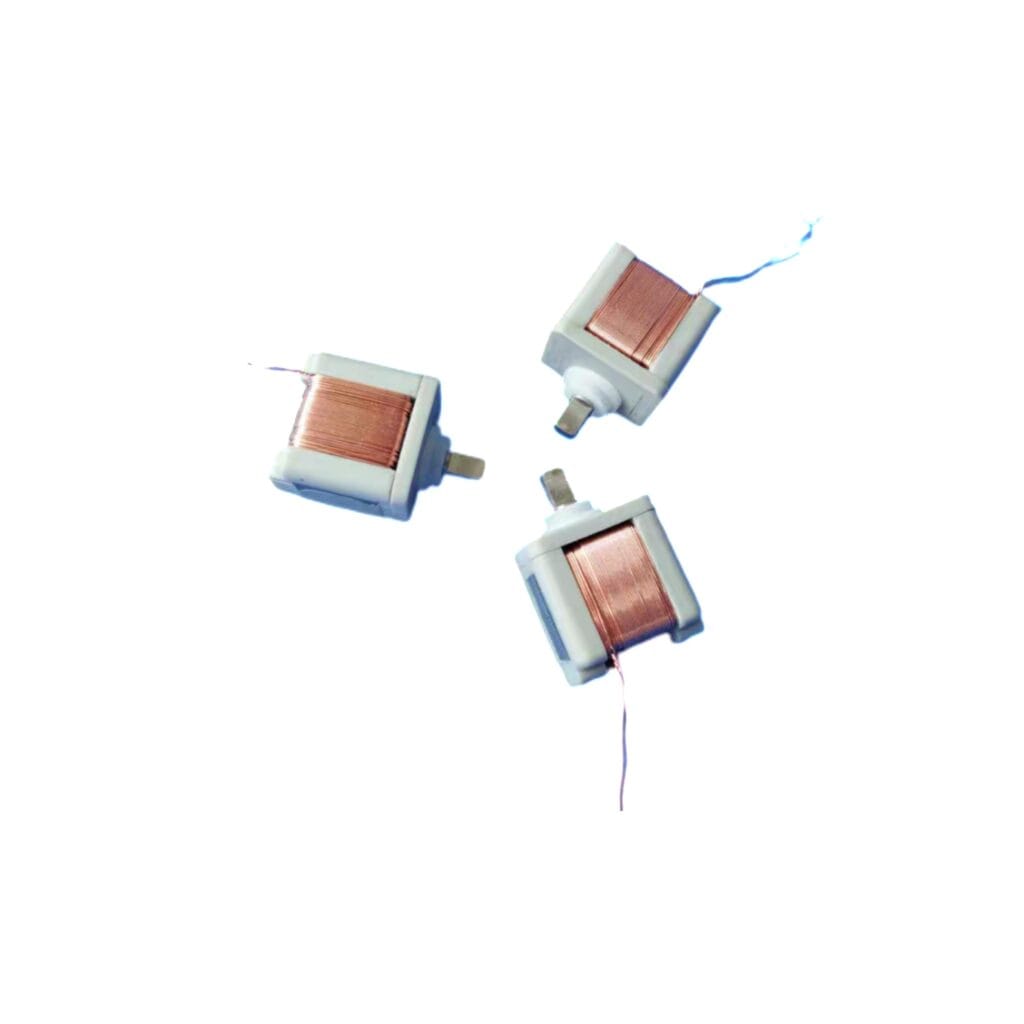

SMD Vibration Motor

Our SMT surface mount vibration motors come in reels of 1000 units each, specifically designed for automatic placement directly from the reel. This eliminates the need for manual installation, allowing the vibration motors to be seamlessly integrated into the PCB assembly process. With this design, the motors can be easily soldered alongside other components, significantly boosting production efficiency and making them an ideal choice for mass production.

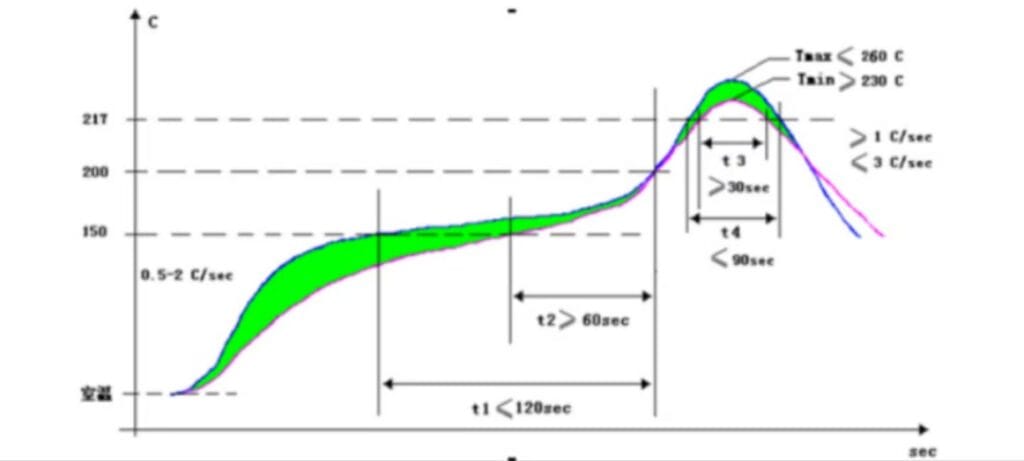

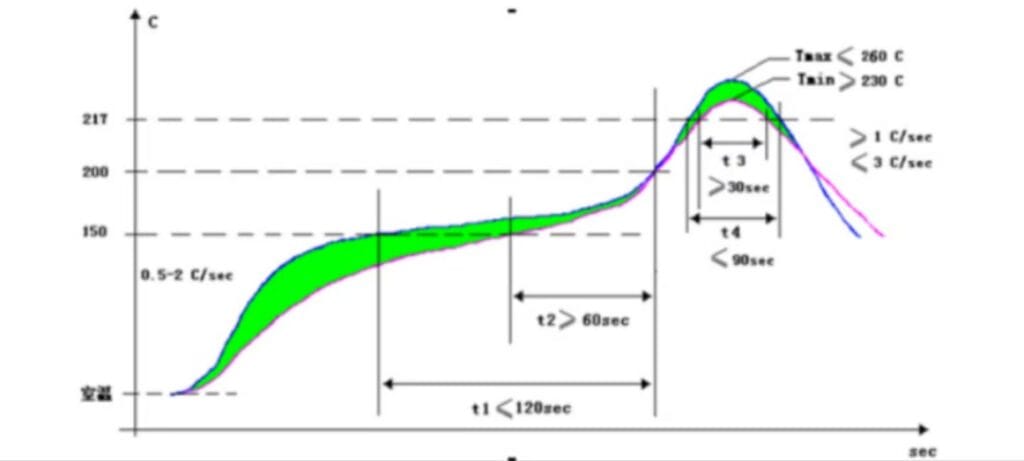

Featuring a “core” structure, these motors are built to endure high temperatures during the reflow soldering process. However, it’s important to avoid overheating to prevent damage, so it’s essential to adhere to the reflow oven temperature guidelines provided in the SMT vibration motor specifications.

Whether you’re developing a new product or enhancing an existing one, our SMD vibration motors are tailored to meet your requirements. Opt for TSL Motors to give your products a competitive edge in the market.

Explore Our SMD Vibration Motor

3 Essential Tips for Using SMD Vibration Motors

Reflow Soldering

When soldering SMD vibration motors, it’s crucial to follow the reflow oven temperature curve outlined in the motor’s datasheet. Exceeding the recommended temperature can damage the internal components of the motor, resulting in reduced performance and shortened lifespan.

Manual Soldering

During prototyping, avoid using flux when soldering the SMD vibration motor. Use a low-wattage soldering iron to ensure minimal heat exposure, and complete the soldering process as quickly as possible to prevent overheating and potential motor damage

Keep Liquids Away

The mini patch vibration motor is not fully sealed, so exposure to any liquids, such as flux washes or conformal coatings, should be avoided. Liquids entering the motor can cause significant damage to its internal structure, compromising its functionality.

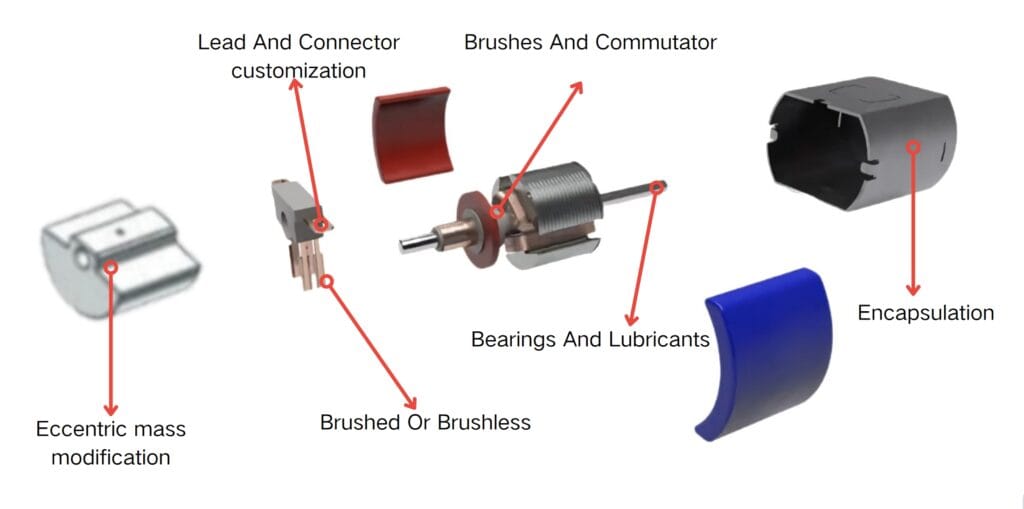

Vibration Motor Customization

We specialize in redesigning and tailoring vibration motors to meet the unique needs of our customers. The interactive graphic below highlights some common customizations we offer for brushed DC vibration motors. We also apply similar modifications to other technologies, including brushless, LRA, solenoid, and piezo motors.

Eccentric Mass

Modification

Modify the size, material, shape, and quantity of the eccentric mass(es) to optimize the vibration frequency and amplitude for the desired performance range.

Brushed Or

Brushless

While long-life brushes come at a higher cost, they remain more affordable compared to adopting brushless technology.a

Lead And Connector

Customization

We offer customized wire sets with a variety of connectors from brands like JST, Hirose, AMP, Molex, AVX, and Kyocera, which can be integrated into any motor we manufacture. Additionally, we can attach PCB “backpacks” to certain motors to reduce local EMI or provide extra circuit functionalities.

Brushes And

Commutator

The brushes and commutator play a crucial role in the performance of any DC motor. The choice of plating type and the method used for the components significantly impact the motor’s lifespan, just as the type of commutator polishing and lubricant applied can also influence its durability.

Bearings And

Lubricants

Our motor designs incorporate a variety of bearings and lubricants, chosen based on the specific application environment. In larger vibration motors, the bearing typically experiences the most wear, primarily due to the centrifugal force generated by the rotation of the eccentric mass. We will provide recommendations to help avoid any issues with the application specifications.

Encapsulation

In certain applications, covering the rotating mass can be beneficial. Additionally, the motor can undergo an extra sealing process to offer enhanced protection against the penetration of fluids.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro vibration motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors, coreless DC motors, LRA vibration motors, and mini BLDC motors. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

The Advantage Of SMD Vibration Motor

Compact and Efficient Design

SMD miniature motors feature a compact size, as small as H3.0W4.0L11mm, making them perfect for applications with limited space, such as wearables and small electronics. Their compact form factor helps save valuable board space.

Optimized for Automated Production

These SMT SMD vibration motors are packaged in reels of 1,000 units, designed for easy pickup and automated placement, making them ideal for high-volume production. This design significantly enhances production efficiency.

High-Temperature Durability

Built with high-temperature-resistant materials, SMD vibration motors can endure the high temperatures involved in 2-3 reflow soldering cycles without compromising performance.

Exceptional Reliability

Operating within a temperature range of -20°C to 70°C, SMD vibration motors offer outstanding durability, long lifespan, and stable performance, ensuring reliable operation over time.

FAQ For SMD Vibration Motots

1.What is SMD?

SMD stands for Surface-Mounted Device. It refers to electronic components that are directly mounted onto the surface of a printed circuit board (PCB). The process of placing and soldering these components onto the PCB is known as Surface-Mount Technology (SMT).

2.What is SMT?

SMT stands for Surface-Mount Technology, which refers to a method of electronic assembly where components are directly mounted onto the surface of a printed circuit board (PCB). This technique is currently the most widely used process in the electronics assembly industry.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!