Imagine your morning: an electric shaver, a coffee grinder, a smart watch vibration alert. At the heart of these everyday devices are small electric motor—the unsung heroes of small home appliances.

However, for makers, designers, or enthusiasts, the sheer variety of motor choices can be overwhelming. The right motor is key to a project’s success.

This guide aims to simplify your selection process. We will explore and recommend three main motor categories, classified by their function:

- Small DC Motors: For speed requirements (the Sprinters).

- Small DC Gear Motors: For power and torque requirements (the Weightlifting Champions).

- Small Vibration Motors: For haptic feedback (the Communication Masters).

Choosing a motor doesn’t have to be confusing. With over 15 years of industry experience in micro motors, TSL MOTOR will guide you through the secrets of micro motors, providing reliable power for your home appliance and creative designs.

Table 1: Motor Type Quick Comparison

| Motor Type | Primary Function | Typical Speed | Typical Torque | Common Small Appliance Applications | Relative Cost |

| Micro DC Motor | High-speed rotation | High | Low | Portable fan, electric toothbrush, foam whisk | Low |

| Micro DC Gear Motor | Low-speed, high-torque output | Low | High | Electronic lock, automatic pet feeder, robot joint | Medium |

| Vibration Motor | Generates vibration and haptic feedback | N/A (Vibration) | N/A (Vibration Force) | Smartphone, wearable device, game controller | Low to Medium |

Key Takeaways

- Small electric motors are categorized into three types: DC, Gear, and Vibration motors.

- Motor selection begins by defining the core need: high speed versus high torque.

- Power supply design must accommodate Stall Current, not just running current, for reliable startup.

- DC Gear Motors utilize a gearbox to sacrifice speed for significantly increased torque.

- Worm gear motors offer a self-locking feature to maintain position when power is off.

- Coreless motors provide high efficiency and fast response, suitable for high-end, battery-powered devices.

- The mounting position and method of Vibration Motors are crucial for effective haptic feedback.

Understanding Your Small Electric Motor Options

This section lays a solid knowledge foundation. It explains the “why” and “how” behind each samll electric motor type. This helps you understand the specifications in the following list.

The Classic Workhorse:Small DC Motors

A DC small electric motor converts DC electrical energy into mechanical rotational energy. It is the simplest and most common motor form. DC small electric motors include brushed and brushless DC types.

- Brushed DC Motors: Use brushes and a commutator for commutation. Simple structure. Low cost.

- Brushless DC Motors (BLDC): Rely on an electronic controller for commutation. No brush friction. High efficiency. Long lifespan.

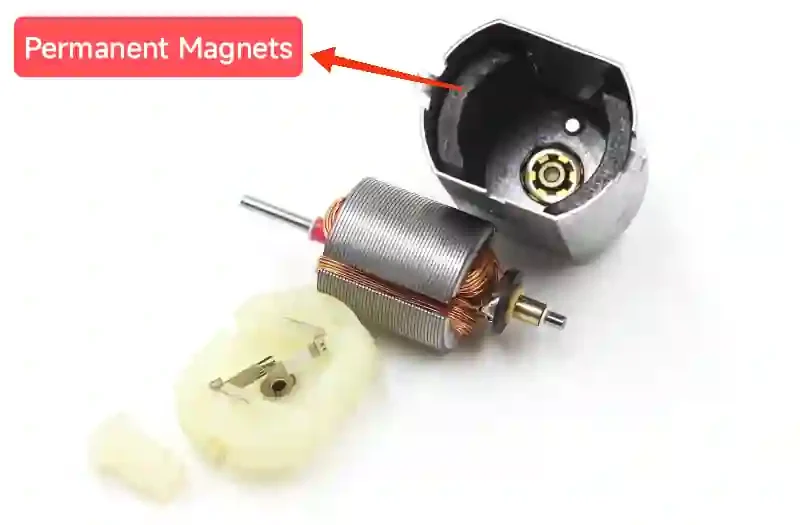

Brushed DC Motor Working Principle

Imagine the small electric motor’s operation as a magnet dance. A fixed magnetic field (stator) interacts with an electromagnetic field on the rotating part (rotor/armature). This interaction generates power. Key components include:

- Stator: The stationary outer shell. In small motors, this often contains permanent magnets.

- Rotor/Armature: The internal rotating part, wound with coils. Current makes the coils electromagnets.

- Commutator and Brushes: A clever mechanical switch. Brushes supply power to the commutator. The commutator reverses the current direction in the coil every half rotation. This ensures continuous “push” and “pull” for sustained rotation. This is the core mechanism of a brushed DC motor.

Tips: If you’d like to learn more about brushed DC motors, please click here. This article will not go into further detail.

Brushless DC Motor Working Principle

Imagine the same magnet dance, but without the mechanical dance partners—the brushes and commutator. An Electronic Controller replaces them. It is the smart conductor, precisely switching current between different coils.

- Stator: Still the fixed outer shell. It usually consists of multiple coils distributed around the circumference.

- Rotor: The internal rotating part. This usually contains embedded permanent magnets.

- Electronic Commutation: No brush friction. Sensors and control circuits determine the rotor’s position. They switch the current direction at the right time. The rotor constantly experiences continuous “push” and “pull,” maintaining smooth rotation.

Tips: If you’d like to learn more about brushless DC motors, please click here. This article will not go into further detail.

Key Characteristics

Speed is proportional to Voltage: A fundamental relationship. Want the motor faster? Increase the voltage. Want it slower? Decrease the voltage.

Torque is proportional to Current: The motor’s turning force (torque) depends on the current it draws. Heavier loads mean the motor draws more current to maintain speed.

High Speed, Low Torque: Standard DC motors are inherently fast but weak. They are great for fans or spindles. They struggle to drive heavy loads directly.

Selection and Application

Two critical points in DC motor selection are often overlooked. These are vital for project success.

First, the decisive role of Stall Current. Stall current is the current drawn when the motor is stopped by external force. This value is much higher than the normal running current.

For example, a motor may draw only 0.11A at no-load. But it can spike to 1.8A when stalled. Many beginners choose a power supply based on the running current. This is a severe error.

Every time the motor starts, it instantaneously draws current close to the stall current to overcome inertia. If the power supply cannot deliver this strong starting current, its output voltage will instantly collapse. This prevents the motor from starting. It can even reset the entire circuit.

Therefore, the power supply must be designed around the stall current baseline, not the running current. This is the primary electrical specification for reliable project startup.

Second, the limited lifespan of brushed motors. Constant physical contact and friction exist between the brushes and the commutator. This causes wear and is the most common failure mode for the motor. This might be fine for a simple hobby project.

But for a small appliance requiring long-term stable operation (like a high-end personal care device), it is a fatal flaw. In contrast, BLDC motors, though more expensive initially, have a much longer lifespan because they have no brush wear issue.

Thus, the choice between brushed and brushless motors is more than a cost consideration. It is a fundamental decision on product life cycle and reliability.

Tips: If you’d like to learn more about brushed DC motors VS Brushless DC Motors, please click here. This article will not go into further detail.

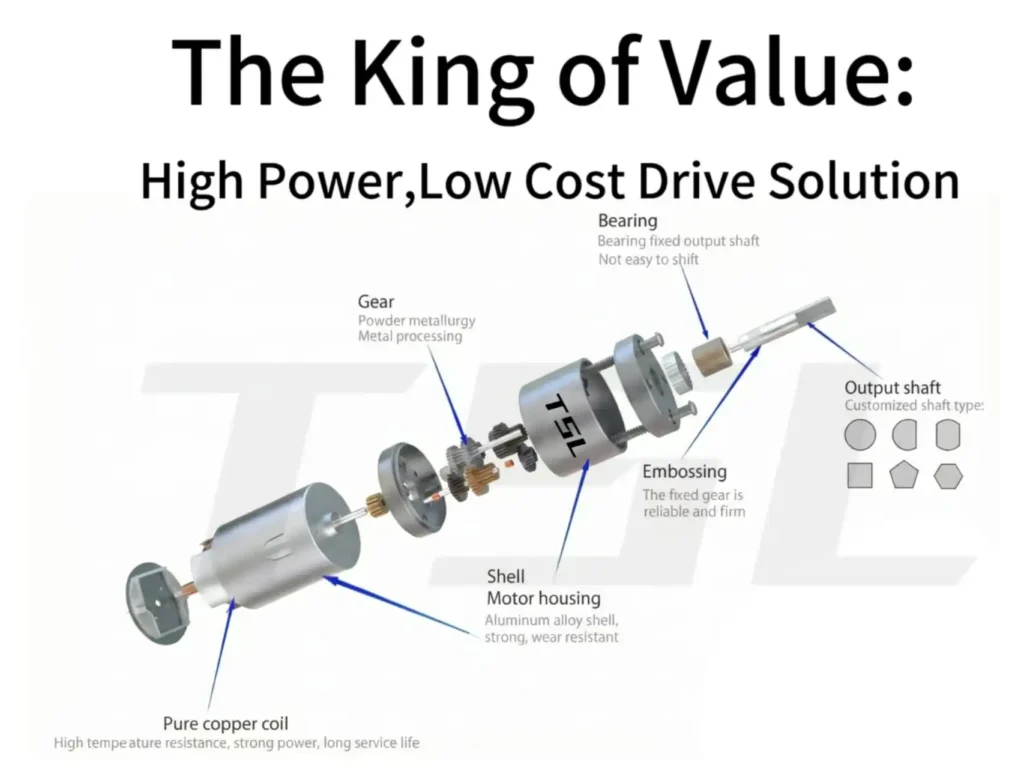

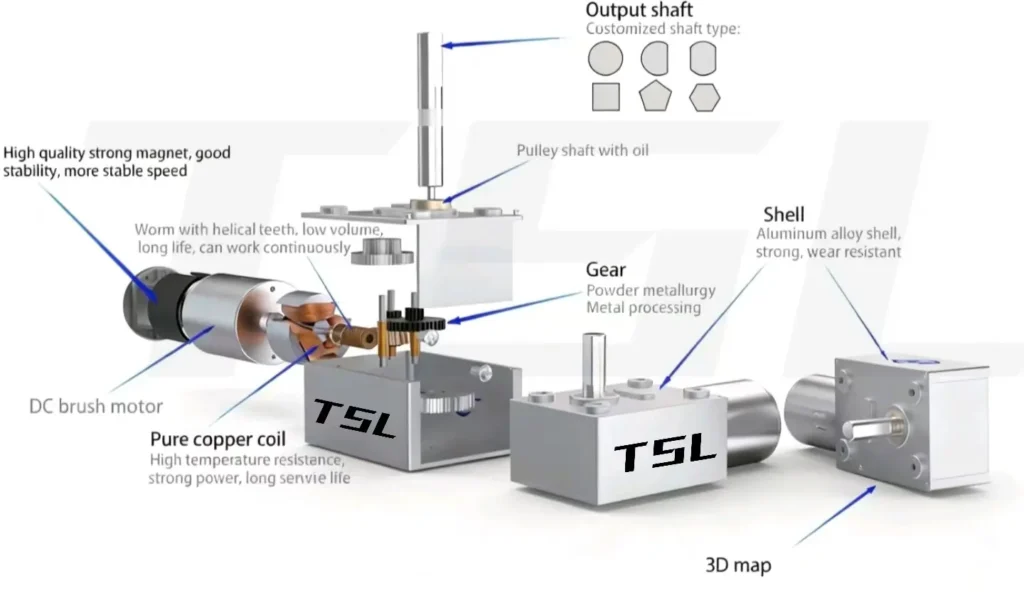

Precision and Power: Small DC Gear Motors

A small dc gear motor is not a new motor type. It is a system: it integrates a standard DC motor with a gearbox into one compact unit.

Gearbox

The gearbox’s core function is to reduce the high speed of the motor’s output shaft. Simultaneously, it proportionally increases its torque. This is like shifting into a low gear on a bicycle uphill. Your legs pedal fast (input speed), but the wheel turns slowly (output speed). However, you output much greater force (output torque).

Gear Ratio is the key parameter measuring this conversion. For instance, a 100:1 gear ratio means the motor’s input shaft must spin 100 times for the final output shaft to spin once. Ideally, this amplifies the torque 100 times.

Gearbox Types

- Spur Gears: Simple structure, cost-effective, suitable for parallel shaft drive.

- Planetary Gears: More complex structure. Provides higher torque and efficiency in a very compact coaxial space.

- Worm Gears: Achieves very large reduction ratios. Features a unique self-locking capability, crucial in some applications.

Tips: If you’d like to learn more about DC Gear motors, please click here. This article will not go into further detail.

Selection and Application

Selecting gear motors also involves details requiring deeper understanding.

The first is the “efficiency loss” of gear drive. Gear systems are not 100% efficient. Friction between gears consumes some energy.

For example, a 10:1 gearbox with 90% efficiency will have a real torque gain slightly less than 10 times. A novice designer might choose a motor based on theoretical calculation. Ignoring efficiency loss, the final actual output torque may be insufficient.

Therefore, in engineering practice, you must account for the gearbox efficiency (usually noted in the specifications). You must also leave a safety margin for the motor/gearbox combo. This ensures the required minimum torque is met under real loads.

The second point is the gearbox as a “control” tool. A gear motor is more than a torque amplifier. It is a means to achieve precise control. It’s hard to run a standard DC motor stably at very low speeds (e.g., 10 RPM) just by voltage adjustment. It might stutter or stop.

However, using a 100:1 gear motor, the output shaft can stably spin at 10 RPM while the internal motor rotates at a stable, efficient 1000 RPM. This explains why gear motors are widely used in robotics and automation. They achieve precise, controllable, low-speed motion. It turns a fast, “hard-to-manage” motor into a slow, precise, and easily controllable actuator.

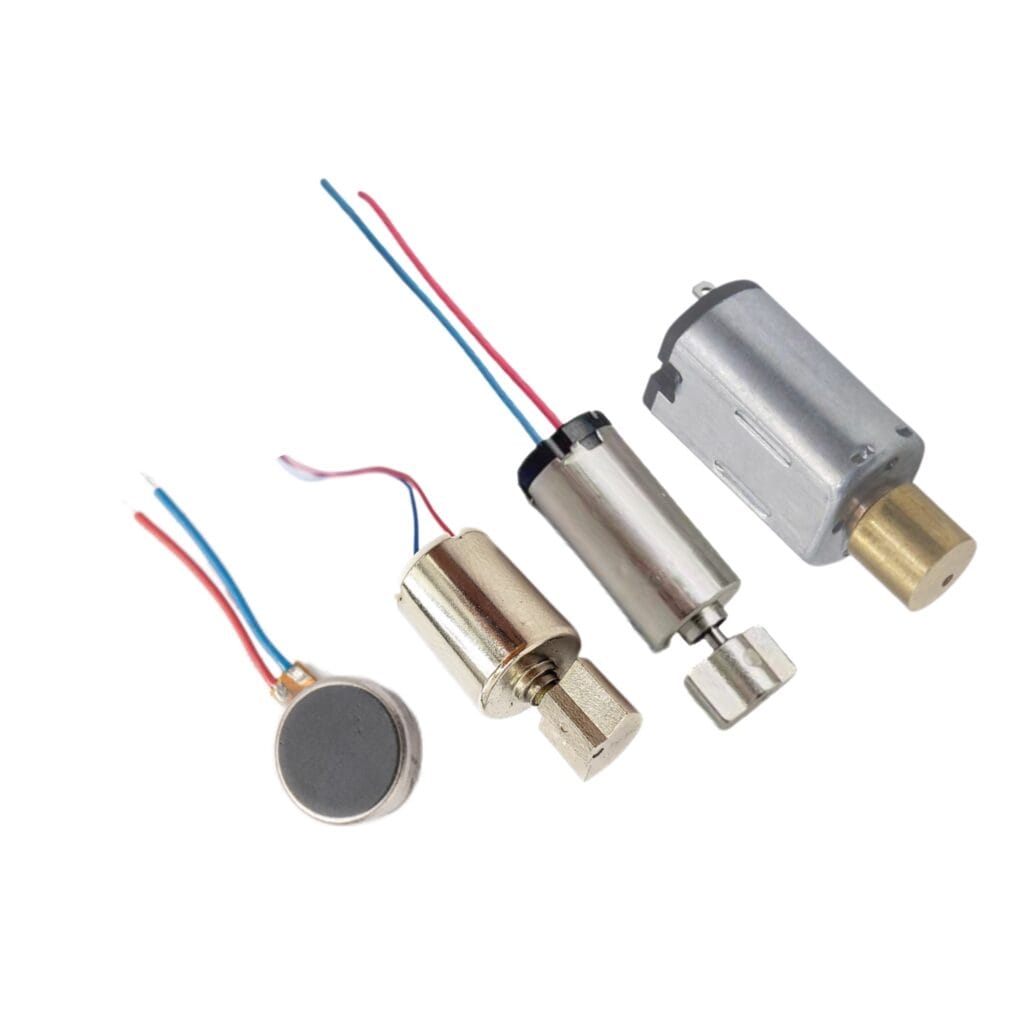

The Language of Touch: Small Vibration Motors

A Vibration Motor is a special-purpose DC motor. Its sole goal is to convert electrical energy into perceptible vibration or haptic feedback.

How Vibration is Generated: The Principle of Imbalance

- Eccentric Rotating Mass (ERM): This is the most common type. Its principle is mounting an eccentric (asymmetrical) weight on a standard DC motor’s shaft. When the shaft spins fast, the unbalanced centrifugal force makes the entire motor shake rapidly, generating vibration.

- Linear Resonant Actuator (LRA): A more advanced alternative. It uses a voice coil, magnets, and springs to generate vibration along a single axis. Instead of rotating, it moves back and forth. LRA offers more precise, crisper feedback. It is ideal for modern haptic technology.

Form Factors and Applications

- Coin Motors (or “Pancake Motors”): Flat and compact ERM or LRA motors. Perfect for slim devices like smartwatches and phones. They provide haptic feedback for the user interface. They often come with adhesive backing for easy installation.

- Cylindrical Motors (or “Pager Motors”): The original form factor. Typically generate stronger vibration. Used for general alerts and notifications, not fine feedback.

Selection and Application

Small vibration motor applications also have considerations beyond basic specifications.

First, vibration is directional; mounting is everything. Vibration force is a vector—it has both magnitude and direction. For optimal haptic feedback, the motor must be mounted in a position and orientation that most effectively transfers vibration to the user’s contact point.

For example, an ERM motor vibrates in two planes (if the shaft is the Y-axis, vibration is on the X and Z axes). An LRA vibrates on only one axis. If a designer places the vibration motor randomly in an empty spot in the device casing, the effect may be greatly diminished. Effective haptic feedback design is a mechanical engineering task, not just electronic selection.

Second, understand the difference between a simple “buzz” and “haptic feedback.”

A simple alert (like an old pager) only needs to be felt. A cheap, strong ERM motor is sufficient. However, modern UIs use haptics to simulate button clicks, confirm touchscreen operations, or create delicate effects in games. This demands extremely fast start/stop times and precise control of amplitude. LRA is ideal for these modern devices due to its precise feedback characteristics.

Therefore, choosing ERM vs. LRA is choosing the level of user experience. For an appliance needing a simple “on/off” alert (e.g., “Coffee is ready”), ERM is cost-effective. For a high-end appliance with a complex touch interface, LRA provides the crisp, responsive feedback users expect from premium devices.

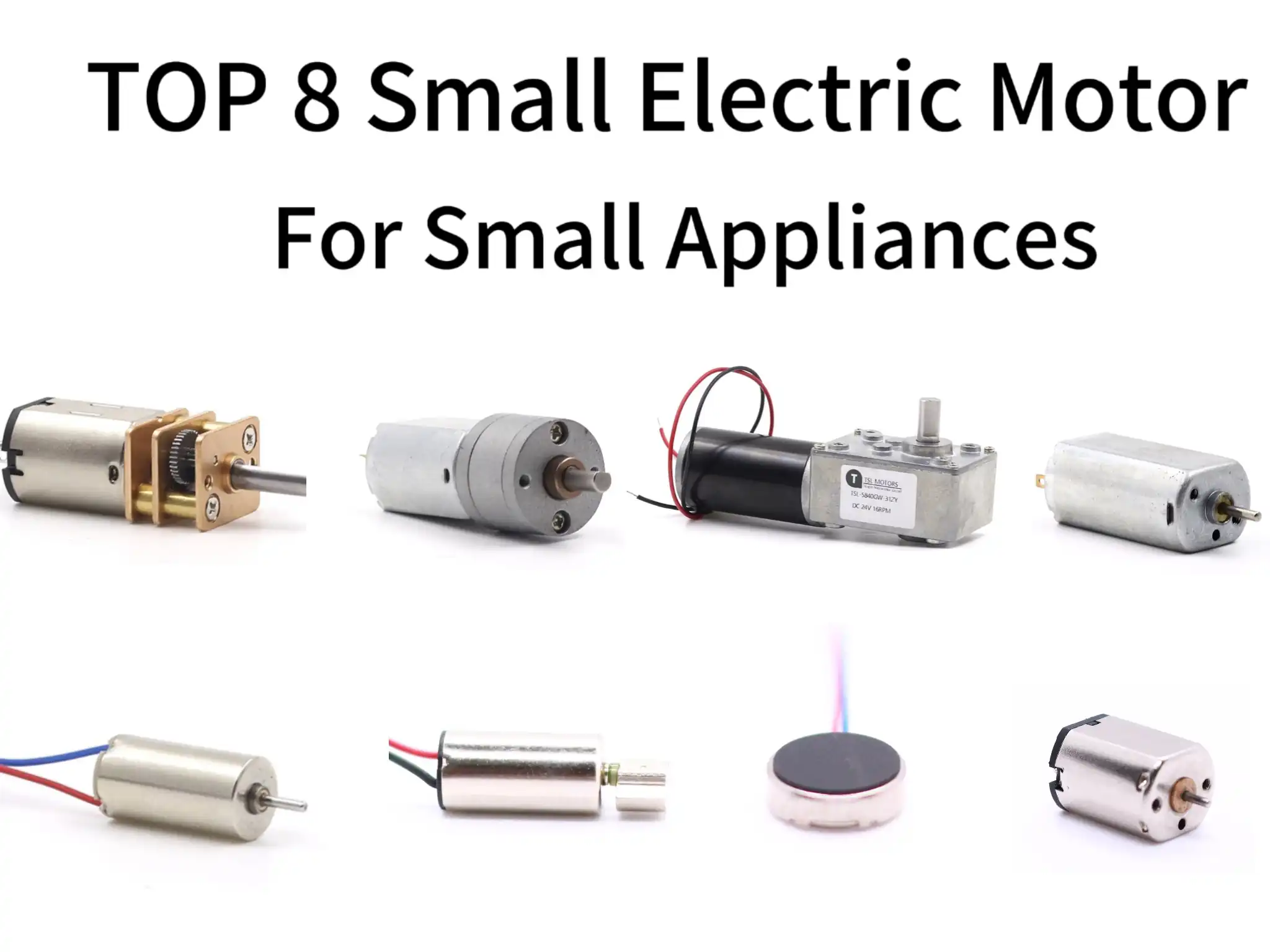

8 Top Small Electric Motors for Small Appliances

This is the core of the guide. Each samll electric motor is introduced as the “top pick” for its category. Its advantages and ideal application scenarios are clearly explained.

Table 2: 8 Top Small Electric Motor Specifications

| Model/Type | Motor Category | Operating Voltage (V) | No-Load Speed (RPM) | Stall Torque (g-cm) | Dimensions (mm) |

| 130 Brushed DC Motor | Small DC Motor | 3-15/Customizable | 4600-16000 | N/A | 20×15×25 |

| N20 DC Motor | Small DC Motor | 3-12/Customizable | >9000 | N/A | 12×10×15 |

| Coreless DC Motor | Small DC Motor | 3.7-12/Customizable | 20,000-50,000+ | N/A | 4-10+ diameter |

| N20 Gear Motor | Small DC Gear Motor | 3-24/Customizable | 3.5-1,000+ | depends on the gearbox and ratio | depends on the gearbox |

| 130 Gear Motor | Small DC Gear Motor | 3-12/Customizable | 10-310 | Medium | Larger |

| Worm Gear Motor | Small DC Gear Motor | 3-24/Customizable | 3-500+ | Extremely High | Right-angle output |

| 10mm Coin ERM Motor | Small Vibration Motor | 3-12V/Customizable | N/A | N/A | Ø10x3 |

| 0612 Cylindrical ERM Motor | Small Vibration Motor | 1.3/Customizable | N/A | N/A | Ø6x12 |

Small DC Motors (Picks 1-3: Speed Experts)

1.130 Brushed DC Motor

Core Specs:

- Operating voltage: 3-15V/Customizable

- No-load speed: 4600-16000RPM

- High stall current :0.73-2.45A

- Size: 20 × 15 × 25 mm

Analysis: This is the classic hobbyist motor. Its main advantages are extremely low cost, widespread availability, and simple two-wire driving. It’s the perfect starting point for any project needing simple high-speed rotation. Its main weaknesses are low torque and the inherent lifespan limit of the brushed design.

Ideal Small Appliance Use: Portable fan, electric toothbrush vibration mechanism, small spinning toys, milk foam whisk.

Expert Tip: Always power this motor via a transistor or motor driver. Never connect it directly to a microcontroller pin. Its huge current draw, especially at startup, will damage the microcontroller.

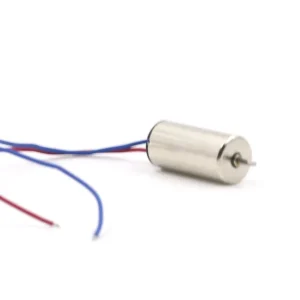

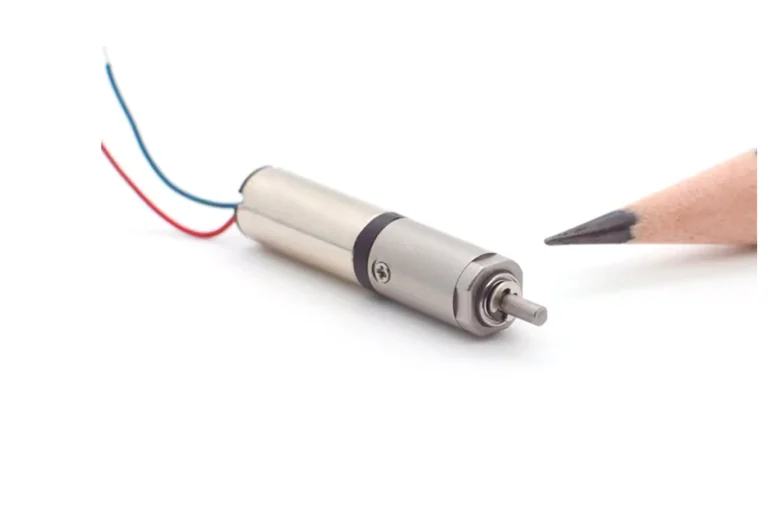

2.N20 DC Motor

Core Specs:

- Operating voltage: 3-12V/Customizable

- No-load speed: usually >9000 RPM

- Size: 12 × 10 × 15 mm (excluding shaft)

Analysis: The N20 is significantly smaller than the 130 type. It’s ideal for space-constrained designs. Despite its small size, its speed is astonishing. Its small size and high speed make it the top choice for applications where miniaturization is crucial.

Ideal Small Appliance Use: Micro drones/toy quadcopters, high-speed portable beauty tools (like nose hair trimmers), micro RC car drive motors.

Expert Tip: Due to its extremely high speed and low inertia, the output shaft can be hard to connect. Look for versions with a “D”-shaped shaft or press-fit gears designed for this model.

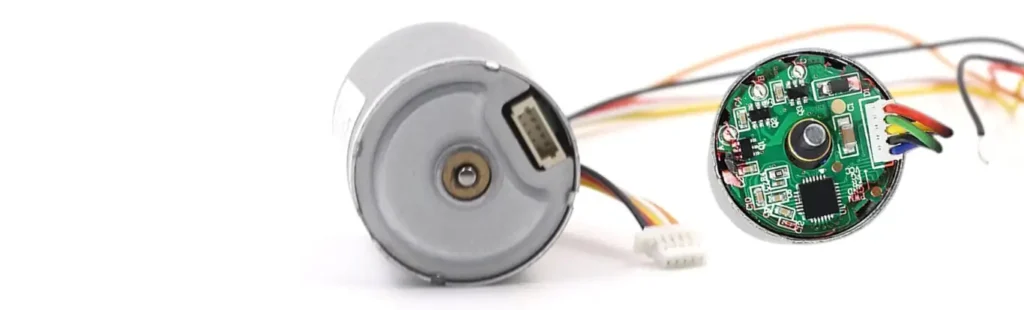

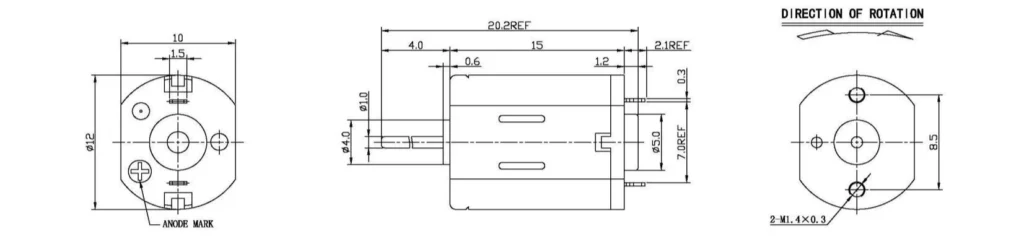

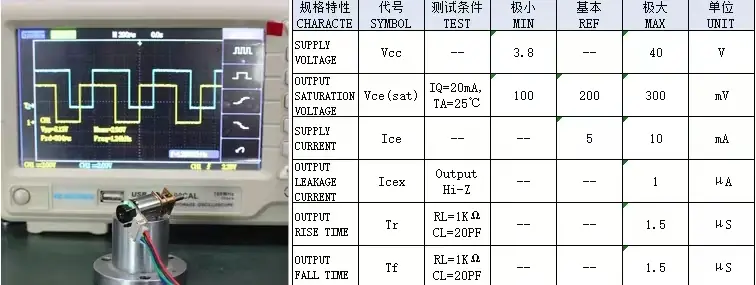

3.Coreless DC Motor

Core Specs:

- Operating voltage: 3.7–12 V/Customizable

- No-load speed: 20,000–50,000+ RPM

- Size: Various, typically cylindrical (e.g., 10 mm diameter)

Analysis: Coreless motors are a performance leap. By removing the iron core from the rotor, the rotational inertia is greatly reduced. This results in extremely fast acceleration/deceleration response, higher efficiency, and smooth operation without “cogging” (the stuttering seen in some motors at low speed). They are more expensive but offer superior dynamic performance.

Ideal Small Appliance Use: High-end electric shavers needing rapid blade vibration, medical/dental tools, camera autofocus or anti-shake mechanisms, advanced haptic feedback devices.

Expert Tip: The high efficiency and low current consumption of coreless motors make them excellent for battery-powered devices where maximizing battery life is paramount.

Small DC Gear Motors (Picks 4-6: Torque Titans)

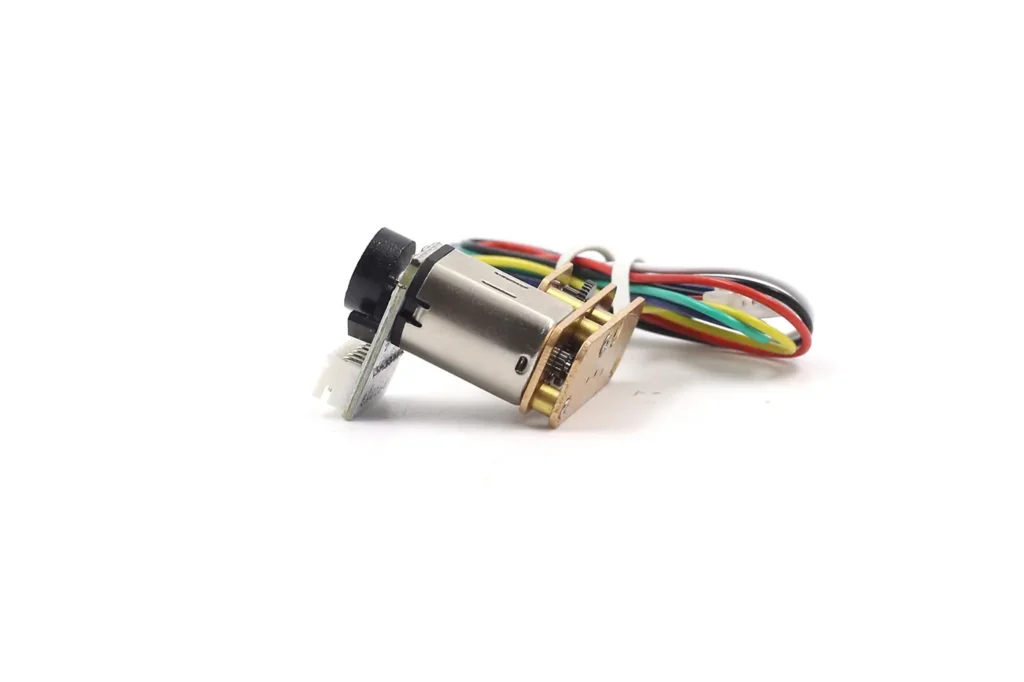

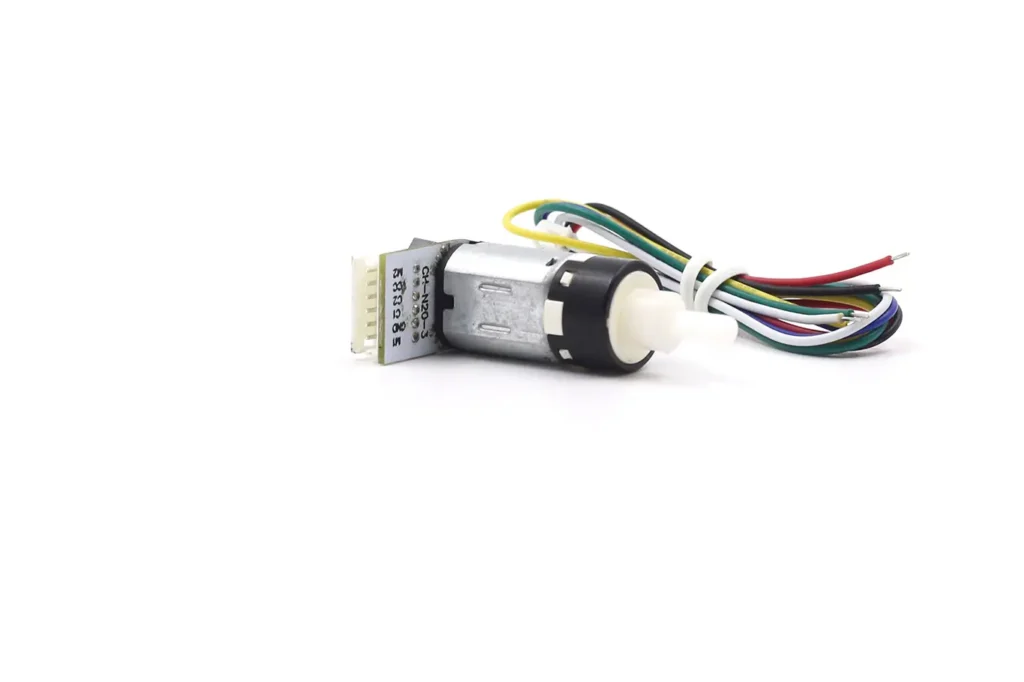

4.N20 Gear Motor

Core Specs:

- Operating voltage:3-24/Customizable

- Output speed: 30–1,000 RPM (depends on gear ratio)

- High stall torque (e.g., >1 kg-cm)

- Size: ~12 × 10 × 26 mm (motor + gearbox)

Analysis: This is arguably the most popular micro gear motor among makers and designers. It combines the compact N20 motor with a durable all-metal gearbox, delivering surprising torque in a tiny package. Its wide range of gear ratio choices (from 30:1 to 1000:1) makes it incredibly versatile.

Ideal Small Appliance Use: Micro robots, electronic door locks, automatic pet feeders, small valve actuators (like smart watering systems), rotating display stands.

Expert Tip: Its high torque can easily damage plastic components. Ensure any arm or linkage connected to the output shaft is strong enough to withstand the motor’s stall torque.

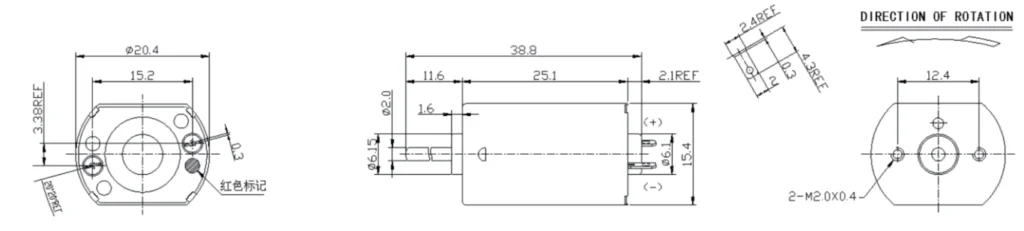

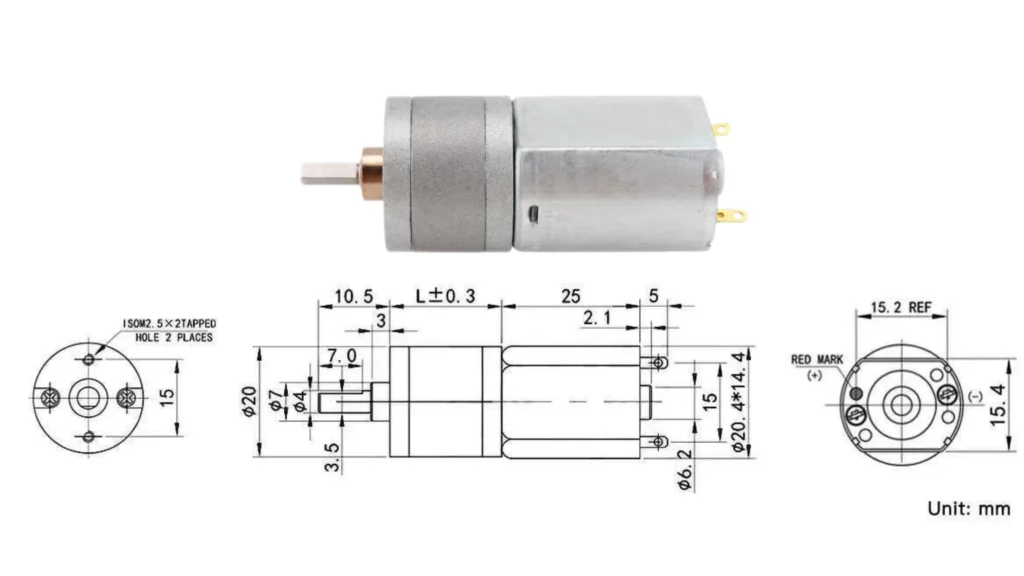

5.130 Gear Motor

Core Specs:

- Operating voltage: 1.5–24 V (common versions include 3 V, 6 V, 12 V)

- Output speed: ranges from ~15 to 290 RPM depending on reduction ratio and voltage

- Rated torque: up to 2.5–3.2 kg·cm (momentary tolerance up to 5.0 kg·cm)

- Size: ~Φ20 mm case diameter, gearbox length 15.9–20.4 mm depending on gear stages

- Shaft: typically Φ4 mm, D-cut or customized options available

Analysis: The GM20-130 integrates a 130-type brushed DC motor with a 20 mm metal spur gearbox. This combination delivers high torque in a compact package, making it suitable for applications requiring reliable low-speed rotation.

Spur gears provide cost-effectiveness and straightforward design, though they are less efficient than planetary gears. The wide range of reduction ratios (from ~29:1 up to ~488:1) allows designers to balance speed and torque for diverse use cases.

Ideal Small Appliance Use:

- Electronic locks and latches

- Automatic feeders or dispensers

- Smart home actuators (curtains, valves, pop-up mechanisms)

- Rotating display stands or precision positioning devices

Expert Tip: Because spur gears are less efficient than planetary gears, torque output may be slightly lower than theoretical values. Always account for gearbox efficiency losses in design. Also, the high stall torque can damage lightweight plastic linkages—ensure robust mechanical connections to the output shaft.

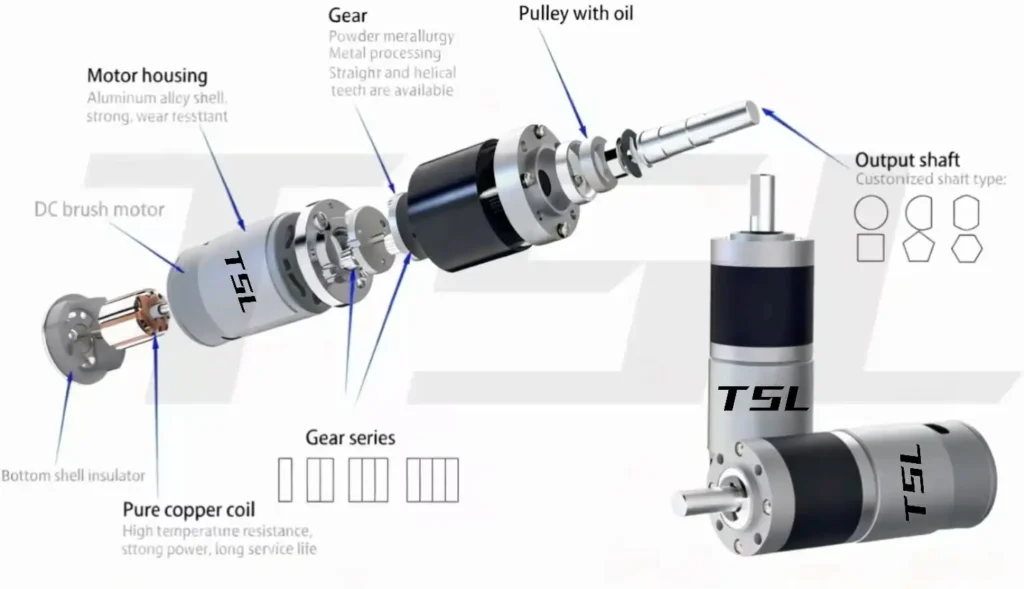

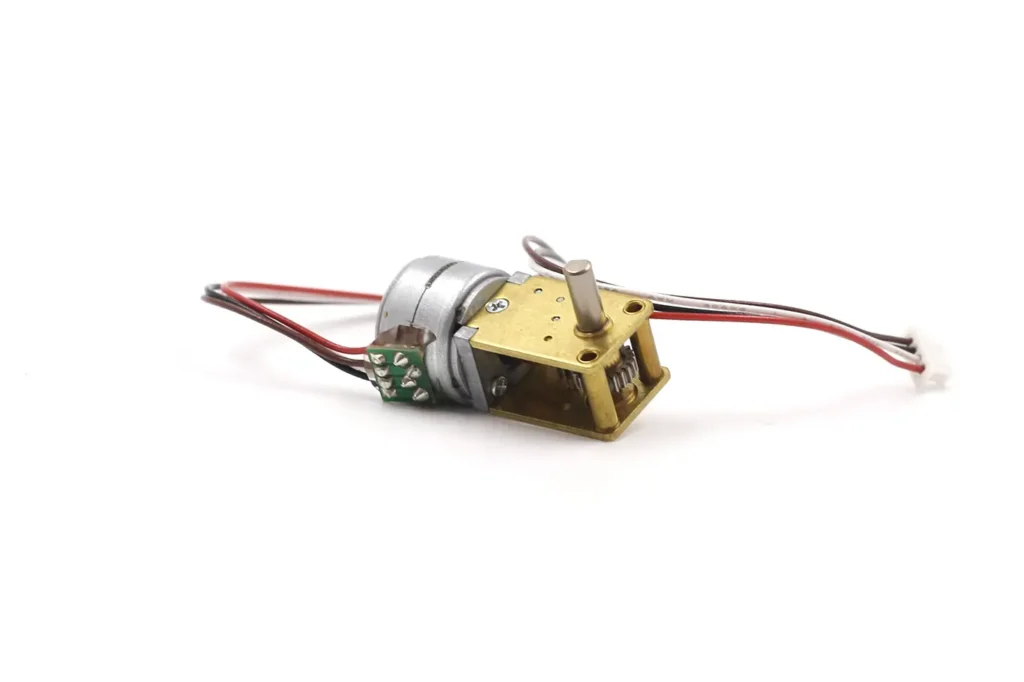

6.Worm Gear Motor

Core Specs:

- Operating voltage: 3–24 V/Customaizable

- Output speed: extremely low (e.g., 10–50 RPM)

- Stall torque: extremely high

- Size: typically a right-angle output shaft

Analysis: The worm gear is a special structure. It achieves a huge reduction ratio in a small space. Most importantly, it is usually non-back-drivable. This means you cannot turn the output shaft by hand when the motor is unpowered; it locks in position. This self-locking feature eliminates the need for an external brake in many applications.

Ideal Small Appliance Use: Small lifting mechanisms (like pop-up cameras or screens in smart home devices), automatic door latches, and any application that needs to resist load and hold position without continuous power.

Expert Tip: Worm gears are less efficient than spur or planetary gears. Be sure to factor this into your power calculations; they will draw more current for the same output torque.

Small Vibration Motors (Picks 7-8: Feedback Experts)

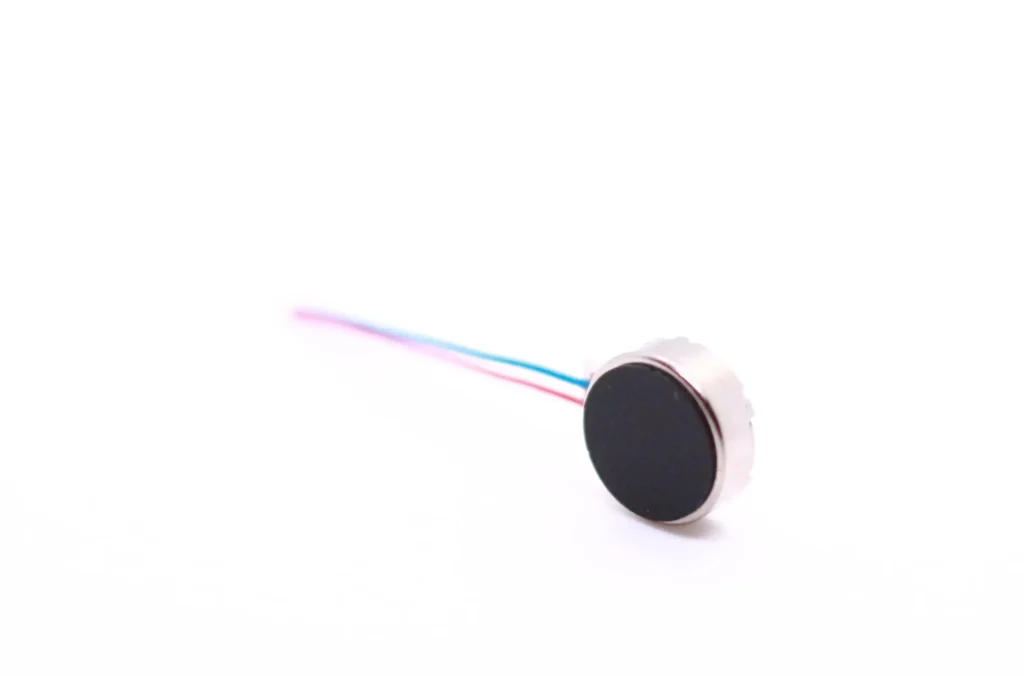

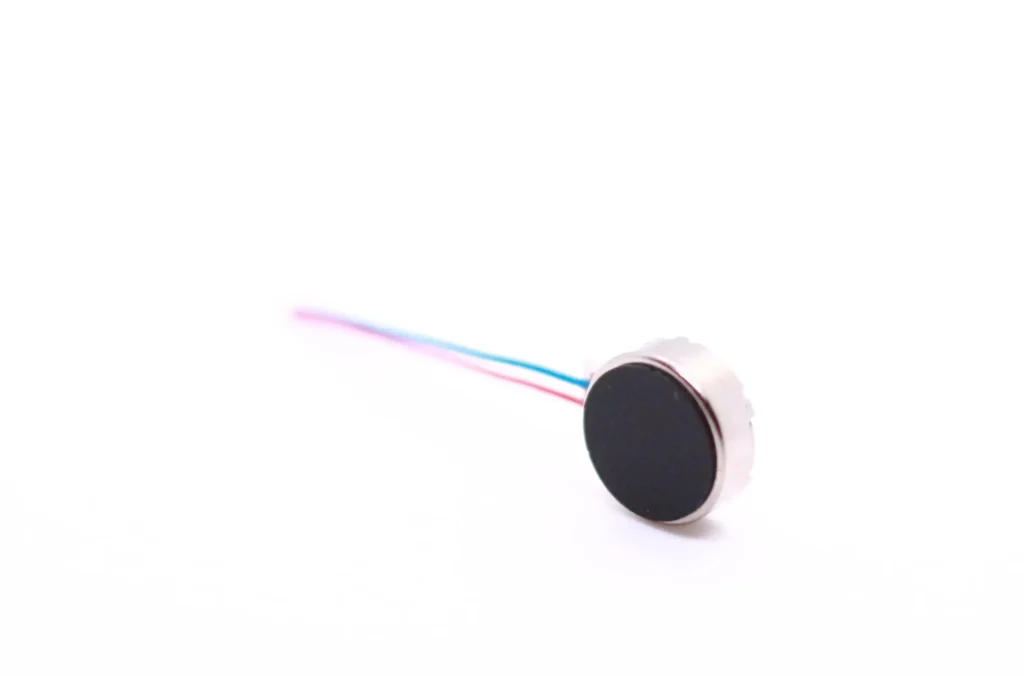

7. 10mm Coin ERM Motor

Core Specs:

- Operating voltage: 3-12V/Customizable

- Vibration type: ERM

- Size: 10 mm diameter

Analysis: The vibration in countless smartphones, smartwatches, and portable electronic devices originates from this motor. Its ultra-thin profile makes it easy to integrate into slim designs. It is designed for delicate, localized haptic feedback. Most versions come with adhesive backing for simple peel-and-stick installation.

Ideal Small Appliance Use: Providing feedback for touch panels or buttons on coffee makers, microwaves, or smart thermostats; silent alerts in wearable health devices.

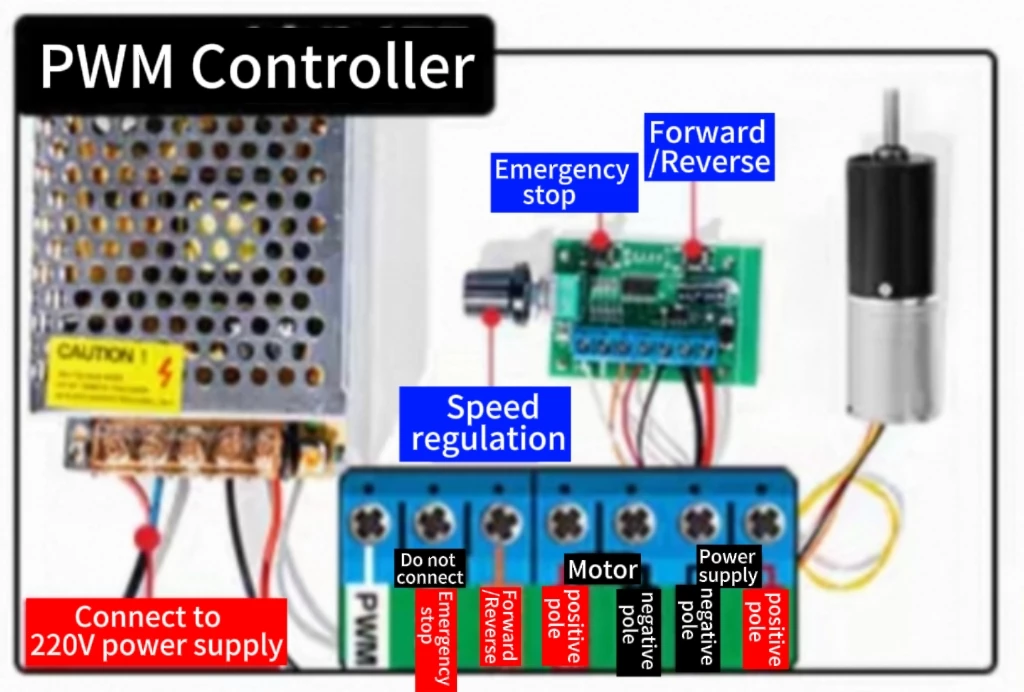

Expert Tip: Vibration intensity is directly related to voltage. You can use a PWM signal to create a range of effects, from a gentle buzz to a strong vibration, improving the user experience.

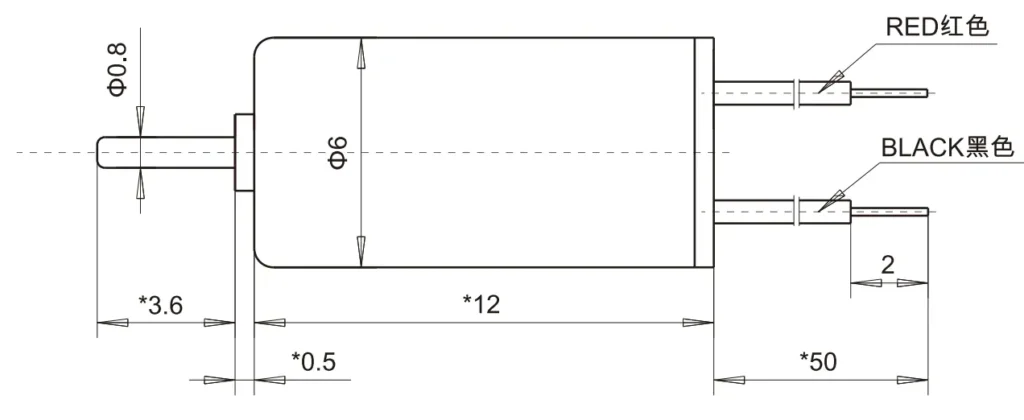

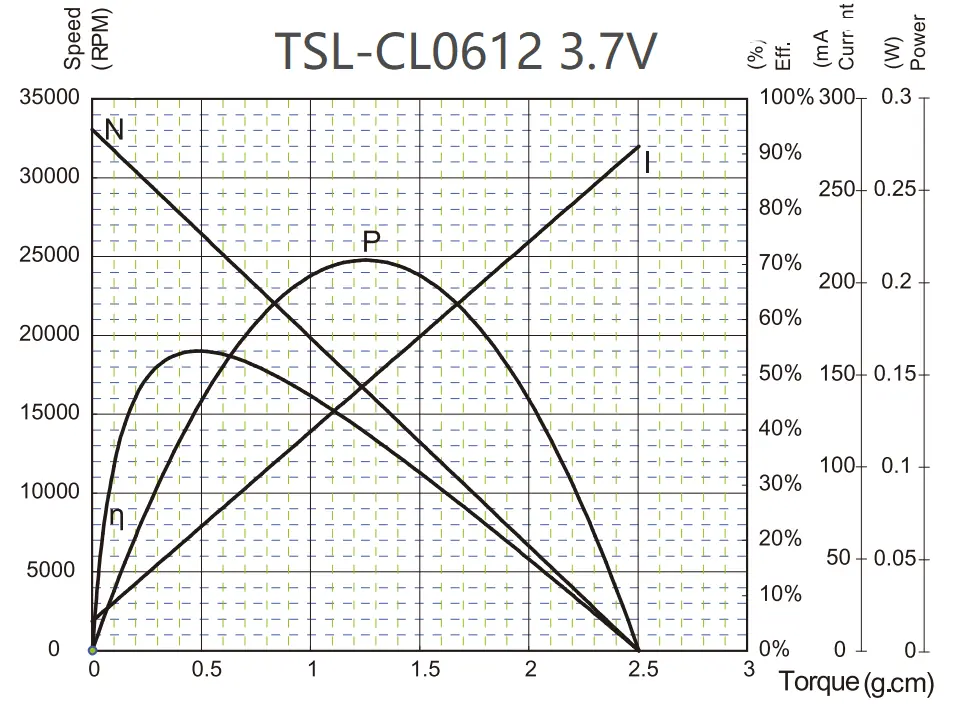

8.0612 Cylindrical ERM Motor

Core Specs:

- Operating voltage: 1.3V/Customizable

- Vibration type: ERM

- Size: e.g., 6 mm diameter × 12 mm length

Analysis: This is the classic “pager motor.” It is larger than the flat motor and typically produces stronger, but less refined, vibration. It’s unsuitable for delicate haptic feedback. However, it is perfect for creating a strong, unambiguous alert that vibrates the entire small device. They are often encapsulated for increased durability.

Ideal Small Appliance Use: Alert functions in medical devices (like pill box reminders), handheld scanners, game controllers, or any device needing a strong, non-auditory notification.

Expert Tip: To maximize the perceived vibration, firmly mount this motor to the main chassis or casing of the appliance. Loose mounting causes the motor to rattle, wasting energy and creating unwanted noise.

How to Pick the Perfect Small Electric Motor

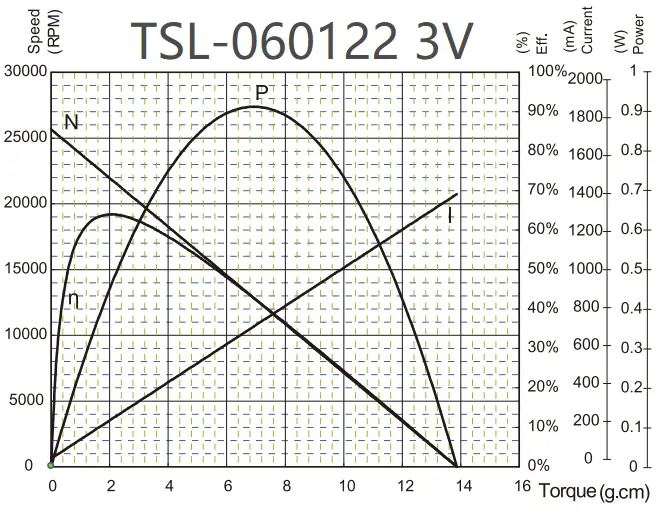

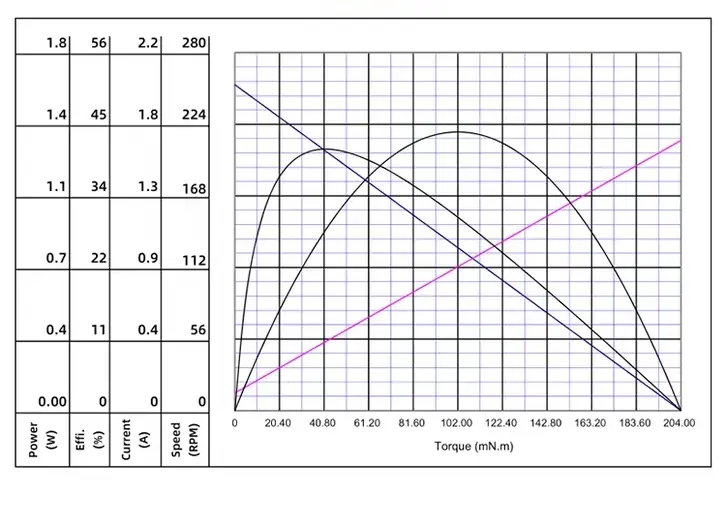

Step 1: Define Your Motion Needs—Torque vs. Speed

First, ask yourself: Does your appliance need fast rotation (like a fan), or does it need to move a component with force (like a door latch)?

This is the first and most crucial decision point. It guides you toward a DC motor or a gear motor. You can refer to the motor’s Speed/Torque performance curve for judgment.

Step 2: Determine Your Power Solution—Voltage, Current, and Efficiency

Match the motor’s rated voltage to your project’s power supply, for example 3.7 V for Li-ion, 5 V for USB, or 12 V for a wall adapter.

The power supply design must handle the stall current, not just the running current. For battery-powered devices, prioritize high-efficiency motors such as coreless or brushless types to maximize battery life.

Step 3: Consider Physical Fit—Size, Weight, and Mounting

Measure the available space within your casing. Miniaturization often forces you to choose smaller motors, like the N20 or flat vibration motors. Also, consider the mounting method: screw holes, adhesive backing (for flat motors), or a custom bracket.

Step 4: Go Beyond the Basics—Lifespan, Noise, and Control

Lifespan: For a frequently used appliance, is the limited lifespan of a brushed motor acceptable? Or do you need a more reliable brushless/coreless motor?

Noise: Is quiet operation essential for a consumer product? If so, consider coreless motors or plastic gearboxes.

Control: Does the application require precise positioning? If so, you may need a gear motor with an encoder to provide position feedback to the microcontroller.

Conclusion: Get Your Ideas Moving

In summary, we explored the three main small electric motor categories and their core advantages. Remember, the “best” motor is always the one that best meets your specific application’s requirements for speed, torque, size, and power.

We hope this list of 8 curated motors serves as a starting point for your project. The selection blueprint provides clear guidance. Now, it’s time to move from planning to practice and turn those creative small appliance ideas into reality.

Throughout this process, TSL MOTOR, with more than15 years of focus on micro motors, is dedicated to providing reliable power for innovation and home appliances. We look forward to being your trusted partner to drive the future with you.

FAQ

Q1: What are the three main types of micro motors?

A1: They are: Micro DC Motors (for speed), Micro DC Gear Motors (for torque), and Vibration Motors (for haptic feedback).

Q2: What is the fundamental relationship for DC motors?

A2: Speed is proportional to Voltage. Torque is proportional to Current.

Q3: Brushed vs. Brushless – what’s the key difference?

A3: Brushed motors use mechanical commutation (simple, low cost, limited lifespan). Brushless motors use electronic controllers (high efficiency, long lifespan).

Q4: Why is Stall Current important?

A4: Stall Current (current when stopped) is much higher than running current. Your power supply must handle this high current to ensure the motor can start reliably.

TSL-Motor: Custom Motor Solutions

Established in 2009, TSL Motor has evolved into a leading innovator in precision drive systems and specialized motor manufacturing. Our 15,000㎡ advanced production facility in Shenzhen houses a skilled workforce of 200+ professionals, delivering an annual output of 2 million units to global markets.

Continuous R&D investment in energy-efficient motor technologies

Lean manufacturing processes ensuring cost-competitive pricing

Agile production capacity scaling for batch customization

Global compliance certifications (CE, RoHS, REACH)

With dual focus on operational excellence and client success, Twin Motor empowers businesses worldwide to achieve technological differentiation. Our engineering team welcomes complex challenges across automotive, robotics, and smart infrastructure applications.

Contact our solutions center to discuss your project requirements or request our technical portfolio.

-

Custom Micro Motors5 products

Custom Micro Motors5 products -

DC Gear Motor139 products

DC Gear Motor139 products-

6mm Planetary Gear Motor4 products

6mm Planetary Gear Motor4 products -

6mm Planetary Metal Gear Motor3 products

6mm Planetary Metal Gear Motor3 products -

Brushless Gear Motor17 products

Brushless Gear Motor17 products -

Micro Gear Motor64 products

Micro Gear Motor64 products-

Coreless Gear Motor11 products

Coreless Gear Motor11 products -

N20 Gear Motor26 products

N20 Gear Motor26 products -

Plastic Gearbox Motor8 products

Plastic Gearbox Motor8 products -

Standard Gear Motor15 products

Standard Gear Motor15 products -

Stepper Gear Motor15 products

Stepper Gear Motor15 products

-

-

Planetary Gear Motor29 products

Planetary Gear Motor29 products -

Spur Gear Motor63 products

Spur Gear Motor63 products -

Worm Gear Motor28 products

Worm Gear Motor28 products

-

-

DC Motor78 products

DC Motor78 products-

Brushed DC Motor16 products

Brushed DC Motor16 products -

Brushless DC Motor21 products

Brushless DC Motor21 products-

Inrunner Rotor BLDC Motor6 products

Inrunner Rotor BLDC Motor6 products -

Outrunner Rotor BLDC Motor13 products

Outrunner Rotor BLDC Motor13 products

-

-

Coreless DC Motor13 products

Coreless DC Motor13 products -

Micro DC Motor15 products

Micro DC Motor15 products -

Stepper Motor13 products

Stepper Motor13 products

-

-

Vibration Motors71 products

Vibration Motors71 products-

Brushless Vibration Motor8 products

Brushless Vibration Motor8 products -

Coin Vibration Motor22 products

Coin Vibration Motor22 products -

Coreless Vibration Motor3 products

Coreless Vibration Motor3 products -

Encapsulated Vibration Motor6 products

Encapsulated Vibration Motor6 products -

Linear Resonant Actuator12 products

Linear Resonant Actuator12 products -

Powerful Vibrating Motor17 products

Powerful Vibrating Motor17 products -

SMD Vibration Motor4 products

SMD Vibration Motor4 products -

Sonic Vibration Motor2 products

Sonic Vibration Motor2 products

-