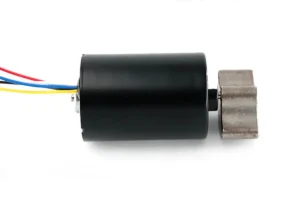

24mm BLDC Vibration Motor – 30mm Type Model TSL-BV2430-SR

If you request a quotation for mass production quantities, contact us for customizations and integration.

24mm Diameter BLDC Vibration Motor with Brushless technology Datasheet

☑️ 2430 BLDC vibration motors come with top quality sintered neodymium iron-boron magnets, which offer outstanding conductivity and long-lasting. They are known for their magnetic field strength as well as their resistance to demagnetization the triple-layer treatment applied to the magnets gives them outstanding rust resistance.

☑️ With a strong temperature range of 80degC up to 200degC, our BLDC vibration motors can endure a variety of operating conditions.

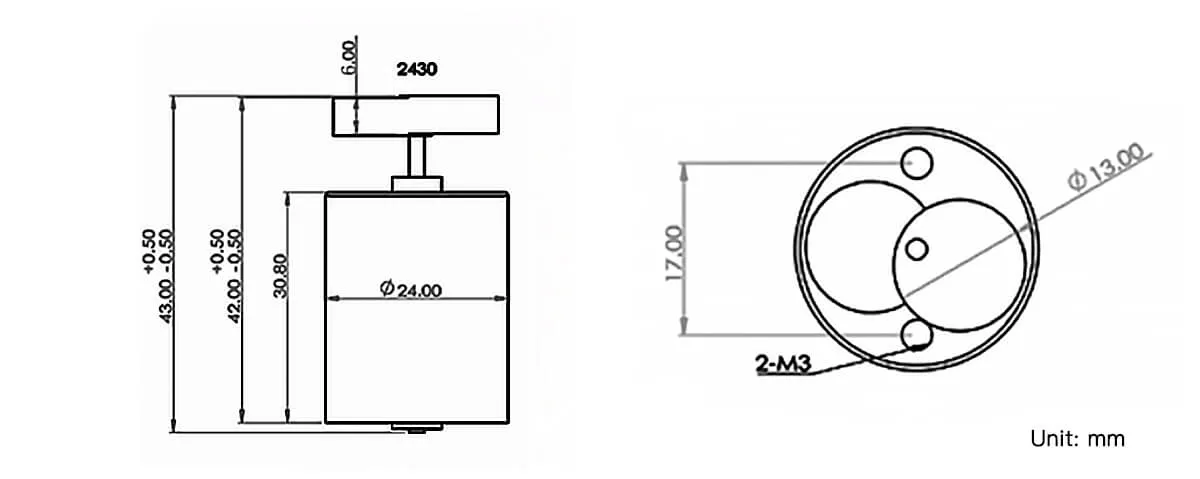

| Motor Model | TSL-BV2430-SR |

| Motor Diameter | 24mm |

| Motor Length | 30.8mm (not include eccentric vibrating head) |

| Total Length | 43mm |

| Eccentric Diameter | 13mm |

| Rated Voltage | 12V / 24V DC |

| Rated Speed | 3,000rpm / 6,000rpm |

| Rotation | CW / CCW |

| Weight | appr. 62g |

Low Current Consumption BLDC Vibration Motor Mechanical Drawing

☑️ TSL-BV2430-SR motors that have built-in brushesless drives that provide simple plug-and play, a high-quality brushless coil protection. Features like stopping and speed control, as well as for both reverse and forward.

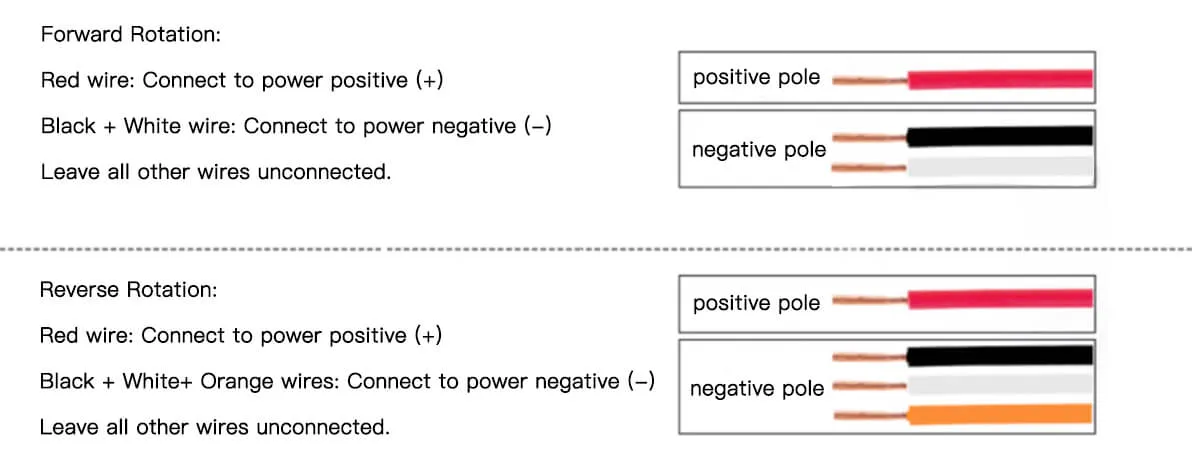

High Power and Efficiency BLDC Vibration Motor Wiring Diagram

Red Wire Connects with the positive (+) terminal of the motor’s power supply. Choose the DC energy source which is compatible with the specifications of the motor.

Black Wire Connects to the Negative (–) terminal of the motor’s power source.

Yellow Wire provides an FG signal output, which can be used by other devices to measure the speed of motors by producing 9 square wave signals for each motor revolution.

White Wire adjusts both the frequency of duty and the pulse width to an interval of 15-25KHz. If it is not being used for adjustment you can connect it directly with the black wire in order to operate the motor at its maximum speed.

Orange Wire controls motor’s direction of rotation (reverse when connected to the black wire) and also features overcurrent protection, with an upper limit of 0.8A. If the current is temporarily higher than 0.8A it will be automatically put into protection mode and then lock. In order to resume functioning, the source must be shut off and turned back on.

⚠️Be aware that positive and negative poles on a brushless motors should not be reversed.

Customized Solutions

Keywords:

Miniature vibration motor high-torque vibrating motor, high-precision vibrating motor

Development Samples:

The quantities of sampling for models that are stocked can be ordered directly online from us.

Engineering & Manufacturing:

Contact any or the Sales Engineers for a quotation for production as well as a consultation regarding customizing and integration services.

Payment Method:

Payment methods: Paypal or T/T

Shipping Method:

1.Delivery: DHL door to door, 5-7 days.

2.Item will be delivered within 1-3 days of the payment.

3.If you’ve not received the item by the delivery Time please send us an email with any queries. In most cases, we will send you a reply within 24 hours If not, please examine the spam in your email inbox. We will try our best to assist you to solve your issues.

4.Please check that your address matches the address of your final shipment before you make payment.

5.In order to make sure you get your order tax-free after importation, we’ll declare it at the lower amount, so please note this in your order, thank you!

FAQ – Frequently Asked Questions

Q:If you are requesting a custom-made version What information do you need to include?

A: You should provide the essential specifications of the motor. This includes Dimensions and Sizes Applications Voltage, Speed, and Torque. It is recommended to send an application-specific prototype drawing to us whenever possible.

Q: What are your primary motor?

A: Diameter 4mm~42mm Dc Micro Motor And Gear Motor, Auto Dc Motor, Electric Motor, Gear Motor, Mini Dc Motor, Brush Dc Motor, Brushless Dc Motor, Spur Gear Motor, Micro Motor, Vibration Motor Etc.

Q: What’s the principal use of the microdc motor?

A Mini DC motors are used extensively in home Applications, Office Equipment, Health-Care Application, Sanitation Industry The High-End Toy Banking System Electronic and Electrical Tools, Automation Industry, Bank Equipments, Payment Equipments, Vending Machines, Power Door Lock, Electric Door Lock.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration.We also offer DC motors and Gear motors.

Reviews

There are no reviews yet.