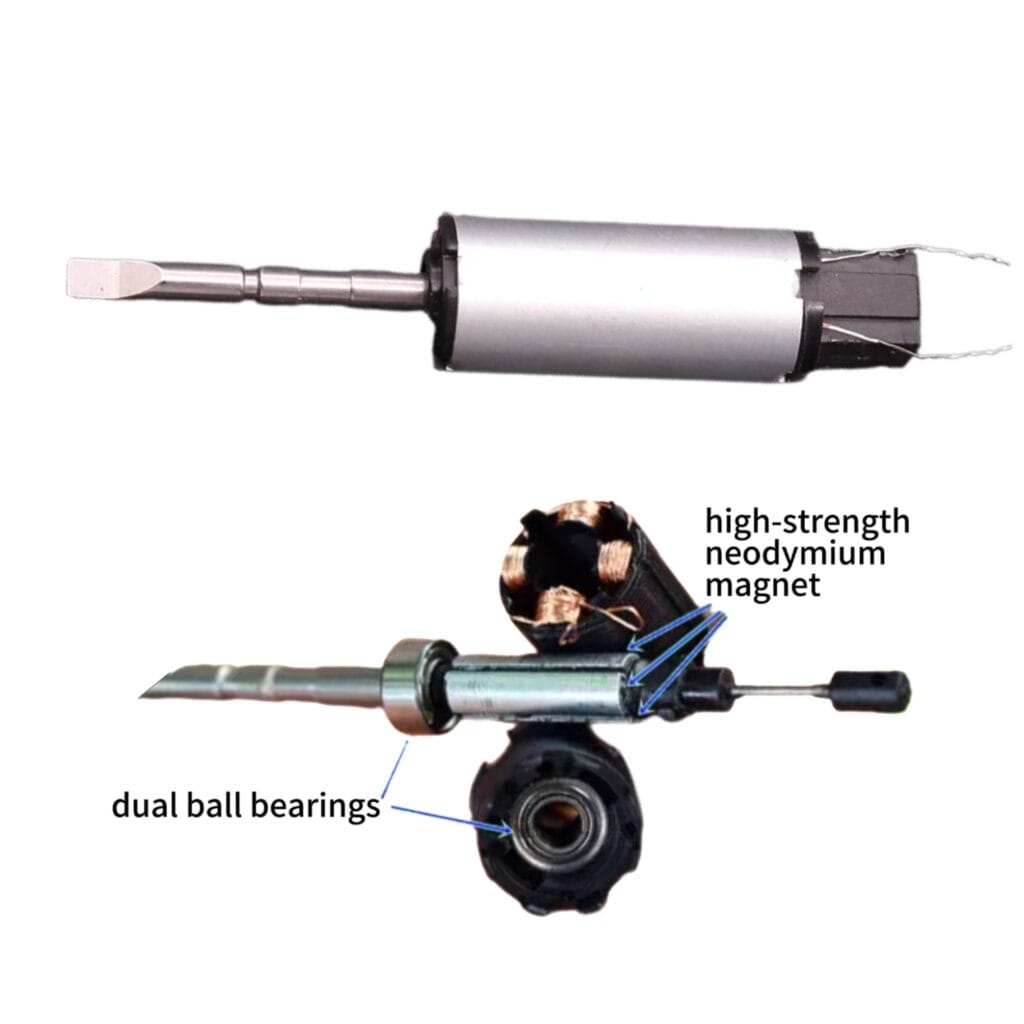

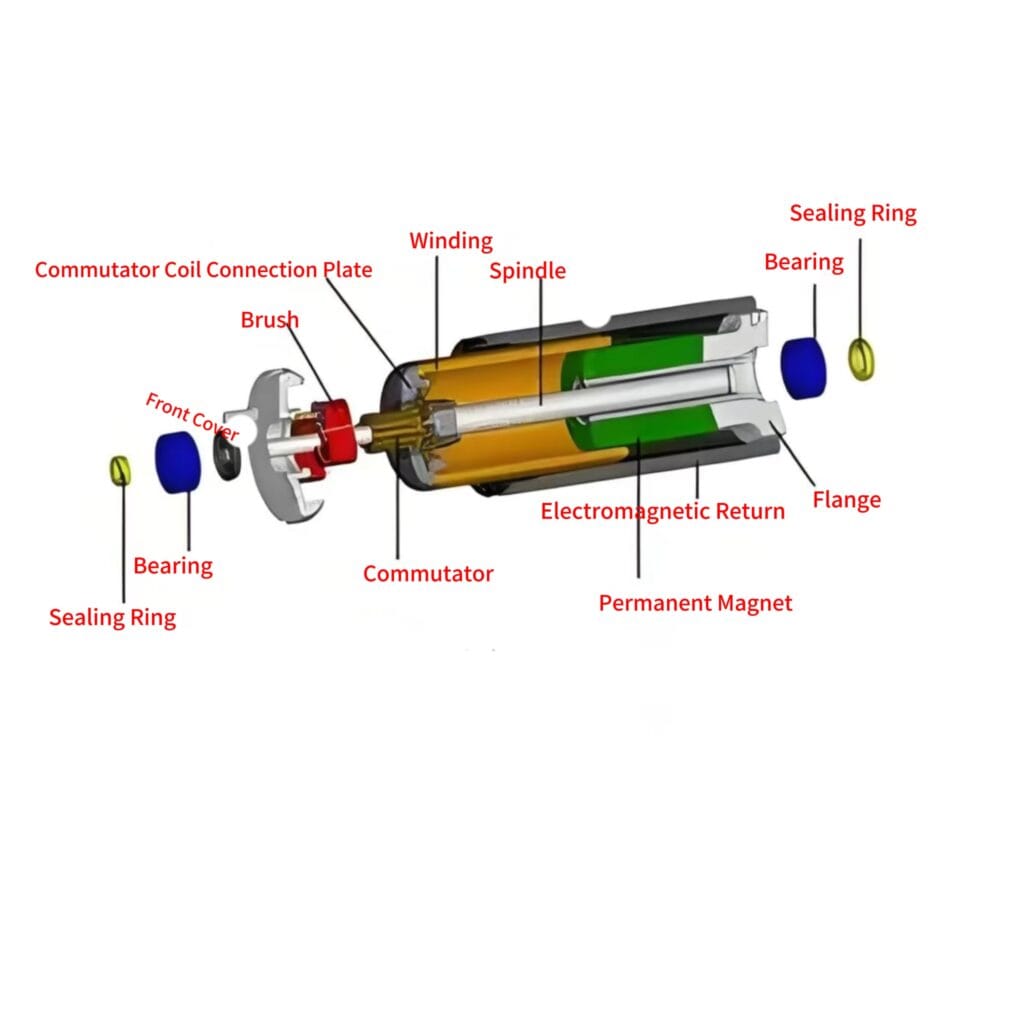

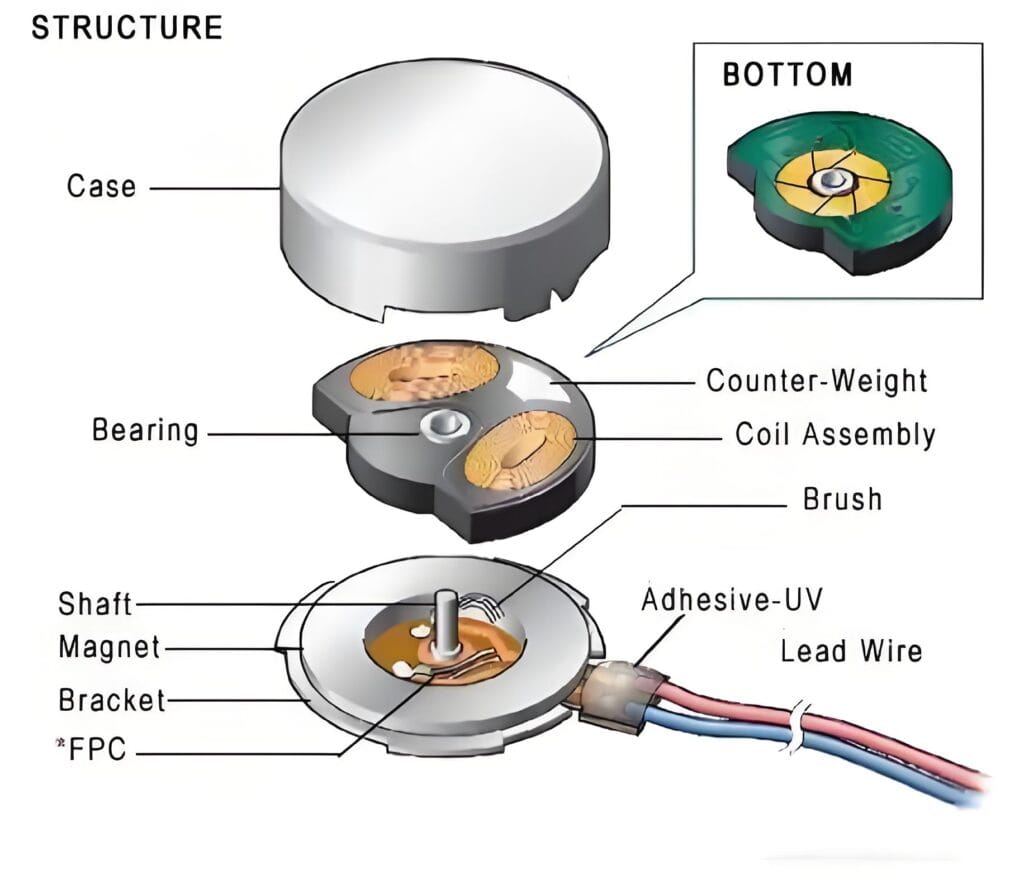

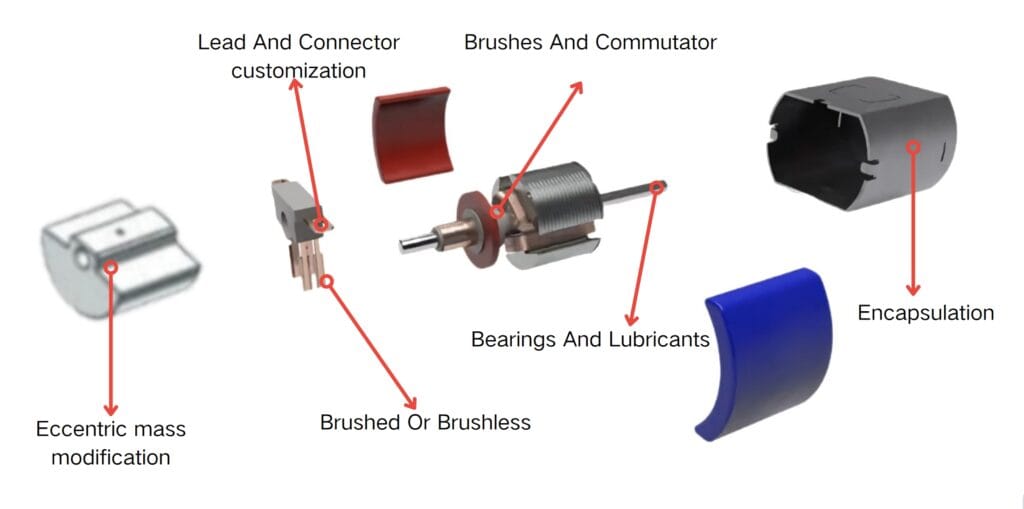

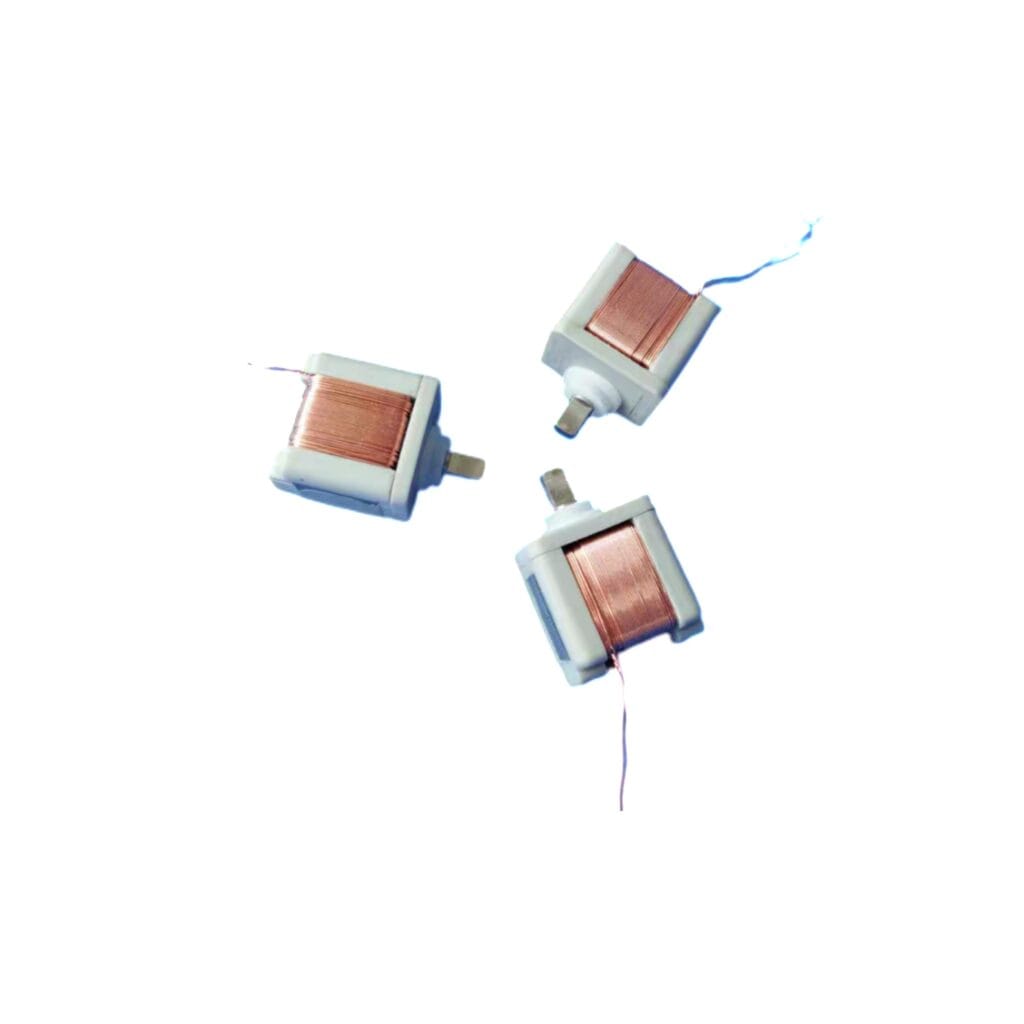

ERM motors can be designed using several motor technologies, such as iron core, coreless, and brushless, available in both cylinder and coin shapes.

The advantages of ERM motors are their simplicity and ease of control, especially with DC motors. For longer lifespans, brushless motors are a good option.

However, a limitation is that the amplitude is geometrically linked to the frequency and speed, making it impossible to adjust them independently.

We offer these motors in three types: iron core for low cost, coreless for medium cost and performance, and brushless for the highest performance and durability.