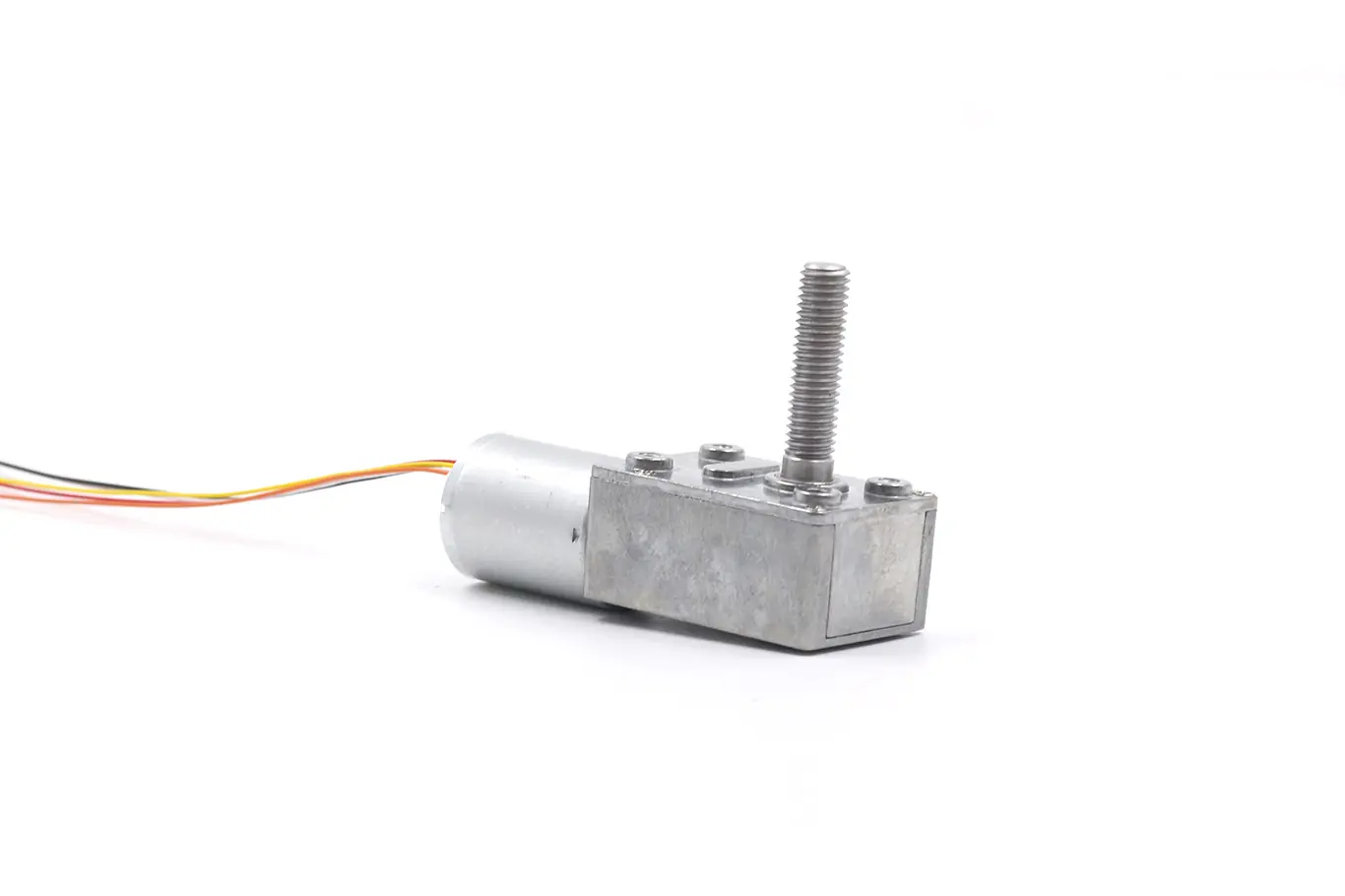

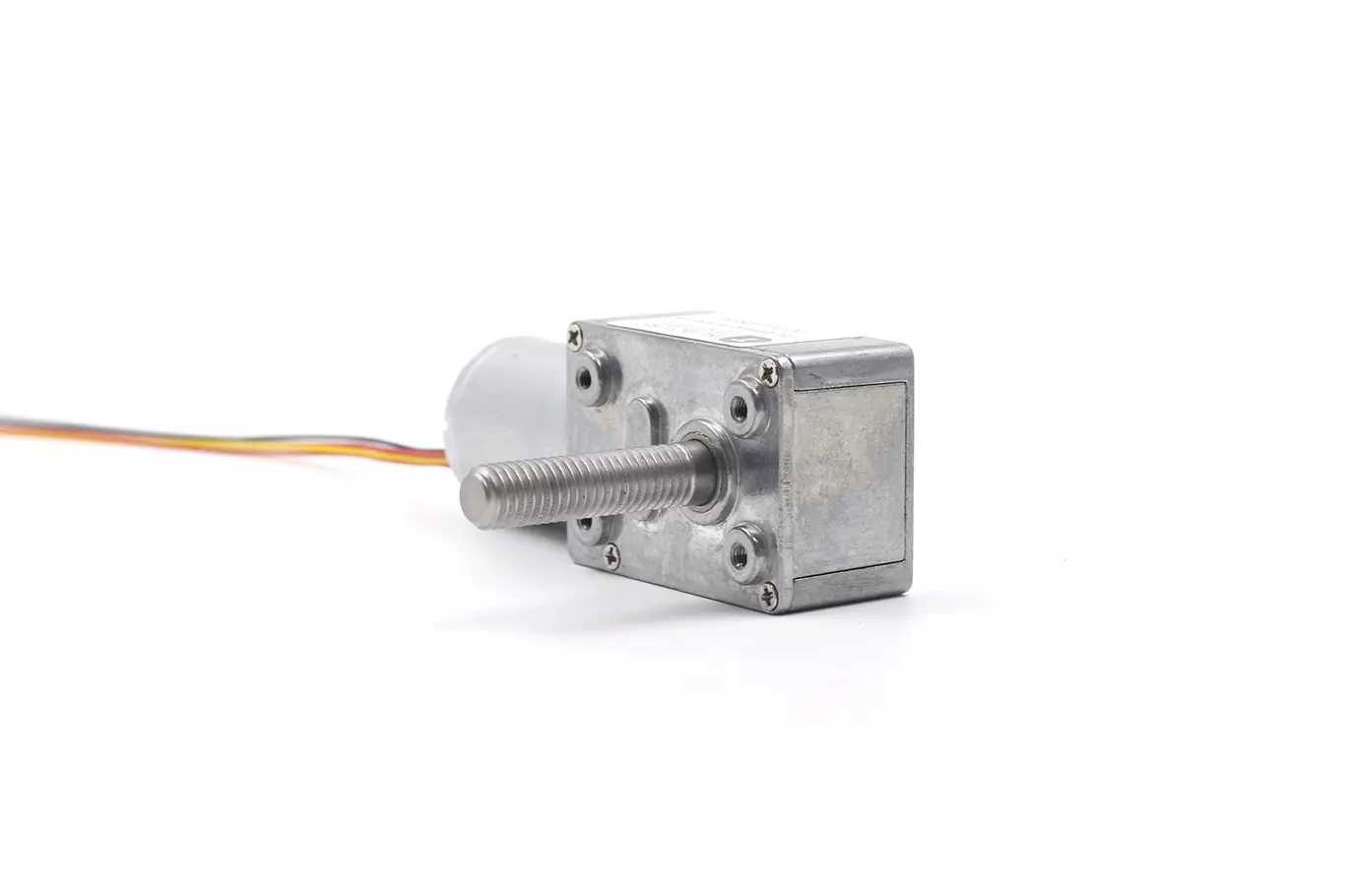

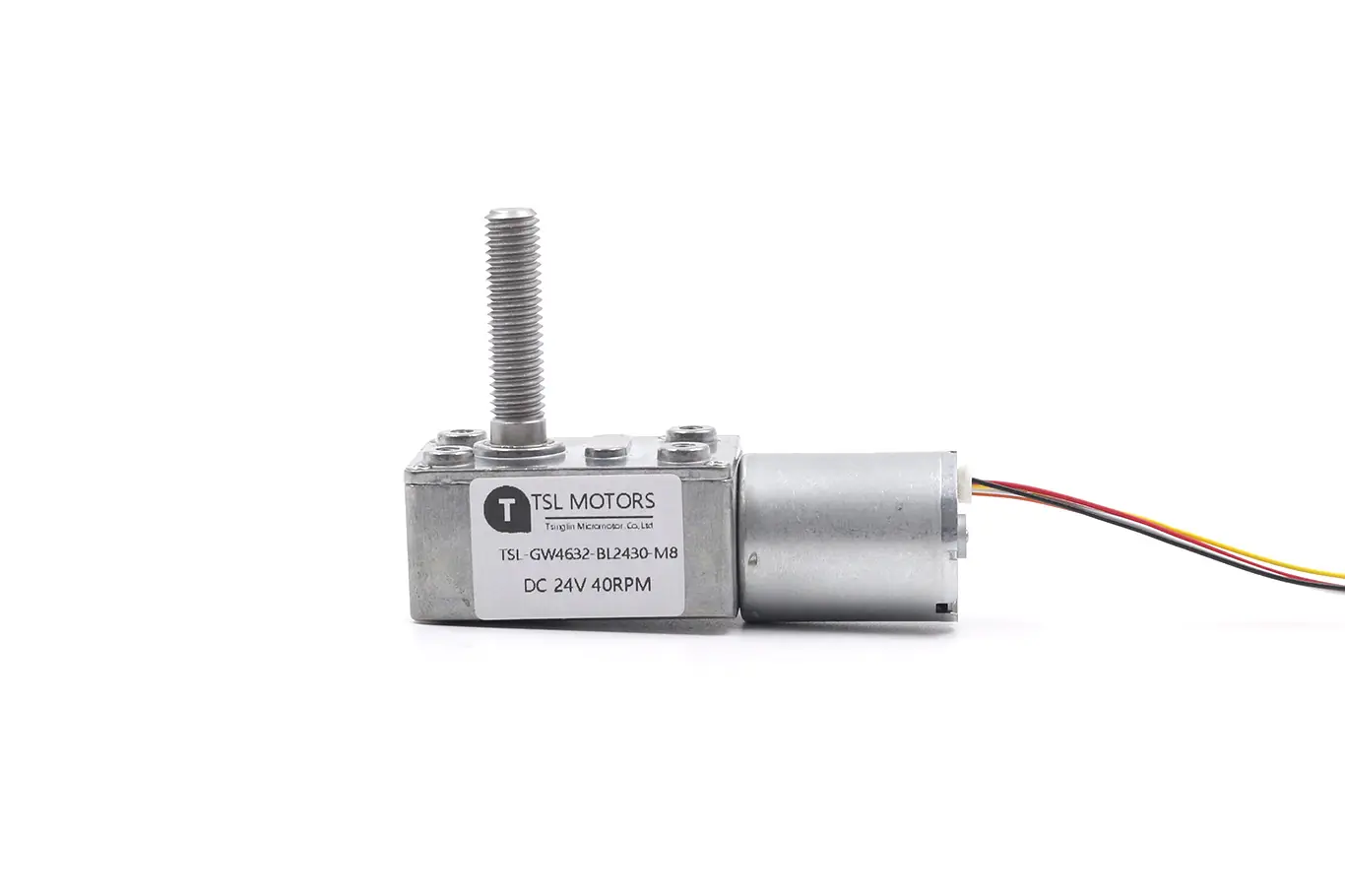

24mm Brushless Worm Gear Motor TSL-GW4632-BL2430-M8

Basic Info:

- Motor Type:Worm Gear Motor

- Motor Model:TSL-GW4632-BL2430-M8

- Rated Voltage:12V /24V DC/Customizable

- Max Rated Torque :25 Kg.cm

- Max Power:7W

- Maximum No-Load Speed:2 RPM

- #More Specifications

- #Outline Drawing

Typical application:

- Automatic Mahjong Table,Automatic Mahjong Machine

- Medical Equipment, Medical Devices

- Automated Teller Machine ,Artificial Intelligence Robot,Parking Lock

Electric Motor DC Brushless With Worm Gearbox Parameters

TSL-GW4632-BL2430-M8, 12 V , 7.2W

| Ratio | No Load | Rated Load | Stall | Starting | ||||

| i : 1 | Speed | Current | Speed | Current | Torque | Current | Torque | Voltage |

| 40: 1 | 150 rpm | 0.12A | 112 rpm | 0.6A | 1.5kg.cm | 2A | 6.4kg.cm | 5V |

| 65: 1 | 90 rpm | 0.12A | 70 rpm | 0.6A | 2.4kg.cm | 2A | 10kg.cm | 5V |

| 90: 1 | 66 rpm | 0.12A | 50 rpm | 0.6A | 3kg.cm | 2A | 13kg.cm | 5V |

| 150: 1 | 40 rpm | 0.12A | 30 rpm | 0.6A | 5.6kg.cm | 2A | 23kg.cm | 5V |

| 200: 1 | 30 rpm | 0.12A | 22 rpm | 0.6A | 7.4kg.cm | 2A | 30kg.cm | 5V |

| 260: 1 | 23 rpm | 0.12A | 17 rpm | 0.6A | 10kg.cm | 2A | 40kg.cm | 5V |

| 340: 1 | 18 rpm | 0.12A | 13 rpm | 0.6A | 12kg.cm | 2A | 52kg.cm | 5V |

| 448: 1 | 13 rpm | 0.12A | 10 rpm | 0.6A | 14kg.cm | 2A | 61kg.cm | 5V |

| 600: 1 | 10 rpm | 0.12A | 7 rpm | 0.6A | 19kg.cm | 2A | 81kg.cm | 5V |

| 1000: 1 | 6 rpm | 0.12A | 4 rpm | 0.6A | 25kg.cm | 2A | 136kg.cm | 5V |

| 1800: 1 | 3 rpm | 0.12A | 2.5 rpm | 0.6A | 25kg.cm | 2A | 136kg.cm | 5V |

| 3000: 1 | 2 rpm | 0.12A | 1.5 rpm | 0.6A | 25kg.cm | 2A | 136kg.cm | 5V |

💕The electric motor dc brushless’s technical specifications are for guidance,we offer custom solutions upon request.

TSL-GW4632-BL2430-M8, 24 V , 7.2W

| Ratio | No Load | Rated Load | Stall | Starting | ||||

| i : 1 | Speed | Current | Speed | Current | Torque | Current | Torque | Voltage |

| 40: 1 | 150 rpm | 0.06A | 112 rpm | 0.3A | 1.5kg.cm | 1A | 6.4kg.cm | 6V |

| 65: 1 | 90 rpm | 0.06A | 70 rpm | 0.3A | 2.4kg.cm | 1A | 10kg.cm | 6V |

| 90: 1 | 66 rpm | 0.06A | 50 rpm | 0.3A | 3kg.cm | 1A | 13kg.cm | 6V |

| 150: 1 | 40 rpm | 0.06A | 30 rpm | 0.3A | 5.6kg.cm | 1A | 23kg.cm | 6V |

| 200: 1 | 30 rpm | 0.06A | 22 rpm | 0.3A | 7.4kg.cm | 1A | 30kg.cm | 6V |

| 260: 1 | 23 rpm | 0.06A | 17 rpm | 0.3A | 10kg.cm | 1A | 40kg.cm | 6V |

| 340: 1 | 18 rpm | 0.06A | 13 rpm | 0.3A | 12kg.cm | 1A | 52kg.cm | 6V |

| 448: 1 | 13 rpm | 0.06A | 10 rpm | 0.3A | 14kg.cm | 1A | 61kg.cm | 6V |

| 600: 1 | 10 rpm | 0.06A | 7 rpm | 0.3A | 19kg.cm | 1A | 81kg.cm | 6V |

| 1000: 1 | 6 rpm | 0.06A | 4 rpm | 0.3A | 25kg.cm | 1A | 136kg.cm | 6V |

| 1800: 1 | 3 rpm | 0.06A | 2.5 rpm | 0.3A | 25kg.cm | 1A | 136kg.cm | 6V |

| 3000: 1 | 2 rpm | 0.06A | 1.5 rpm | 0.3A | 25kg.cm | 1A | 136kg.cm | 6V |

💕The electric motor dc brushless’s technical specifications are for guidance,we offer custom solutions upon request.

⇒Unit Coversion: 1 g·cm ≈ 0.098 mN·m ≈ 0.014 oz·in;1 mm ≈ 0.039 in;1 g ≈ 0.035 oz1

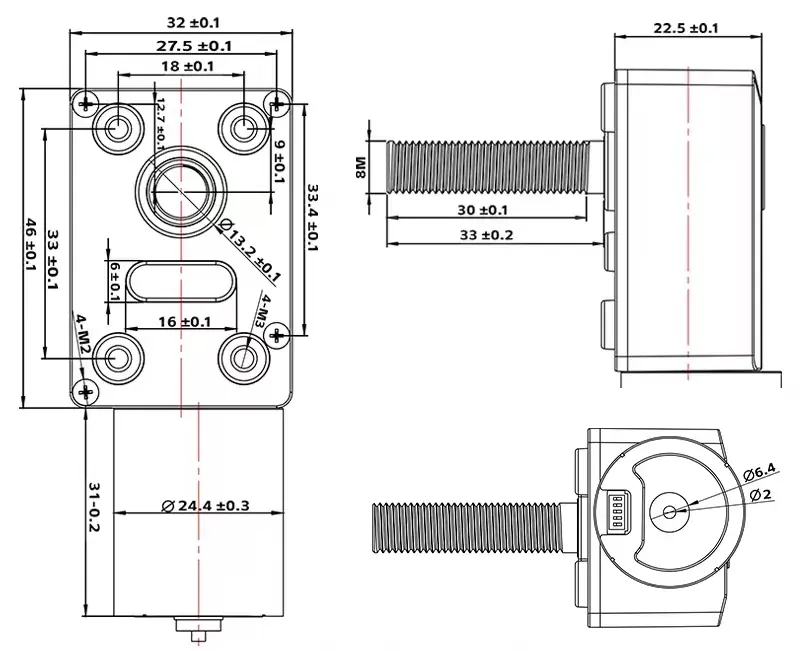

Electric Motor DC Brushless With Thread Shaft Mechanical Drawing

Unless otherwise stated, all dimensions are in millimeters. The provided drawings are for illustrative purposes; please contact us to verify precise specifications.

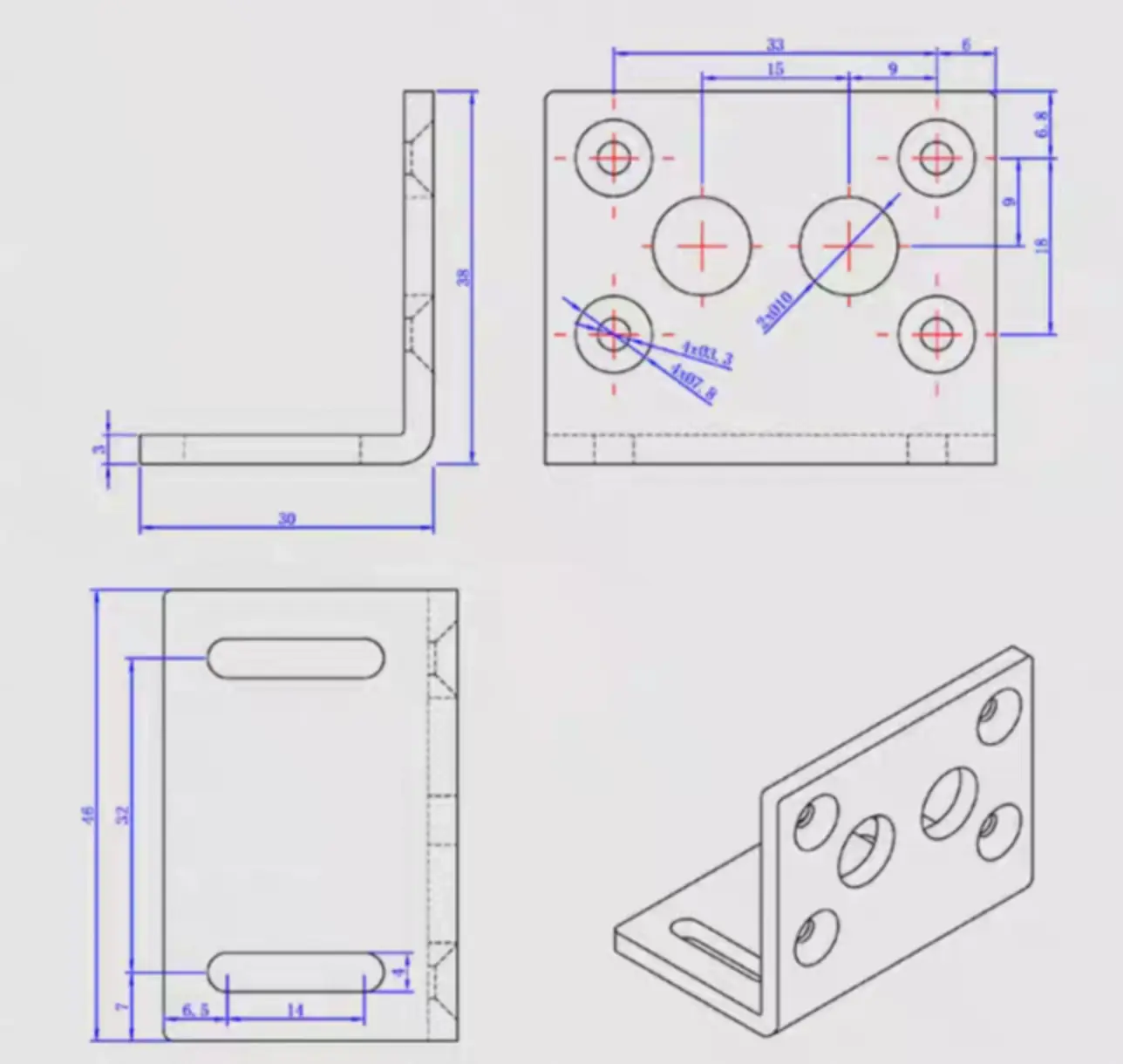

Electric Motor DC Brushless 4632 Worm Gearbox Mounting Bracket

Unless otherwise stated, all dimensions are in millimeters. The provided drawings are for illustrative purposes; please contact us to verify precise specifications.

Electric Motor DC Brushless Custom Shafts Available

These are just a few examples of our output shafts. For customization or special requests, please contact us.

Electric Motor DC Brushless Datail Presentation

Threaded Output Shaft

The threaded output shaft provides a reliable connection that is easy to install and remove. Furthermore, it boasts excellent self-locking capability, high structural strength, and good retraction/extension performance.

Metal Gears are Stable and Efficient

All are made of high-quality metal materials, which have the characteristics of good impact resistance, durability, and noise reduction, thereby prolonging the service life of the reducer. The output shaft is made of 1140 steel, which is more durable and wear-resistant.

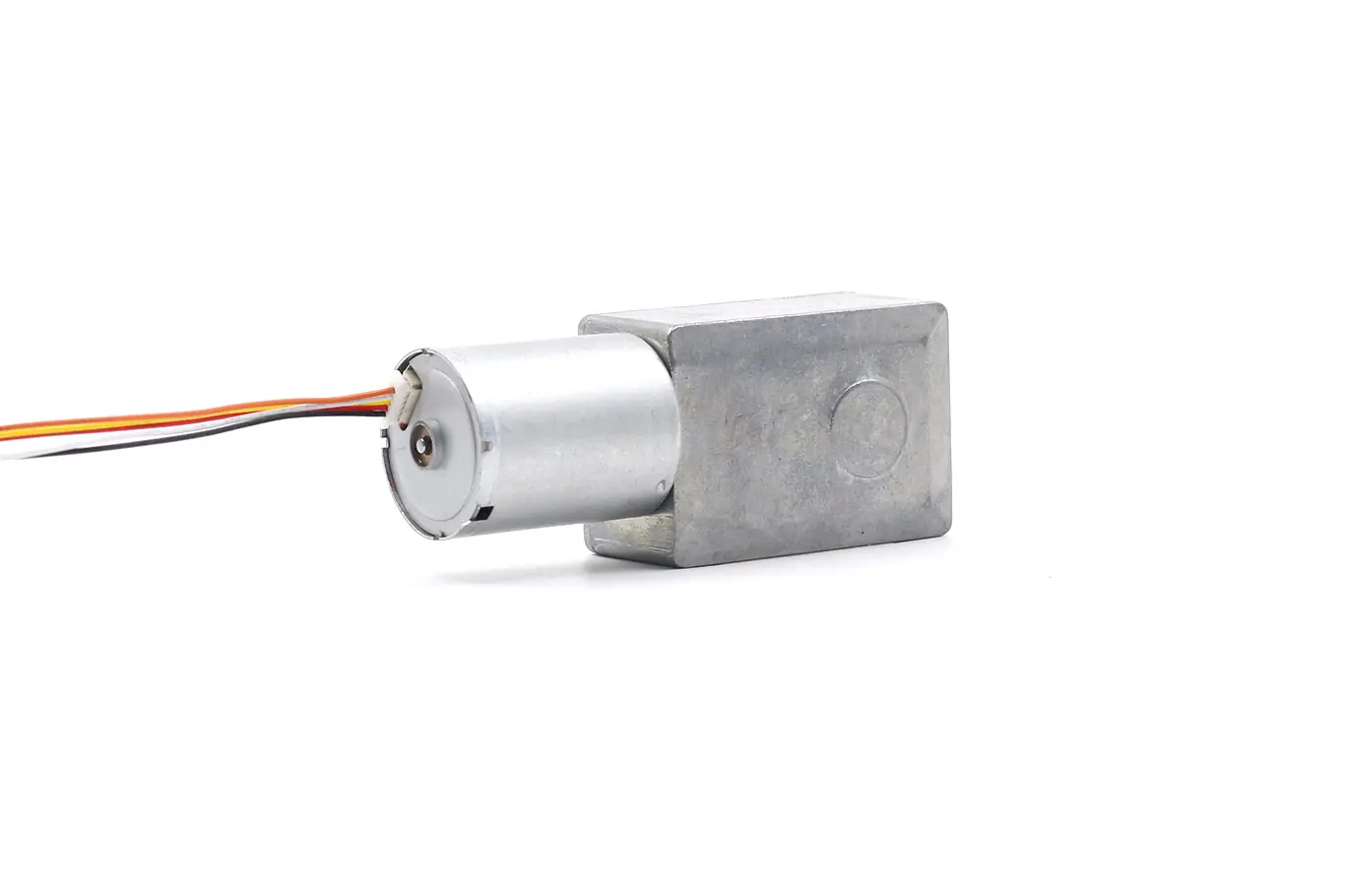

Built-in Hall Driver

Pulse PWM speed regulation function, free switching between forward and reverse rotation, FG signal speed regulation function, overcurrent protection function 0.8A, overvoltage protection function 30V, overtemperature protection function 80°C.

Small Body And Big Power

100% pure copper coils have less resistance than aluminum wires and stronger conductivity. At the same time, copper wires also have the characteristics of low heat generation and long service life, maximizing the reduction of energy loss and making the motor’s power output continuously.

Electric Motor DC Brushless Installation Knowledge

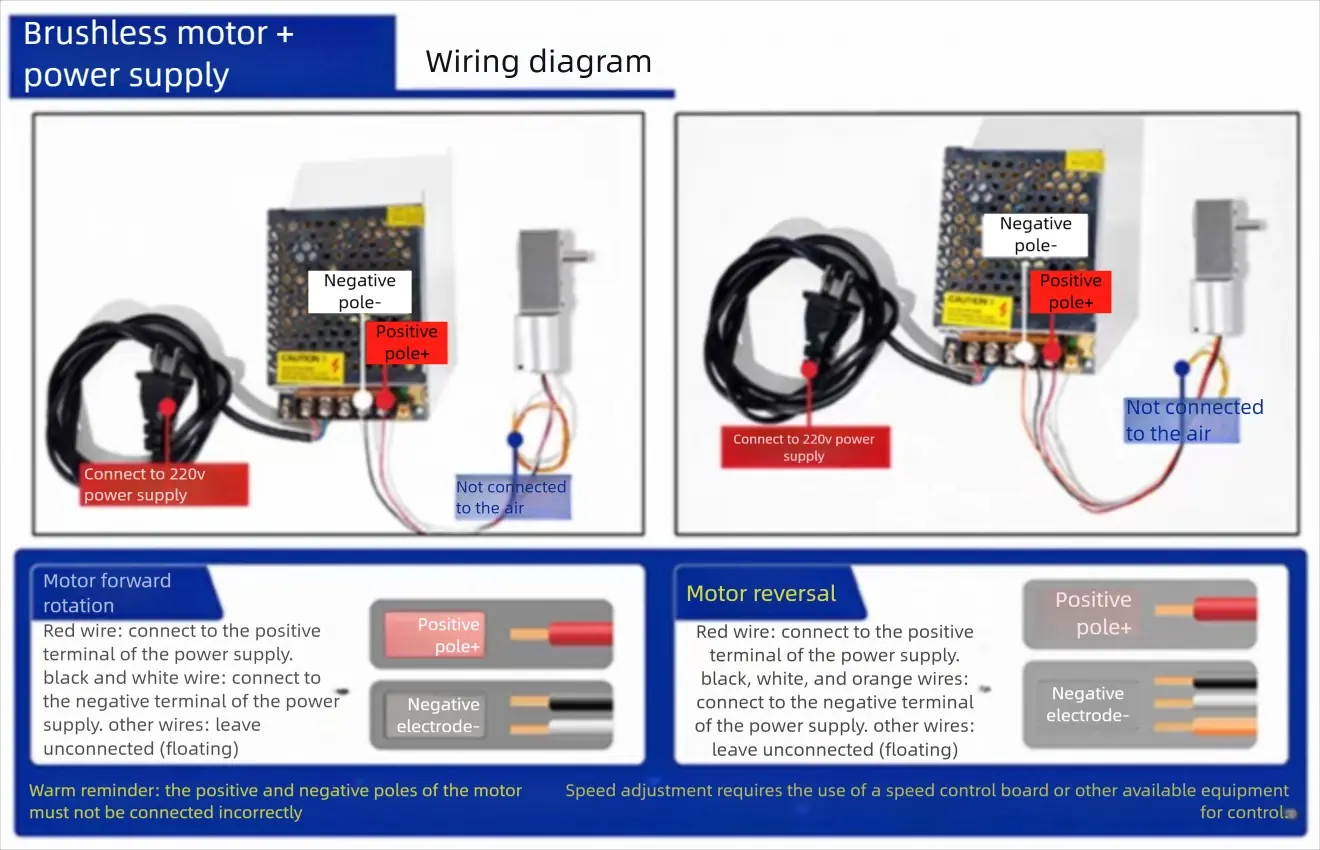

Electric Motor DC Brushless Wiring Mode

| Wiring Sequence Description of 2418 (Built - in Drive Version) Brushless Motor | |||||

| No. | Signal | I/O | specs | Remark | |

| 1 | Motor Power Supply Port (VCC) | Input | DC12V (OPERATING RANGE: 8V - 15V), DC24V (OPERATING RANGE: 8V - 26V) | red lead, motor power supply input | |

| 2 | Ground(GND) | Input | Ground | black lead, ground | |

| 3 | CW&CCW | Input Voltage | Input | 0-5.0V | range lead, direction switching |

| High - level VIH | Min 5V | reverse rotation, high - level = CCW | |||

| Low - level VIL | Max 0.3V | forward rotation, low - level = CW | |||

| 4 | Frequency Generator (FG) | High - level VOH | Ouput | 1.5V ≤ U ≤ 5.0V, AT 5V | yellow lead, this is an open - collector output (NPN), and the FG output can be used to detect the speed according to the phase shift |

| Low - level VOL | 0.6V Max | ||||

| Signal current | 3 MA Max | ||||

| Number of pulse outputs | 9 pulses | ||||

| 5 | Pulse Width Modulation (PWM) | Input Voltage | Input | 0-5.0V | white lead |

| High-Level VIH | Min 5V | motor stops, high - level = motor stops | |||

| Low-level VIL | Max 0.23V | motor runs, low - level = motor runs | |||

| recommended pulse usage range 15KHZ - 35KHZ | speed regulation from 0.23V to 5V, the motor runs at high speed to low speed until it stops | ||||

Remarks

- The positive and negative poles must not be connected incorrectly and must not be used interchangeably.

- When changing the direction, be sure to stop the motor before switching the direction; otherwise, the electronic and mechanical parts may be damaged!

- Due to the reduction gear structure, the factory – set rotation direction of the motor is not uniformly forward/reverse (some reduction ratios may default to reverse/forward output).

- Lowering the speed will reduce the output torque. Please select the output speed reasonably (the reduction ratio determines the torque).

Keywords:

thread shaft motor,bldc motor,low speed high torque bldc motor,brushless dc electric motor

Development Samples:

If you need samples, please contact us.

Engineering & Manufacturing:

Contact any or the Sales Engineers for a quotation for production or consultation on the integration and customization of your product.

Payment:

1.Payment methods : Paypal, T/T

Shipping:

1.Delivery: DHL/FedEx 3-5 days.

2.Item will be shipped within 1-3 business days after the payment.

3.If you haven’t received the item on the Delivery Time, pls contact us by email if you have any questions. Normally, we will give you a reply within 24 hours, if not, pls check the spam of your email box. We will do our best to help you solve the problems.

4.Please make sure your address is matched with the finally shipping address before you pay.

FAQ for Brushless DC motor

Q:What is Brushless DC motor?

A:A brushless DC motor eliminates the need for a commutator and brushes by placing permanent magnets on the rotor. The rotor’s rotation is controlled by detecting its magnetic poles and adjusting the current flow through the coils accordingly.

If you want a video to explain the principle of Brushless DC motor, you can click on this link:https://www.youtube.com/watch?v=1AaUK6pT_cE

Q:Can worm Gear Motor Be Customized?

A: Yes,worm gear motor can be customized. TSL Motors, a top manufacturer, offers options to adjust torque, speed, and voltage. This ensures the motor meets the specific needs of your application.

Q: How do I place an order?

A: Send us an inquiry and we will send you a quote – make arrangements – confirm the sample – sign the contract/deposit mass production – delivery ready for delivery. Balance/delivery

Q: What about Sample Order?

A: Sample are available to you. Contact us for specifics. If we charge you a cost for the sample, you can take it at ease, as it will be the refund you receive when you make a formal order.

Q: If it is a customized version the information you provide, what should you include?

A: You should give the fundamental specifications of the motor, for example Dimensions Applications, Sizes as well as Voltage, Speed and Torque. It is better to provide an application-specific prototype drawing to us when you can.

Tap:If you request a quotation for mass production quantities, contact us for customizations and integration.

Motor Customization Guide

Please tell us your requirements. Our engineers will give you the best solution for your application.

✅Collaborate with Specialists

Our engineering team brings decades of motor technology expertise to every project.

✅Seamless Global Partnership

Communicating with us is a breeze.

We’ll adapt to your time zone, making sure that information and ideas are exchanged promptly.

Right from the start, you can rest assured that your thoughts are fully grasped.

Get In Touch

Start a discussion with our team today!