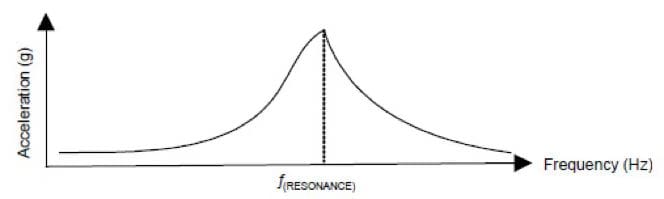

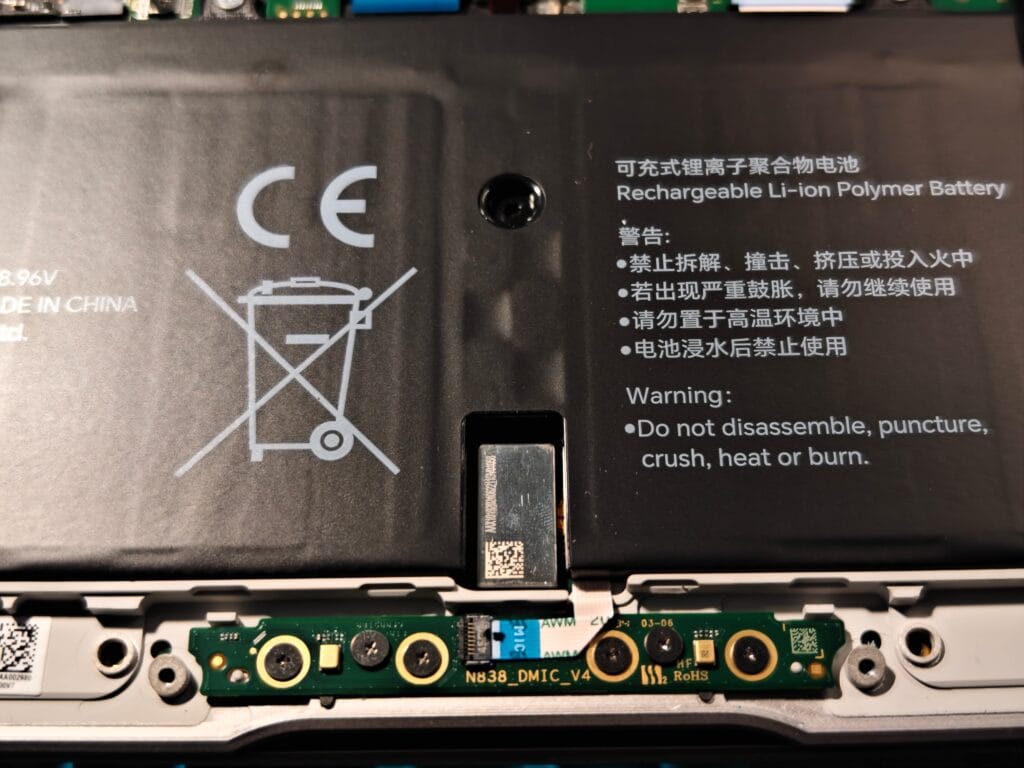

A linear resonant actuator (LRA) is a vibrating motor that produces oscillating force along a single axis. LRAs respond more quickly than ERM coin motors. For example, an LRA takes only 50ms to reach the highest vibration level, while a coin motor takes between 100ms and 200ms. LRAs, particularly Z-axis vibrating motors, provide tactile feedback perpendicular to their surface, improving acceleration and feedback quality.

As a result, many high-end applications prefer LRAs. Unlike brushed motors, which wear down over time due to brushes, the LRA motor is brushless, using a voice coil to drive the mass, with only the spring being the movable part that can fail. LRA motors generally last over five times longer than traditional coin motors.

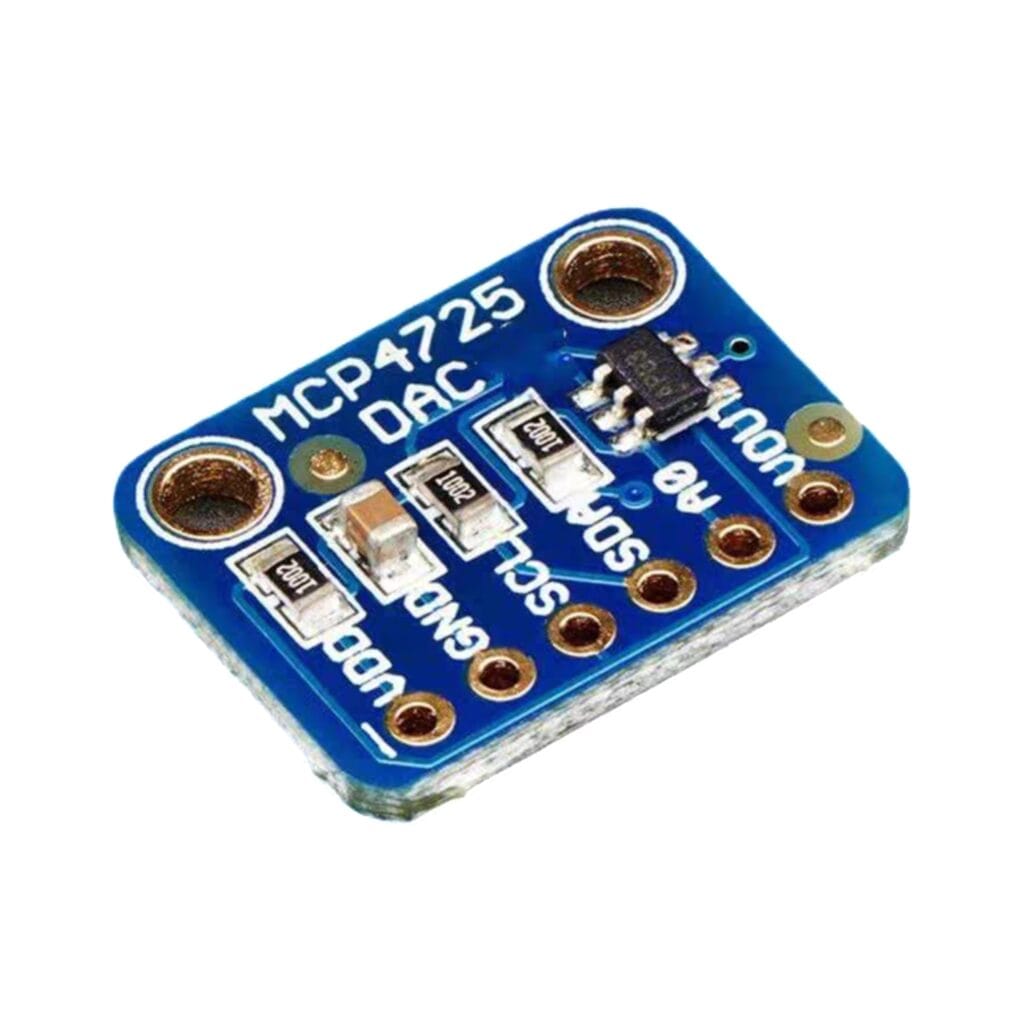

It is important to note that LRA motors operate on AC power, meaning users need to add IC drivers to the PCB board to activate them.