Worm gearbox is a mature mechanical transmission. It features a compact structure, high reduction ratio, and excellent self-locking performance. It is widely used in automation equipment, lifting systems, and precision drives that require low speed and high torque.

TSL MOTORS has over 15 years of experience in micro reduction motors. With expertise and innovation, we provide high-performance worm gearbox solutions to customers worldwide.

Key Takeaways

- The worm gearbox achieves high reduction ratios and high torque.

- The worm and worm wheel transmit power through sliding engagement.

- The self-locking feature prevents load back-driving when powered off.

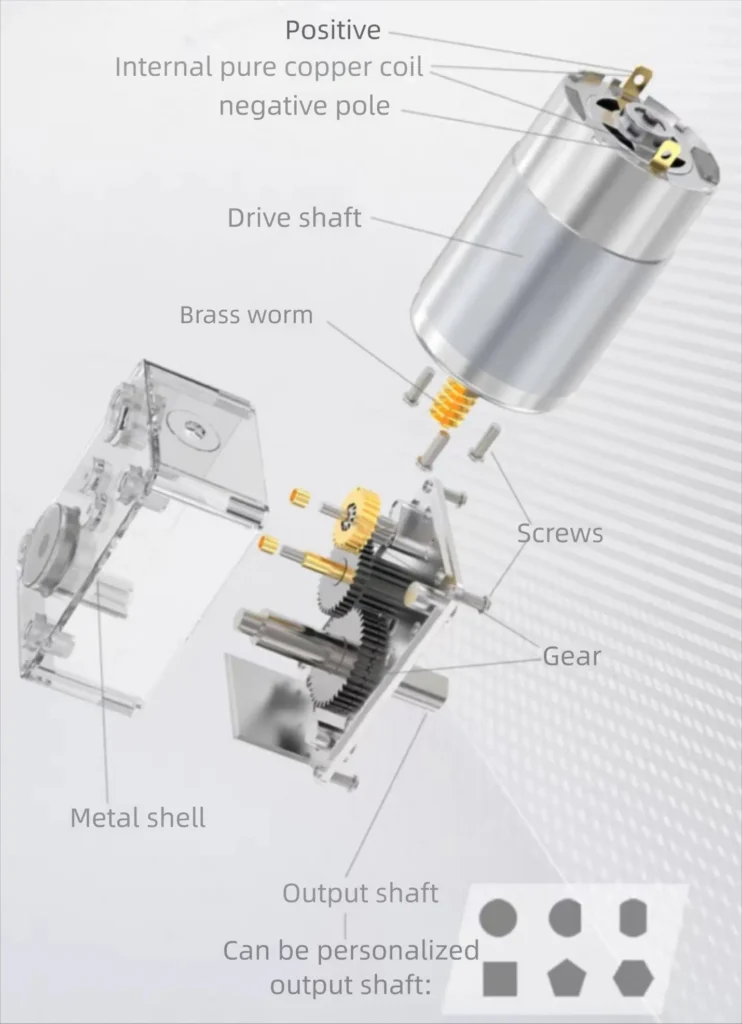

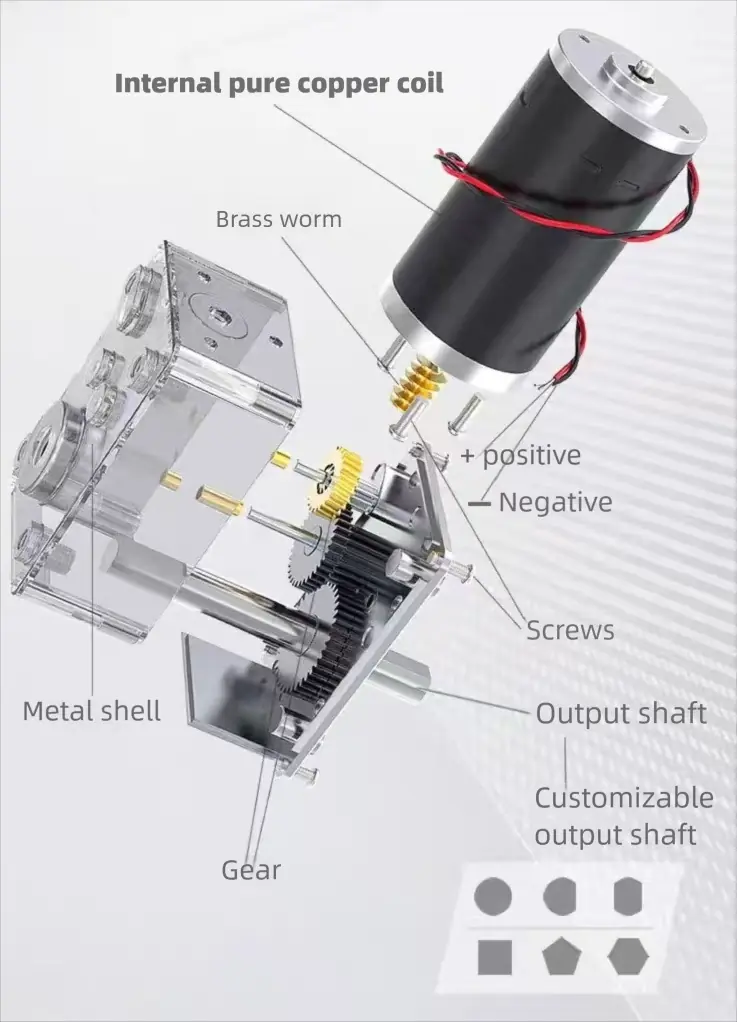

- The micro worm gearbox consists of a single-stage worm and a spur gear transmission system.

- In the worm gearbox, the brass worm wheel reduces friction and noise, while the steel spur gear ensures strength.

- The worm gearbox is suitable for micro actuators, robotic hands, medical devices, and smart hardware.

What is a Worm Gearbox?

A worm gearbox consists of a worm screw (worm) and a worm wheel meshing together. Its core is the sliding friction between the worm’s helical teeth and the worm wheel teeth. This geometry allows a single-stage transmission to achieve a very high reduction ratio.

- The worm resembles a threaded shaft.

- The worm wheel resembles a helical or angled gear.

Unlike standard gears, a worm does not transmit power through rolling. It mainly relies on sliding contact. This affects reduction capability, self-locking, and material selection.

The worm and worm wheel axes are usually arranged at 90°, allowing direction change and reduction in a compact space.

How Does a Worm Gearbox Work?

The working principle of a worm gearbox is essentially the transmission process of the worm and worm wheel.

The transmission process of a worm gear can be imagined as a screw (the worm) turning a specially designed nut (the worm wheel).

Input rotation: The motor or power source drives the worm along its axis.

Helical push: The worm’s helical teeth slide along the worm wheel teeth, generating two key forces:

- Tangential force: rotates the worm wheel.

- Normal force: keeps the teeth engaged and creates friction.

Reduced output: The worm rotates many times to turn the worm wheel once, producing a large reduction ratio and amplifying torque.

Why Can Worm Gearbox Self-Lock?

When the worm has a shallow thread angle and high friction, you cannot turn the worm by twisting the nut. This is the principle of self-locking.

In a worm screw gearbox, the lead angle of the worm is usually very small. When the lead angle is smaller than the friction angle, the worm wheel teeth cannot overcome friction to drive the worm.

This is the core condition of self-locking.

The worm can easily drive the worm wheel, because the power source provides enough tangential force. But the worm wheel cannot back-drive the worm, since its force is not enough to overcome friction and geometry.

Sliding friction not only reduces efficiency, but also creates damping when no power is applied. This further enhances the self-locking effect.

Advantages of Worm Gearboxes

Worm gearboxes combine single-stage high reduction, reliable self-locking, smooth quiet operation, and compact structure. They are ideal for applications requiring safe positioning, low noise, and space efficiency.

Single-stage high reduction: One stage can achieve dozens of times reduction, simplifying structure and reducing maintenance.

Reliable self-locking: The wheel cannot drive the worm. Systems maintain position without power.

Note: Self-locking is not absolute. In strong vibration or impact, backup brakes are recommended.

Smooth and quiet: Sliding contact avoids gear impacts. Suitable for medical and precision equipment.

Compact structure: Axes at 90° allow direction change and space-saving design.

Typical Applications of Worm Gearboxes

Worm gearboxes bring unique advantages. They solve critical pain points: safety, holding, compactness, silence. In these applications, performance trade-offs make them the optimal choice. No substitute delivers the same balance.

Micro Actuators & Positioning Systems

In precision positioning systems, the self-locking characteristic is a decisive factor. The geometric structure of worm gears inherently offers a one-way transmission advantage: the motor can easily drive the load when activated, yet the load can barely push the worm shaft backward when exerting a reverse force.

This translates to three key benefits:

- No additional brakes are required after power-off, and the system remains stable and secure.

- The structure is simplified, reducing the number of components and enhancing operational reliability.

- In scenarios such as optical focusing and precision experimental platforms, it ensures that lenses or probes stay firmly in place after micron-level adjustments, without shifting due to vibration or reverse load forces.

This is the reason why worm gearboxs are the preferred choice for many micro linear actuators and electric adjustment mechanisms.

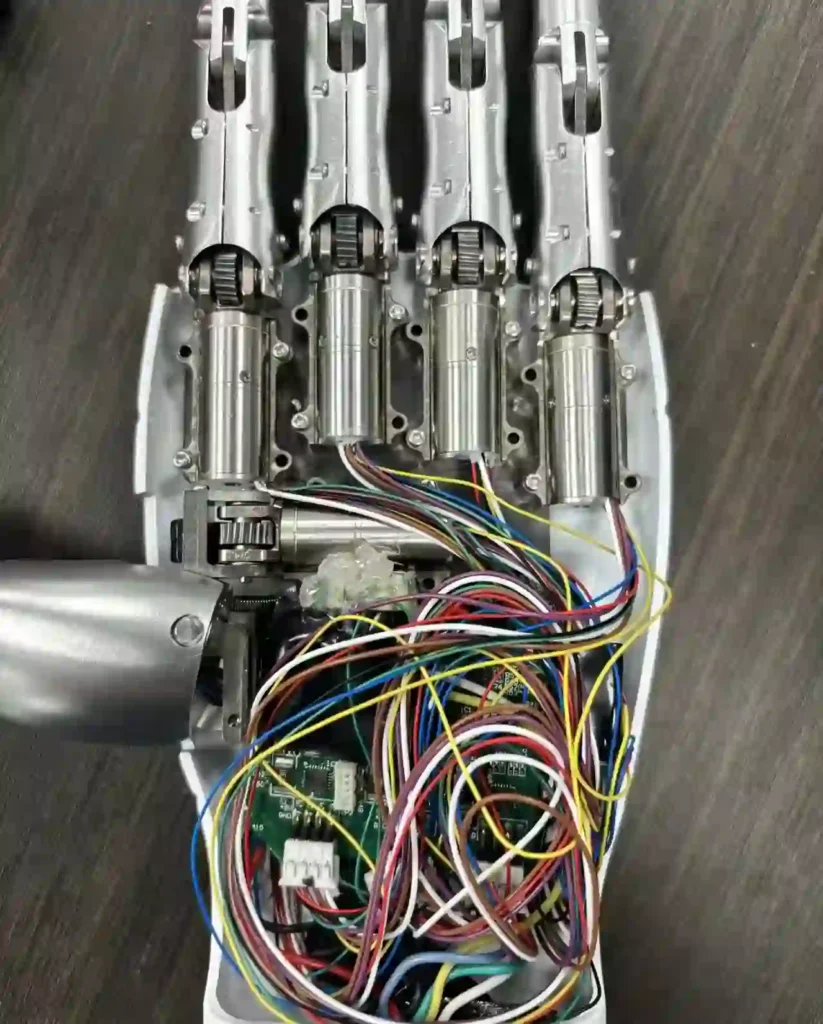

Dexterous Hands and Thumb Mechanisms

In the design of bionic robots or dexterous hands, the thumb is one of the most complex and critical joints.It needs to not only grasp objects.But also perform multi-degree-of-freedom movements.Such as pinching, rotating, and opposing fingers.

The advantages of worm gears here are very prominent:

- High reduction ratio and compact structure: Achieve high reduction ratio in limited space. Ensure the thumb has sufficient grasping force.

- Self-locking for stability: Remain firm when powered off or stationary. Won’t loosen due to external forces.

- Smoothness and precise control: Sliding meshing enables smooth movements. Facilitates fine angle adjustment.

- Safety and bionic performance: Avoid reverse impact. Make movements safer and closer to the natural performance of human hands.

Therefore, in the design of dexterous hands.Especially for thumb joints.Worm gears are often used as the first reduction stage.Subsequently combined with gear or link structures.To achieve a compact and reliable transmission solution.

Medical and Laboratory Equipment

The design philosophy of medical equipment is this: quiet, stable, safe.The advantages of worm gears stand out here:

- Low noise: The sliding meshing characteristic of worm gears makes their operation much quieter than spur gears.

- Smoothness: There is almost no gear meshing impact during transmission. Adjustments of hospital beds or testing equipment are gentler.

- Safety: The self-locking feature prevents sudden movement of equipment during power failure or malfunction. It reduces risks.

Take examples like the lifting mechanism of hospital beds and the angle adjustment module of laboratory instruments.Worm gears not only provide sufficient torque.They also ensure user safety.

Valves and Fluid Control Actuators

Industrial valve actuators are a traditional stronghold for worm gears.The reason is simple:

- Valves require low speed and high torque to overcome fluid pressure.

- Once adjusted to the desired position, they must maintain the opening for a long time.The self-locking feature of worm gears meets this requirement perfectly.

They feature a compact structure and easy maintenance.For decades, they have been a reliable choice in industrial sites.This is why worm gear actuators remain mainstream in industries such as petrochemicals, power generation, and water treatment.

Micro-Automation and Smart Hardware

In smart devices and small automation modules, the design goals are often defined as:small size, high reduction ratio, and cost control.

Worm gear reducers can achieve a high reduction ratio in an extremely small space.When paired with DC motors or brushless motors, they deliver sufficient torque.

Their manufacturing process is mature.Costs are relatively low.They are suitable for large-scale applications.

In smart homes, micro-robots, and automation modules, worm gears often serve as the invisible transmission core.

Worm Gearbox:Why Worm Gear+ Spur Gears for Larger Reduction Ratios?

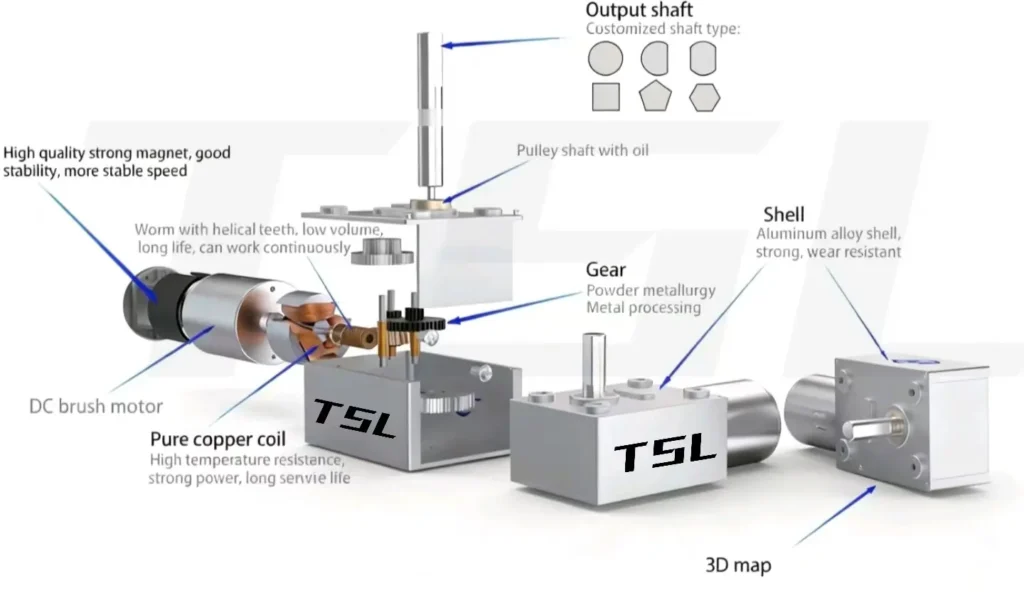

As shown in the figure below, in a micro worm screw gearbox, only the worm and gear are responsible for the first-step large reduction ratio + self-locking.Spur gears take charge of subsequent efficient amplification.

Limitations of Worm and Gear

They are suitable for achieving a large reduction ratio (tens to hundreds of times) in one step.But their efficiency is low (due to high sliding friction).They are not suitable for infinite series connection.Otherwise, efficiency will drop sharply, heat generation will be severe, and service life will be shortened.

Reasonable Division of Labor

- First stage: Worm and gear → Quickly obtain a large reduction ratio in limited space. Meanwhile, provide self-locking performance.

- Subsequent stages: Spur gears → Further amplify the reduction ratio. They feature high efficiency, strong transmission strength and long service life.

Advantages of Spur Gears

Their meshing method is rolling contact, resulting in low friction.Efficiency can reach over 95%.They have high strength and can withstand larger loads.With mature manufacturing processes and low costs, they are suitable for multi-stage series connection.

Why Brass Worms/Gears & Steel Spur Gears in Worm Gearboxes?

In a micro worm screw gearbox, worm and gear are made of brass for friction reduction and protection.Spur gears are made of steel for strength and efficiency.This soft-hard combination not only ensures the reliability of the gearbox.But also extends the overall service life.

Worm and Gear → Brass

- Reduce friction: Worm and gear adopt sliding meshing, leading to severe friction. Brass has excellent friction reduction performance.

- Prevent scuffing: Avoid seizure and scuffing issues caused by steel-to-steel contact.

- Low noise: Brass gear surfaces operate more quietly. They are suitable for scenarios such as medical and precision equipment.

Subsequent Spur Gears → Steel

- High strength: Spur gears bear rolling meshing with large loads. Steel ensures strength and service life.

- High efficiency: Spur gear efficiency can exceed 95%, making them suitable for multi-stage transmission.

- Durability: Steel gears are wear-resistant and fit for long-term operation. They have mature manufacturing processes and low costs.

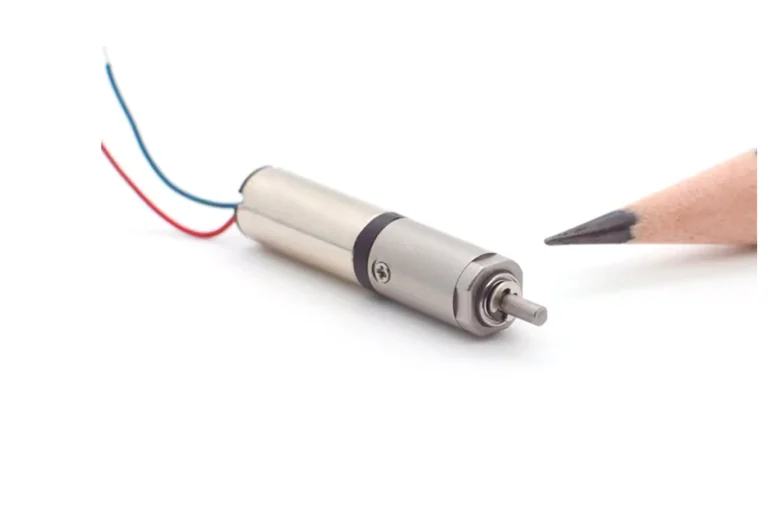

TSL MOTOR Micro DC Motor with Worm Gearbox

At TSL MOTOR, we do not supply standalone worm gear reducers.Instead, we offer highly integrated micro geared motors that combine motors and worm gear reducers as one unit.

This integrated design enables better overall control of output torque, efficiency, noise, temperature rise and service life.Compared with simple module assembly solutions, its reliability is significantly improved.

Motor Parameter Customization

Our regular motor customization requirements include:voltage, maximum no-load output speed, maximum no-load torque, high and low temperature requirements, diameter and length range, shaft output size and shape, wire length + terminal type, etc.

We ensure that motor characteristics are precisely matched with worm gear transmission characteristics.This guarantees stable operation under actual load conditions.

Structural Design Logic

All TSL MOTOR worm gear geared motors adopt single-stage worm gear output.This is because multi-stage worm gear series connection tends to cause efficiency loss and excessive heat generation.We ensure system service life and stability from the structural design stage.

Two Proven Solution Architectures

With over 15 years of manufacturing and R&D experience, TSL MOTOR has not only accumulated abundant engineering application data.We have also developed two mature, validated worm gear geared motor solutions:

Spur/Planetary Gearbox + Worm Gear Combination

The front or middle stage uses spur or planetary gear mechanisms for high-efficiency speed reduction.The motor output shaft directly drives the worm gear, which serves as the critical stage to achieve large reduction ratio and self-locking function.

This design balances motor efficiency, torque density and compactness.It is suitable for micro systems with high performance requirements.

Standardized Worm Gear Geared Motor

The motor output shaft is connected to a single-stage worm gear transmission.Subsequent transmission is completed by spur gears.This solution features a simple structure and compact size.

It meets the requirements of self-locking, low-speed high-torque output and space constraints.It is ideal for mass production and mature application scenarios.

Customization & Engineering Optimization

TSL MOTOR is always customer-oriented.We do not simply “stack parameters”.Instead, we carry out engineering optimization based on years of experience.We comprehensively consider load characteristics, operating conditions and space limitations.Products are delivered only after full internal testing and evaluation, ensuring reliability and consistency.

Output Shaft Customization

We support customization of shaft diameter, shaft length, D-shaped shaft, flat shaft, spline shaft, hollow shaft and special interface structures.This facilitates direct integration with customer systems.

Through integrated design, rational structural division of labor and engineering customization, TSL MOTOR’s micro worm gear geared motors not only ensure performance and reliability.They also provide flexible integration methods, suitable for various precision and intelligent application scenarios.

Conclusion

The worm screw gearbox is designed not for maximum efficiency but for large reduction, stable output, and reliable holding in limited space. Its sliding contact offers self-locking, low noise, and compactness, making it essential in micro actuators, robotic hands, medical devices, valves, and smart hardware.

In micro systems, the worm screw handles the main reduction and self-locking. Spur gears provide efficient subsequent transmission. The brass worm wheel + steel spur gear combination balances friction, strength, noise, and durability.

TSL MOTOR’s integrated design avoids performance mismatch from modular assembly and follows single-stage worm output principles to control efficiency loss, temperature rise, and lifespan risk.

With mature standard solutions and flexible custom options, TSL MOTOR delivers reliable, mass-producible, long-lasting micro worm screw motor solutions. For applications needing high torque, power-off holding, and compact, quiet operation, the worm screw gearbox remains a proven, rational choice.

FAQ

Q1:What is a worm screw gearbox?

A mechanical transmission that uses a worm and a worm wheel. It achieves high reduction ratios in a compact design.

Q2:How does it achieve self-locking?

The worm’s small lead angle and high friction prevent the worm wheel from driving the worm backward.

Q3:Why use brass for the worm wheel and steel for the spur gear?

Brass reduces friction and noise for sliding contact, while steel ensures strength and high efficiency for rolling contact.

Worm Gear Motor

TSL Motors is a leading manufacturer specializing in custom worm gear motors, offering dependable solutions tailored to meet the specific needs of various applications. With our in-depth knowledge of DC worm gear motors and gear technology, we assist OEMs in developing, identifying, and implementing innovative geared motor solutions with greater speed. These compact, quiet, self-locking motors, also capable of static damping, provide exceptional torque density.