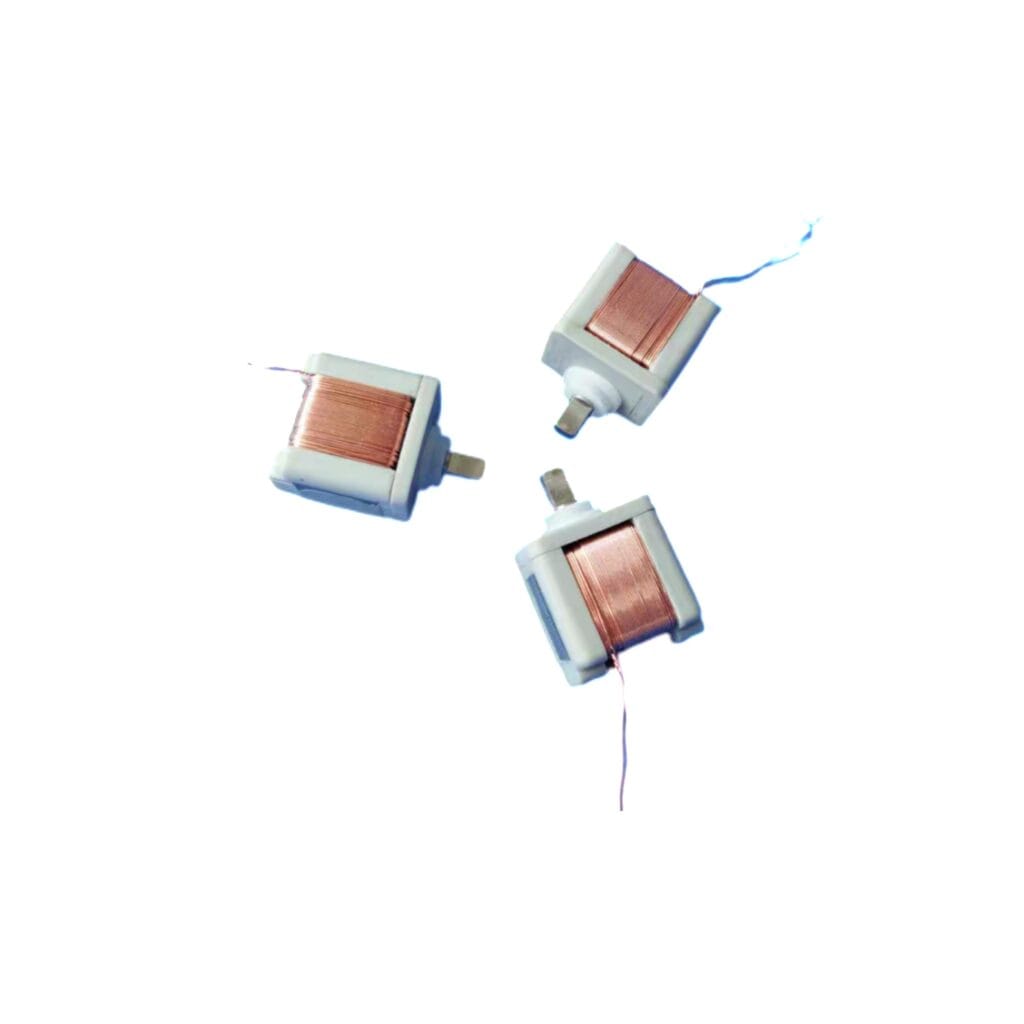

Sonic Vibration Motor

The sonic vibration motor can reach up to 43,000 vibrations per minute, effectively cleaning teeth and removing plaque. Its small and compact design makes it easy to integrate into various products. Additionally, the motor is easy to control and can be configured to operate across a broad frequency range.

With over 15 years of experience, Toothbrush Sonic Vibration Motors has built a solid reputation for high-quality products and excellent customer service. We also offer custom services for terminals and wiring, using connectors from renowned brands such as Molex, JST, and Hirose.

Explore Our Sonic Vibration Motors

The Technologies Of Sonic Vibration Motors

Sonic Vibration Motor

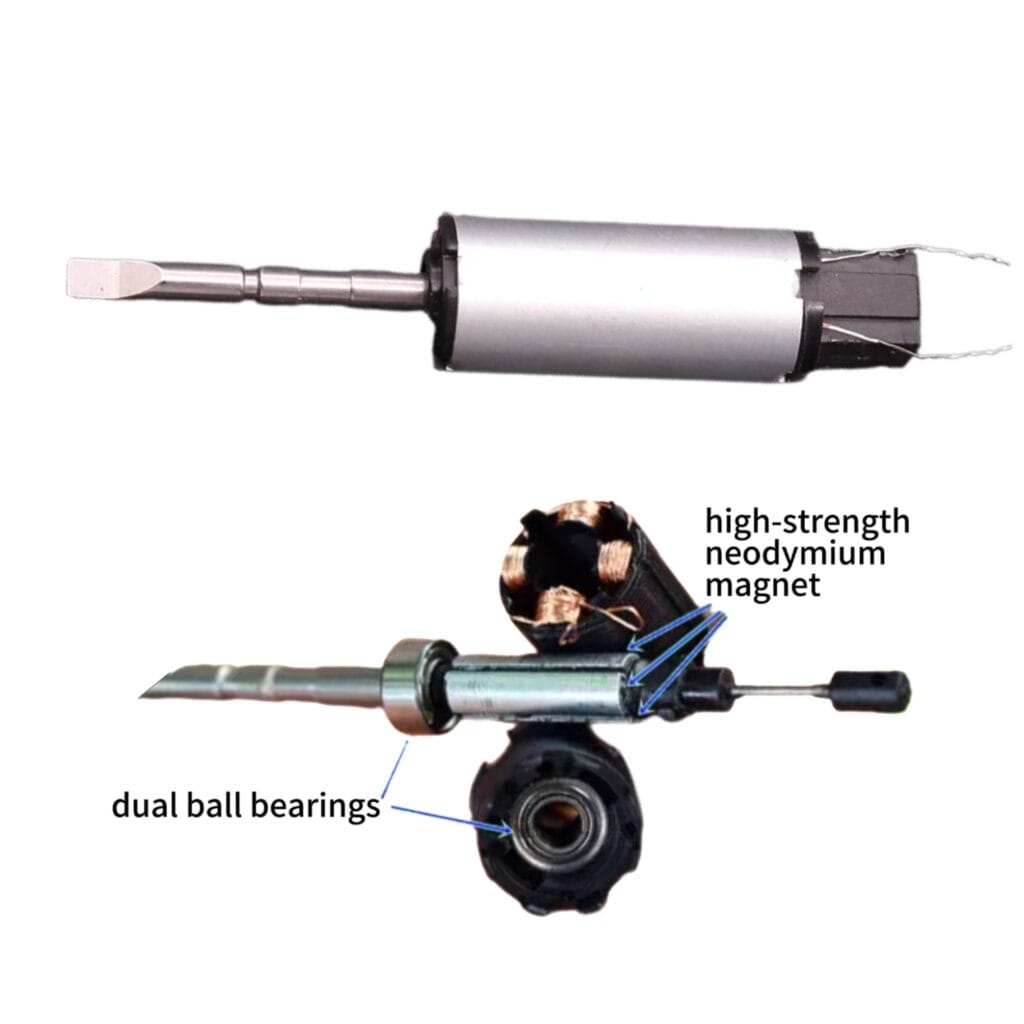

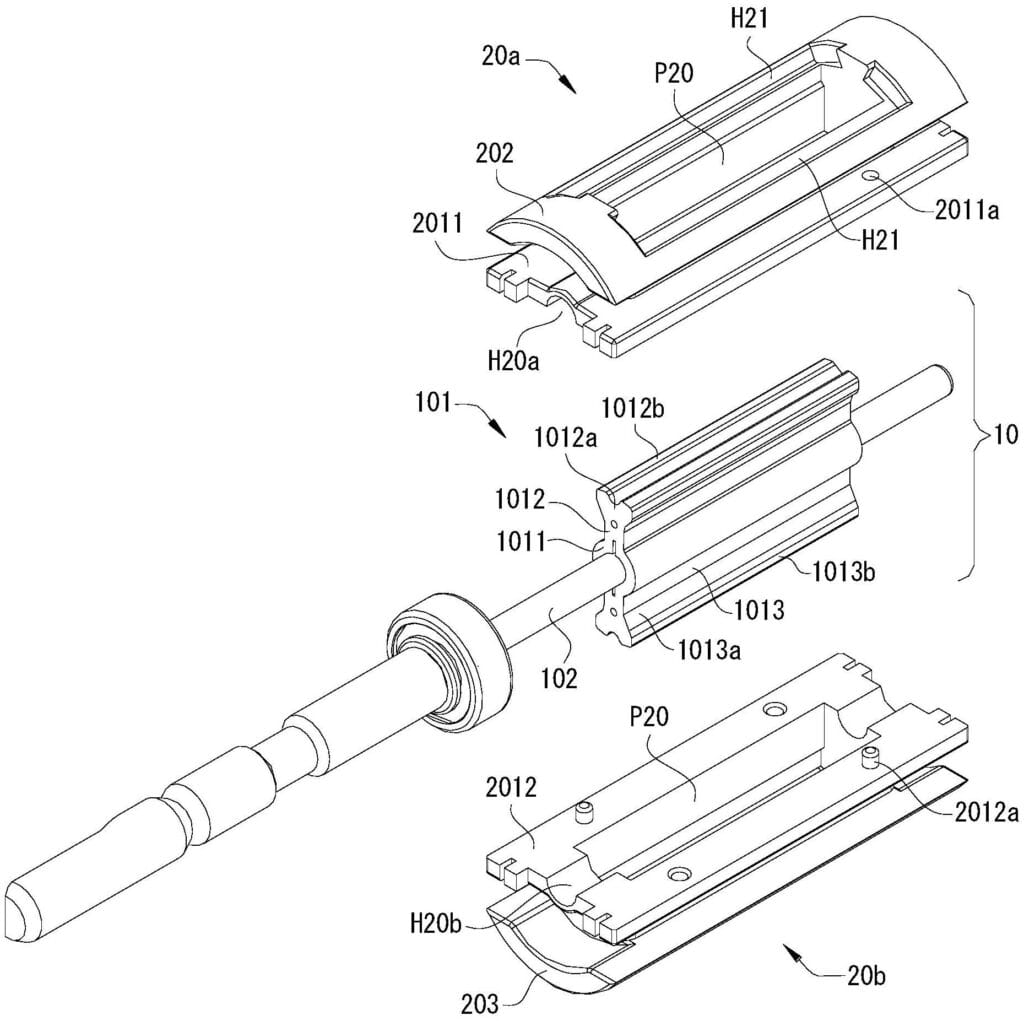

A toothbrush sonic vibration motor is a compact electric motor that creates vibrations to assist in cleaning teeth. It is commonly found in rechargeable electric toothbrushes and powered by a small battery. The motor typically vibrates at frequencies between 25,000 and 40,000 Hertz (cycles per second). This high-speed vibration creates a scrubbing action that helps remove plaque and food debris from the teeth and gums.

The motor is usually housed in the toothbrush handle and connects to the brush head via a shaft or similar mechanism. The vibrations aid in loosening plaque and food particles, making them easier to clean away. Additionally, the motor can stimulate the gums and improve circulation, supporting healthier gums.

Ultrasonic Vibration Motors Used In Electric Toothbrush

Vibration Mechanism

A sonic vibration motor in a toothbrush generates rapid vibrations, typically between 25,000 and 40,000 Hertz, which assist in removing plaque and food particles from teeth and gums.

Gum and Tooth Care

The motor’s vibrations help stimulate gums, improve circulation, and reduce the pressure needed during brushing, minimizing the risk of gum damage or tooth abrasion.

Soothing Vibration

The vibrations not only aid in cleaning but also create a more pleasant brushing experience by providing soothing sensations that help relax the user.

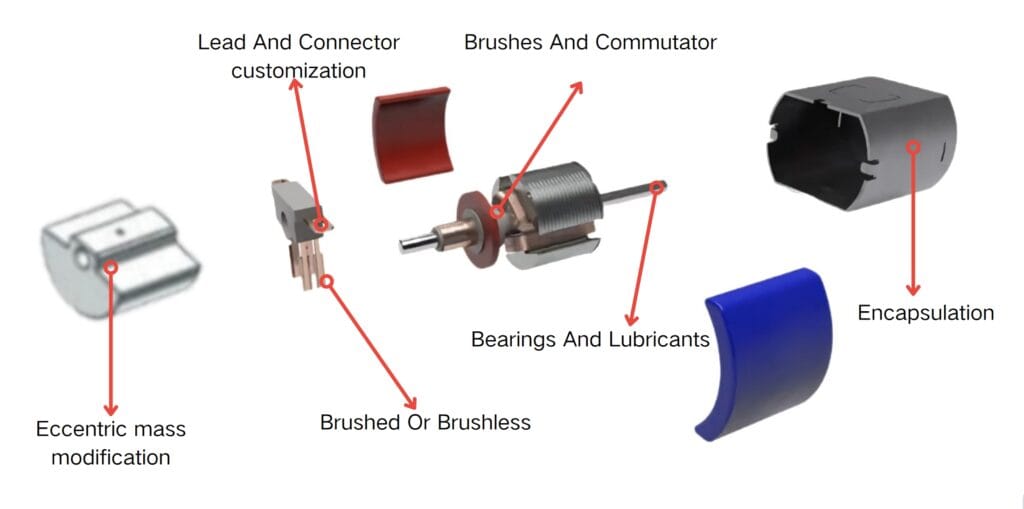

Vibration Motor Customization

We specialize in redesigning and tailoring vibration motors to meet the unique needs of our customers. The interactive graphic below highlights some common customizations we offer for brushed DC vibration motors. We also apply similar modifications to other technologies, including brushless, LRA, solenoid, and piezo motors.

Eccentric Mass

Modification

Modify the size, material, shape, and quantity of the eccentric mass(es) to optimize the vibration frequency and amplitude for the desired performance range.

Brushed Or

Brushless

While long-life brushes come at a higher cost, they remain more affordable compared to adopting brushless technology.a

Lead And Connector

Customization

We offer customized wire sets with a variety of connectors from brands like JST, Hirose, AMP, Molex, AVX, and Kyocera, which can be integrated into any motor we manufacture. Additionally, we can attach PCB “backpacks” to certain motors to reduce local EMI or provide extra circuit functionalities.

Brushes And

Commutator

The brushes and commutator play a crucial role in the performance of any DC motor. The choice of plating type and the method used for the components significantly impact the motor’s lifespan, just as the type of commutator polishing and lubricant applied can also influence its durability.

Bearings And

Lubricants

Our motor designs incorporate a variety of bearings and lubricants, chosen based on the specific application environment. In larger vibration motors, the bearing typically experiences the most wear, primarily due to the centrifugal force generated by the rotation of the eccentric mass. We will provide recommendations to help avoid any issues with the application specifications.

Encapsulation

In certain applications, covering the rotating mass can be beneficial. Additionally, the motor can undergo an extra sealing process to offer enhanced protection against the penetration of fluids.

Why Choose TSL?

We are here to assist you throughout the entire process, from prototype development to large-scale, cost-efficient mass production.

Founded in 2009, TSL Motors has been at the forefront of micro vibration motor design and manufacturing. With ISO 9001, ISO 14001, and ISO 45001 certifications, TSL is committed to delivering high-quality products that meet international standards.

We offer a wide range of motor solutions, including coin vibration motors, coreless DC motors, LRA vibration motors, and mini BLDC motors. Our motors are engineered to be cost-effective, reliable, and customizable, catering to various applications across diverse industries.

At TSL, we strive to provide our valued customers with innovative solutions tailored to their specific needs.

Designing motors and mechanisms for a diverse array of industrial, medical, and consumer applications.

Our skilled sales engineers are adept at quickly grasping your unique requirements and offering tailored services. These custom services encompass motor performance parameters such as rated voltage, speed, and current, along with additional features like connectors, wire lengths, rubber boots, plastic/metal capsules, brackets, and spring contacts.

We provide comprehensive support, including detailed drawings and specifications, throughout the entire process from prototype development to mass production.

Our motor manufacturing process is designed to be flexible, enabling us to accommodate both large-scale production and specialized, high-value custom builds to meet diverse customer needs.

We use in-house designed dynamometers to thoroughly test and validate every sample and production batch, ensuring the highest standards of quality and performance.

TSL Motor is an ISO 9001:2015 certified company, committed to ensuring that each motor meets your precise specifications and performance standards. We have developed a comprehensive after-sales support system, offering prompt responses to customer inquiries and addressing any issues or needs that may arise. Our commitment doesn’t end with delivery—we are here to support you every step of the way.

The Applications Of Sonic Vibration Motor

Smart Kitchen & Bath

In appliances like smart faucets, dishwashers, and refrigerators, sonic vibration motors provide haptic feedback to alert users to actions like water flow, temperature changes, or appliance status updates.

Medical Devices

In physical therapy equipment, these motors help provide therapeutic vibrations to aid in muscle relaxation and recovery, promoting circulation.

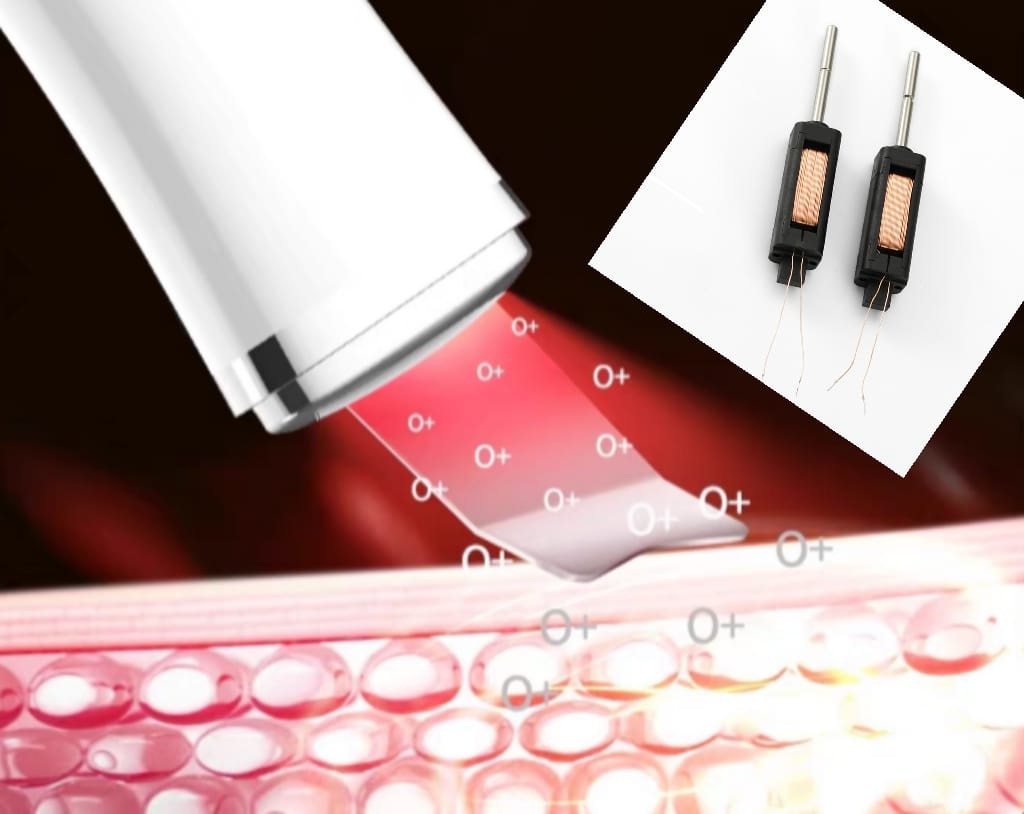

Beauty Instruments

Sonic vibration motors are commonly found in beauty devices like facial cleansers and massagers. These motors generate high-frequency vibrations that help improve blood circulation, promote relaxation, and provide deep cleansing.

The Advantages of Sonic Vibration Motors

High Efficiency

Sonic vibration motors operate with low energy consumption, making them ideal for battery-powered devices. They deliver effective vibrations without draining the power source too quickly.

Precise Vibration

Sonic vibration motors generate high-frequency, accurate vibrations, providing delicate and consistent tactile feedback, perfect for devices requiring precision, such as facial cleansers and medical devices.

Versatility

From healthcare to beauty devices, sonic vibration motors are highly adaptable, offering flexible applications across multiple industries.

Innovative User Experience

This reliable and well-tested technology supports projects throughout their entire lifecycle, from initial prototypes to large-scale production, ensuring consistency and efficiency at every stage.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!