Coin Vibration Motor

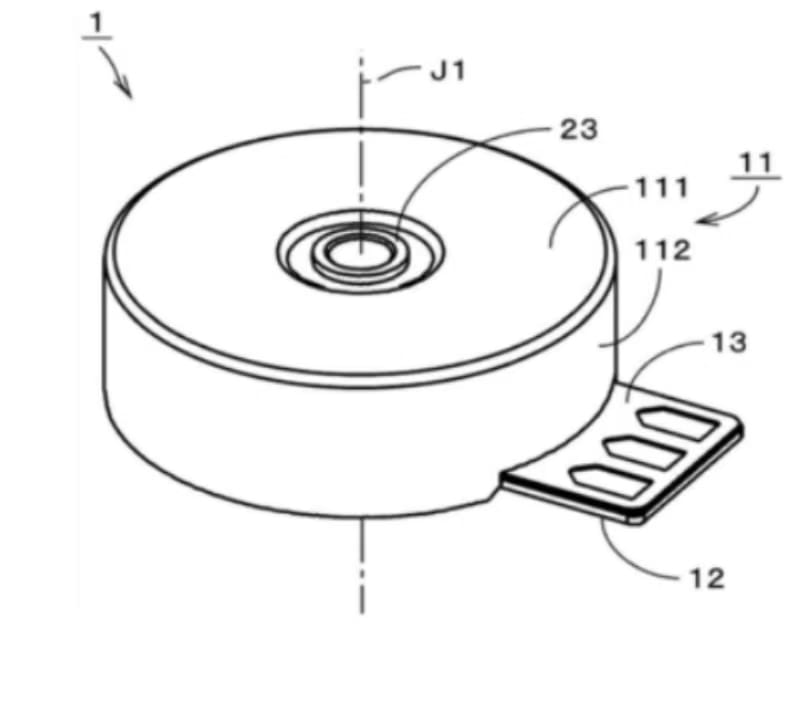

TSL Motors offers a variety of coin vibration motors, also known as shaftless or pancake motors, with diameters typically ranging from Ø6mm to Ø12mm. These flat motors feature an enclosed design, making them simple to use and integrate into various applications. They are commonly mounted using powerful permanent adhesives for secure attachment. Customers can choose from a range of connection options, including spring contacts, FPC, or bare contact pads. Additionally, TSL Motors is flexible and can modify base designs, such as adjusting lead wire lengths or connectors, to meet specific requirements. For enhanced customization, we also offer sponge and double-sided tape in various thicknesses.

It is important to note that coin vibration motors require a higher starting voltage compared to cylindrical coreless motors. Typically, the coin motors start at around 2.3 volts (rated at 3 volts). This should be considered when designing your application, as inadequate voltage may prevent the motor from starting properly.

Explore Our All of Coin Vibration Motors

10mm Coin Vibration Motor – 2mm Type Model TSL-C1020

10mm Coin Vibration Motor – 3mm Type Model TSL-C1027

10mm Coin Vibration Motor – 3mm Type Model TSL-C1030

10mm Coin Vibration Motor – 3mm Type Model TSL-C1034

12mm BLDC Brushless Vibration Motor – 3mm Type Model TSL-WS1234

12mm Coin Vibration Motor – 3mm Type Model TSL-C1234

12mm Coin Vibration Motor – 3mm Type Model TSL-C1234-KLB016F

14mm Coin Vibration Motor – 3.4mm Type Model TSL-FLAT-C1434

14mm Coin Vibration Motor – 3mm Type Model TSL-C1434

6mm BLDC Brushless Vibration Motor – 2.5mm Type Model TSL-WS0625

7mm Coin Vibration Motor – 2mm Type Model TSL-C0720

7mm Coin Vibration Motor – 2mm Type Motor Model TSL-FLAT-0720-PCB

The List of All Coin Vibration Motors

| Motor Model | Size(mm) | Rated Vol. | Rated Speed | Rated Current | Starting Current | Starting Vol. | Operating Vol. | Amplitude | |

| Diameter | Thickness | V DC | RPM | mA | mA | V DC | V DC | G | |

| TSL-WS0625 | 6.00 | 2.50 | 3.00 | 10000Min | 80.0Max | 175.0Max | 2.5Max | 2.7~3.3 | 0.55Min |

| TSL-C0720 | 7.00 | 2.00 | 3.00 | 15500±2500M iN | 90.0Max | 150.0 Max | 2.3 Max | 2.3~4.0 | 0.80 |

| TSL-FLAT-0720-PCB | 7.00 | 2.00 | 3.00 | 10000Min | 90.0Max | 150.0Max | 2.3Max | 2.3~3.3 | 1.20 |

| TSL-WS0825 | 8.00 | 2.50 | 3.00 | 14,000 ± 3,500 | 80.0Max | 175.0Max | 2.5Max | 2.7 ~ 3.3 | 1.00Min |

| TSL-FLAT-C0816 | 8.00 | 1.60 | 3.00 | 14,000±3000 | 80.0Max | 150.0Max | 2.5Max | 2.7~3.3 | 0.5Min |

| TSL-C0820 | 8.00 | 2.00 | 3.00 | 13000±2500Min | 80.0Max | 120.0Max | 2.3Max | 2.3~4.0 | 0.55 |

| TSL-C0827 | 8.00 | 2.70 | 3.00 | 13000±2500Min | 80.0Max | 120.0Max | 2.3Max | 2.3~4.0 | 0.75 |

| TSL-C0834 | 8.00 | 3.40 | 3.00 | 11000±2500 Min | 80.0 Ma | 120.0Max | 2.3Max | 2.3~4.0 | 0.7 |

| TSL-WS0934 | 9.00 | 3.40 | 3.00 | 11,500 ± 2,500 | 80.0Max | 175.0Max | 2.5Max | 2.7 ~ 3.3 | 1.4Min |

| TSL-C1020 | 10.00 | 2.00 | 3.00 | 12000±2500Min | 80.0Max | 120.0Max | 2.3Max | 2.3~3.3 | 0.8 |

| TSL-C1027 | 10.00 | 2.70 | 3.00 | 11000±2500 Min | 80.0Max | 120.0Max | 2.3Max | 2.3~3.3 | 1.0 |

| TSL-C1030 | 10.00 | 3.00 | 3.00 | 11000±2500Min | 80.0Max | 120.0Max | 2.3Max | 2.3~3.6 | 1.0 |

| TSL-C1034 | 10.00 | 3.40 | 3.00 | 12000±2500Min | 80.0Max | 120.0Max | 2.3Max | 2.3~3.3 | 1.2 |

| TSL-WS1234 | 12.00 | 3.40 | 3.70 | 8,000Min | 85.0Max | 200.0Max | 2.5Max | 3.0~4.5 | 2Min |

| TSL-C1234 | 12.00 | 3.40 | 3.00 | 13,500±2,000Min | 150.0Max | 200.0Max | 1.0Max | 1.5~3.0 | 1.85 |

The Technology Of Coin Vibration Motors

Coin Vibration Motor

Our coin or pancake vibrating motors are Eccentric Rotating Mass (ERM) motors, similar to pager motors in terms of operation. They follow the same motor drive principles, including H-bridge circuitry for active braking.

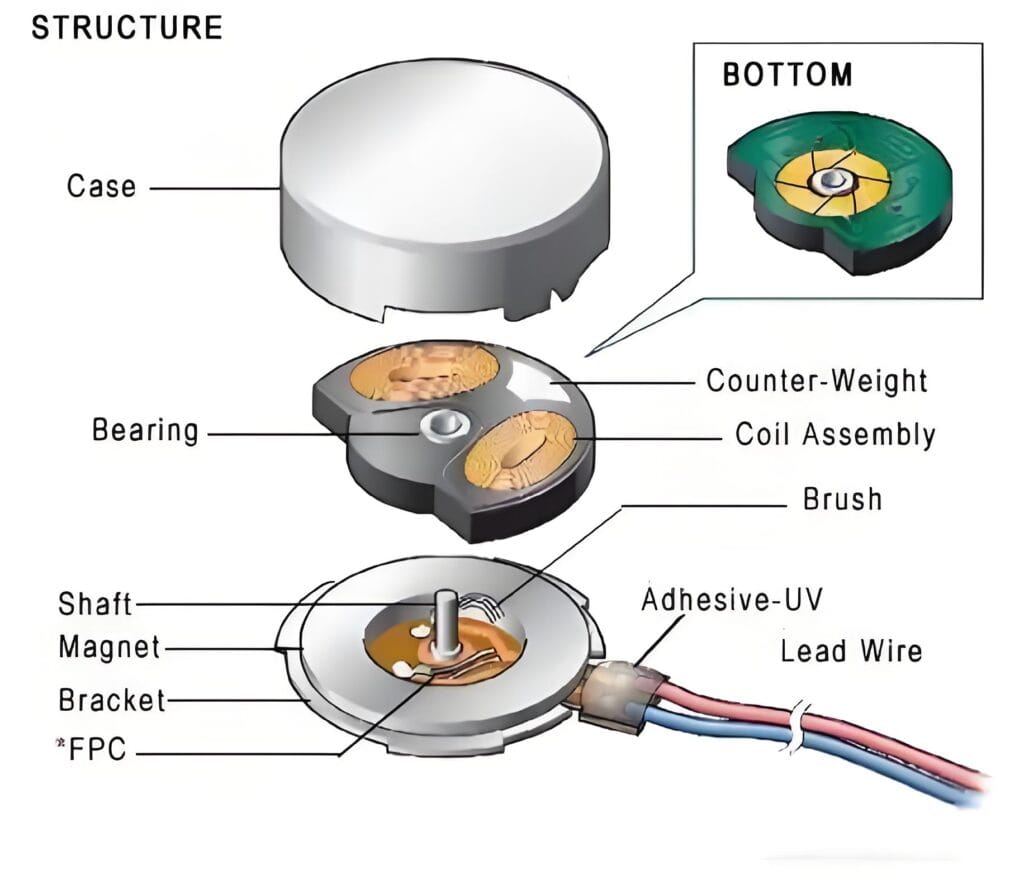

Brushed coin vibration motors feature a flat PCB with a 3-pole commutation circuit placed around a central internal shaft. The rotor of the vibration motor consists of two “voice coils” and a small mass, integrated into a flat plastic disc with a central bearing, which sits on a shaft. Two brushes on the underside of the disc contact the PCB commutation pads to power the voice coils, generating a magnetic field.

This field interacts with the flux produced by a disc magnet attached to the motor chassis. The commutation circuit alternates the direction of the magnetic field in the voice coils, which interacts with the N-S pole pairs in the neodymium magnet. As a result, the disc rotates, and the off-centered eccentric mass creates vibrations.

Motor Customized Solutions

At TSL, we transform your unique requirements into high-performance, reliable motor solutions. From concept to mass production, our engineering expertise ensures your devices stand out with durability and efficiency.

To Accelerate Your Project, Prepare These Details:

- Electrical Requirements: Operating voltage , Current consumption limits, Drive signal type , etc.

- Mechanical Constraints:Max dimensions,Mounting method,Shaft direction,etc.

- Performance Targets:Vibration force (G-level) at specific frequencies ,Start/stop response time ,Durability,etc.

- The timeline for this project and the annual consumption of motor products.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro vibration motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors, coreless DC motors, LRA vibration motors, and mini BLDC motors. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

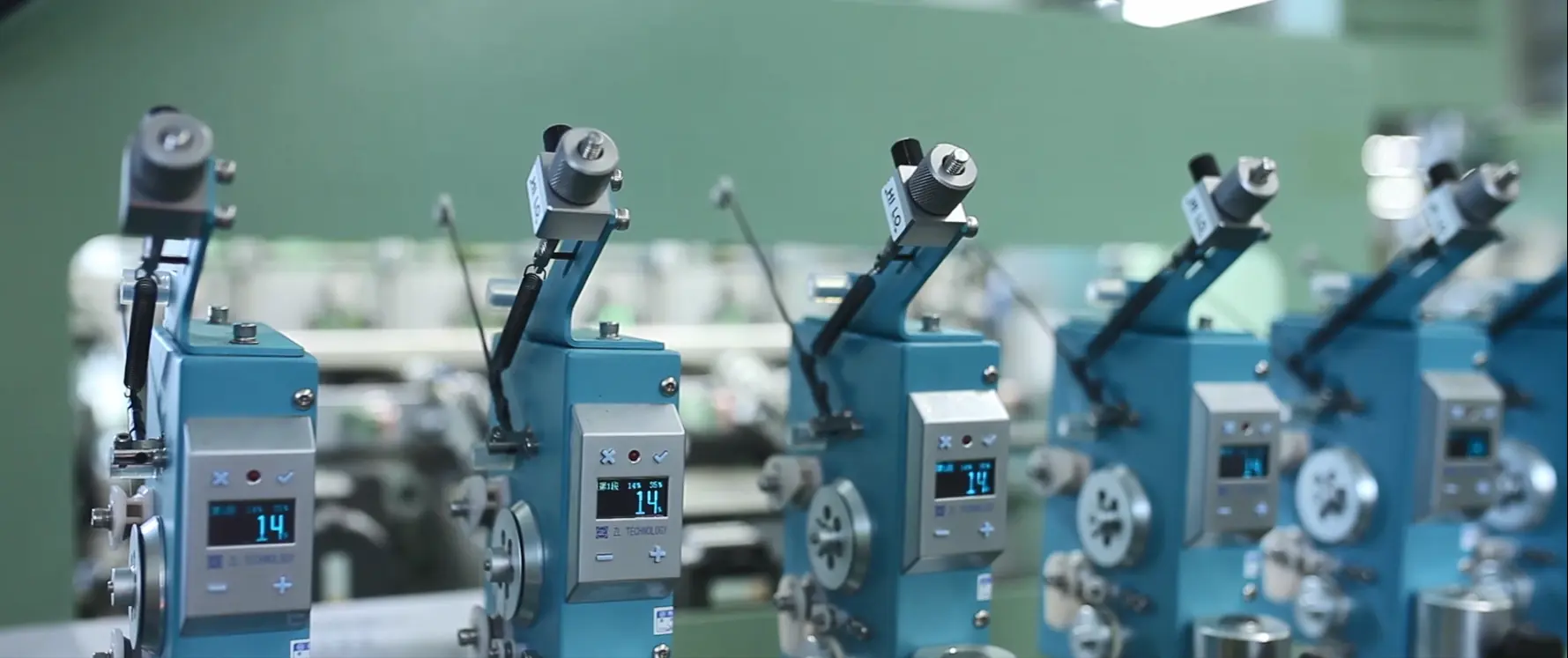

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

Applications Of Coin Vibration Motors

As people’s ideas continue to evolve and innovate, the use of coin vibration motors has become increasingly widespread. The range of applications is vast and ever-expanding, making it difficult to cover them all in one place. To assist you, we’ve highlighted some of the most notable and commonly used applications of coin vibration motors over the years.

Tech giants such as Apple, Microsoft, Google, Huawei, and Xiaomi have all ventured into the wearable device market, each creating their own line of smartwatches and smart bands. These innovations continue to push the boundaries of technology, offering users advanced features for fitness tracking, communication, and convenience.

Notably, these tech giants have widely adopted coin vibration motors in their wearable devices. This small vibration motor is commonly used in smartwatches and smart bands to provide subtle yet effective tactile feedback. For instance, when users receive notifications, calls, or messages, the coin vibration motor alerts them through a gentle vibration, enhancing the interaction and convenience.

In the context of electronic cigarettes, this technology is increasingly used to alert users when the device is powered on or off, or when it reaches certain operational states, such as a low battery or high temperature. The coin vibration motor’s compact size makes it ideal for integration into small, portable devices like e-cigarettes, where space is limited but tactile feedback is still essential for user awareness.

As electronic cigarette technology continues to evolve, incorporating more sensory feedback mechanisms like coin vibration motors will likely play an increasingly significant role in enhancing the user experience, contributing to both usability and overall satisfaction. This application of vibration motors is in line with trends in wearable devices and consumer electronics, where haptic feedback is becoming a key element of interactive design.

Vibration motors, including coin vibration motors, are extensively used in gaming controllers and virtual reality (VR) gloves, significantly enhancing user interaction through tactile feedback. Devices like the Nintendo Switch, PlayStation Portable (PSP), Xbox controllers, and VR gloves have integrated these motors to provide users with a more immersive experience. These motors create vibrations that correspond to in-game actions, such as character movements, impacts, or environmental changes, helping players to physically feel the game world in a more intuitive way.

The use of coin vibration motors in gaming and VR applications is part of a broader trend toward enhancing sensory experiences in consumer electronics. As research and development continue, these technologies are likely to become even more advanced, allowing for more complex and realistic feedback, and further enhancing user immersion in digital environments.

Handheld devices like blood glucose meters and supermarket checkout scanners also utilize flat vibrating motors to enhance user interaction and provide feedback. These motors are particularly valuable in devices where compact size, reliability, and precise feedback are essential. In blood testing machines, for example, vibration motors offer users a tactile alert when a test is complete or if there is an error, ensuring the process is intuitive and user-friendly. Similarly, in supermarket scanning devices, flat vibrating motors provide operators with immediate feedback, such as confirmation of a successful scan or a need for a rescan.

The Advantages of Coin Vibration Motors

Compact Size

Coin vibration motors are small and lightweight, making them perfect for applications where space is limited.

Customizable Feedback

coin vibration motors can now be tuned for varying vibration patterns, speeds, and intensities.

Simple Installation

These vibration motors are designed for quick and straightforward installation, thanks to the adhesive backing that allows you to easily attach them to your devices.

Established Technology

This reliable and well-tested technology supports projects throughout their entire lifecycle, from initial prototypes to large-scale production, ensuring consistency and efficiency at every stage.

FAQs For Coin Vibration Motors

1.Why are coin vibration motors so easy to install?

The self-adhesive tape on the motor’s front or back allows for simple attachment to your PCB or product housing. Moreover, these motors offer multiple connection options, such as lead wires, connectors, FPCB, spring, and pad mountable types, allowing you to choose the best method for your application.

2.What are the different types of coin vibration motors you can provide?

We offer three types of coin vibration motors: the ERM (Eccentric Rotating Mass) type, coin brushless types, and the LRA (Linear Resonant Actuator) type. All of these motors feature a flat, coin button-shaped casing.

3.How long does a vibration motor last?

The lifespan of coin vibration motors is a common question. For TSL Motors, the standard durability is 864,000 cycles, with each cycle consisting of 1 second on followed by 2 seconds off. This translates to approximately 72 hours of continuous operation based on this cycle pattern.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!